Twisting device for preparing hollow fiber membrane

A fiber membrane and twisting technology, which is applied in the field of hollow fiber membrane manufacturing equipment, can solve the problems of easy distortion and affecting the quality of hole hollow fiber membranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

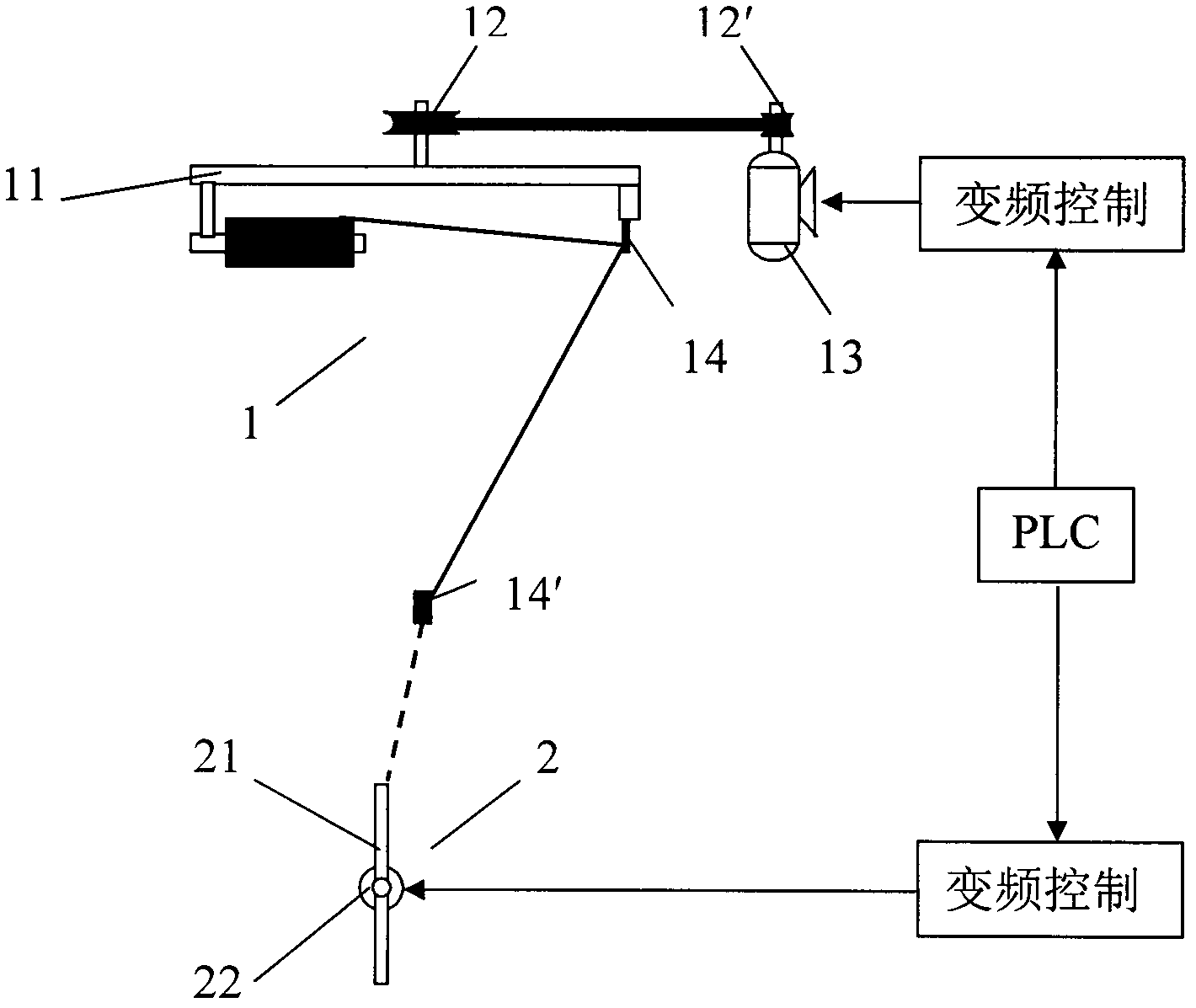

[0008] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof. The specific examples are only for further clearly illustrating the skeining device of the present invention for producing hollow fiber membranes by stretching and pore formation, and do not constitute limitations on the claims of the present invention.

[0009] The skeining device of the present invention for preparing hollow fiber membranes by stretching holes is composed of an untwisting system 1 and a skein winding system 2 when the precursor is unwound (see figure 1 ). Unwinding system 1 is made up of frame 11, transmission pulley 12,12 ', variable frequency speed regulating motor 13, guide wire hook 14,14 ';

[0010] During skeining processing, firstly hang the polypropylene hollow fiber precursor filament tube to be post-stretched-heat-setting on the frame of the unwinding device 1, and the precursor filament bundle passes through the guide wire hooks 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com