A barrel winding mold

A winding molding and mold technology, which is applied in the field of barrel winding molding molds, can solve the problems of adverse effects on product molding quality, insufficient strength and rigidity, and impact on product accuracy, etc., and achieves light weight, low cost, and self-weight reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Taking a large cylinder winding mold as an example, the design and preparation technology of the present invention will be further described in detail through examples.

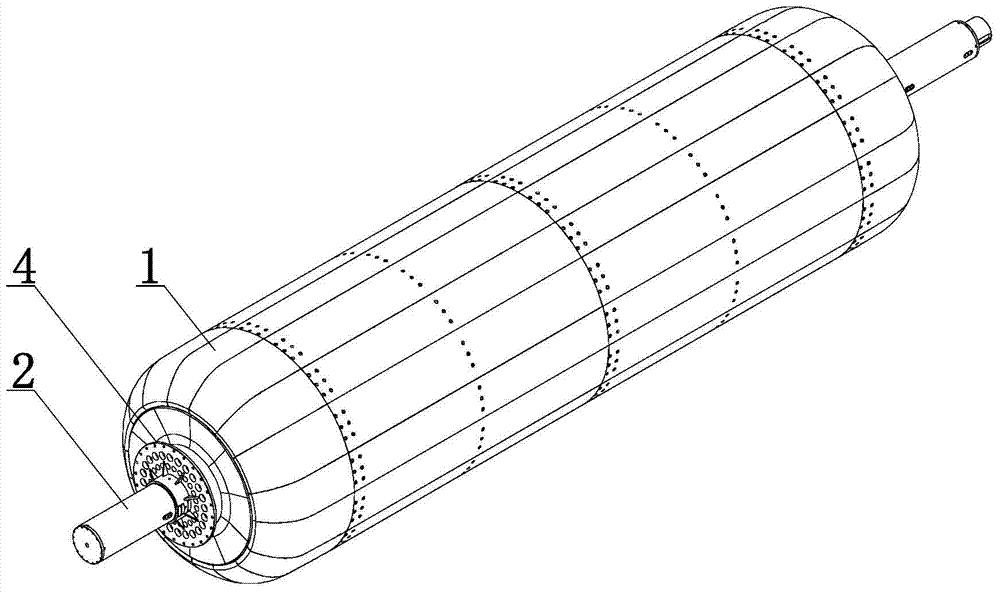

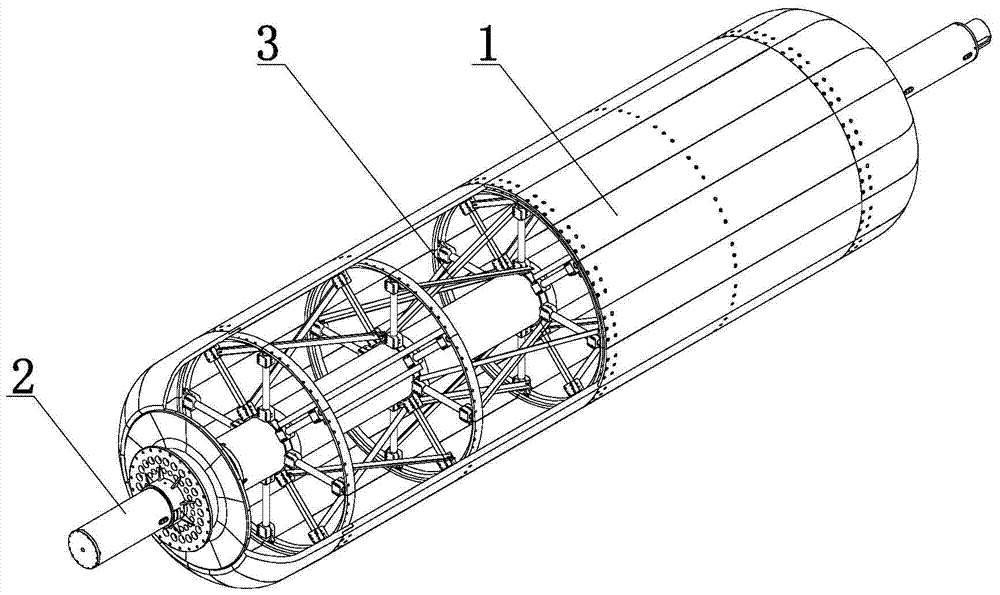

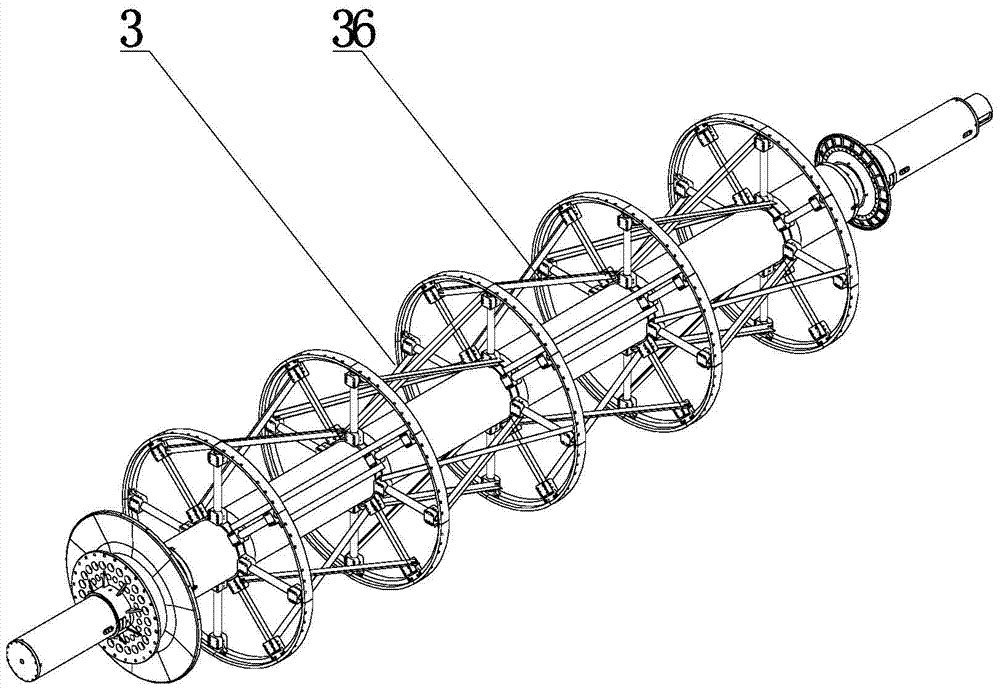

[0025] In this embodiment, a cylinder winding mold is combined with figure 1 and figure 2 As shown, it is composed of a housing 1, a mandrel 2, a support mechanism 3 and a head positioning device 4. The support mechanism 3 is divided into an inner ring 31, an outer ring 32, a support rod 33, a locking block 1 34 and a locking block 2 35, the inner ring 31 is an integral structure, and the locking block 1 34 is welded on it; the outer ring 32 is a split structure, which is connected as a whole by the bolts of the locking block 2 35; the support rods 33 are evenly distributed radially along the mandrel 2 , one end of which is connected to the locking block 1 34 of the inner ring 31, and the other end is connected to the locking block 2 35 of the outer ring 32; the inner ring 31 of the support mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com