Synthetic leather with crazy horse contracted patterns

A technology for synthetic leather and pattern, applied in the field of synthetic leather, can solve the problems of poor leather feeling of synthetic leather, many embossing process equipment, poor visual effect of patterns, etc., and achieve the effects of full hand feeling, unique visual effect and realistic leather effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

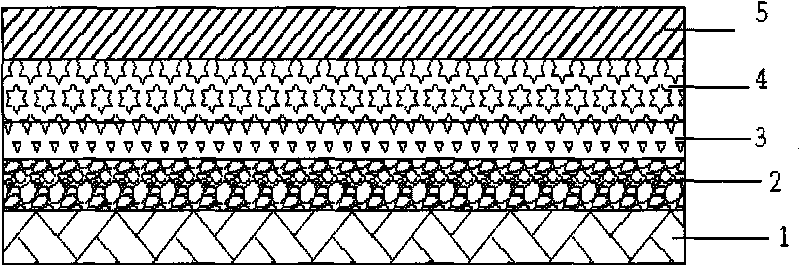

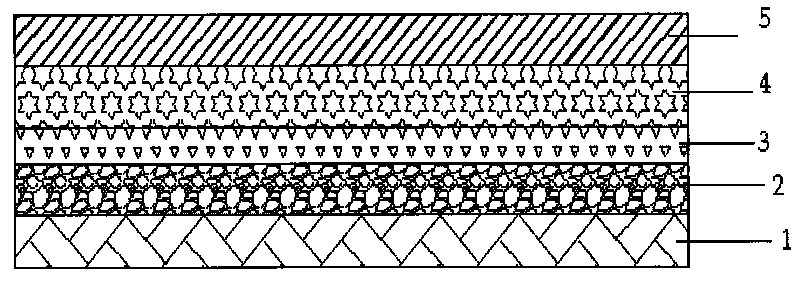

[0016] Such as figure 1 Shown, a kind of synthetic leather with crazy horse contraction pattern, it comprises base fabric layer 1, the polyurethane foam layer 2 that is coated on described base fabric layer 1, the polyurethane adhesive that is coated on polyurethane foam layer 2 The knot layer 3, the crazy horse resin 4 coated on the polyurethane bonding layer 3, the modified polyurethane resin 5 coated on the crazy horse resin 4, and the acrylic modified resin layer 6 coated on the modified polyurethane resin 5 .

[0017] For the above-mentioned synthetic leather with crazy horse contraction patterns, the modified polyurethane resin 5 may preferably be silicone modified polyurethane, acrylic modified polyurethane, epoxy modified polyurethane or water-based modified polyurethane.

[0018] The above synthetic leather, in which the crazy horse resin coated on the polyurethane bonding layer, after the post-water kneading treatment, has fluff growing out, has a special velvet fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com