Hydraulic indexing tool rest

A tool holder and hydraulic technology, applied in the field of machine tool holder, can solve the problems of large positioning impact, difficult position control of induction motor and hydraulic rotary cylinder, slow tool change speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the content of the present invention easier to understand clearly, the present invention will be described in further detail below according to specific embodiments in conjunction with the accompanying drawings,

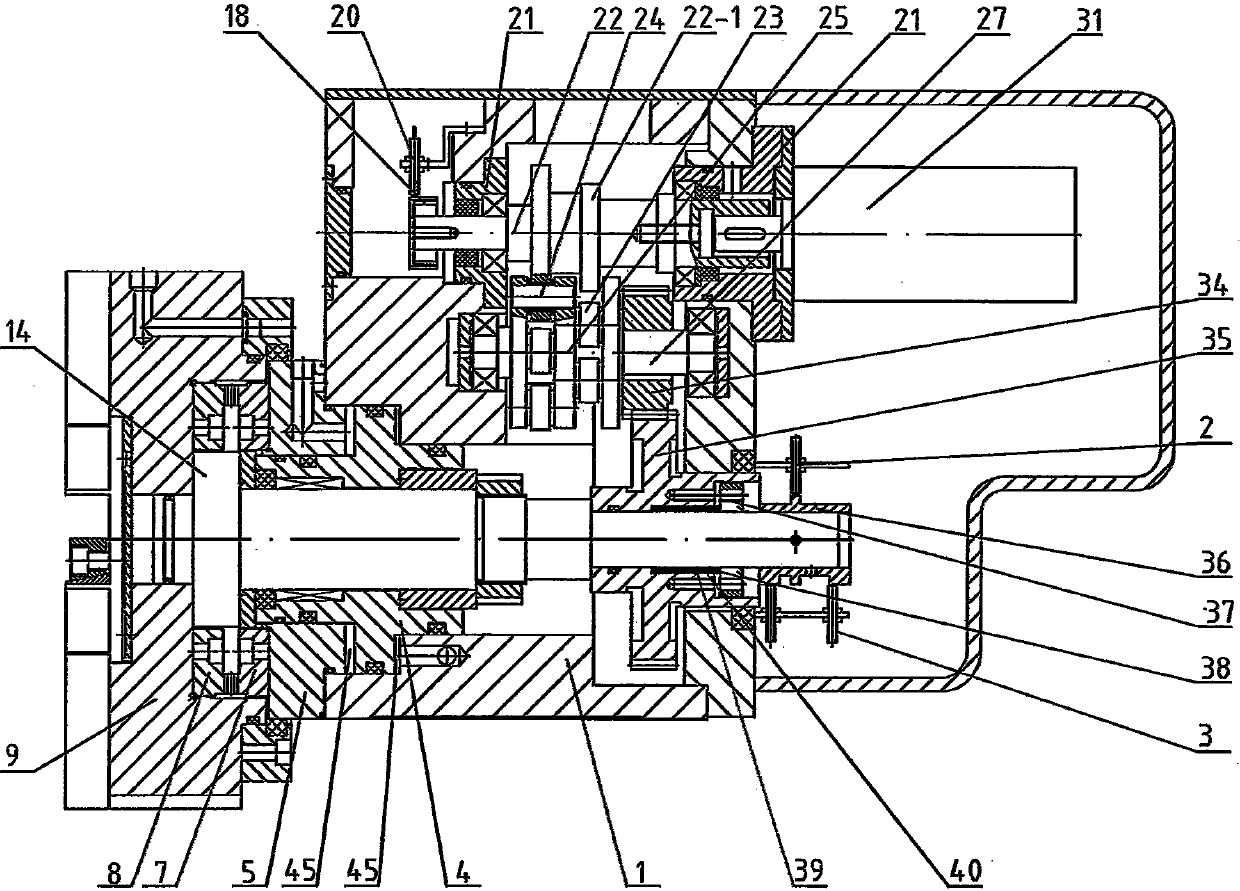

[0013] Such as figure 1 As shown, a hydraulic indexing tool holder, which includes a box body 1, a fixed shaft 14, a cutter head 9, a fixed ring gear 7, a movable ring gear 8, a gear plate connecting plate 5, a piston 4, a hydraulic motor 31, and a driving gear 34. Fixed shaft gear 35, parallel conjugate cam indexing mechanism, signaling wheel 36, cutterhead locking sensor 2, tool position transposition sensor 20, detection wheel 18, multiple tool position sensors 3 and control The control system for the action of the piston 4 and the action of the hydraulic motor 31. The fixed shaft 14 is supported on the box body 1 and can move axially relative to the box body 1. The cutter head 9 is fixedly sleeved on the head end of the fixed shaft 14. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com