Disc type tool magazine for horizontal machining center

A horizontal, disk-type technology, applied in the field of small and medium-sized horizontal machining centers, can solve problems such as relatively large impact, and achieve the effects of fast tool change, shortened tool change time, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

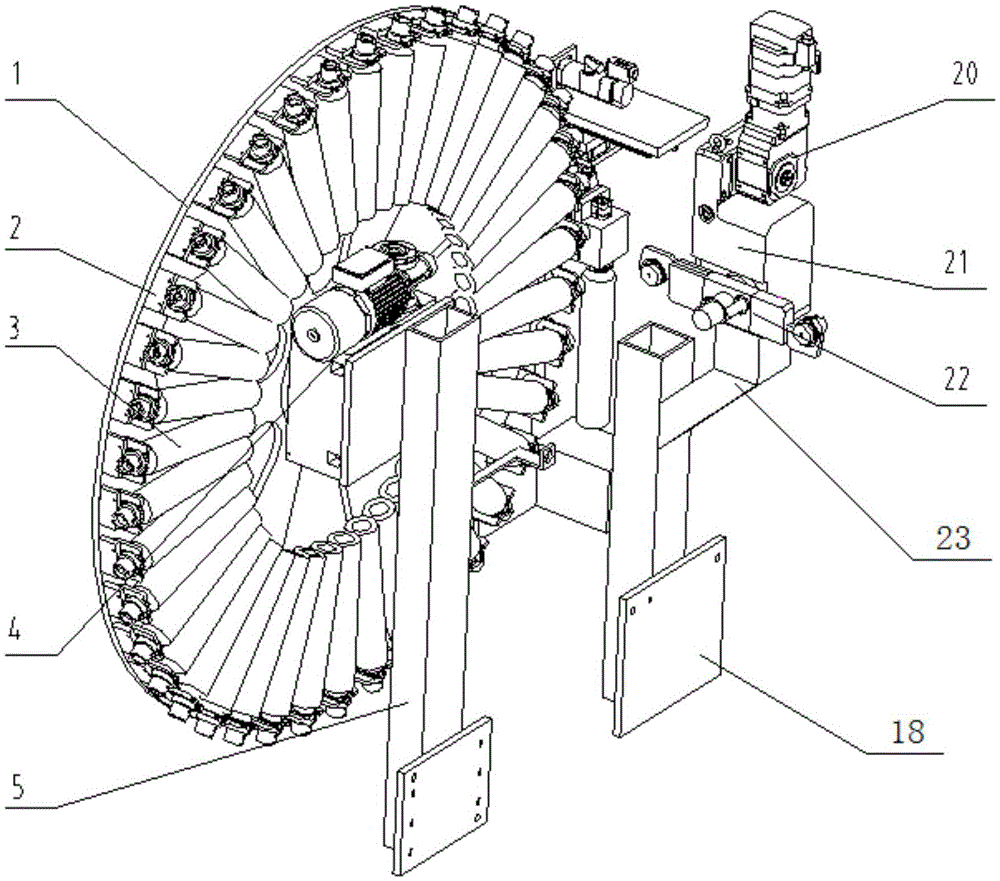

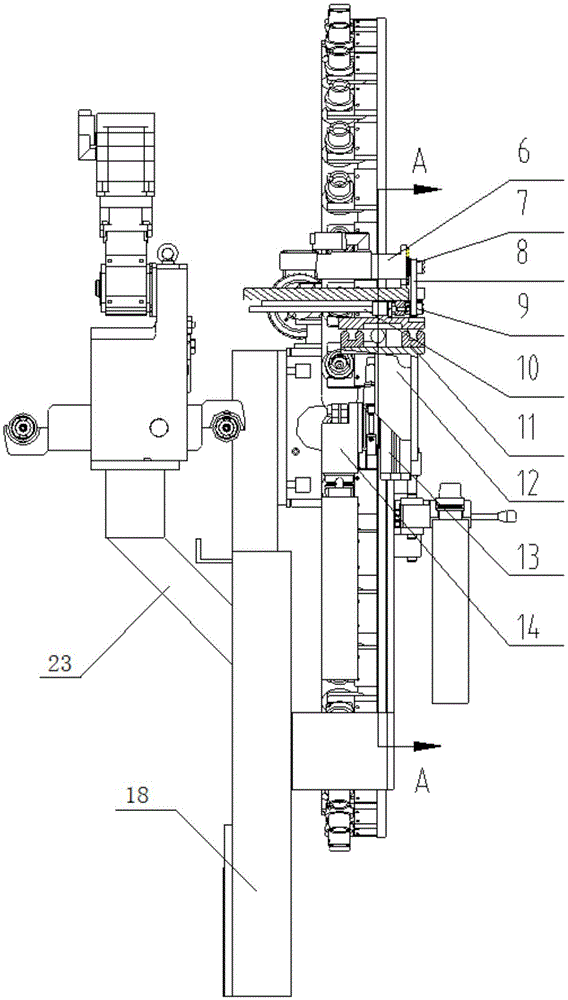

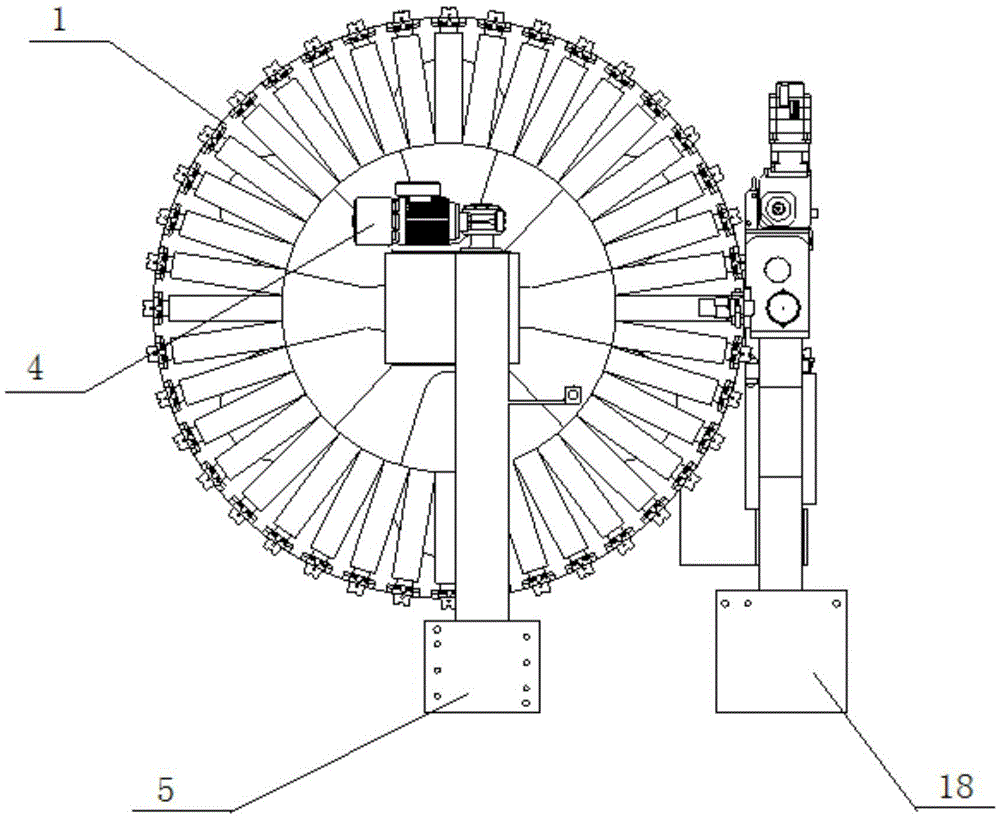

[0019] The invention will be described in further detail below in conjunction with the accompanying drawings. The invention is a disc-type tool magazine for a horizontal machining center, which has a tool magazine body, a tool conveying mechanism matched with the tool magazine body, and a tool changing mechanism.

[0020] like figure 1 and image 3 As shown, the specific structure of the tool storage body created by the present invention is as follows: a disc 1 is installed on the fixed bracket I5, the disc 1 can rotate around its own center through the rotating shaft, and several tool holders 2 are installed on the edge of the disc 1, each Each tool holder 2 is parallel to the axis of the disc 1 and is evenly distributed along the edge of the disc 1 . The axis of the tool holding part of the tool holder 2 is parallel to the disc surface of the disc 1, so that after the tool 3 is installed on the tool holder 2, the axis of the tool 3 is parallel to the disc surface of the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com