Patents

Literature

66results about How to "Move at the same speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

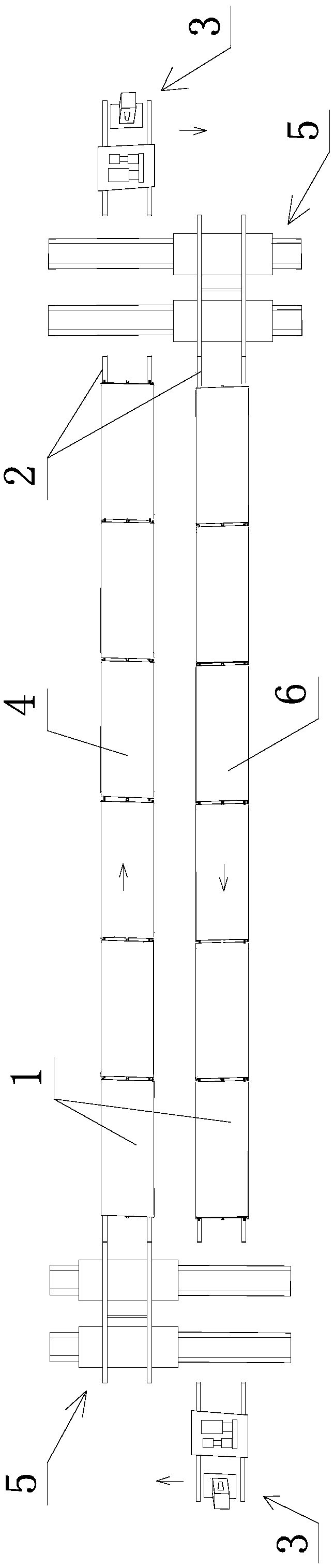

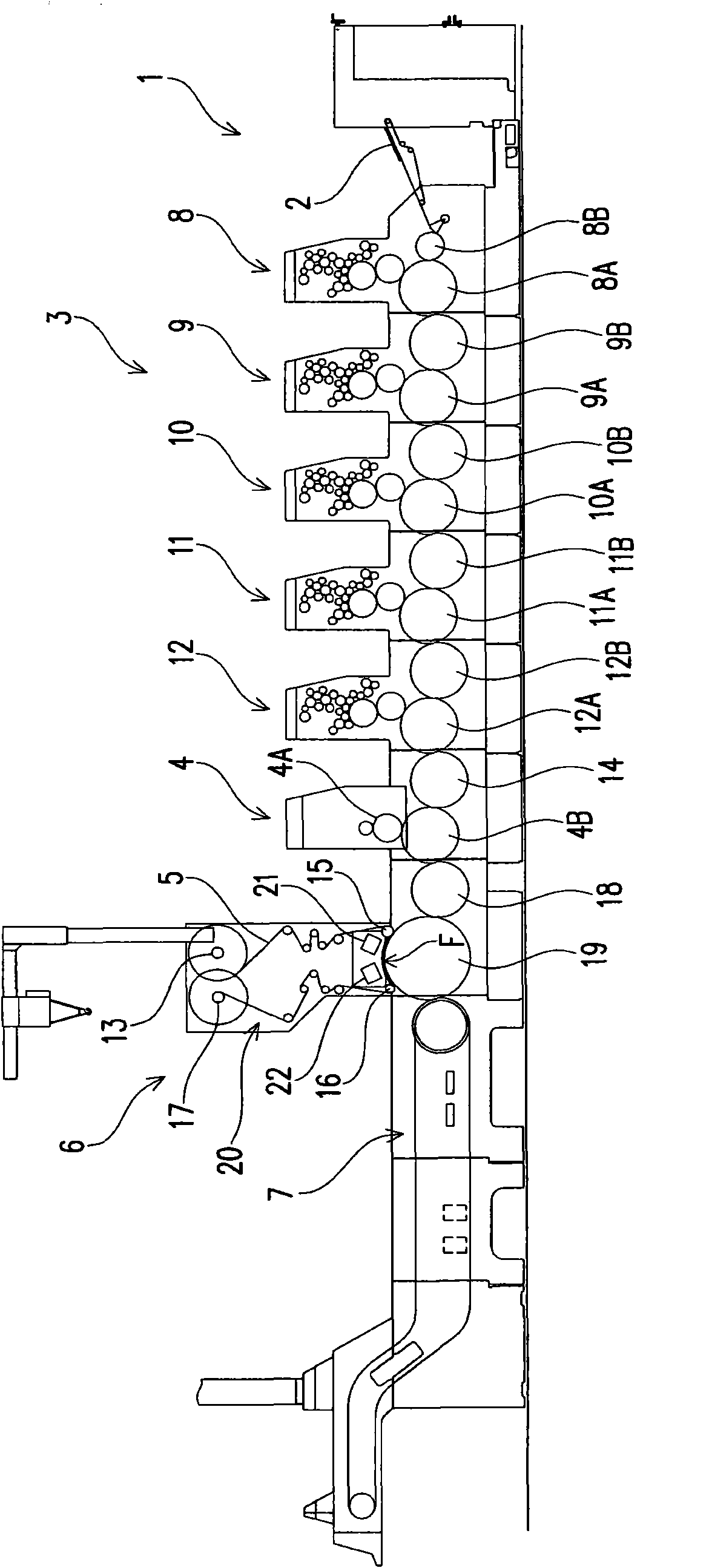

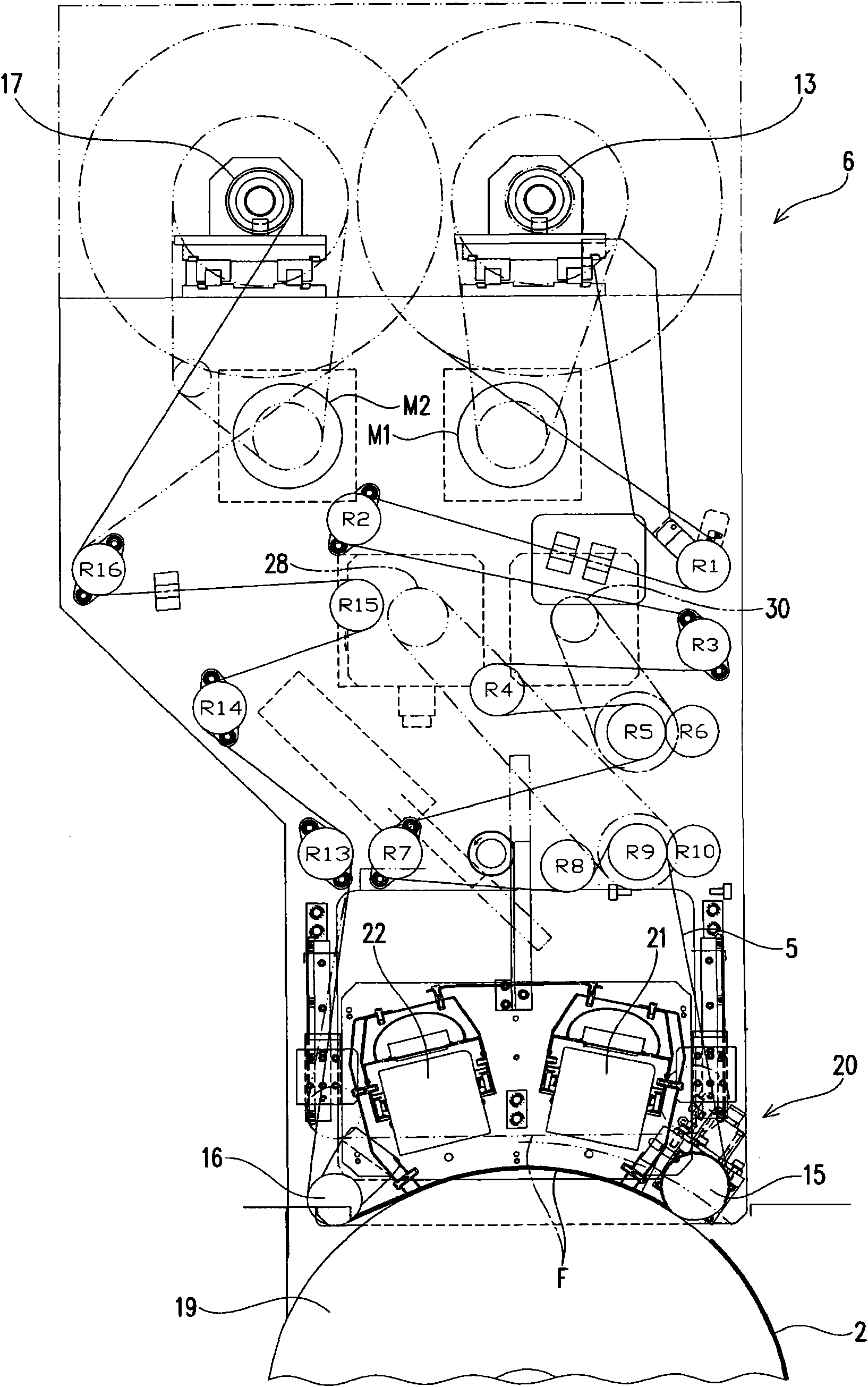

Conveying operation method and conveying operation device

InactiveCN101112746AHigh precisionIncrease productivityAutomatic control devicesControl devices for conveyorsIndustrial engineering

