Automatic pouring and steel bar unloading device

A technology of steel bars and feeding pipes, applied in the direction of supply devices, manufacturing tools, etc., can solve problems such as easy lumps, agglomeration, affecting pouring effect, uneven feeding, etc., to achieve convenient repair and maintenance, high practical value, Anti-adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

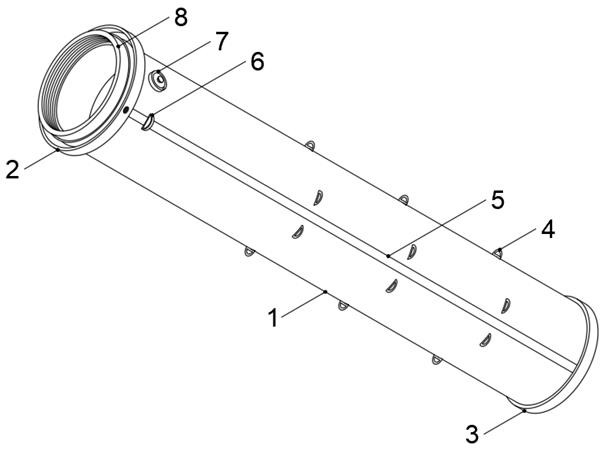

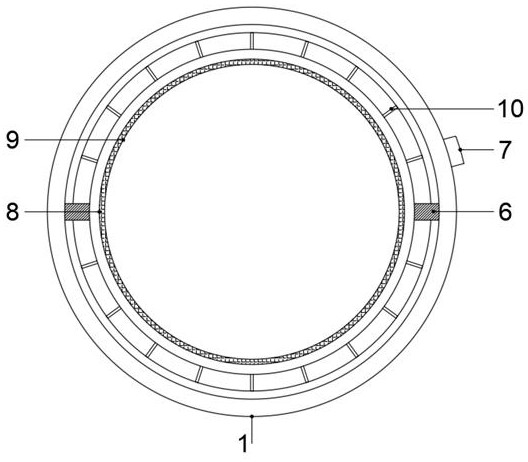

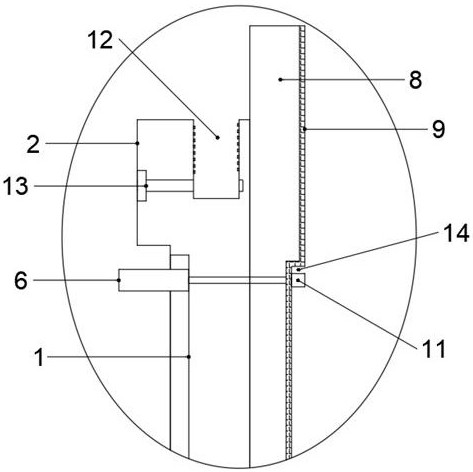

[0022] Example: as Figure 1-4 As shown in the figure, the present invention is an automatic pouring lower reinforcement device, which includes a feeding pipe body 1, a connecting ring 2 is installed at one end of the feeding pipe body 1, a bolt hole 13 is formed through the outer wall of the connecting ring 2, and a top end of the connecting ring 2 is provided with a connecting ring 2. Thread groove 12, a water inlet valve 7 is installed on the side of the outer wall of the feeding pipe body 1 close to the connecting ring 2, a chute 5 is longitudinally opened on the outer wall of the feeding pipe body 1, and a sliding block 6 is installed in the chute 5, and the lower The other end of the material pipe body 1 is provided with a discharge port 15, a reinforcing ring 3 is installed on the surface of the discharge port 15, a rubber ring 16 is sleeved on the surface of the reinforcing ring 3, and a ring is installed on the side of the outer wall of the feeding pipe body 1 close to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com