Polypropylene honeycomb-core glass fiber polypropylene composite plate and manufacture method thereof

A honeycomb core glass fiber polypropylene, polypropylene glass fiber layer technology, applied in chemical instruments and methods, synthetic resin layered products, glass/slag layered products, etc. Mildew and other problems, to achieve the effect of good smell, good recyclability and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

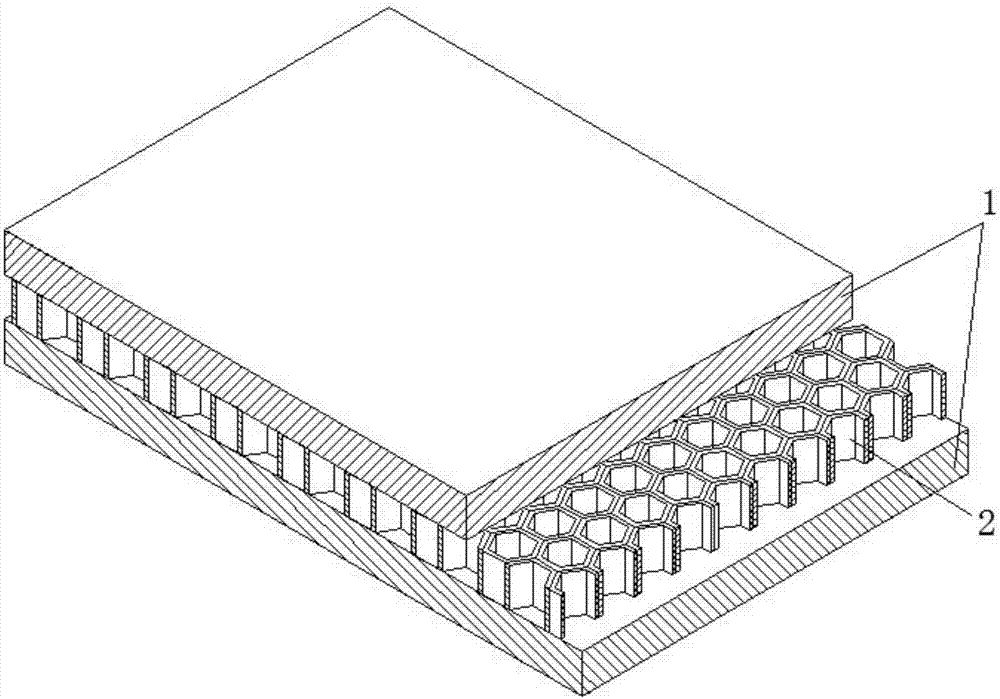

[0024] Referring to the accompanying drawings, a polypropylene honeycomb core glass fiber polypropylene composite board, the composite board is composed of polypropylene glass fiber layer 1, polypropylene honeycomb core 2 and polypropylene glass fiber layer 1 stacked sequentially from bottom to top , The components of the composite board are by weight, including 29.5 parts of polypropylene fiber, 35 parts of glass fiber, 0.5 part of carbon black, and 35 parts of polypropylene honeycomb core.

[0025] Preferably, the polypropylene honeycomb core is a honeycomb structure in which hollow polypropylene thin-walled tubes are stacked and bonded to each other.

[0026] Preferably, the raw material of the polypropylene honeycomb core includes two kinds of melting point polypropylene materials in parts by weight, wherein 90 parts of polypropylene and 10 parts of low melting point polypropylene.

[0027] Preferably, the polypropylene glass fiber layer includes 35 parts of glass fiber, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com