Owner:HONDA MOTOR CO LTD

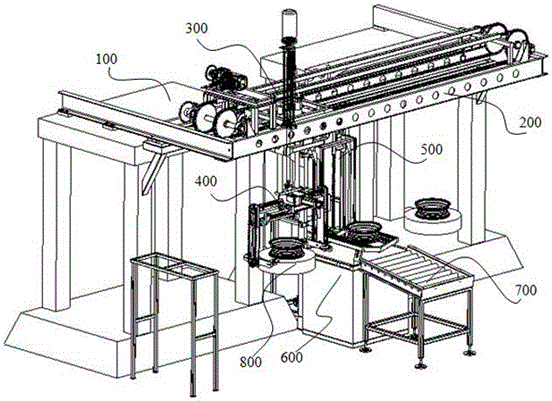

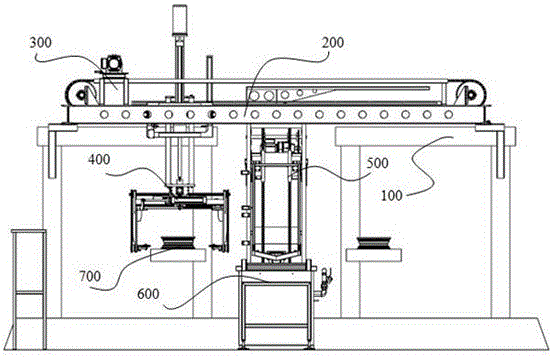

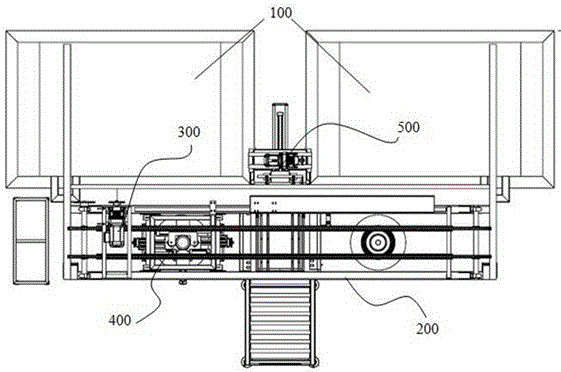

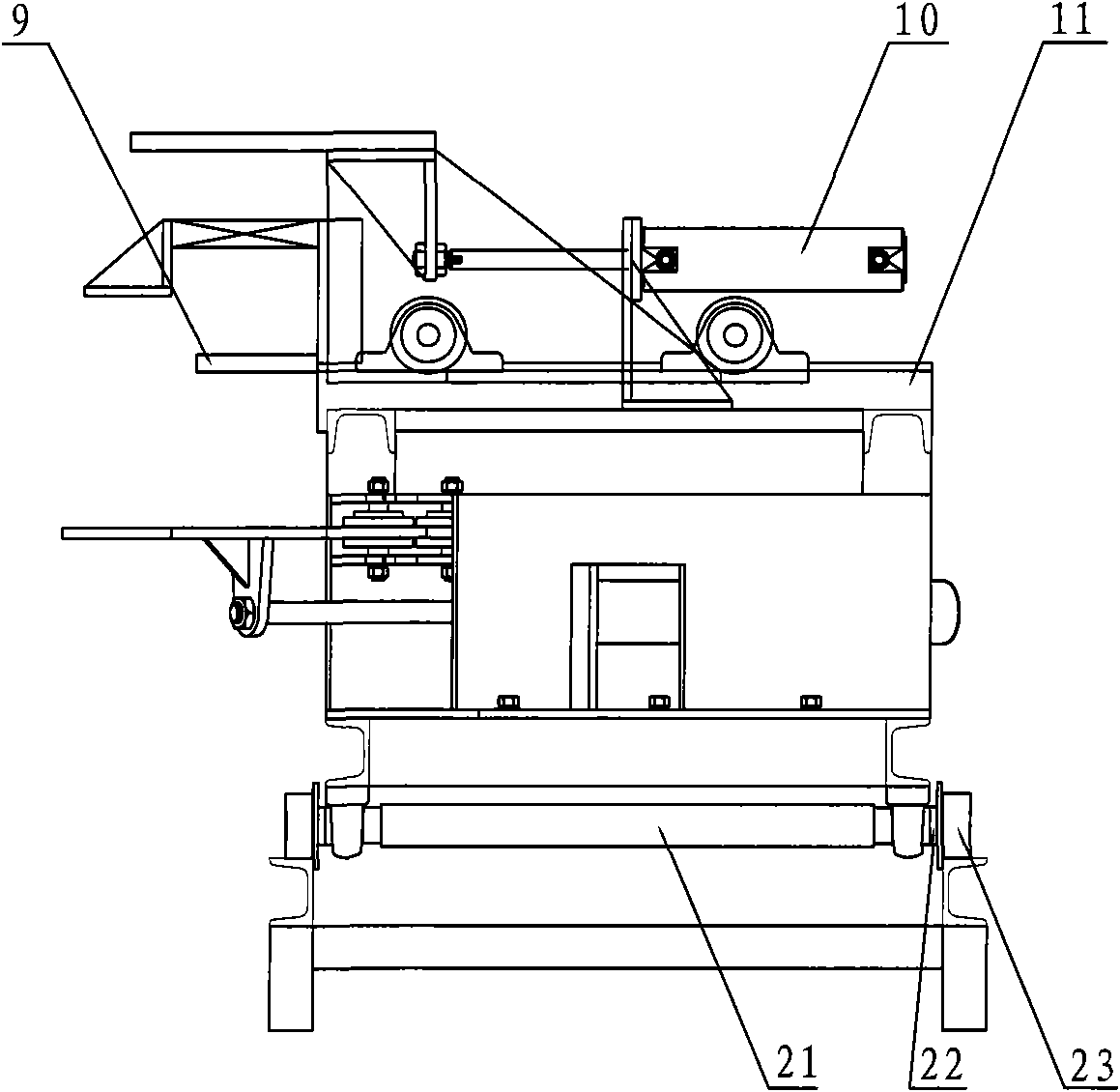

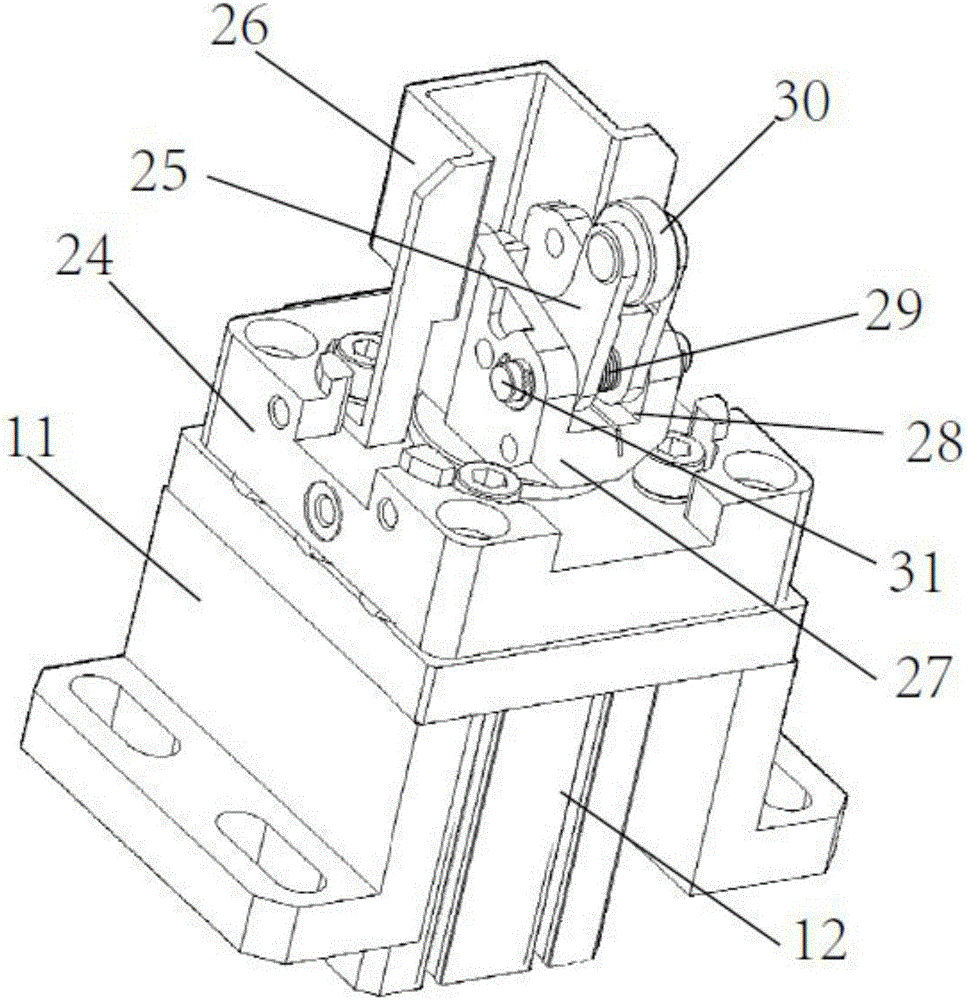

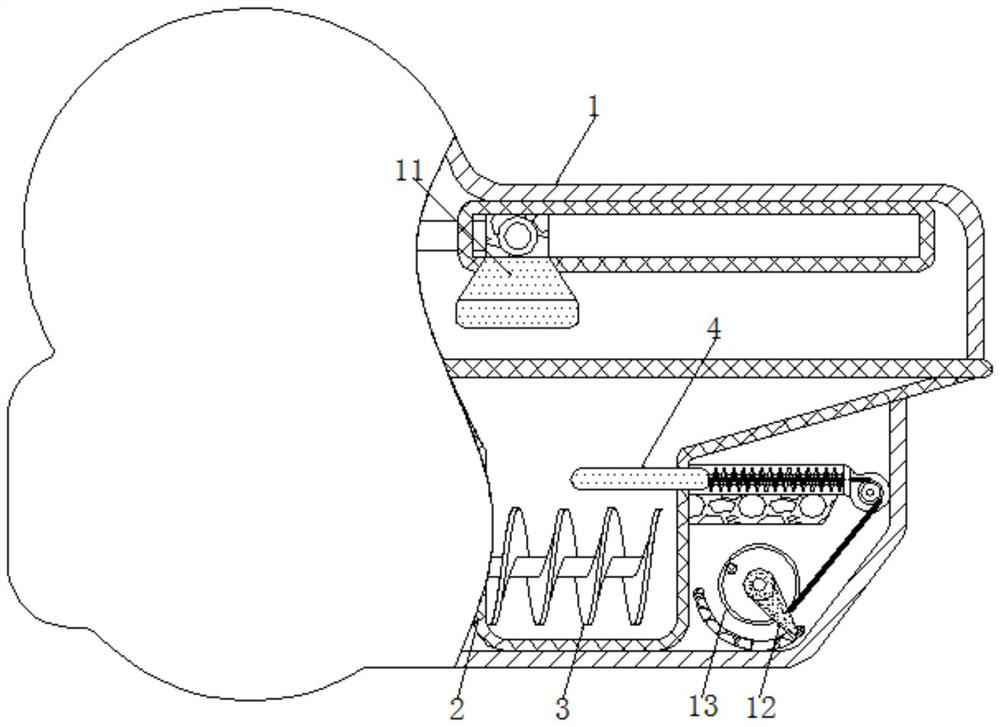

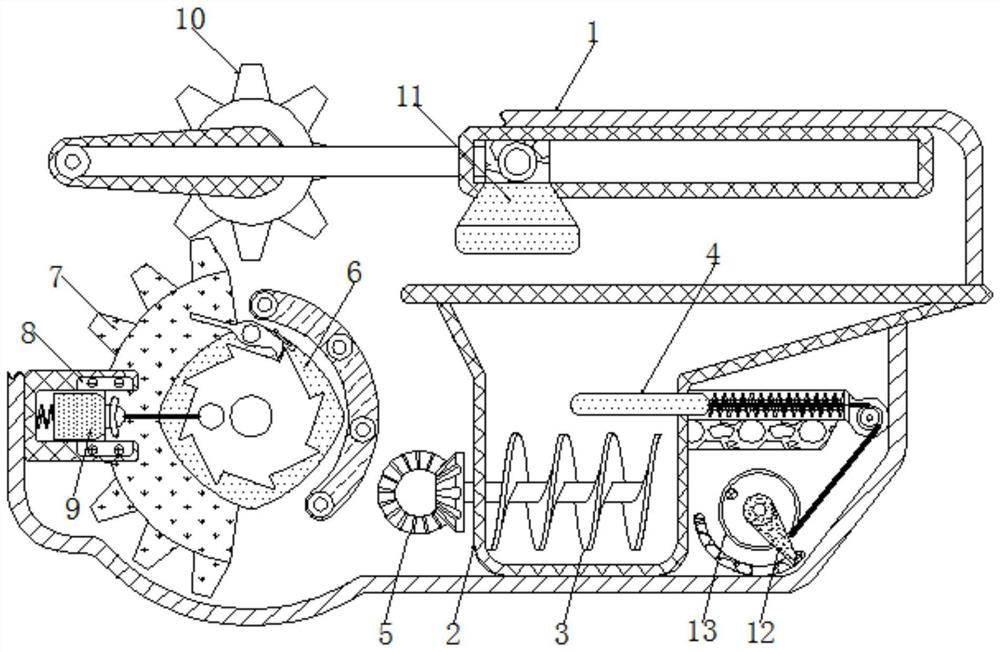

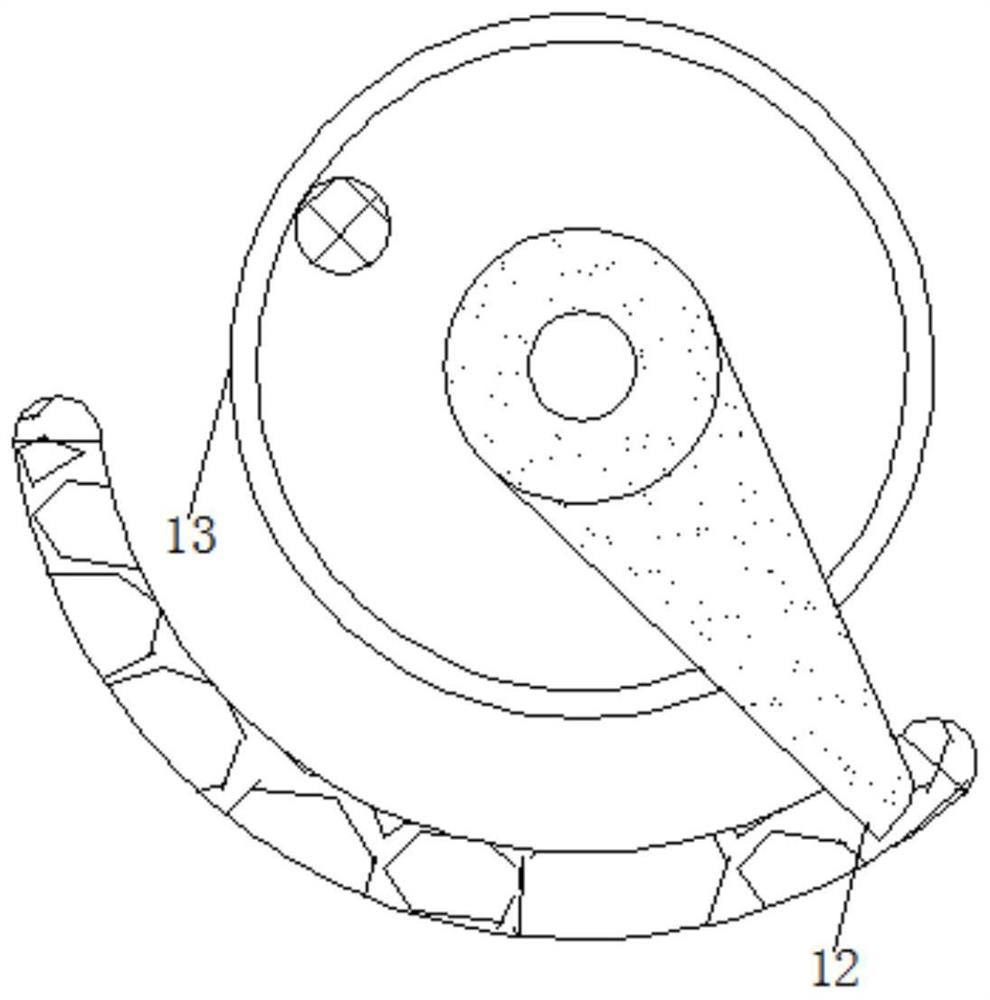

Cooling manipulator of die-casting machine for automobile aluminum alloy hub

The invention provides a cooling manipulator of a die-casting machine for an automobile aluminum alloy hub. The cooling manipulator comprises two supporting seats, a bracket, a transverse driving mechanism, a mechanical grabber, a longitudinal driving mechanism, a cooling water tank and a discharging rack, wherein the two supporting seats are arranged in parallel, and the bracket is mounted on the two parallel supporting seats; the transverse driving mechanism is mounted on the bracket; the mechanical grabber, comprising a moving rack, a first cylinder and a grabber body, is mounted on the transverse driving mechanism and is driven by the transverse driving mechanism to horizontally move; the longitudinal driving mechanism is mounted below the transverse driving mechanism; the cooling water tank is mounted in front of the longitudinal driving mechanism; the discharging rack is mounted at the front side of the cooling water tank. The cooling manipulator of the die-casting machine for the automobile aluminum alloy hub is simple in structure, high in automation degree, and free of manual carrying of the hub casting; the automobile aluminum alloy hub can be automatically clamped, moved, cooled, turned over and discharged in production, so that the automation level of a hub production device can be improved.

