Electromagnetic piston type tool changing device

A tool changing device and piston type technology, applied in the field of electromagnetic piston tool changing device, can solve the problems of affecting the tool changing speed, unable to lock the tool, low safety operation factor, etc., and achieve fast tool changing speed and safe operation factor of equipment. High, anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

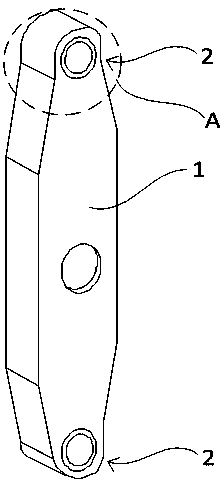

[0028] Please refer to figure 1 and figure 2 . An electromagnetic piston type tool changing device according to an embodiment of the present invention, such as figure 1 As shown, it includes the tool changing arm 1 and the tool changing hand 2. During the tool changing process, the tool changing arm 1 can rotate around the rotation axis at its center and move up and down. The two tool changing hands 2 are respectively located at the ends of the tool changing arm 1 At both ends, the tool changer 2 is used to hold the tool. Two ends of the tool changing arm 1 are respectively provided with a clamping hole, and a tool changing hand 2 is installed in the two clamping holes.

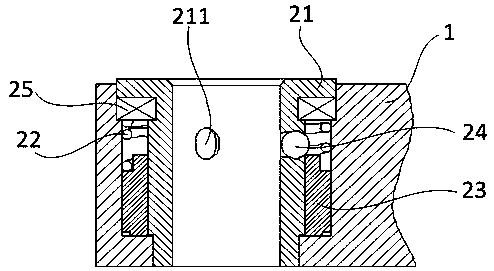

[0029] Such as figure 2 As shown, the tool changing hand 2 includes a clamping seat 21 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com