Waterproof chemical-corrosion-resistant heat tracing cable sheath material and preparation method thereof

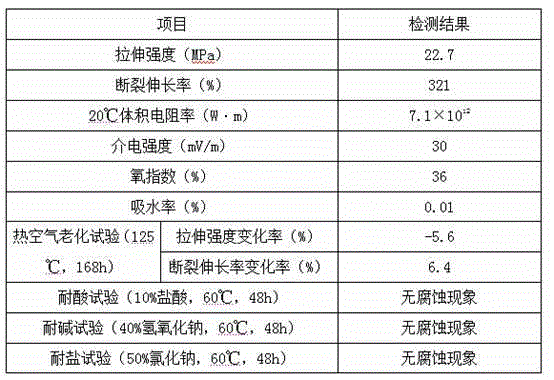

A technology for chemical-resistant and heat-tracing cables, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor water resistance and chemical corrosion resistance, and easy damage to the sheath layer, and achieve excellent mechanical damage resistance and waterproof Strong performance and good chemical corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] A waterproof and chemical-resistant heat tracing cable sheathing material, made of the following raw materials in weight (kg): high-density polyethylene 45, polyethylene terephthalate-1,4-cyclohexane dimethanol ester 28. Random copolymer polypropylene 22, silica fume powder 16, alum powder 12, tribasic calcium phosphate 4.5, zinc hydroxystannate 6, polymethyltriethoxysilane 2.5, basalt fiber powder 18, barium naphthenate 2. Calcium rosinate 3.5, dioctyl terephthalate 12, strontium hydroxide 8, N-hydroxymethyl stearamide 4, tricresyl phosphate 10, calcium borate 12, 4-chloro-N-(stearyl) Amidomethyl) pyridine 1.5, auxiliary 3.5;

[0014] The preparation method of the auxiliary agent is as follows: (1) Take the following raw materials by weight (kg): thiourea dioxide 2, calcium sulfite 5, chloro bridge acid anhydride 3, flue ash 10, ethylhexyl palmitate 2, succinic acid Diethyl ester 4, aluminum titanate 6, chromium chloride methacrylate complex 2, sucrose benzoate 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com