Owner:徐州智驾谨行科技有限公司

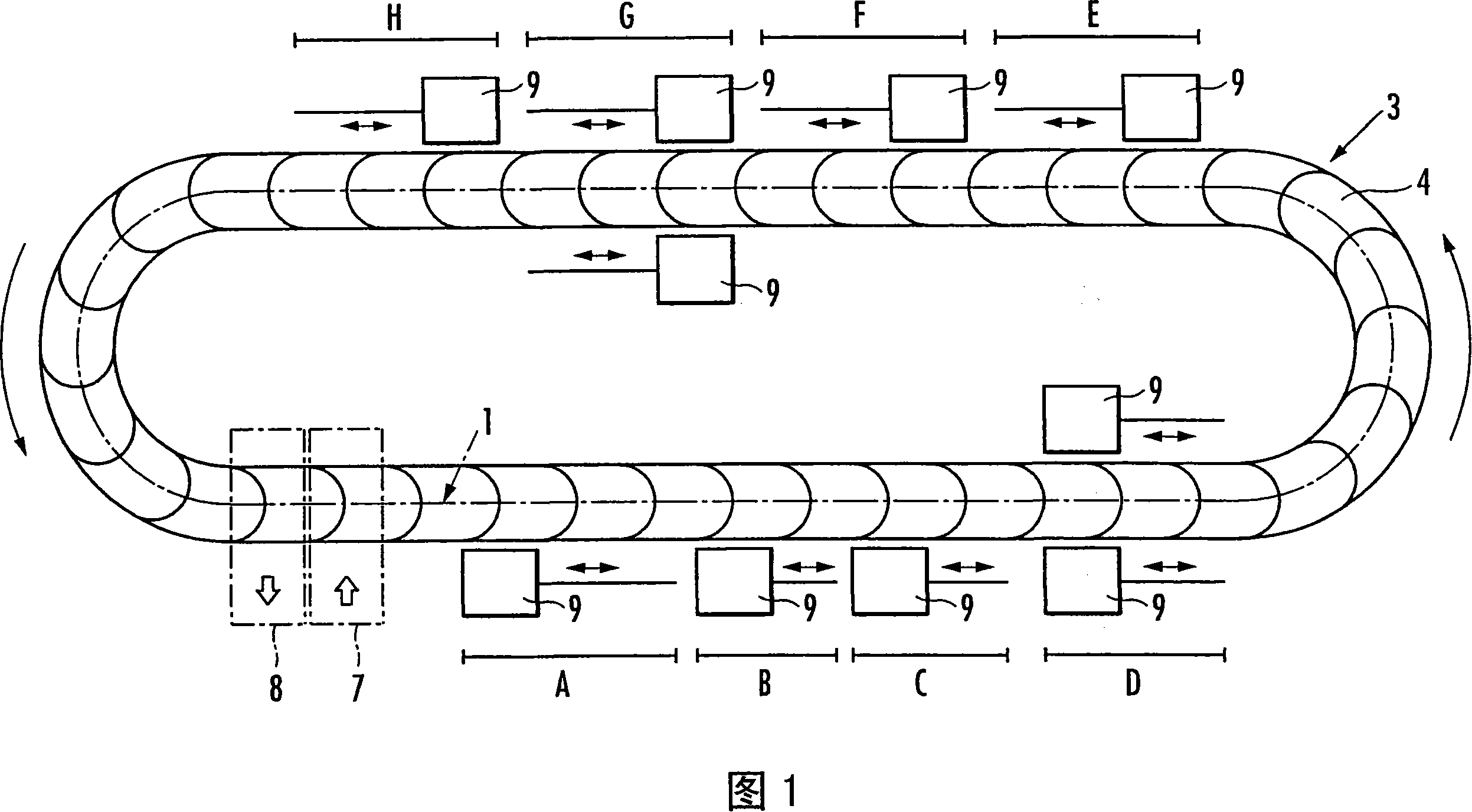

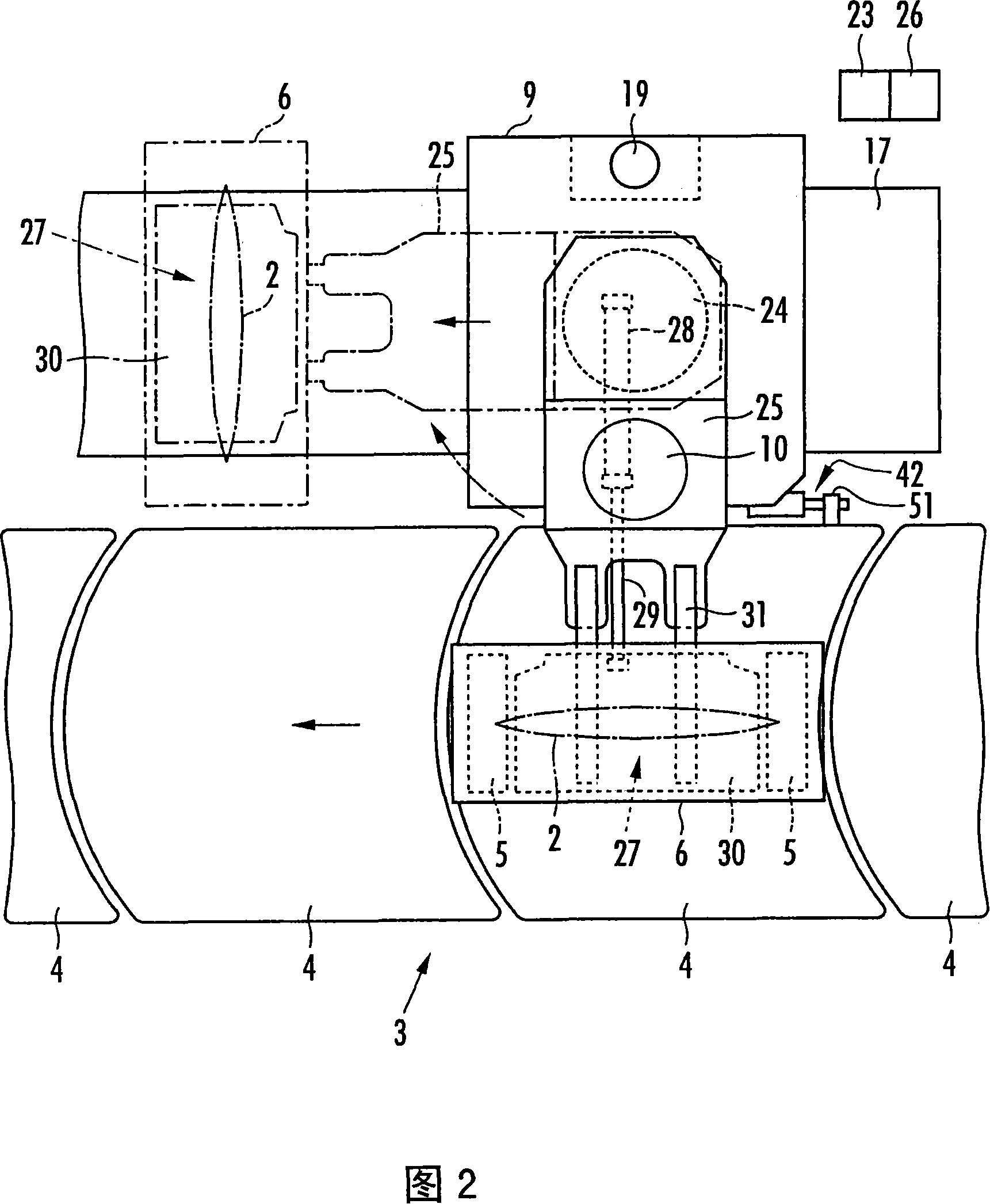

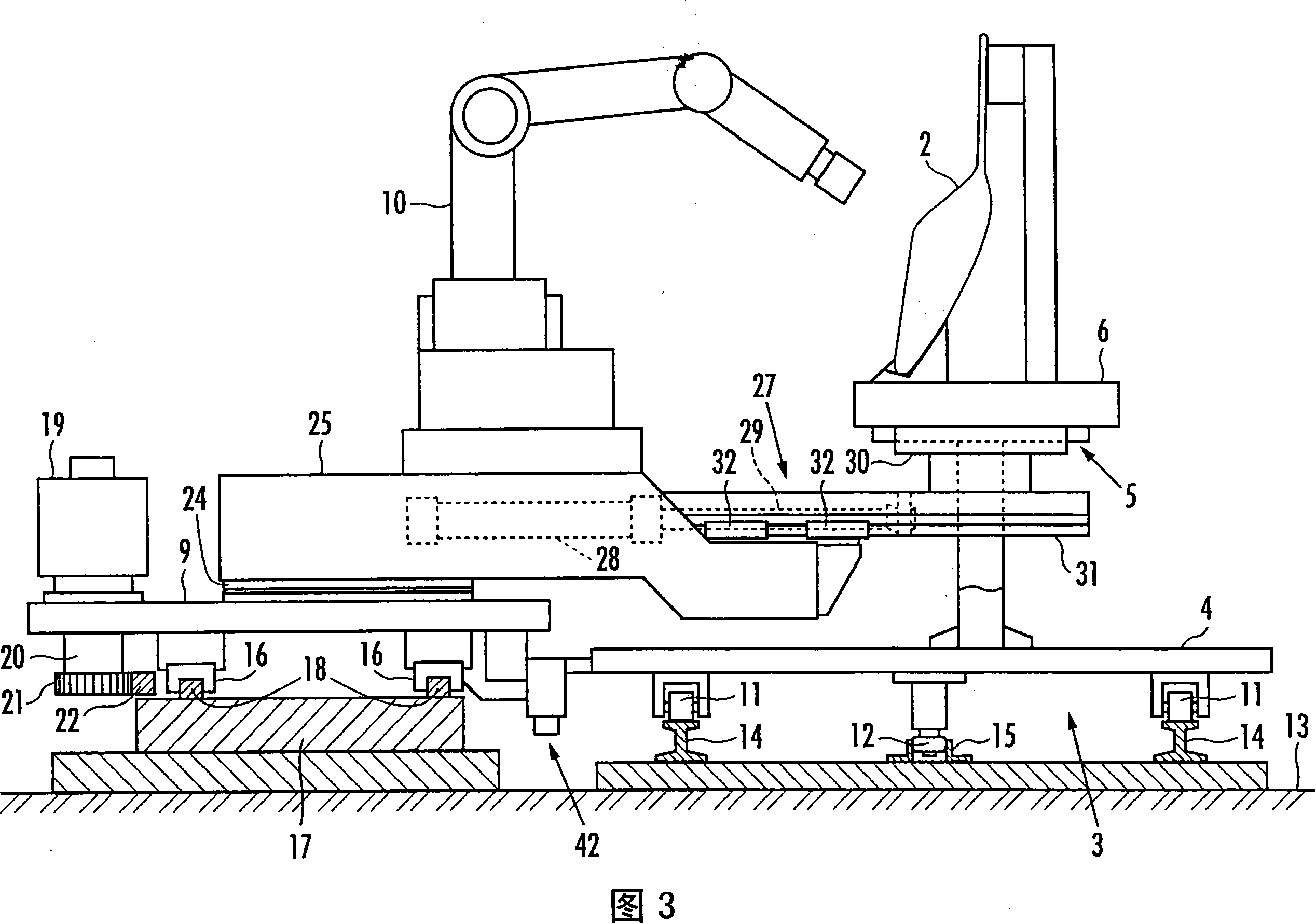

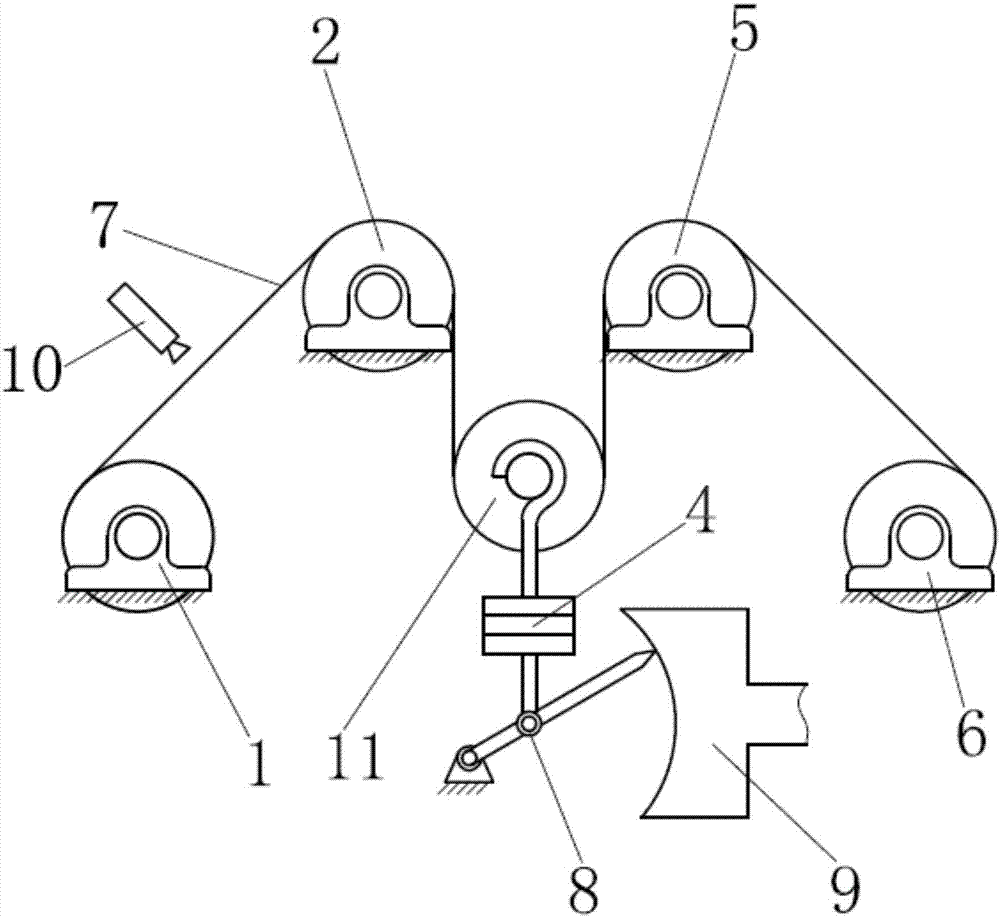

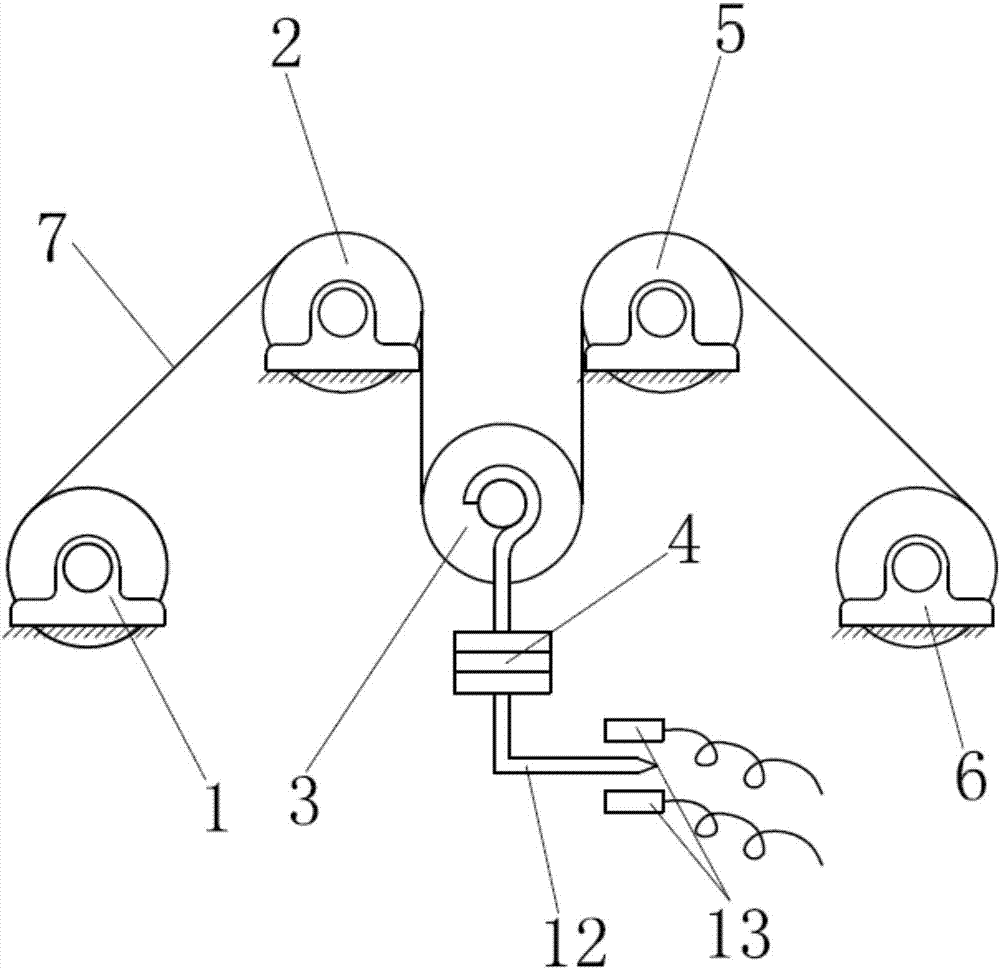

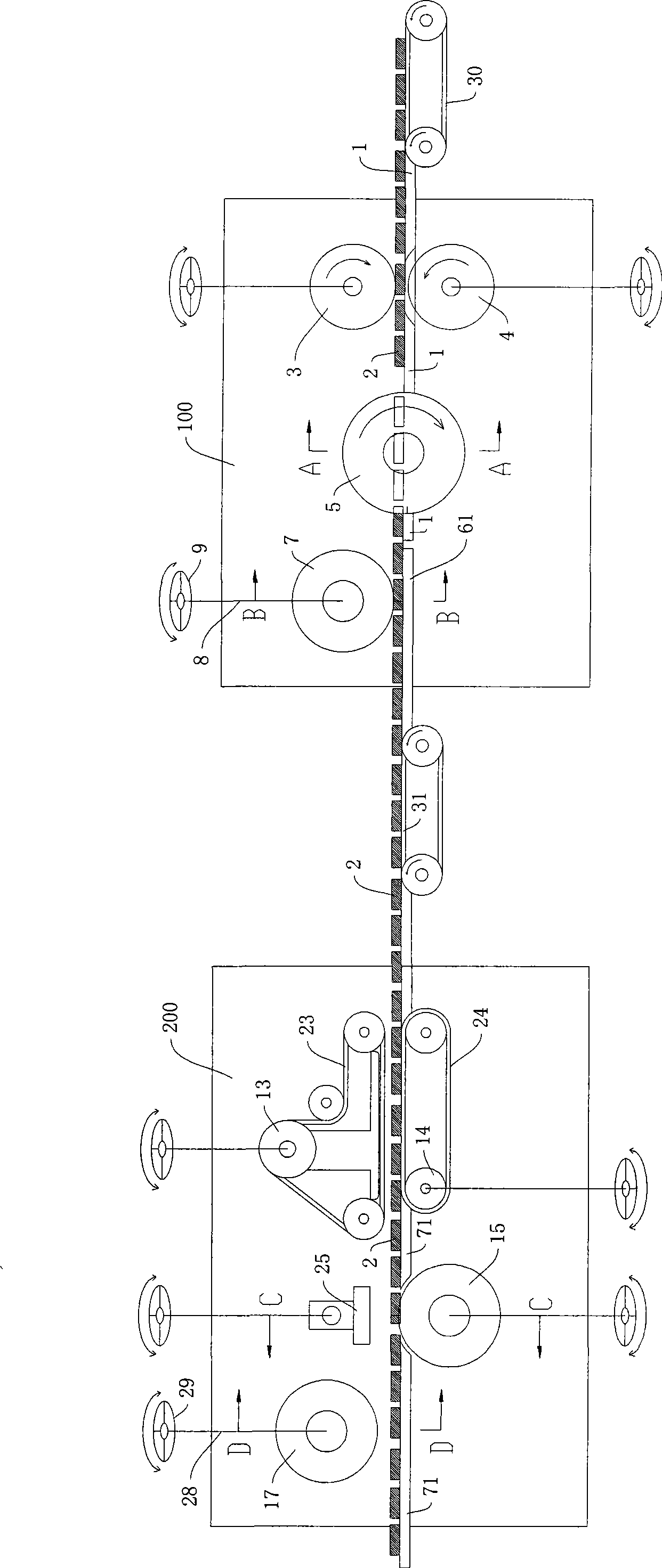

Method and device for rotationally hanging, tracking and positioning manipulator on paint line

InactiveCN101618798AMove at the same speedSpeed matchLiquid surface applicatorsConveyorsManipulatorPower unit

