Combined punching device and punching process for electric spark wire cutting machine tool

A perforating device and technology of cutting machine tools, which are applied in the field of mechanical processing, can solve the problems of being unable to adapt to the needs of CNC machining and multi-functional perforating, wire cutting and perforating processing cannot be completed alone, and the perforating device cannot be applied to wire cutting machine tools, etc., to achieve excellent performance , complete functions and obvious processing advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

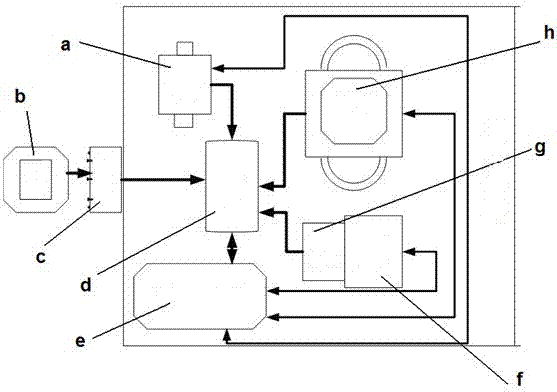

[0033] Embodiment 1. Combined perforating device for wire electric discharge machine tool, wherein: the high-frequency pulse power supply a is unidirectionally connected to the perforating mechanism d, the special fixture b is unidirectionally connected to the connector c, and the connector c is unidirectionally connected to the perforating mechanism d. The piercing mechanism d is bidirectionally connected with the control and detection system e, the high-frequency pulse power supply a is bidirectionally connected with the detection system e, the detection system e is bidirectionally connected with the working fluid circulation system h, the detection system e is bidirectionally connected with the stepping system f, and the stepping system f is unidirectionally connected to the perforating mechanism d through the micro-stepping system g, and the working fluid circulation system h is unidirectionally connected to the perforating mechanism d.

Embodiment 2

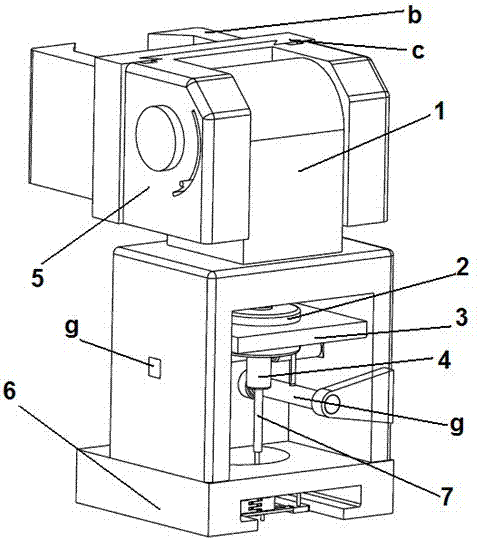

[0034] Embodiment 2, combined perforation device of wire electric discharge machine tool, perforation mechanism d includes rotating arm 1, motor 2, mobile platform 3, Z-axis feeding ultrasonic motor 4, indexing mechanism 5, online grinding mechanism 6 and electrode holder holding mechanism 7; wherein: the rotating arm 1 is movably connected with the special fixture b through the connector c, the two sides of the rotating arm 1 are provided with an indexing mechanism 5, and the rotating arm 1 is connected with the online grinding mechanism 6; the motor 2, the mobile platform 3 , Z-axis feeding ultrasonic motor 4, micro-stepping system g and electrode clamping mechanism 7 are set in the online grinding mechanism 6, the motor 2 is set on the mobile platform 3, Z-axis feeding ultrasonic motor 4 is directly installed on the motor 2 The main shaft is connected with the mobile platform 3 through the connecting rod. The micro-stepping system g is fixedly installed with the online grind...

Embodiment 3

[0035]Embodiment 3, combined perforation device of wire electric discharge machine tool, wherein: the micro-stepping system g includes a photoelectric controller 8, a length compensation mechanism 9, a glass substrate 10, a guide shaft 11, an ultraviolet generator 12, a liquid crystal material 13, a photoinduced Deformable material 14, reserved motion gap 15, slider 16, fixed pipe wall 17, propeller 18, drive shaft 19, light-shielding outer wall 20 and fast response light source 21; the micro-stepping system g is fixed to the mobile platform 3 through the drive shaft 19 connection; the photoelectric controller 8 is fixedly connected to one end of the micro-stepping system g, and the quick-response light source 21 and the ultraviolet generator 12 are embedded on the light-shielding outer wall 20; the guide shaft 11 is connected to the propeller 18, and the length compensation mechanism 9 is fixedly connected to the One end of the micro-stepping system g; the liquid crystal mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com