Automatic tool changer of circular cutter holders for CNC machining center

A technology of automatic tool change and rotary tool holder, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of fast tool change speed and large number of tools, and achieve fast tool change speed and high machining accuracy , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

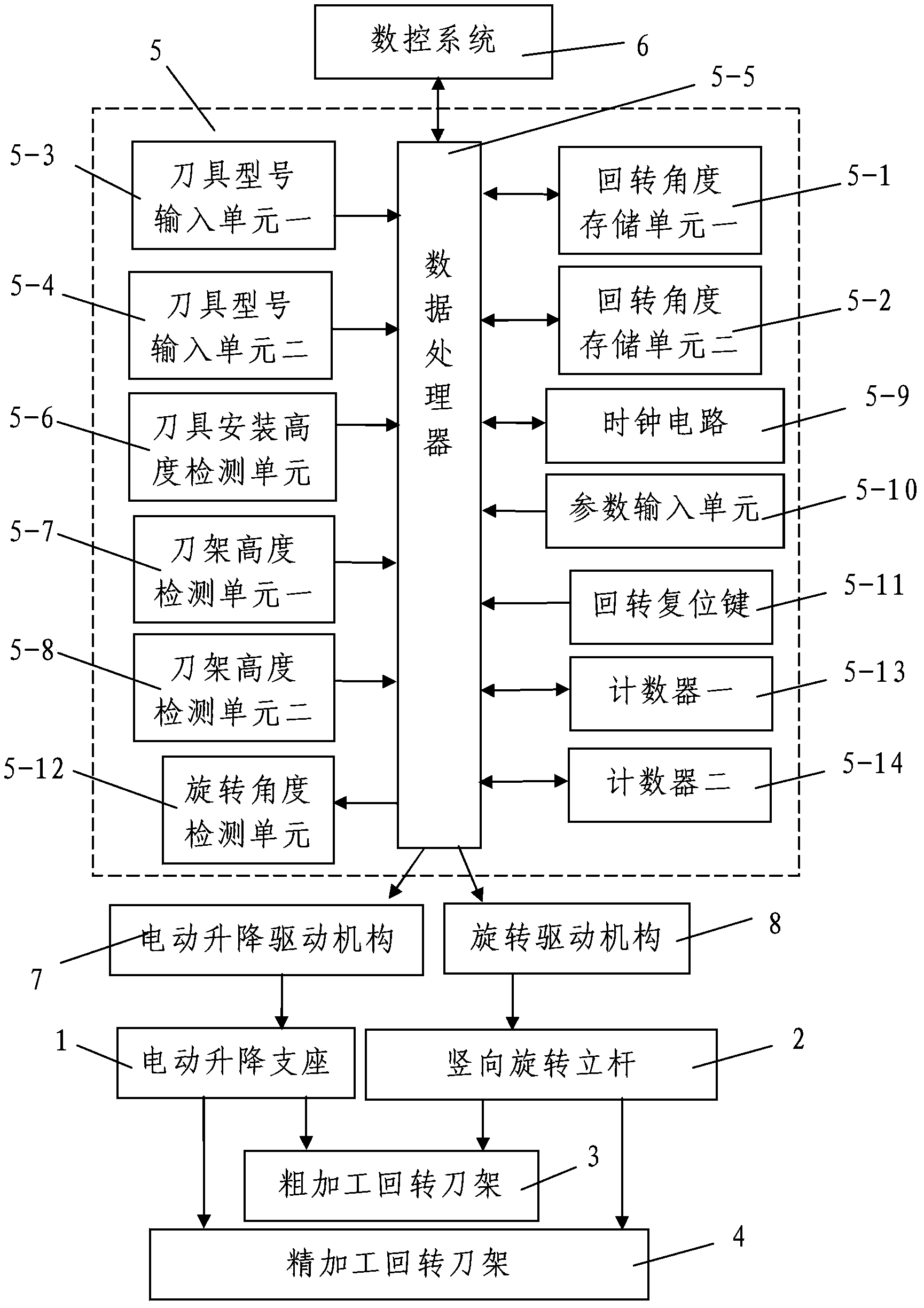

[0028] Such as figure 1 As shown, the present invention includes an automatic tool change control system 5, an electric lifting support 1, an electric lifting drive mechanism 7 for driving the electric lifting support 1, and a vertical rotating pole installed on the electric lifting support 1 through a bearing. 2. The rotary drive mechanism 8 that drives the vertical rotation pole 2 to rotate 360°, the rough machining rotary tool rest 3 installed on the vertical rotation pole 2 and the finishing machine installed on the vertical rotation pole 2 The rotary tool rest 4, the automatic tool change control system 5 is connected with the numerical control system 6 of the numerical control machining center. The finishing rotary tool rest 4 is located directly below the rough machining rotary tool rest 3, and the rough machining rotary tool rest 3 includes rough machining tool rests arranged horizontally. Evenly distributed tool mounting positions one. The finishing rotary tool hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com