Drilling-milling tapping machine

A tapping machine, drilling and milling technology, applied in the direction of metal processing machinery parts, large fixed members, clamping, etc., can solve the problems of unstable load, poor mechanical stability, easy mechanical wear, etc., to achieve constant load and not easy to wear , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

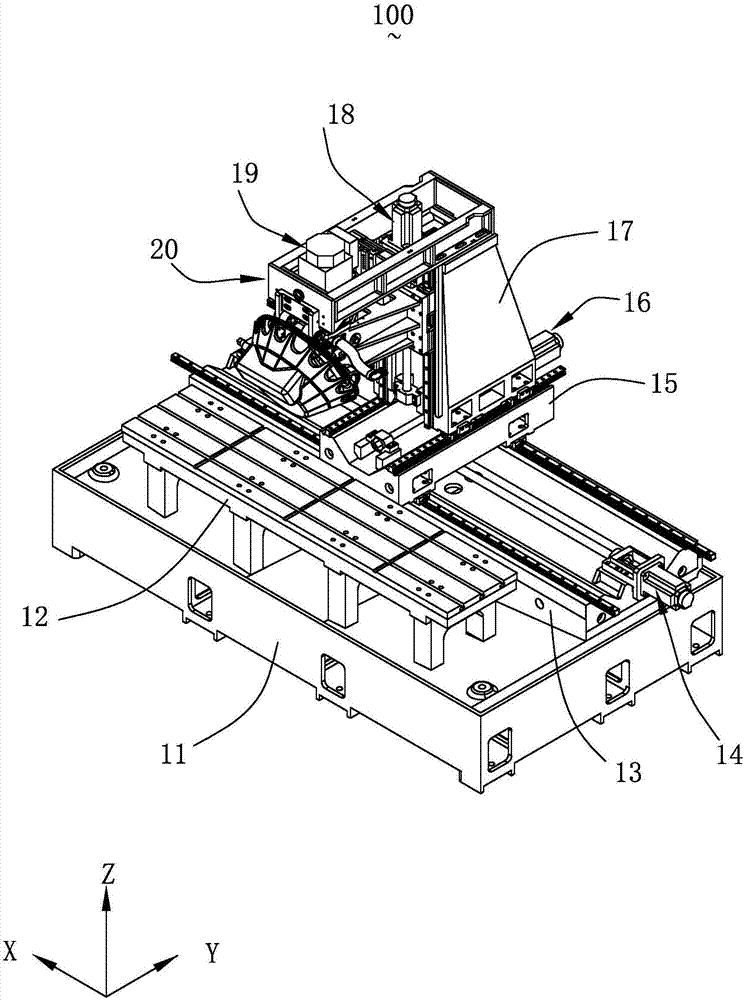

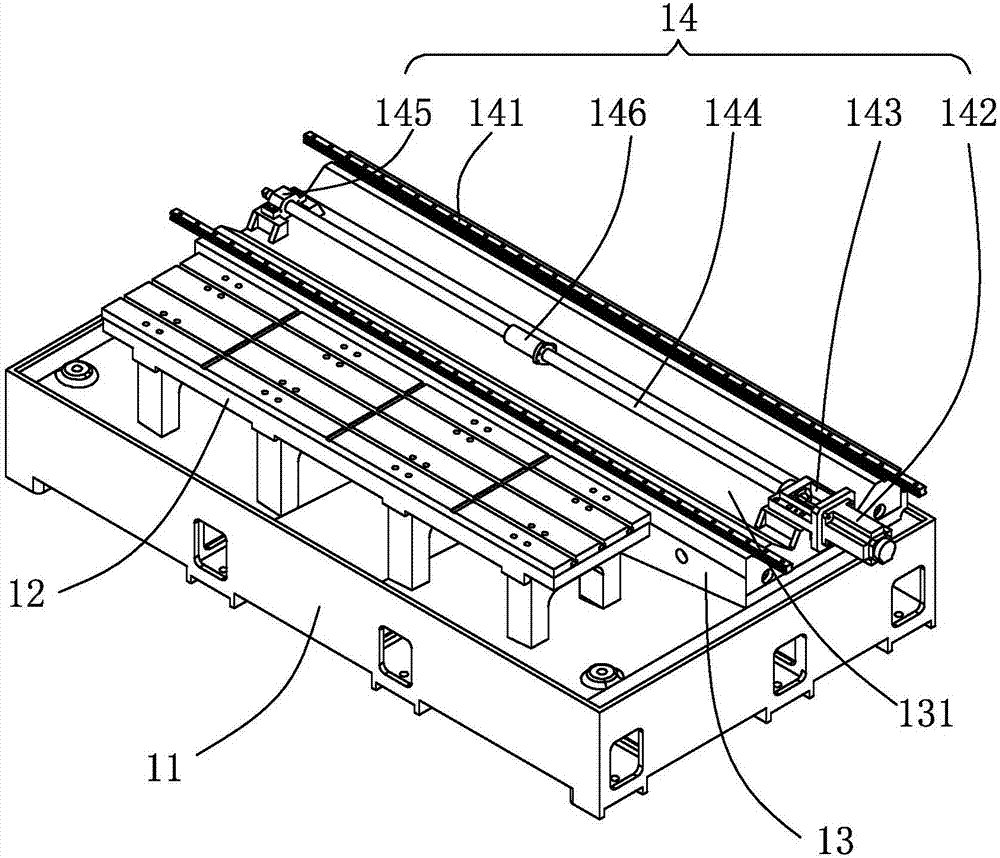

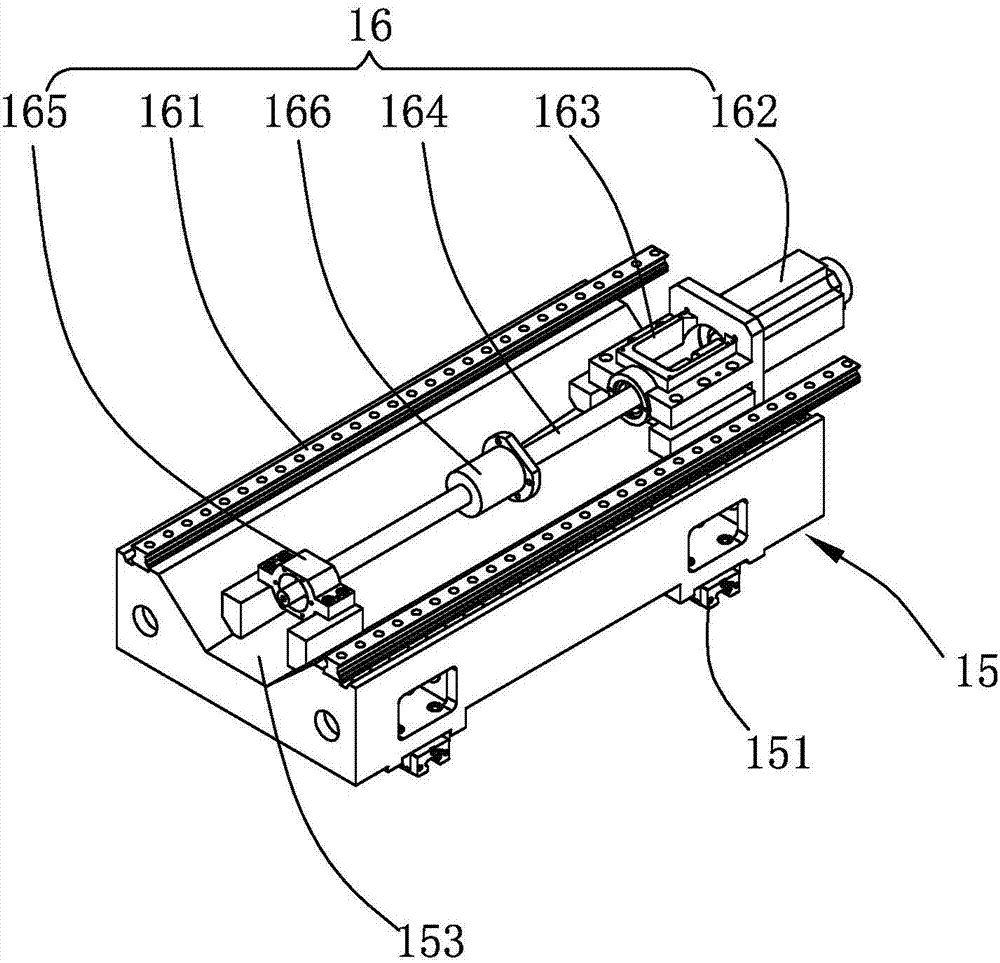

[0030] see figure 1 , is a structural schematic diagram of the drilling, milling and tapping machine provided by the present invention. The drilling, milling and tapping machine 100 includes a base 11, a workbench 12 fixed on the base 11, a mounting platform 13 located on the base 11 and one side of the workbench 12, and a mounting platform 13 located on the mounting platform. The X-axis driving mechanism 14 of 13, the saddle 15 mounted on the mounting table 13 and driven by the X-axis driving mechanism 14, the Y-axis driving mechanism 16 arranged on the saddle 15, and the saddle 16 arranged on the saddle 15 and a column 17 driven by the Y-axis drive mechanism 16, a Z-axis drive mechanism 18 located on one side of the column, a spindle box located on one side of the column 17 and driven by the Z-axis drive mechanism 18 19. A tool changing system 20 fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com