High-speed and high-precision die cutting machine control system based on four-axis motion controller

A technology of motion controller and control system, applied in general control system, control/adjustment system, computer control, etc., can solve the problems that the speed cannot be matched, it is impossible to increase the speed of the die-cutting and creasing machine, and reduce it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

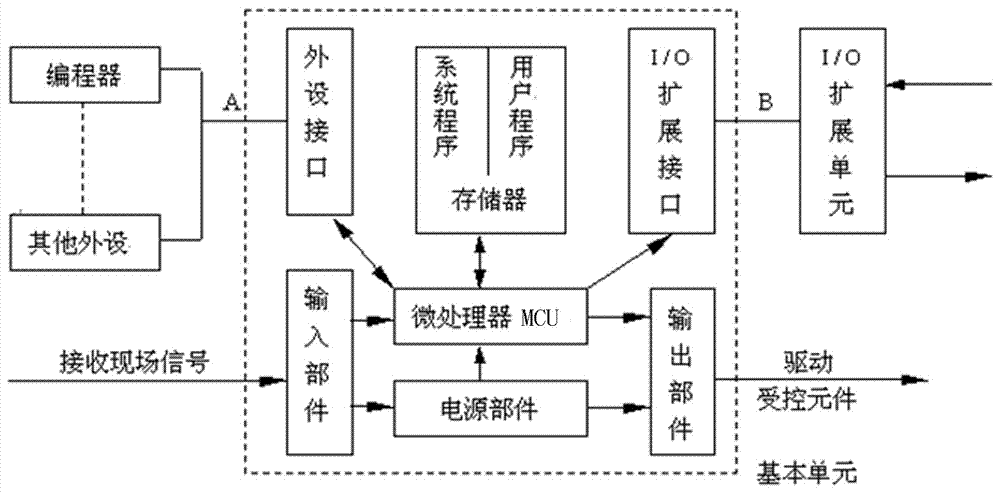

[0013] Such as figure 1 As shown, the high-speed and high-precision die-cutting machine control system based on the four-axis motion controller of the present invention includes a basic unit, a programmer, and an I / O expansion unit, wherein the basic unit is provided with a microprocessor MCU, memory, and input components And the output part, etc., the output part is connected with the controlled element, and is used to drive the controlled element. The controlled components include servo motors or stepping motors; the basic unit has 4 adjustable pulse outputs, which can be equipped with four-axis servo motors or stepping motors, and the highest frequency of each pulse output can reach 5MHz, with repeatable accuracy ±0.1Hz; the number of pulses is -2,147,483,647~+2,147,483,648 (32 bits).

[0014] The microprocessor MCU adopts the Harvard architecture of the embedded MCU, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com