Material-saving whole fast manufacturing method of metal part

A technology of metal parts and manufacturing methods, which is applied in the field of overall rapid manufacturing of metal parts, can solve problems such as complex process, long production cycle, and inability to form a whole, and achieve the effects of obvious processing advantages, reduced material utilization, and shortened design cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

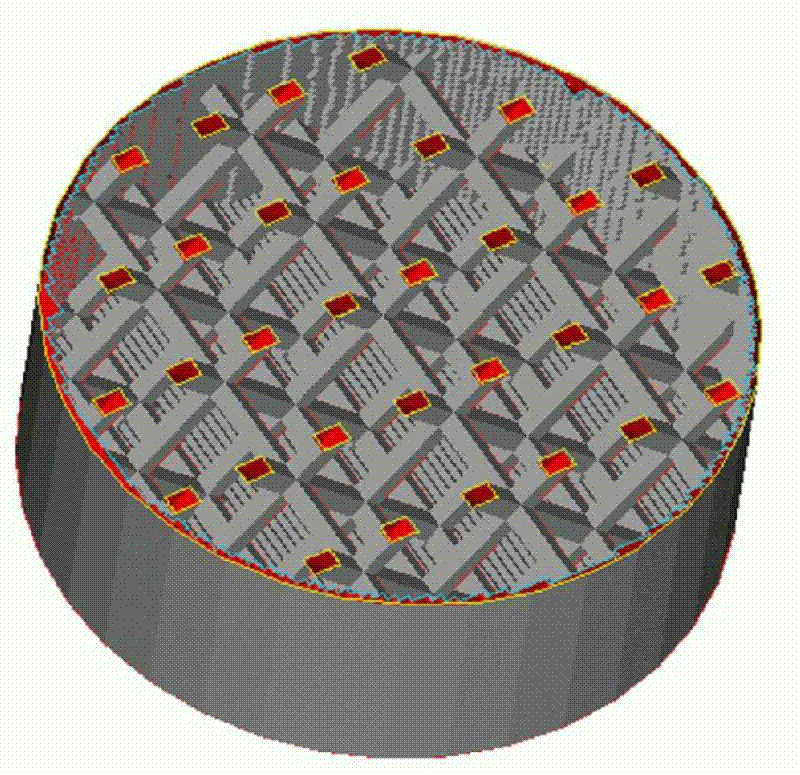

[0031] In UG4.0, the model of the metal parts of the engine impeller without internal structure is modeled. Export the file to STL format. That is to convert 3D model slices into slice information. Import the STL format file into the rapid prototyping process planning software 2008 (developed by Wuhan Aulo Software Co., Ltd.), process it, and perform operations such as adding internal structures and hollowing out at the impeller shaft. Send the data information of the STL file to the SLM rapid prototyping system.

[0032] Using 304L stainless steel powder as raw material, vacuumize the SLM forming cavity and pass argon protective gas. The thickness of each layer of powder coating is 0.11mm, and the particle size of the powder is -300 mesh. The laser used is a fiber laser with a power of 98W. Scanning The spacing is 0.1mm, the scanning speed is 40mm / s, the powder spreading delay is 3s, the scanning delay is 2s, the number of borders is 1, and the scanning method is alternatin...

