Automatic tool changing device of high-speed machining center

A machining center and automatic tool changing technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems such as maintenance costs that cannot be ignored, high prices, and difficult processing of cambered indexing cams, and achieve structural Simple, fast tool change, easy to create effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

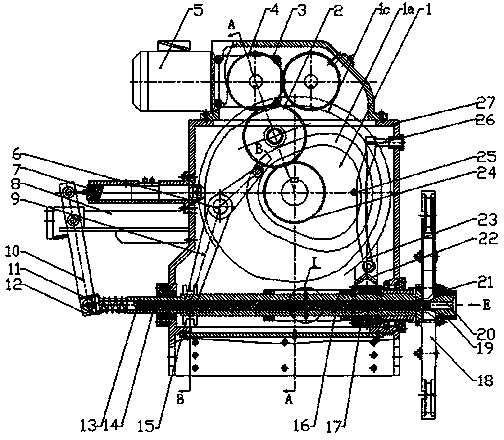

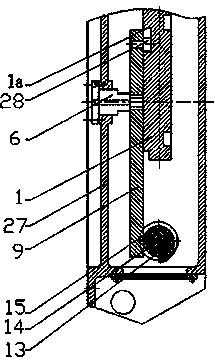

[0022] like figure 1 The automatic tool changing device of the high-speed machining center shown includes a box body 27, a tool arm spindle 13, a tool changing arm 18, a power transmission mechanism, a tool inserting mechanism, a tool changing mechanism, a tool locking mechanism, a transmission clutch mechanism, and a tool The arm main shaft 13 is supported on the casing 27 by a bearing, the knife arm main shaft can reciprocate axially, and the tool changing arm 18 is fixed on the front end of the knife arm main shaft 13 .

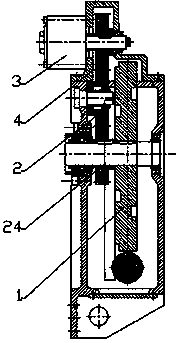

[0023] powertrain such as figure 1 , 2 As shown, the motor 5 is connected to the reducer 3, and the reducer is transmitted to the compound cam 1 through the gears 4, 2, 24. The compound cam is supported on the box through the rotating shaft. The axis of the compound cam is perpendicular to the axis of the tool changer arm. The compound cam It is composed of three contour curves 1a, 1b, 1c with different functions, which respectively control the mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com