Aquosity foaming synthetic leather with knurling shrunken patterns

A synthetic leather, water-based technology, applied in the field of synthetic leather, can solve the problems of many embossing process equipment, poor pattern visual effect, short pattern retention time, etc., and achieve the effect of excellent covering effect, soft hand feeling and good overall effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

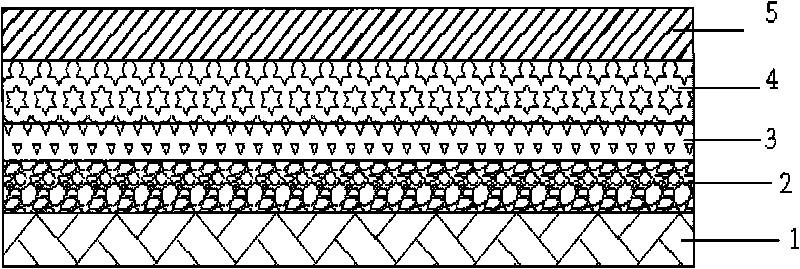

[0022] Such as figure 1 Shown, a kind of water-based foamed synthetic leather with embossed shrink pattern, it comprises base cloth layer 1, the polyurethane foam layer 2 that is coated on described base cloth layer 1, is coated on polyurethane foam layer 2 The water-based polyurethane adhesive layer 3, the water-based foamed resin layer 4 coated on the water-based polyurethane adhesive layer 3, and the silicone-modified polyurethane 5 coated on the water-based foamed resin layer 4.

[0023] The above synthetic leather, after the water-based foaming resin layer is foamed at a high temperature of 170 ℃ in the later stage, has a strong three-dimensional effect of bumps and convexes. The combination of foam layer, shrinkage layer and embossing treatment has a more three-dimensional effect and a unique effect. Among them, the silicone-modified polyurethane resin coated on the water-based foaming resin layer, due to the different polarity of the two, used in combination, the modifi...

Embodiment 2

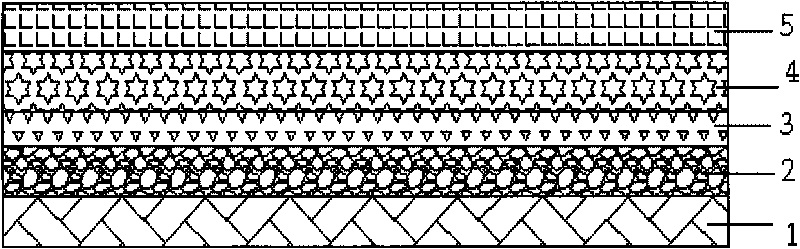

[0025] Such as figure 2 Shown, a kind of water-based foamed synthetic leather with embossed shrink pattern, it comprises base cloth layer 1, the polyurethane foam layer 2 that is coated on described base cloth layer 1, is coated on polyurethane foam layer 2 The water-based polyurethane adhesive layer 3, the water-based foamed resin layer 4 coated on the water-based polyurethane adhesive layer 3, and the acrylic modified polyurethane 5 coated on the water-based foamed resin layer 4.

Embodiment 3

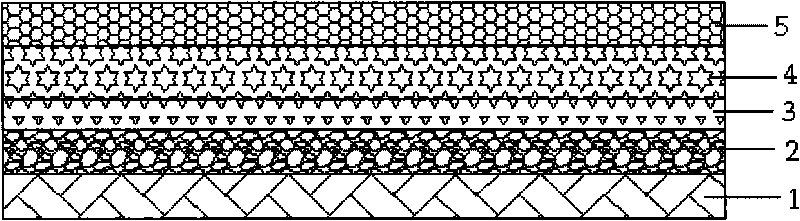

[0027] Such as image 3 Shown, a kind of water-based foamed synthetic leather with embossed shrink pattern, it comprises base cloth layer 1, the polyurethane foam layer 2 that is coated on described base cloth layer 1, is coated on polyurethane foam layer 2 The water-based polyurethane adhesive layer 3, the water-based foamed resin layer 4 coated on the water-based polyurethane adhesive layer 3, and the water-based modified polyurethane 5 coated on the water-based foamed resin layer 4. The above is only a preferred embodiment of the present invention, it should be pointed out that, for those of ordinary skill in the art, without departing from the principle of the present invention, some improvements and modifications can also be made, and these improvements and modifications can also be made. It should be regarded as the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com