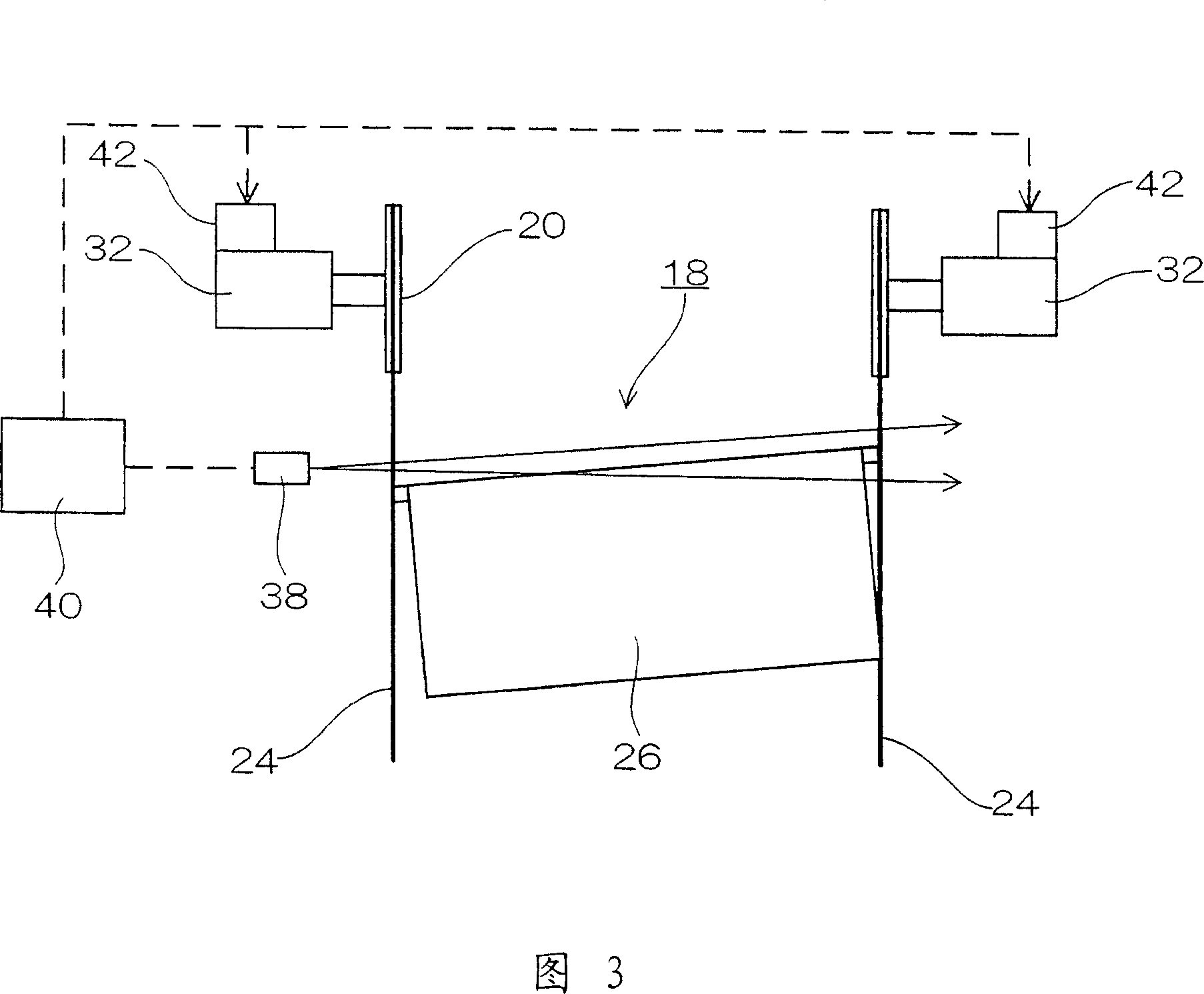

The invention relates to a method for tracking and positioning cargoes conveyed on a conveyer, and the tracking and positioning processes start at a first moving position of the conveyer and end at a second moving position of the conveyer; a tracking and positioning device is used in the tracking and positioning processes, and comprises a clamping unit, a connecting unit, a power unit, a detecting unit and a control unit. Because the tracking and positioning device moves forwards by depending on the power of the conveyer in the tracking and positioning processes, the tracking and positioning device can keep the consistent moving speed with the conveyer, thereby the speed of the tracking and positioning device can be well matched with the transporting speed of the manipulator, and the whole production line is in a highly effective operating process.

Owner:SUZHOU LIUSH MACHINERY EQUIP

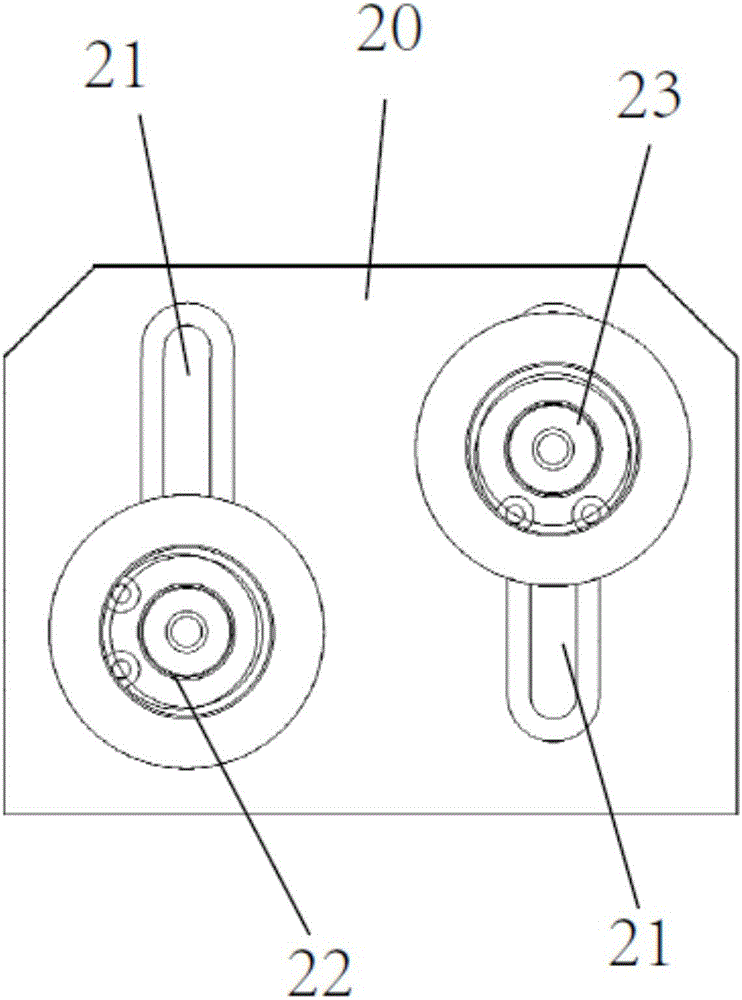

Mobile electrode of electric dust collector

ActiveCN1939592AEasy to moveAvoid leaningElectrode carrying meansElectrode constructionsDrive wheelEngineering

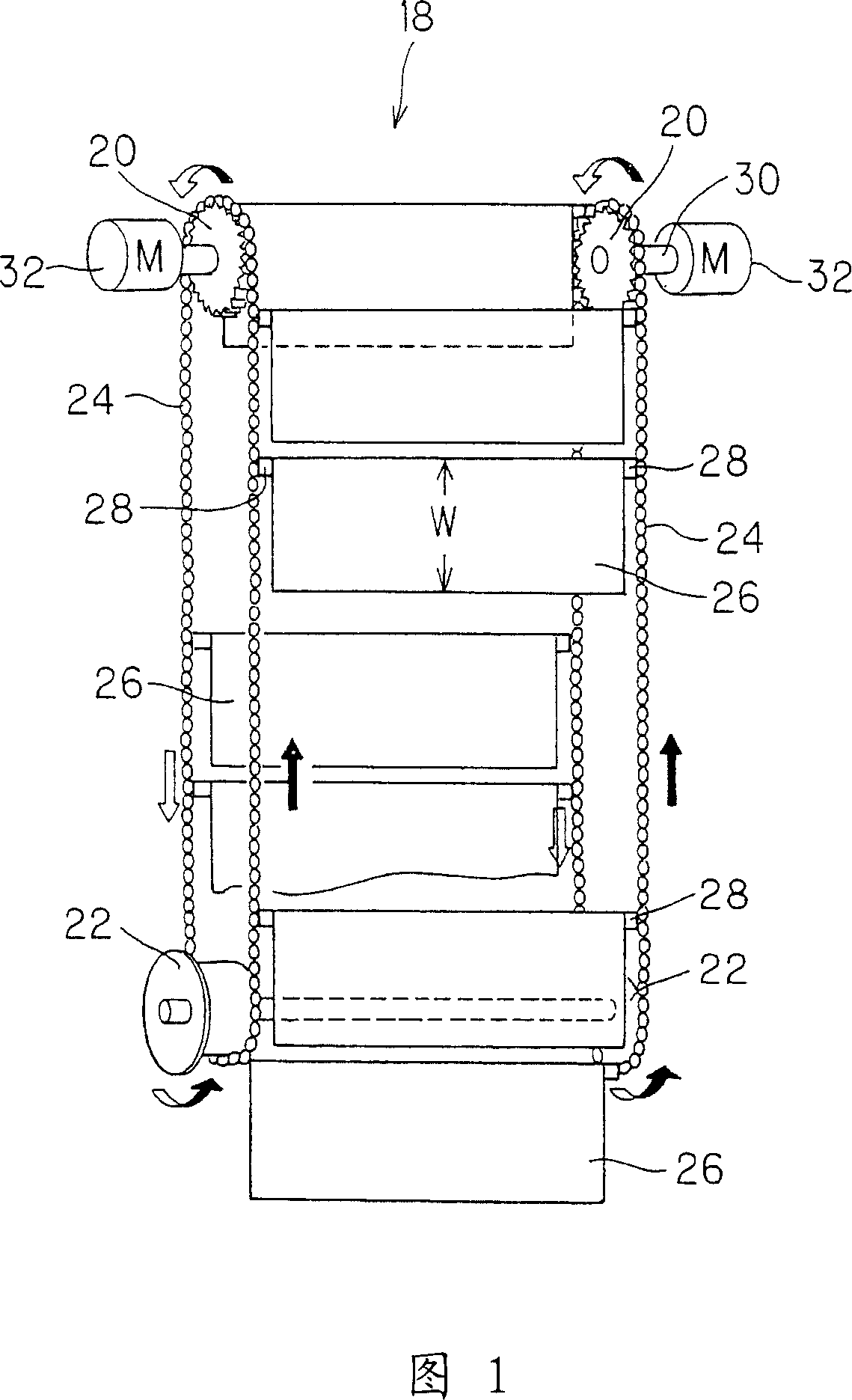

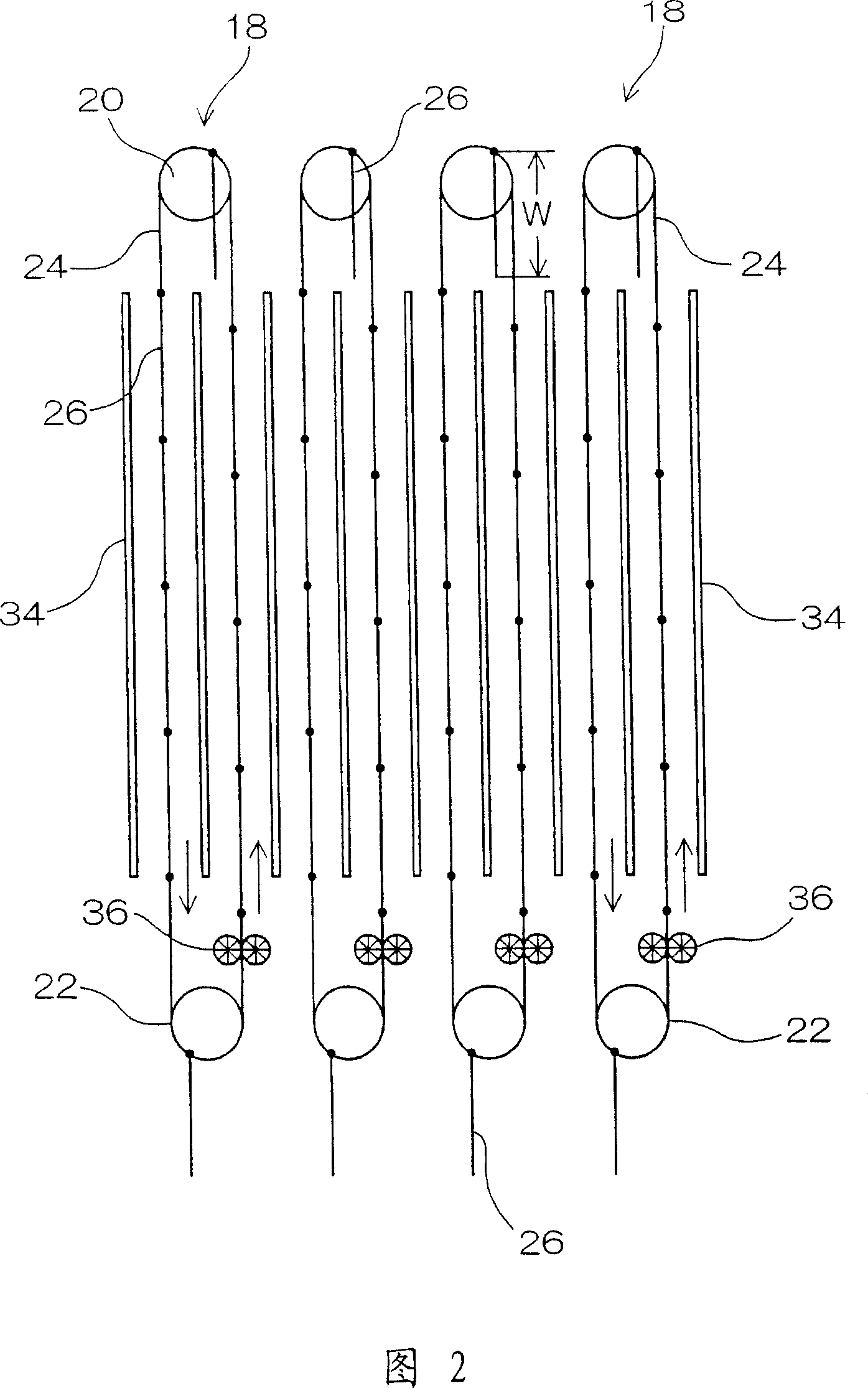

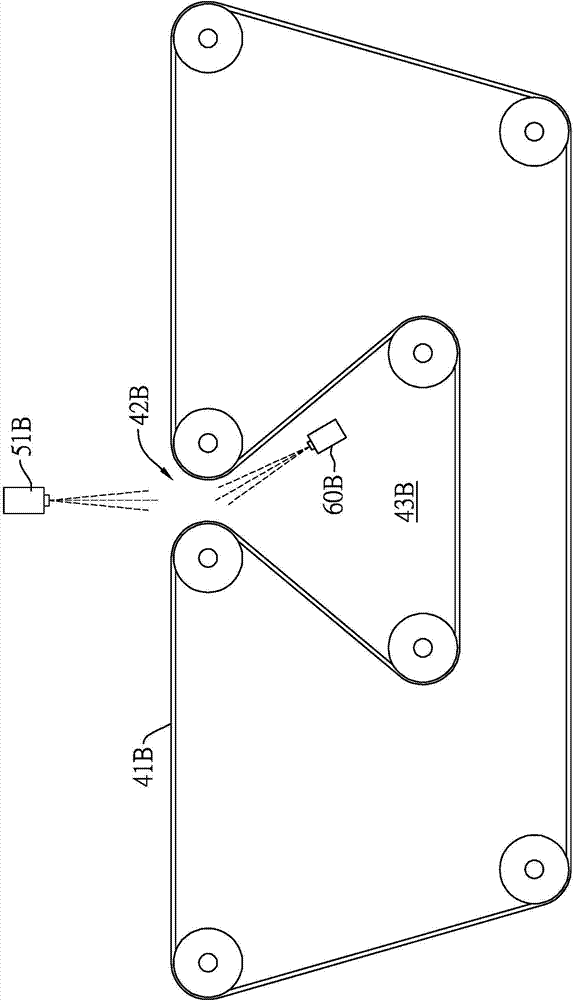

The purpose of the present invention is to increase the width of each dust-collecting electrode plate and reduce the number of parts, and to make the connection part for connecting the dust-collecting electrode plate to the ring-shaped cord body compact. A mobile electrode of an electrical dust collecting device, comprising a pair of driving wheels (20) arranged above and a pair of driven rollers (22) arranged below, for connecting the driving wheels (20) and the driven rollers (22) And a pair of endless chains (24) of stretching and a plurality of dust collecting pole plates (26) that are connected on this pair of endless chains (24), a plurality of dust collecting pole plates (26) rotate and move around the discharge electrode, Wherein, on the upper end position of each dust collection pole plate, each dust collection pole plate (26) is freely rotated relative to the endless chain (24), and at the same time, from the moving area of the dust collection pole plate (26) by the cantilever shaft ( 30) to support the drive wheel (20).

