Integrated chained tool magazine capable of automatically picking up and replacing tools

A self-pickup tool change, chain tool magazine technology, applied in the field of integrated chain tool magazine, can solve problems such as unfavorable machine tool production line layout, influence of machine tool accuracy retention, occupation of machine tool side space, etc. Optimized design, avoids knife sleeve throwing out, and takes up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

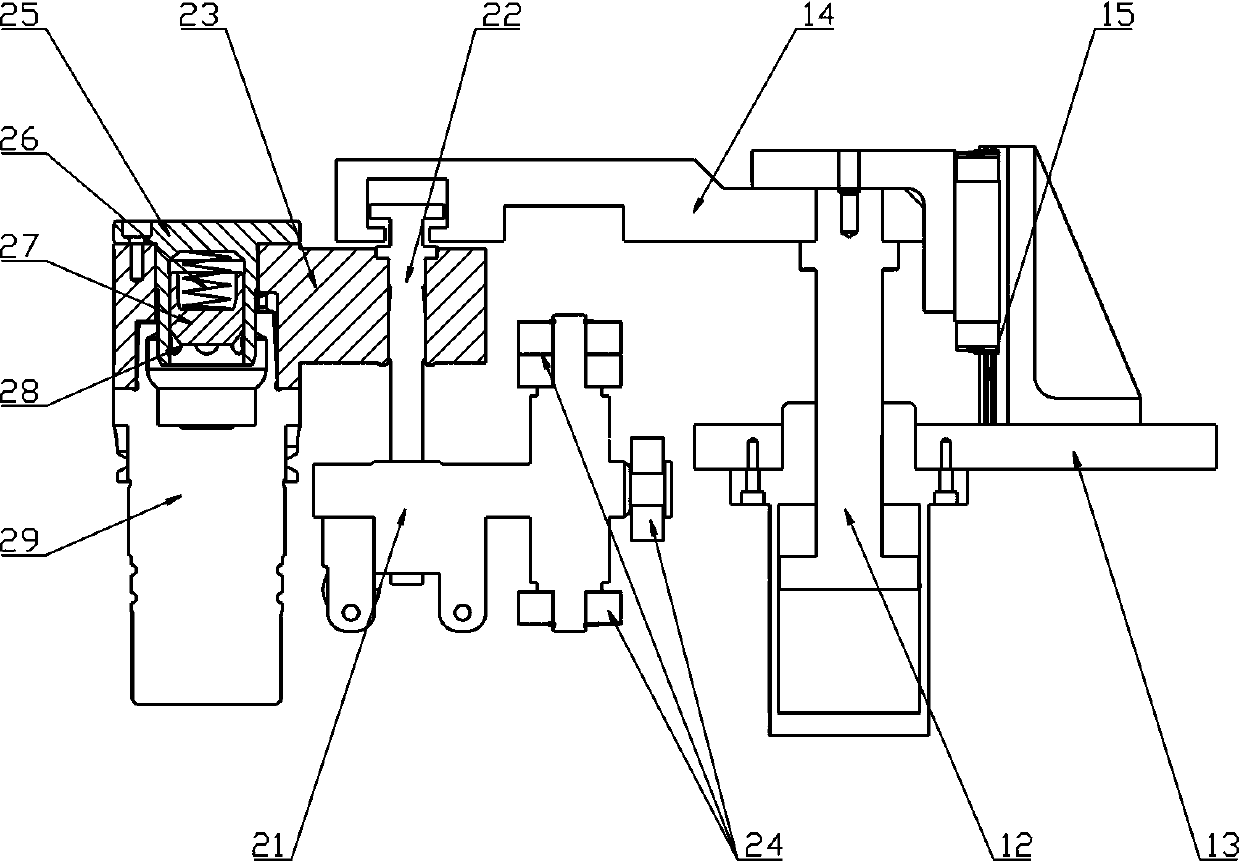