example 2

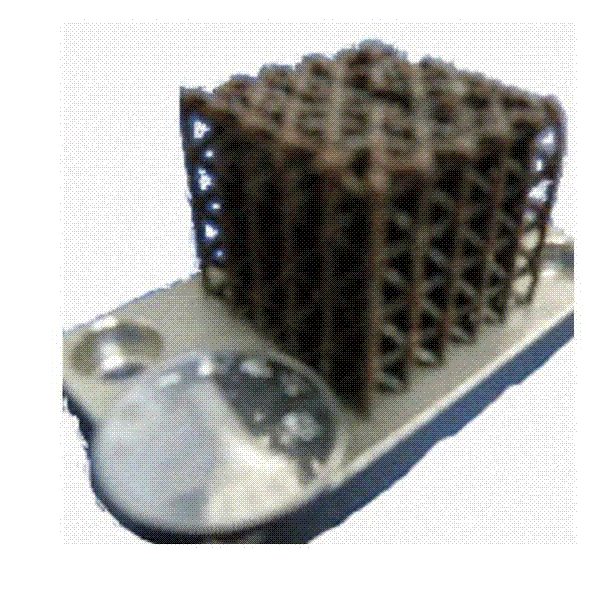

[0035] In UG4.0, the model of cubic metal parts without internal structure is modeled. Export the file to STL format. That is to convert 3D model slices into slice information. Import the STL format file into the rapid prototyping process planning software 2008, process it, hollow out the wall thickness to 0, and perform operations such as adding internal structures and hollowing out. Send the data information of the STL file to the SLM rapid prototyping system.

[0036] Fe powder is used as raw material, the SLM forming cavity is evacuated and protected by argon gas. The thickness of each layer of powder layer is 0.08mm, and the particle size of powder is -200 mesh. The laser used is a fiber laser with a power of 95W and a scanning distance of 0.08mm, the scanning speed is 70mm / s, the powder spreading delay is 3s, the scanning delay is 2s, the number of borders is 1, and the scanning method is progressive scanning.

[0037] After evacuating, pass argon protection to proces...

example 3

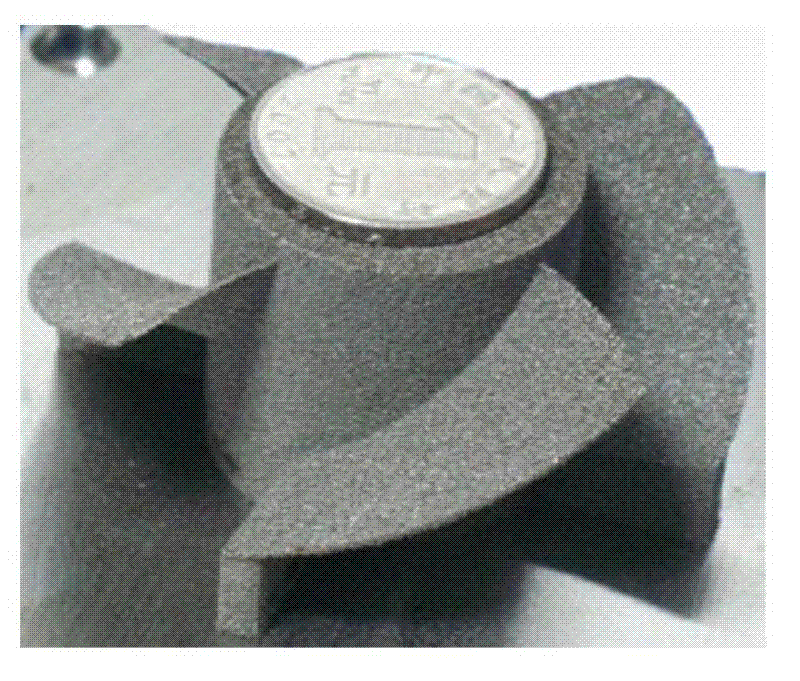

[0039] In UG4.0, the model of the metal parts of chess pieces without internal structure is modeled. Export the file to STL format. That is to convert 3D model slices into slice information. Import the STL format file into the rapid prototyping process planning software 2008, process it, manually hollow out, add rotating escalators and other operations. Send the data information of the STL file to the SLM rapid prototyping system.

[0040]Using 316 stainless steel powder as raw material, the SLM forming cavity is vacuumed and then protected by argon gas. The thickness of each layer of powder coating is 0.1mm, and the particle size of the powder is -300 mesh. The laser used is a fiber laser with a power of 98W and a scanning distance The scanning speed is 0.1mm, the scanning speed is 45mm / s, the powder spreading delay is 3s, the scanning delay is 2s, the number of borders is 1 time, and the scanning method is partition-changing scanning.

[0041] After evacuating, pass argon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com