Owner:三菱动力环保有限公司

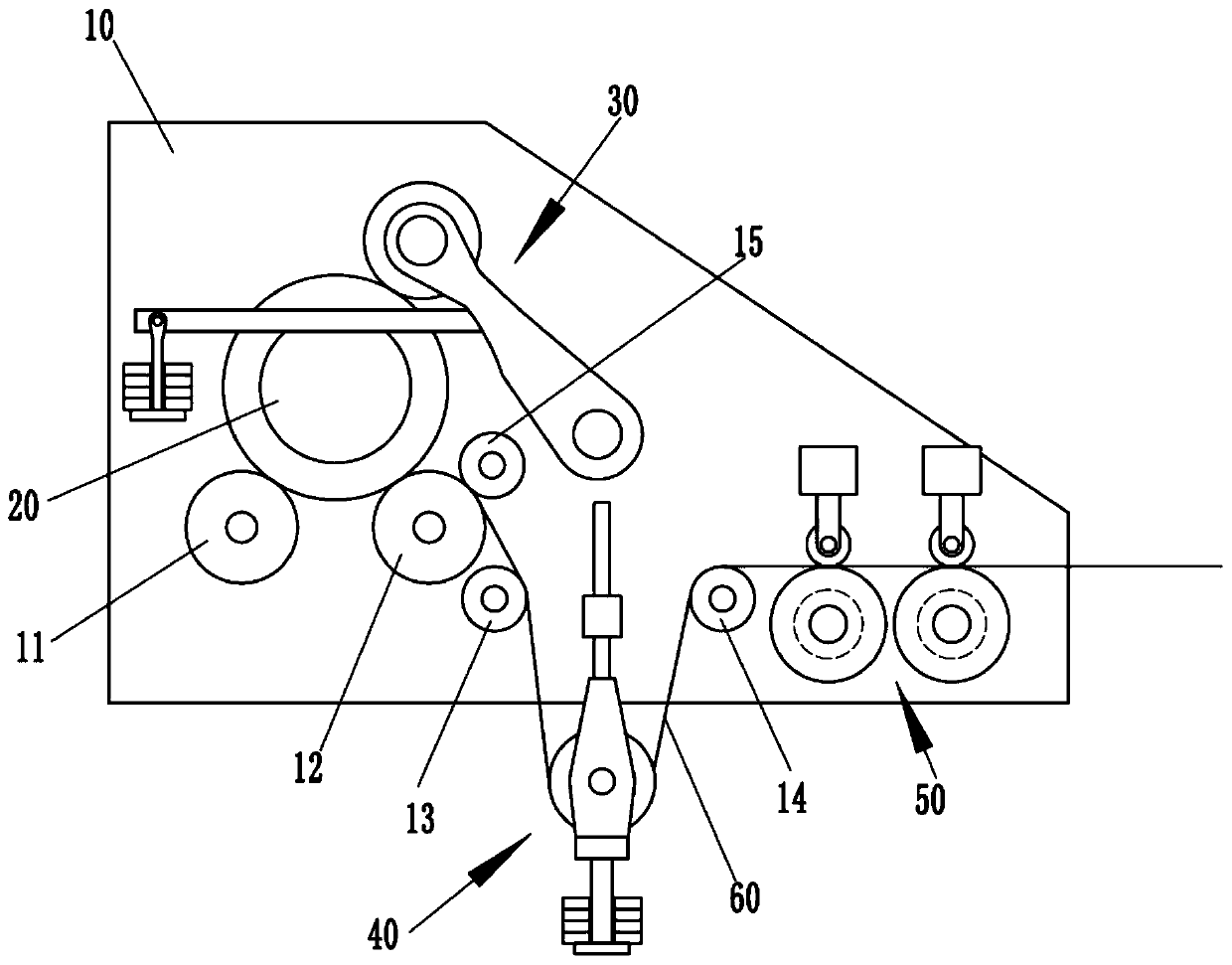

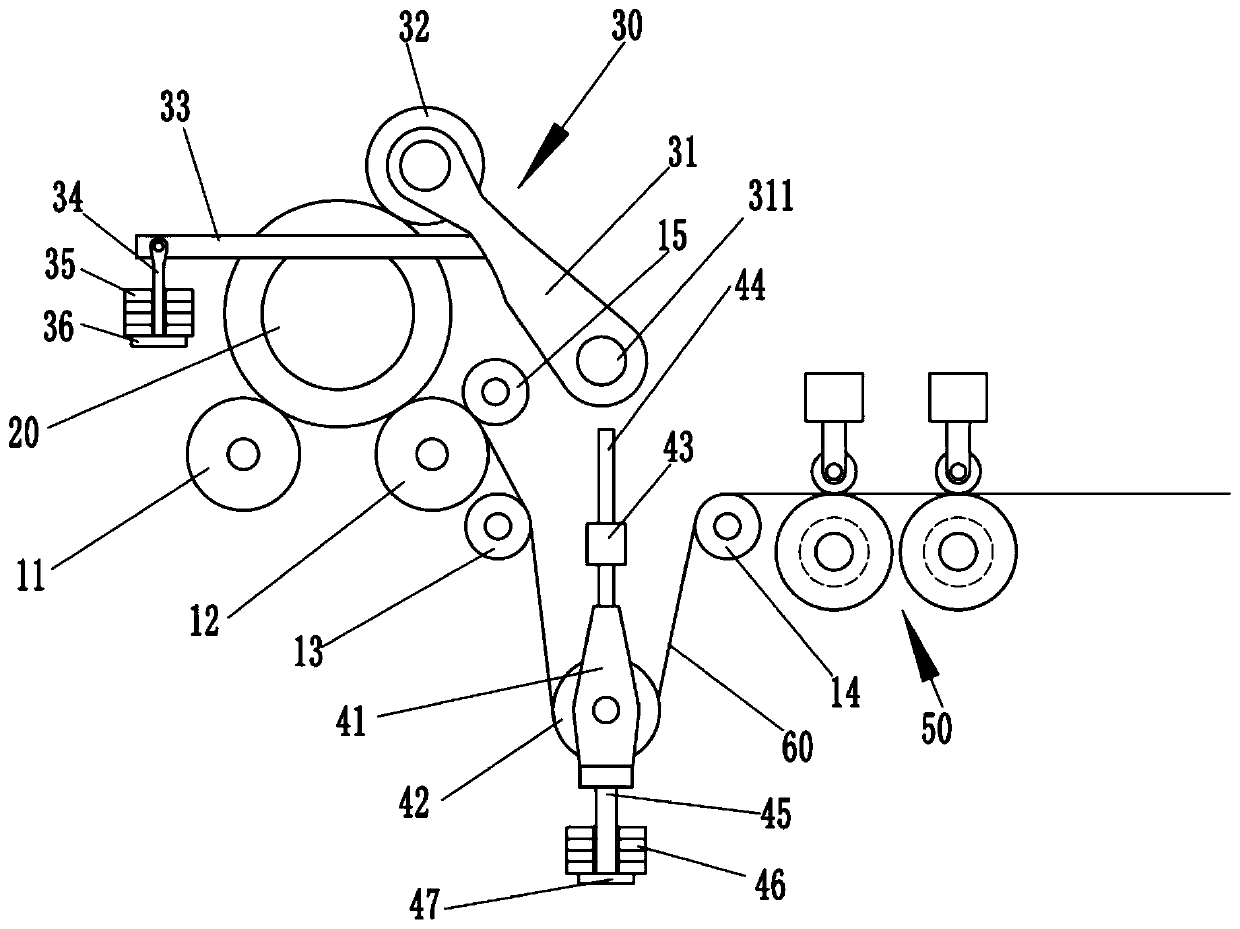

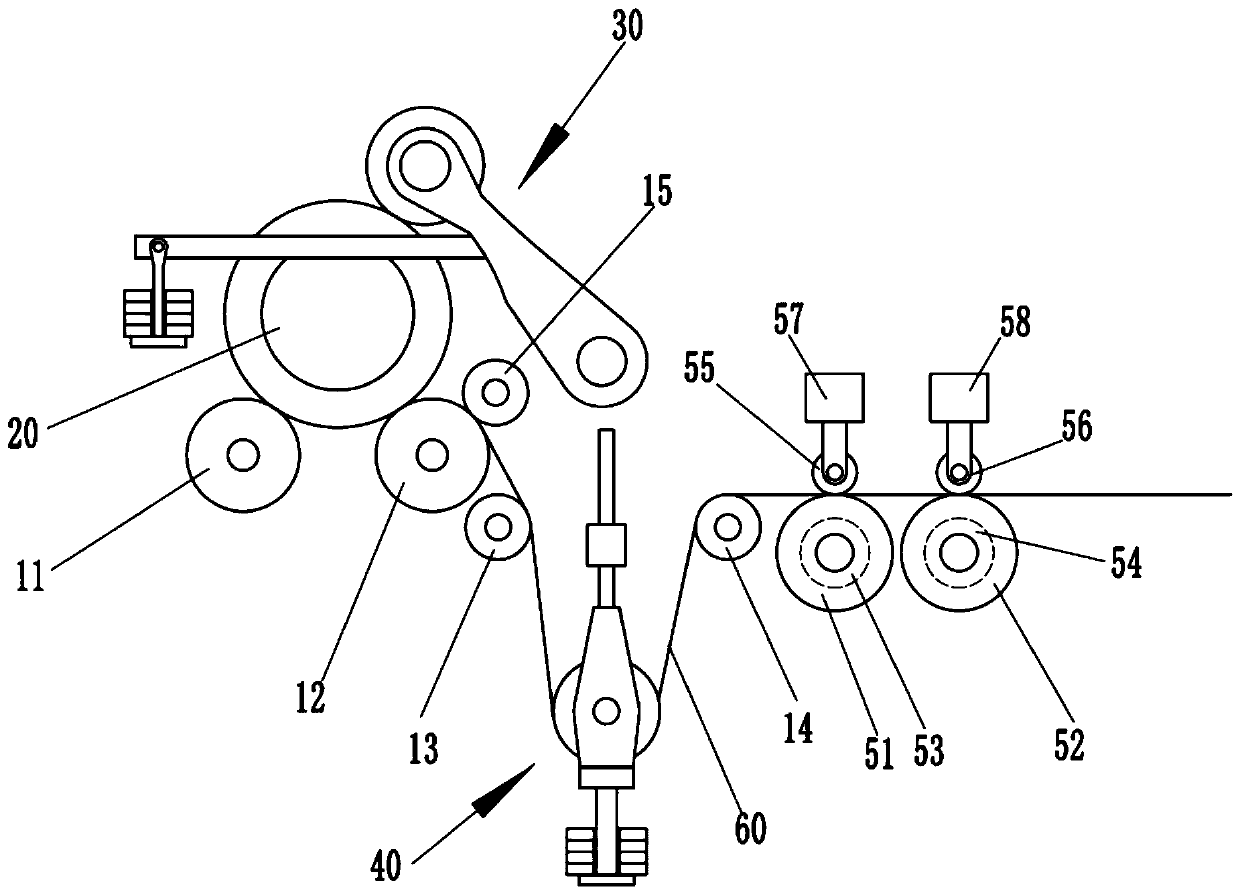

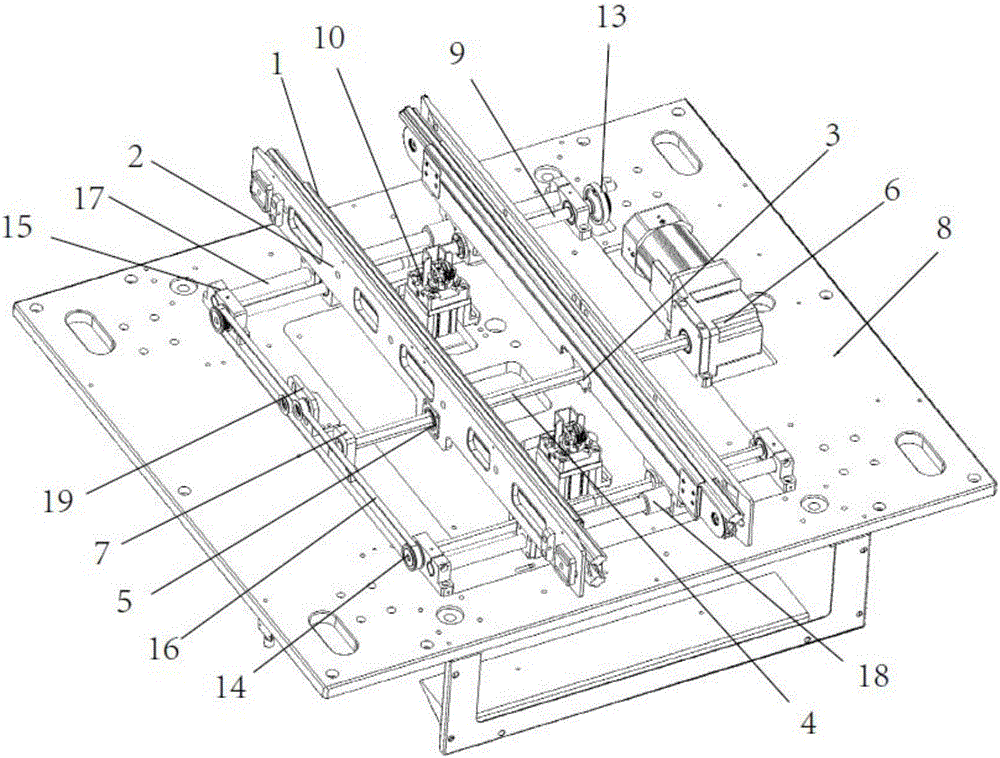

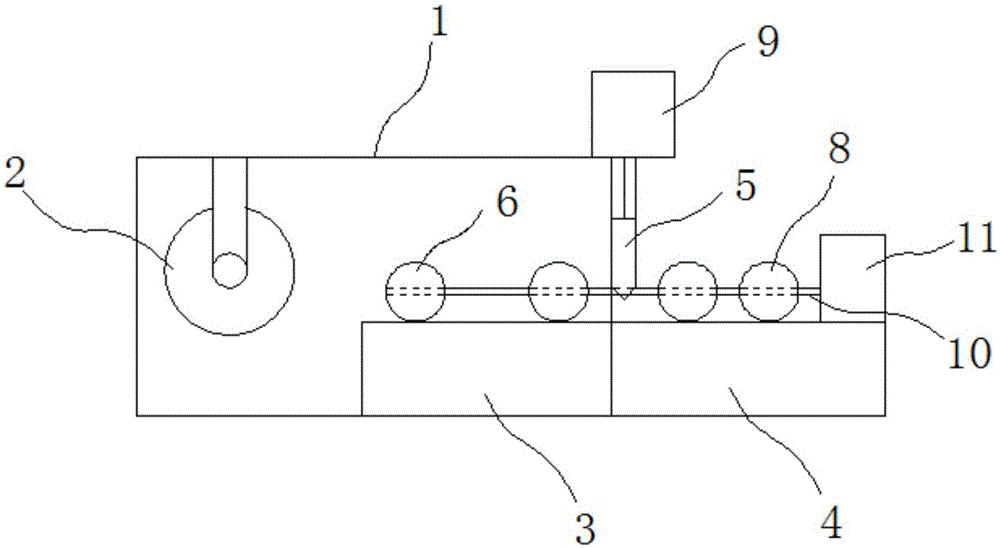

Constant-tension unreeling device of pillow type packaging machine

The invention provides a constant-tension unreeling device of a pillow type packaging machine. The constant-tension unreeling device comprises a base plate, a left supporting wheel, a right supportingwheel, a resisting mechanism, a first guide wheel, a second guide wheel, a balance weight mechanism and a drive wheel set, wherein the left supporting wheel is pivoted to the base plate; the right supporting wheel is pivoted to the base plate, and a film placement roller is supported jointly by the right supporting wheel and the left supporting wheel; the resisting mechanism is arranged on the base plate and abuts against the film placement roller; the first guide wheel is pivoted to the base plate, and the first guide wheel is located on the lower right of the right supporting wheel; the second guide wheel is pivoted to the base plate; the balance weight mechanism is movably arranged on the base plate and located between the second guide wheel and the first guide wheel; and the drive wheel set is arranged at the right end of the second guide wheel and is used for driving a composite film to move so that the film placement roller can carry out unreeling. According to the constant-tension unreeling device of the pillow type packaging machine, the tension of the composite film can be adjusted, and after being adjusted, the tension is in a constant value all the time.

