End surface milling and multi-position end surface drilling and tapping compound machine tool

A face milling and compound machine tool technology, applied in the field of machine tools, can solve the problems of low processing efficiency, poor equipment rigidity, unsuitable for large size and large cutting allowance, etc., to achieve fast tool changing speed, strong equipment rigidity, clamping The effect of automatic adjustment of the holding position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

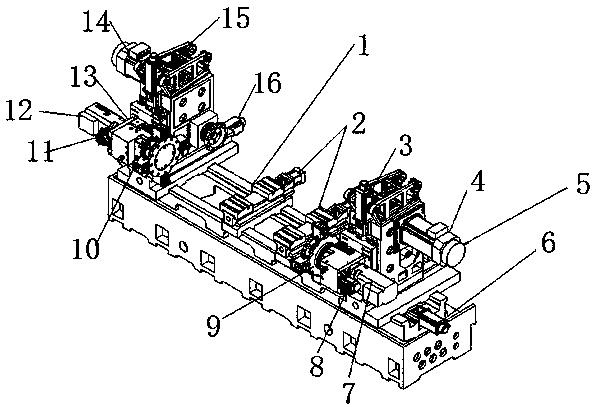

[0021] refer to figure 1 , an end face milling, multi-position end face drilling, and tapping compound machine tool in an embodiment of the present invention, including a bed 1 and a servo control system, the bed 1 is provided with guide rails, and fixtures are symmetrically provided on the guide rails System 2, a processing mechanism with symmetrical left and right ends of the guide rail. The processing mechanism includes a sliding seat. It is characterized in that a first feeding mechanism and a second feeding mechanism are respectively arranged on the two sliding seats. The first feeding mechanism The left power turret 10 and the right power turret 9 are respectively arranged on the feed mechanism and the second feed mechanism, and the first powerful milling power motor 14 and the second power motor 14 are respectively installed on the first feed mechanism and the second feed mechanism. Powerful milling power motor 5, cutter is all installed on the first powerful milling po...

Embodiment 2

[0025] On the basis of the first embodiment, the servo control system is composed of two channels or two systems, which realize simultaneous processing on both sides without interfering with each other, and can realize the left and right double linkage function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com