Water-based polyacrylate emulsion

A polyacrylate emulsion, water-based technology, used in textiles, papermaking, fiber treatment, etc., can solve the inherent quality (drying resistance, washing performance can not be guaranteed, product dispersion, poor stability, washing resistance and cold resistance, etc. problem, to achieve the effect of improving self-crosslinking performance, water resistance and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

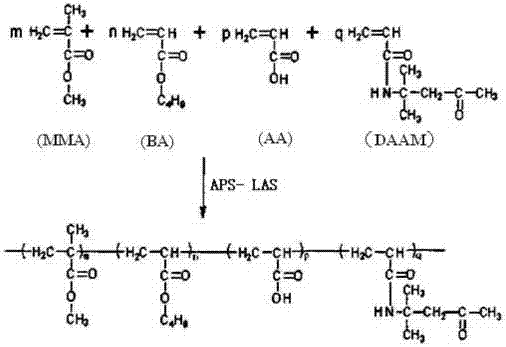

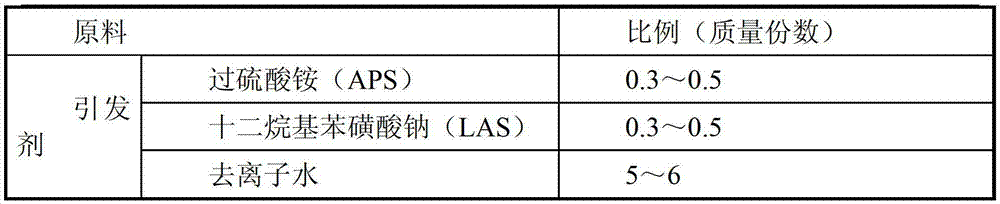

[0015] A method for preparing self-crosslinking water-based polyacrylate powder-free base paste for clothing adhesive lining, comprising the following steps: first, mixing water-based polyacrylate emulsion, auxiliary agents and deionized water, wherein the water-based polyacrylate Acrylate emulsion is prepared by pre-emulsion, seed emulsion, sub-emulsion, 10% adipic hydrazide aqueous solution and ammonia water. The pre-emulsion is composed of methyl methacrylate, butyl acrylate, acrylic acid, diacetone acrylamide , sodium alkylamide ethylene sulfonate, fatty alcohol polyoxyethylene ether and deionized water. The seed emulsion is prepared from a composite initiator and a polymerization bottom material. Oxyethylene ether and deionized water are prepared, the composite initiator is prepared from ammonium persulfate, sodium dodecylbenzenesulfonate and deionized water, and the secondary emulsion is composed of monomers and emulsifiers, The monomer is composed of methyl methacrylate...

preparation example 1

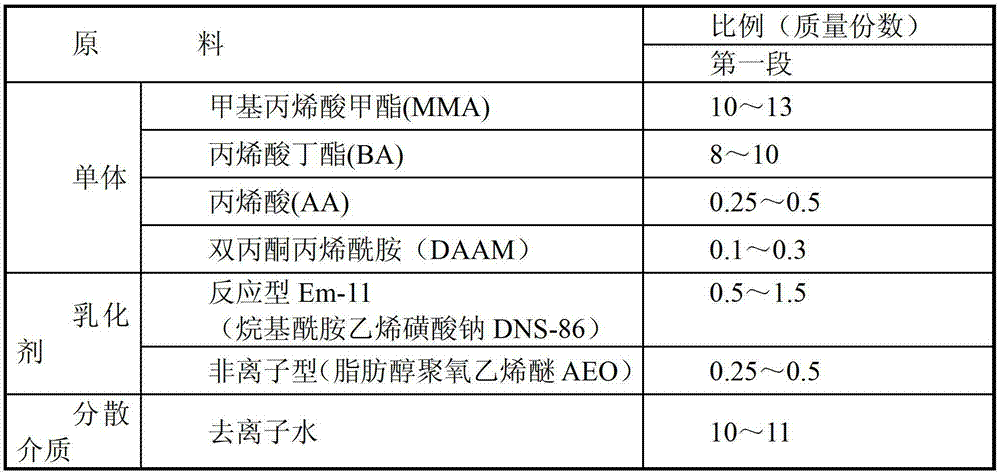

[0075] The present invention adopts the semi-continuous emulsion polymerization process and seed emulsion polymerization method of pre-emulsified monomers to carry out conventional emulsion polymerization and core-shell emulsion polymerization respectively on the same formula, and designs the composition of the core-shell to synthesize a series of polymer emulsions. The formulation composition is shown in Table 1.

[0076] Table 1 Different polymerization methods and formula composition

[0077]

[0078] Table 2 shows the stability and emulsion properties of different polymerization methods.

[0079] Table 2 Stability and emulsion properties of different polymerization methods

[0080]

Embodiment 1

[0082] Take the PRA-2 sample emulsion in Preparation Example 1 and cool it down to room temperature, slowly add 10% adipic hydrazide (ADH) aqueous solution, and neutralize it with ammonia water until the pH value is 7-8. Filtration, discharge, to obtain a milky white emulsion in blue light, which is the product of the present invention—a main emulsion of self-crosslinking type water-based polyacrylate powder-free base slurry for clothing adhesive interlining.

[0083]The basic formula of the powder-free base pulp includes, in addition to the medium water, the base main emulsion, pH regulator, thickener, tackifier, whitening agent, preservative and defoamer, etc. Calculate the amount of deionized water and main emulsion according to the preset plan, adjust the pH value of the system to neutral with ammonia water, and then add the corresponding water-based additives to adjust the viscosity [viscosity <30000 (mPa·s / 20°C)] After that, the product of the present invention can be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com