Owner:WENZHOU POLYTECHNIC

Conveying line with blocking effect

InactiveCN106241210AEfficient retentionImprove buffering effectConveyorsPackagingBlock effectElectrical and Electronics engineering

Owner:SUZHOU LANGKUN AUTOMATION EQUIP CO LTD

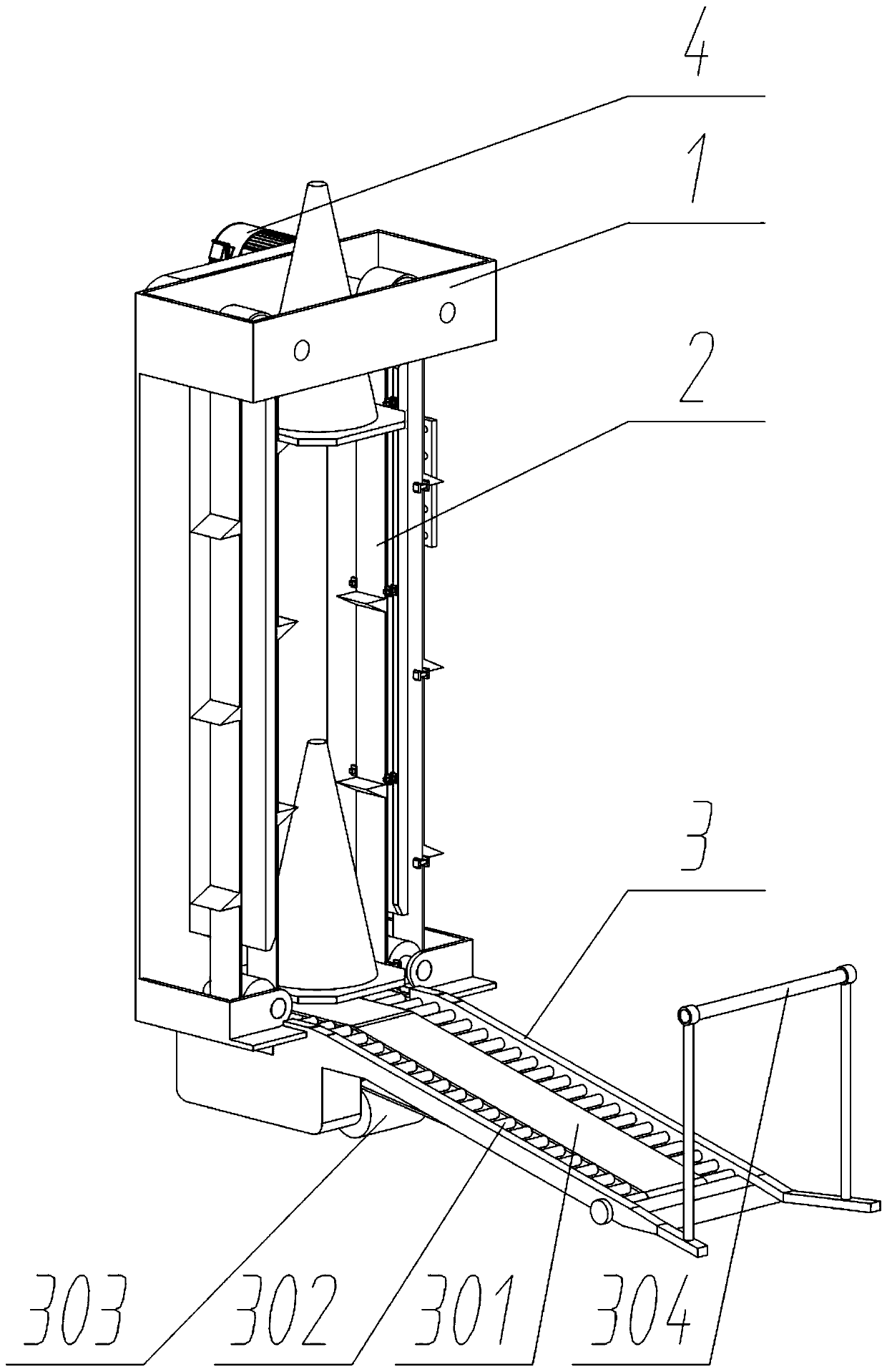

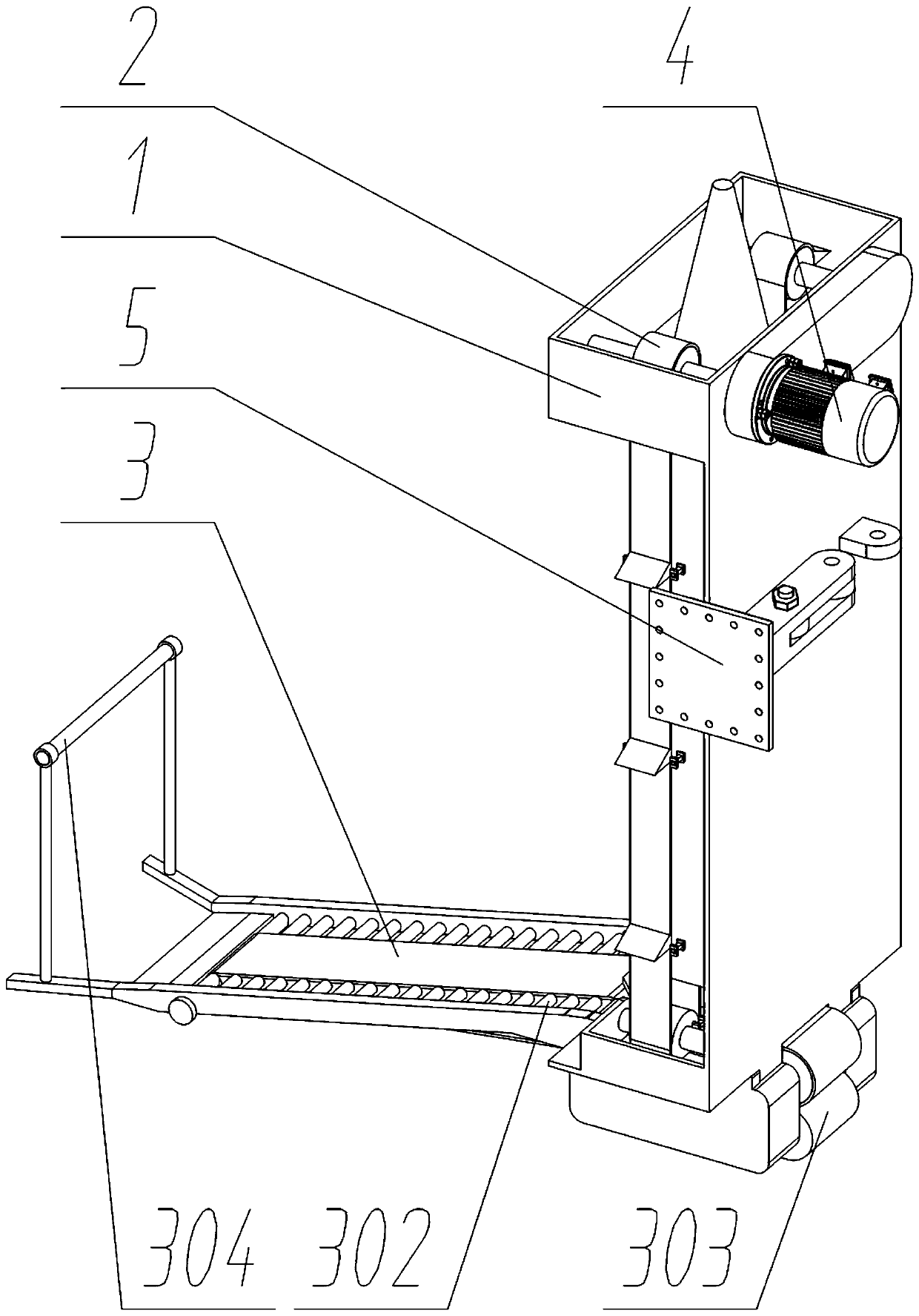

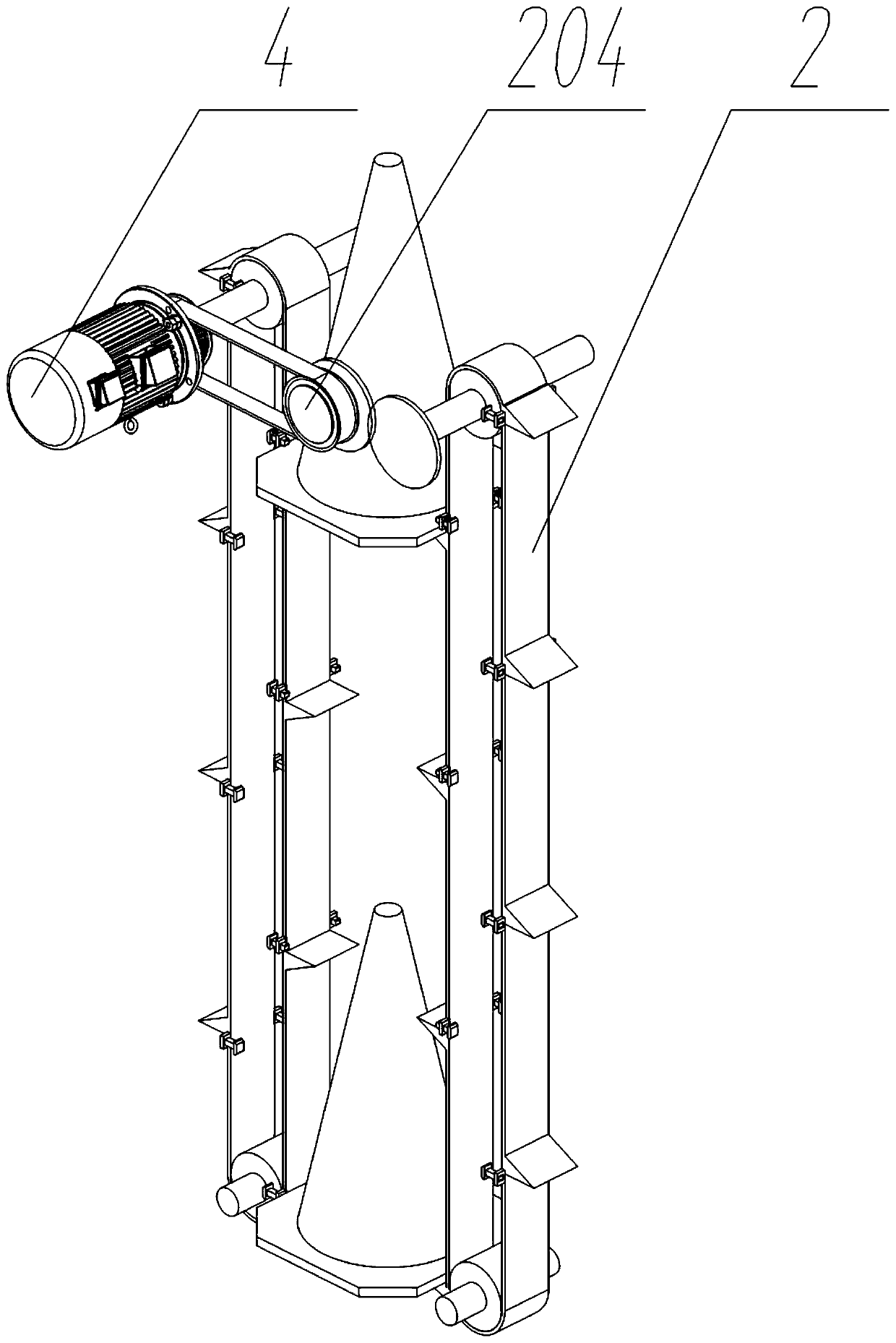

Traffic cone automatic collecting and placing machine

ActiveCN110644394APrevent throwingEasy to fixTraffic signalsRoad signsControl engineeringElectric machinery

The invention provides an traffic cone automatic collecting and placing machine, belongs to the technical field of traffic management machines and tools, and aims to solve the problem that when existing traffic cone automatic collecting and placing equipment is used, the equipment cost is relatively high, management and maintenance are inconvenient, traffic cones are prone to fall down, and the placing effect is not ideal. The machine comprises a supporting frame main body, wherein a lifting mechanism is arranged at the upper part of the supporting frame main body, a motor is fixedly connectedto the left end surface of the supporting frame main body, a horizontal conveying device is fixedly connected to the bottom of the supporting frame main body, and an installing mechanism is hinged tothe left end surface of the supporting frame main body. The machine can fix the traffic cones, the situation that the traffic cones are thrown out due to inertia and the like in the driving process of an engineering vehicle is avoided, automatic fixing and loosening are achieved without control, the traffic cones are placed more smoothly and more steadily, the situation that the traffic cones fall down is greatly reduced, meanwhile, collecting and placing are achieved by using one device, the expenditure is saved, and the management and maintenance of the device are facilitated.

Owner:HANGZHOU GAODA TRAFFIC FACILITY ENG

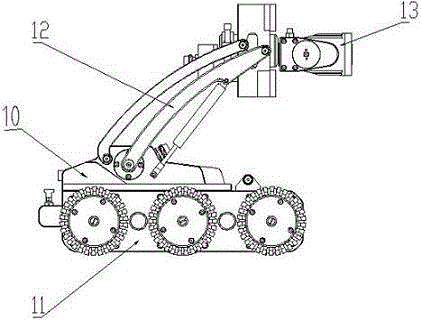

Pipeline robot and method for conducting pipeline detecting through pipeline robot

The invention relates to a pipeline robot and a method for conducting pipeline detecting through the pipeline robot. The robot comprises a control box (20) and a robot body (10). The part of the robot body (10) comprises a crawl device (11), a lifting arm (12) and a camera (13). A rocker or button on a control cabinet (20) is operated, the robot body (10) will execute corresponding motion, and execution of the motion needs to be controlled through control software. The control software can control zooming of the camera (13), can feed back the zooming times to a motor part, used for controlling the camera (13) to rotate and pitch, in the control software, and can change the rotating speed of rotation and pitching motors according to the zooming times of a lens.

Owner:SINOTECHO WUHAN INTELLIGENT TECH CO LTD

Tension controlling and speed measuring system of coating machine

InactiveCN106865325AIncrease or decrease can be adjustedCompact structureArticle deliveryWebs handlingClosed loop feedbackElectric machinery

The invention discloses a coating machine tension control and speed measurement system. Including; winding roller, first idle roller, tension roller, second idle roller, unwinding roller, substrate, speed sensor, wherein; winding roller is driven by a servo motor, and the servo motor controls the speed of winding roller; tension roller Equipped with a tension sensor, the speed measuring roller floats freely and is in contact with the upper surface of the substrate, and uses its own weight to provide tension to the substrate; the substrate passes through the unwinding roller, the second idler roller, the tension roller, and the second roller respectively from the moving direction. An idler roller and a winding roller; the first idler roller, the second idler roller, the unwinding roller, and the winding roller are all fixed on the bracket; the unwinding roller contains a clutch; the clutch and the tension sensor form a closed-loop feedback circuit, and the servo The motor and speed sensor form a closed-loop feedback circuit. The invention has a compact structure, reduces the space occupied by equipment, provides a simple and reliable feedback mechanism, applies controllable tension to the base material and improves the accuracy of speed measurement.