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

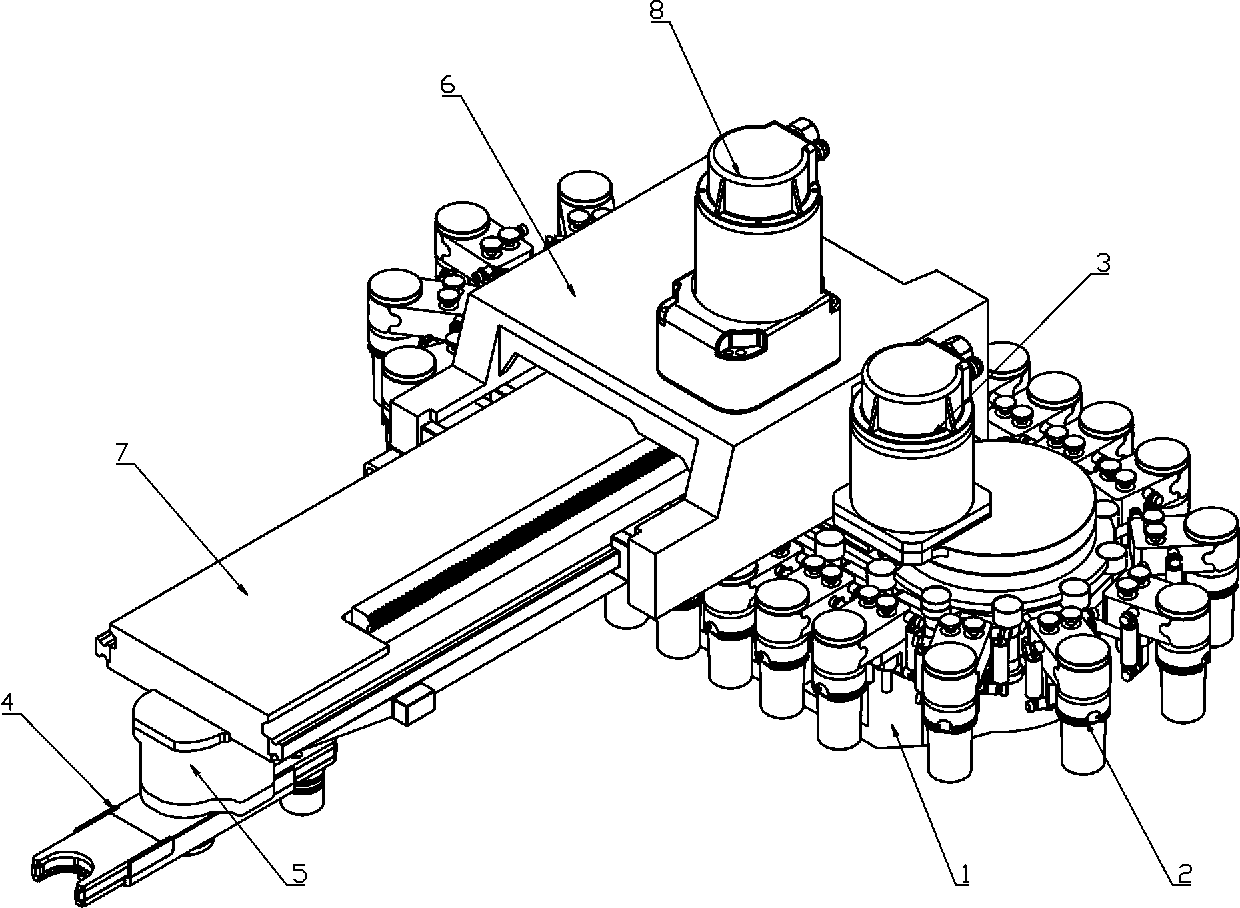

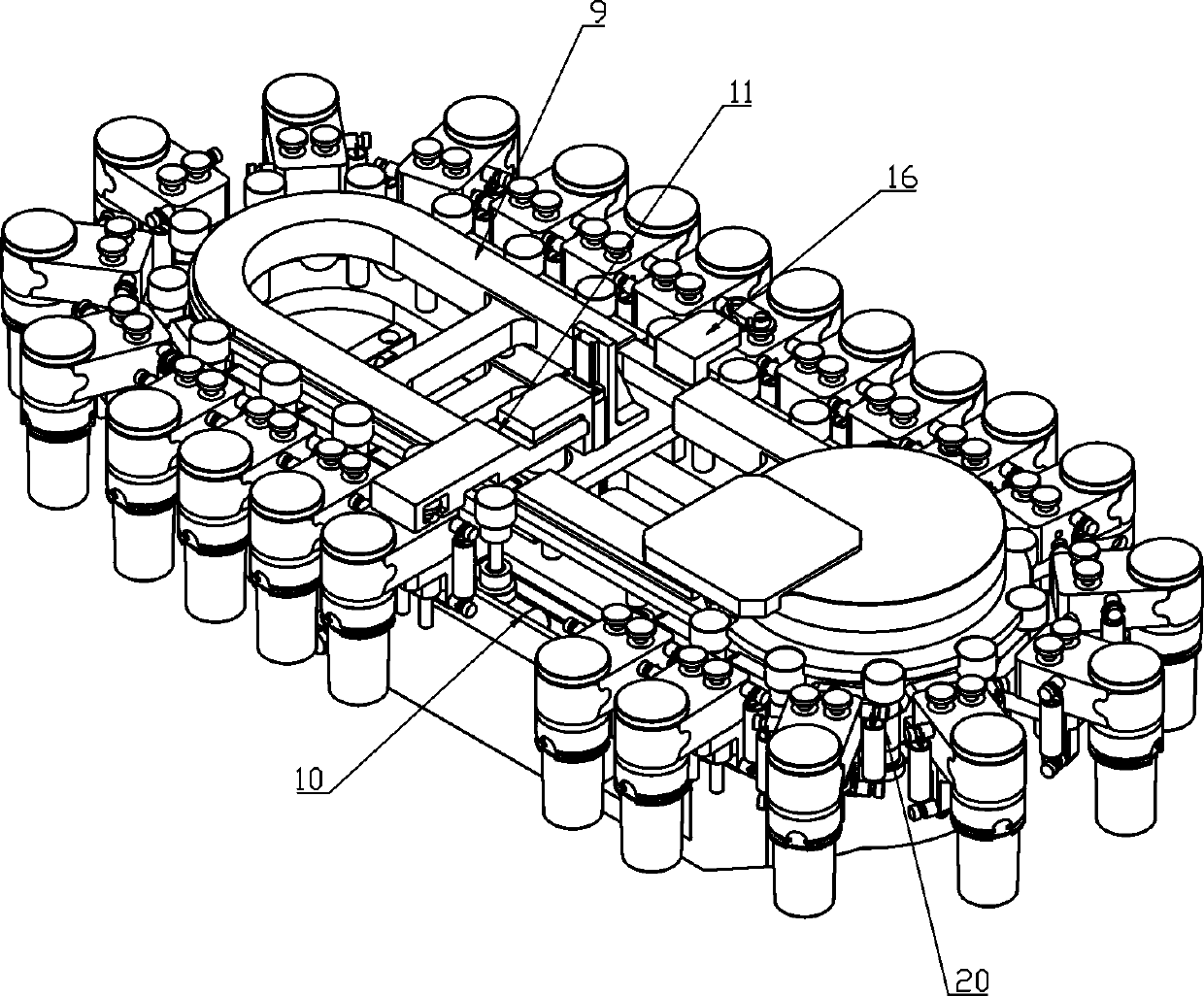

[0020] combine Figure 1 to Figure 2 As shown, an integrated chain tool magazine for self-picking and tool change of the present invention consists of a base 1, a chain mechanism 2, a chain drive unit 3, a tool changing manipulator 4, a manipulator rotation drive unit 5, a push-out slide 6, The ejection slide plate 7, the mobile ejection drive unit 8, the annular slide rail 9 and the guide groove 10 are composed.

[0021] The ring-shaped slide rail 9 is fixed on the base 1, and the chain mechanism 2 is arranged around the ring-shaped slide rail 9, which can rotate along the ring-shaped slide rail 9 under the action of the chain drive unit 3, and is guided by the guide groove 10 in the full stroke, effectively reducing the Noise and chatter during chain mechanism 2 rotation.

[0022] The push-out sliding seat 6 and the push-out slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com