Owner:苏州威格半导体材料有限公司

Dust removing device of plastic granulator

InactiveCN105936098AAchieve flushingImprove processing efficiencyCleaning using liquidsDrive motorEngineering

The invention discloses a dust removing device of a plastic granulator, and relates to the field of plastic processing. The dust removing device of the plastic granulator comprises a support, grinding wheels and a drive motor. The grinding wheels are arranged on the edge of the rack, and the drive motor can drive the grinding wheels to rotate. The support is rotationally connected with a plurality of transmission roller shafts arranged side by side, and the drive motor can drive the transmission roller shafts to rotate. A flushing mechanism arranged on the rack is arranged above the transmission roller shafts. The flushing mechanism comprises a plurality of sprayers and a high-pressure water pipe, and all the sprayers are connected with the high-pressure water pipe. The device integrates plastic transporting, plastic cleaning and plastic edge grinding, and therefore the plastic processing efficiency can be improved.

Owner:重庆敏驰塑胶有限公司

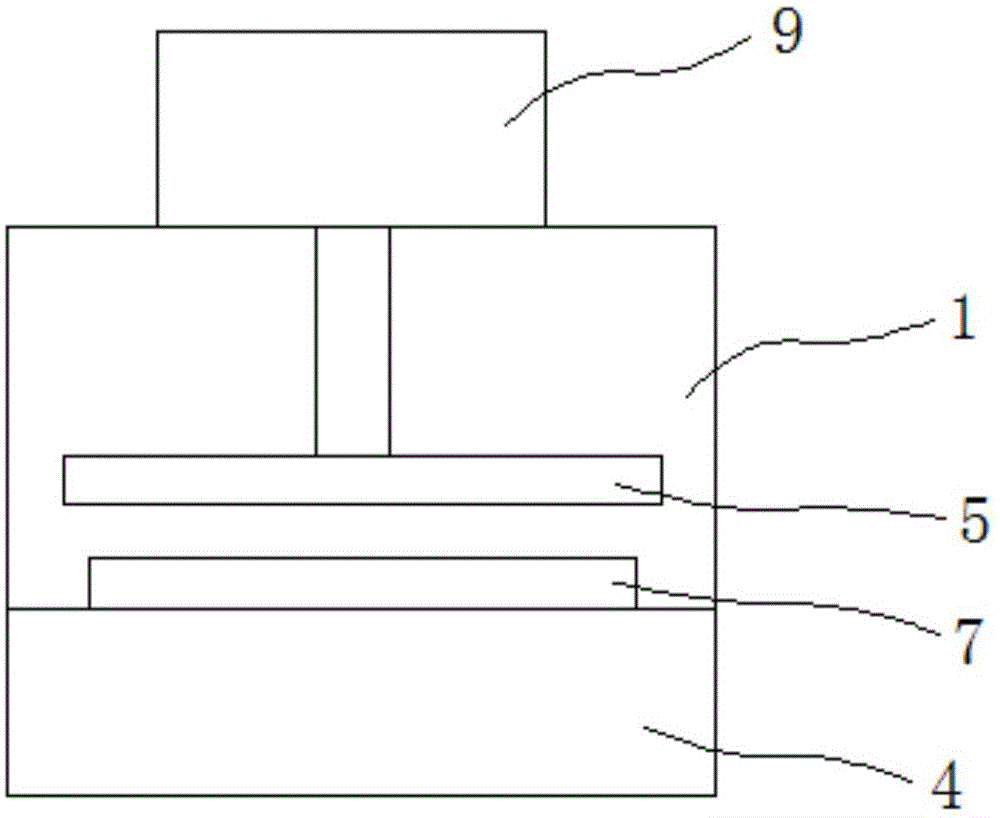

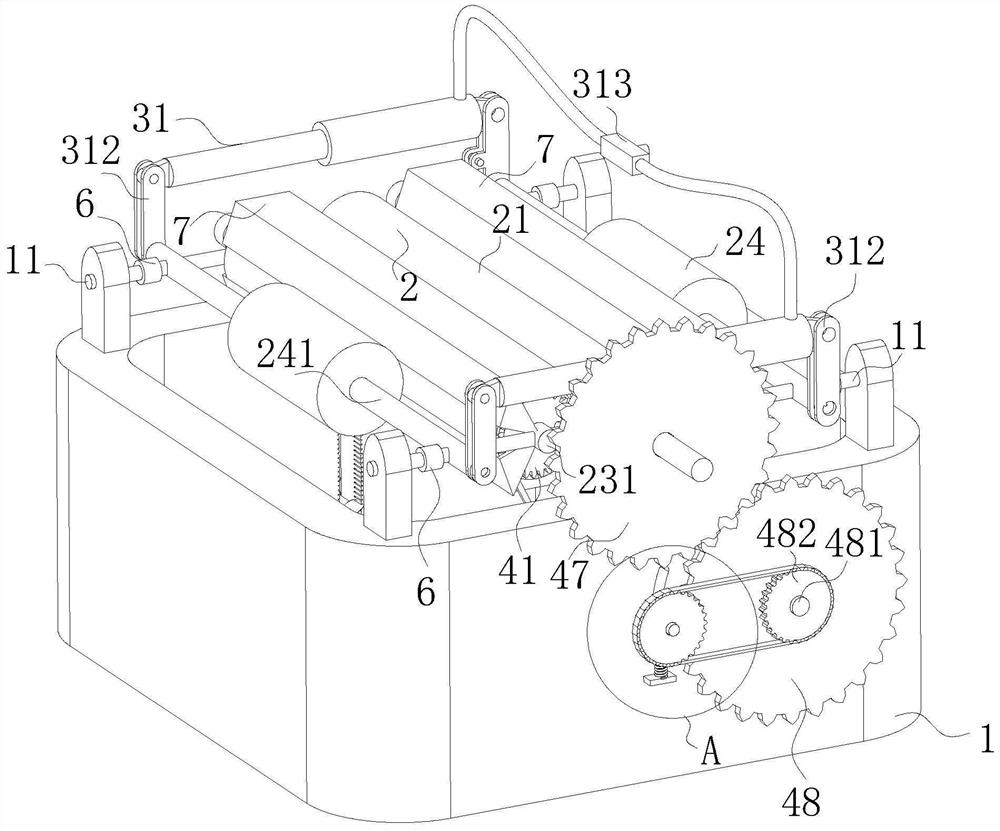

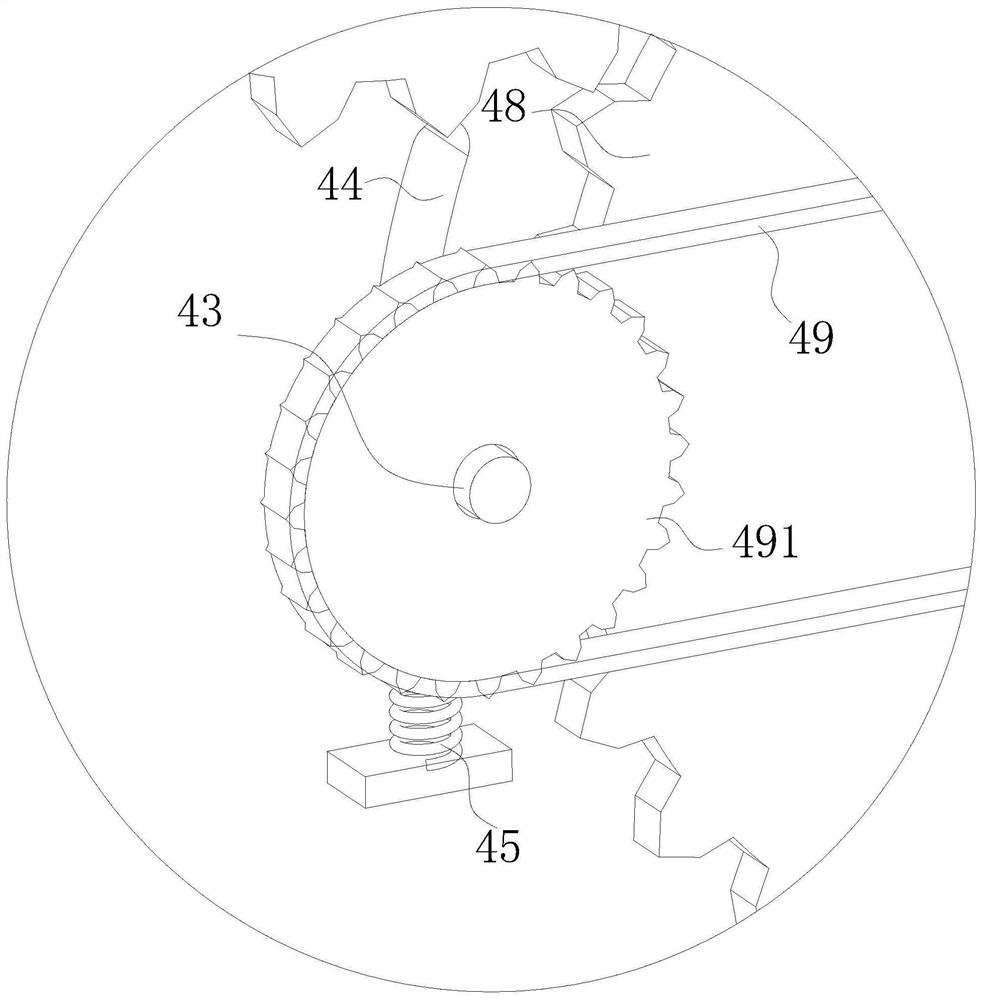

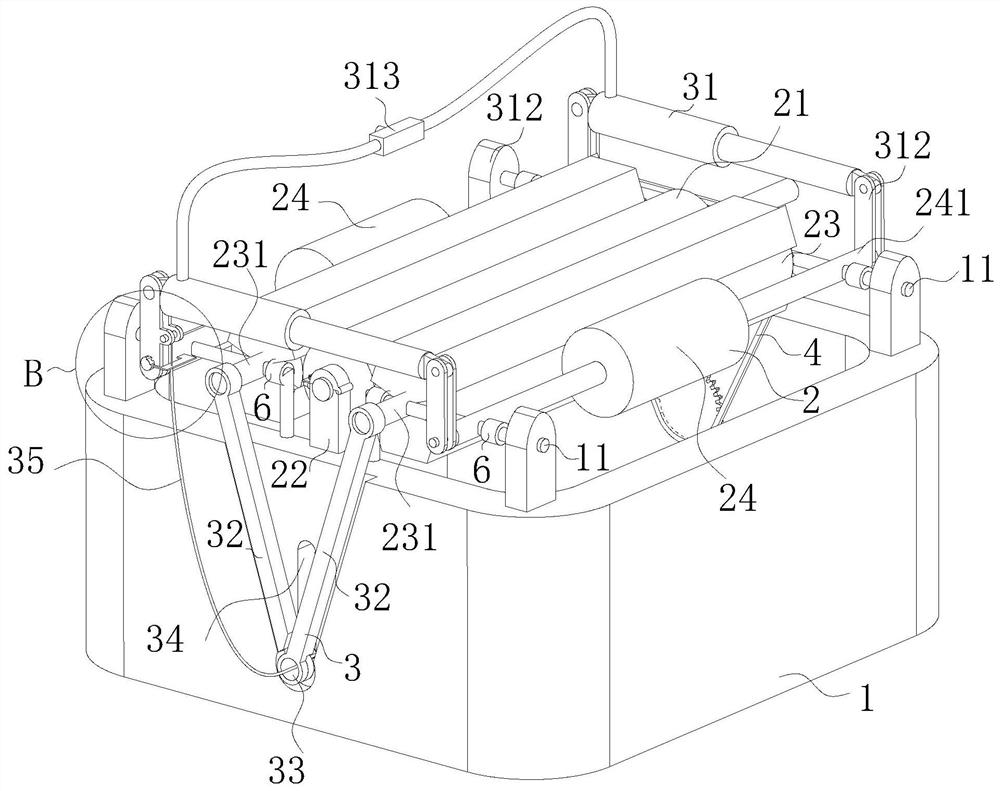

Coiled-paper-scrap cutting machine

InactiveCN105014719AQuality improvementAvoid errorsMetal working apparatusPulp and paper industryScrap

The invention relates to a coiled-paper-scrap cutting machine. The coiled-paper-scrap cutting machine comprises a shell, a paper tube wheel, an inner supporting base, an outer supporting base and a cutter. The paper tube wheel is rotationally arranged in the shell. An opening is formed in the side wall of the side, close to the paper tube wheel, of the shell, and the paper tube wheel can be taken out of the opening. The inner supporting base is fixedly arranged in the shell. The inner supporting base is provided with a plurality of rotary inner pressing wheels. The outer supporting base is arranged at the position, corresponding to the inner supporting base, of the outer side of the shell. A paper outlet is formed in the side wall between the inner supporting base and the outer supporting base. A plurality of rotary outer pressing wheels are arranged on the outer supporting base. The inner pressing wheels, the paper outlet and the outer pressing wheels are located on the same straight line. The cutter is located on the outer side, corresponding to the paper outlet, of the side wall of the shell in a vertical moving manner. A hydraulic device is fixedly arranged at the upper end of the cutter. An output shaft of the hydraulic device can regularly drive the cutter to cut towards the paper outlet. Compared with the prior art, the coiled-paper-scrap cutting machine can carry out timing automatic cutting, the cut paper is in the set length, and the paper cutting quality is improved.

Owner:桂林威迈壁纸有限公司

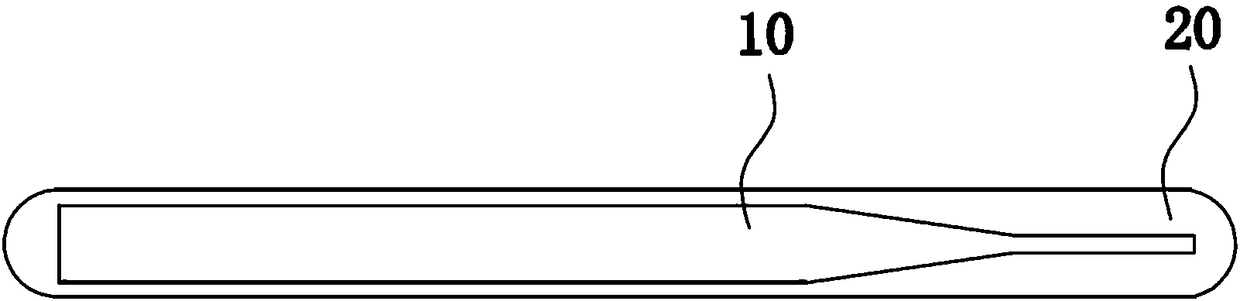

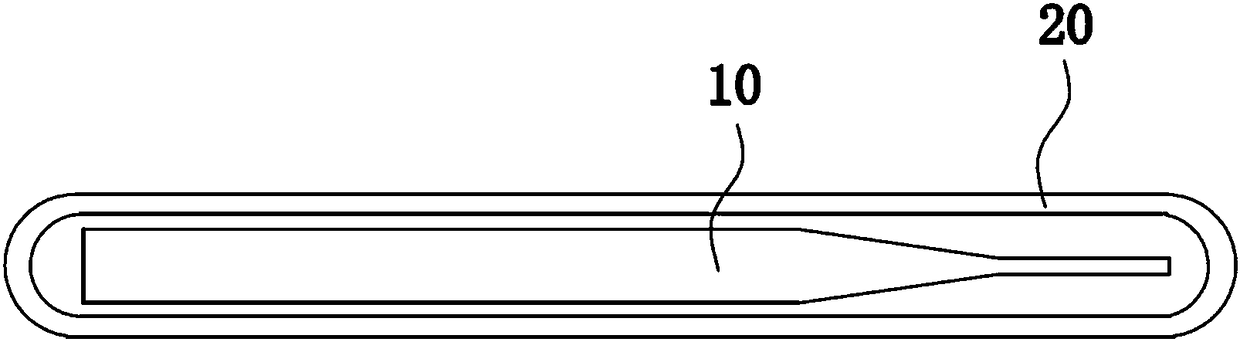

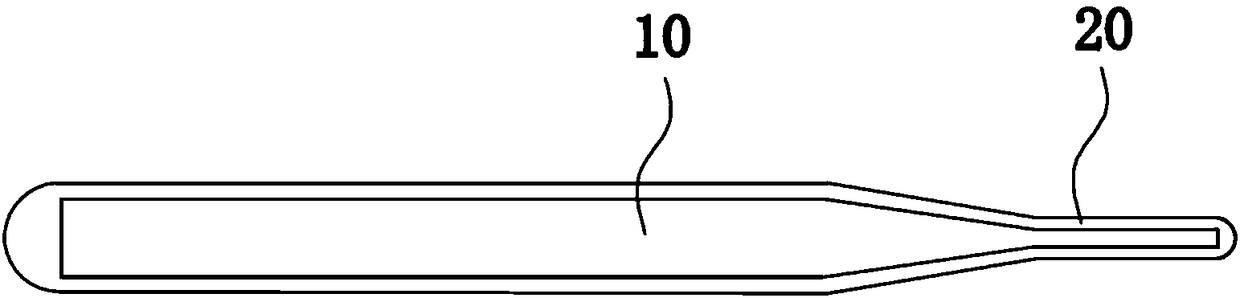

Super-slip guide wire outer wrapped layer solid solution molding device and wrapping method thereof

The invention discloses a super-slip guide wire outer wrapped layer solid solution molding device including a wrapping mold, a wrapping material supply device, a variable speed traction device and a cooling device; a molding channel for a core wire to pass through and a melt runner intersected with the molding channel are formed on the wrapping mold; the wrapping material supply device is used forproviding a wrapping material melt for the wrapping mold; the variable speed traction device is used for pulling a core wire out from the molding channel at different speeds according to the diametersizes of the core wire in different regions, wherein the core wire passes through the molding channel and is coaxial with a second molding channel of the molding channel; the cooling device is used for cooling the core wire removed out of the wrapping mold. The core wire is wrapped tightly by a solid solution way, so slipping is not easy, a head end of the core wire is prevented from puncturing the outer wrapping layer, and the risk of scrapping a chamber channel by a guide wire is reduced; at the same time, with adopting of the variable speed traction way, different-diameter regions of the core wire have more fit wrapping time and wrapping material melt amount, and uniform, smooth and reliable outer diameter of the guide wire after wrapping can be guaranteed.

Owner:SUZHOU HIGHWIRE MEDICAL DEVICES CO LTD

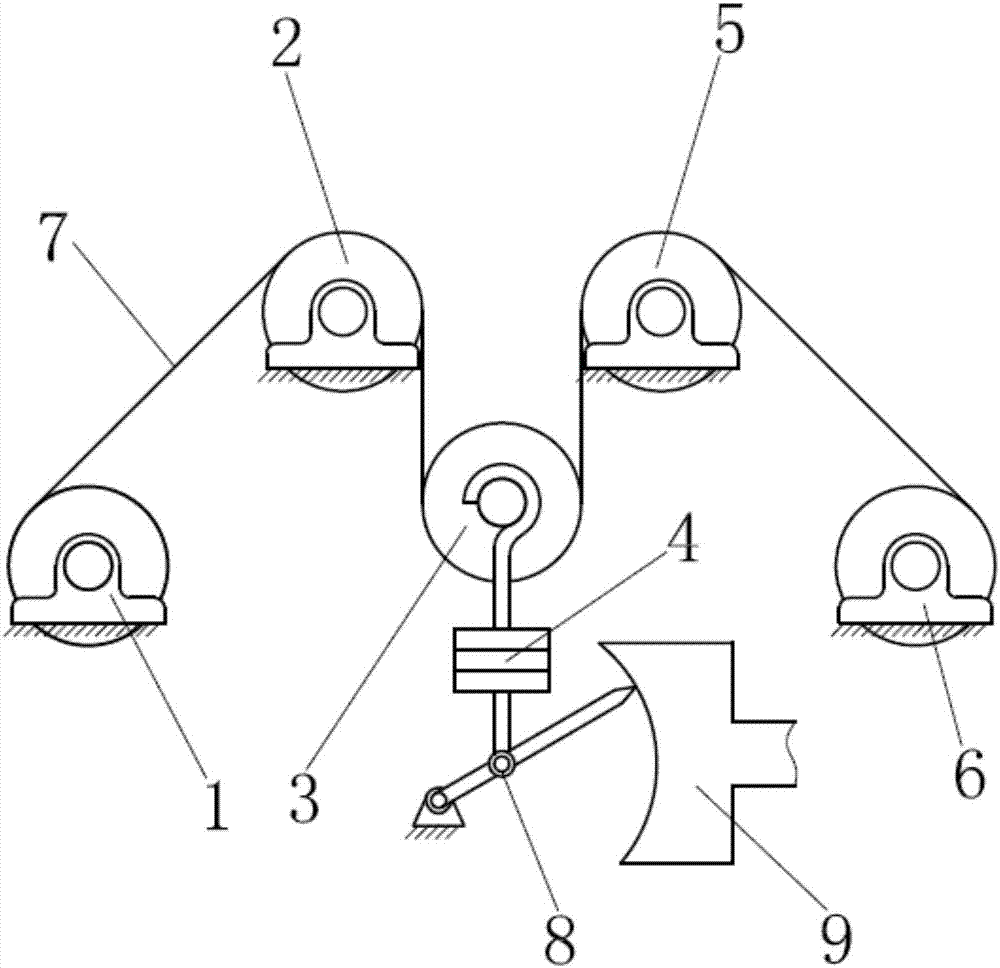

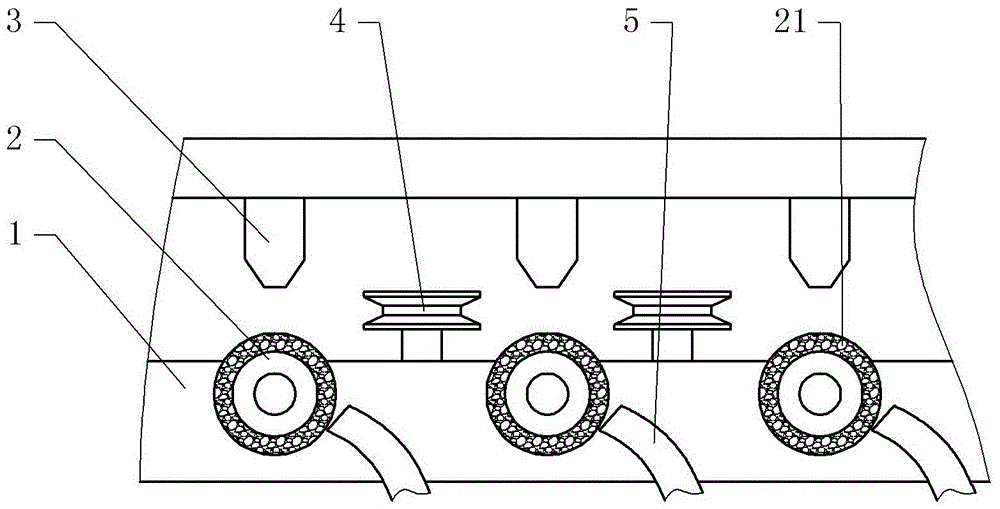

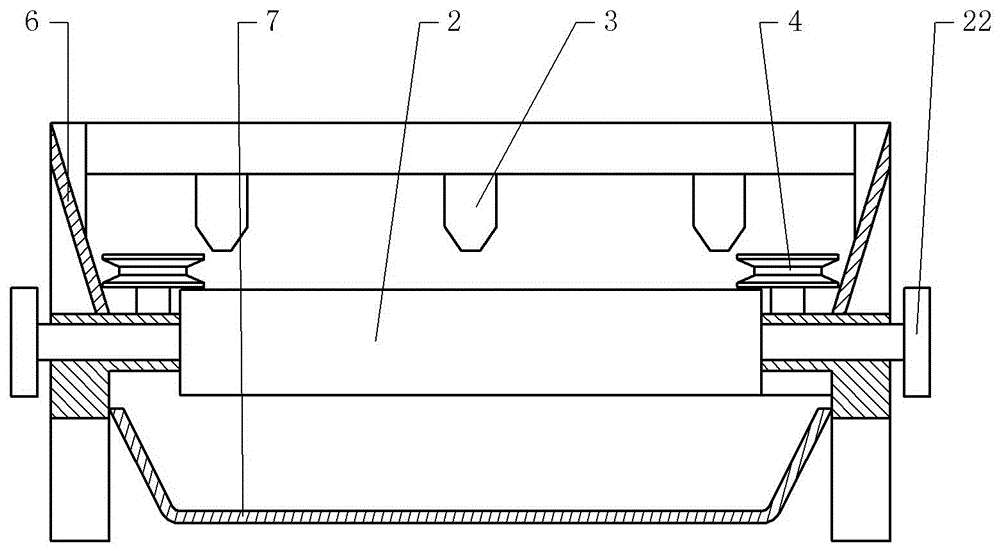

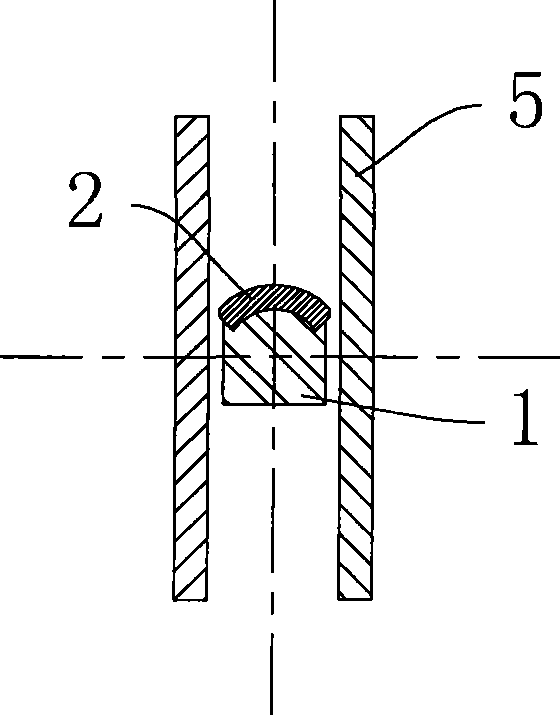

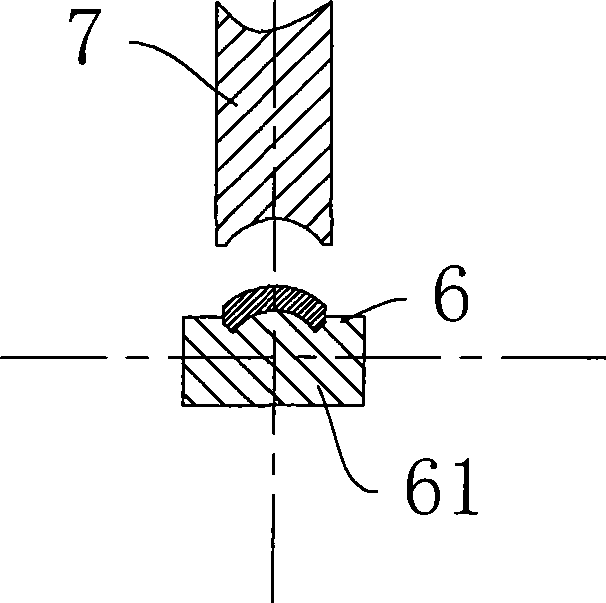

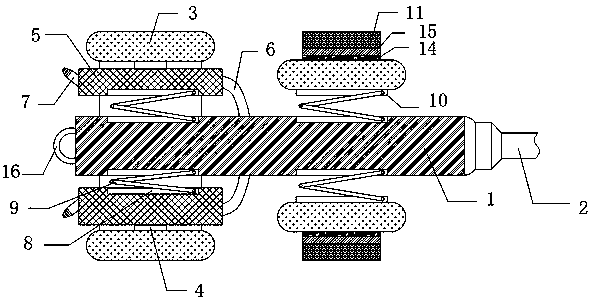

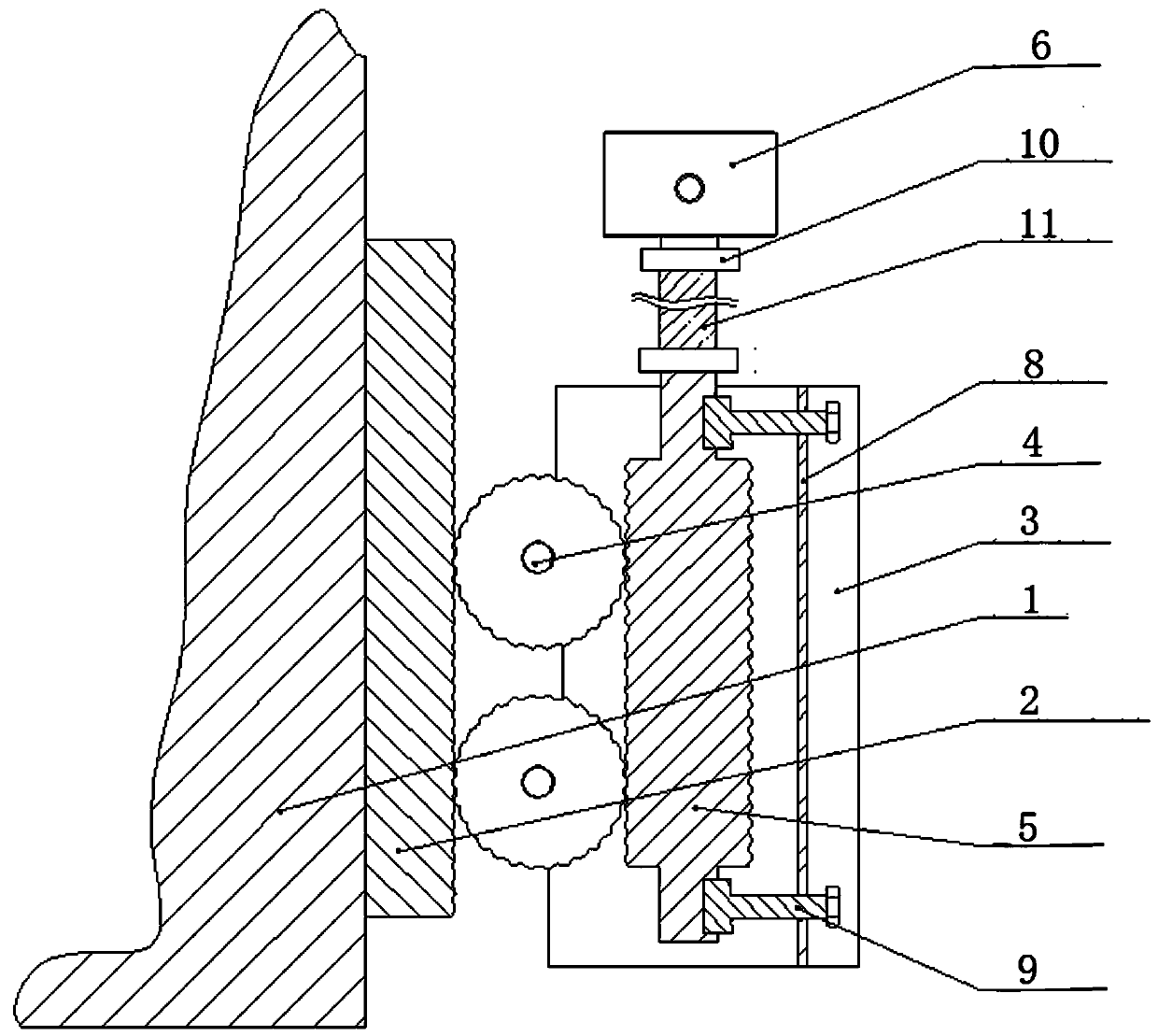

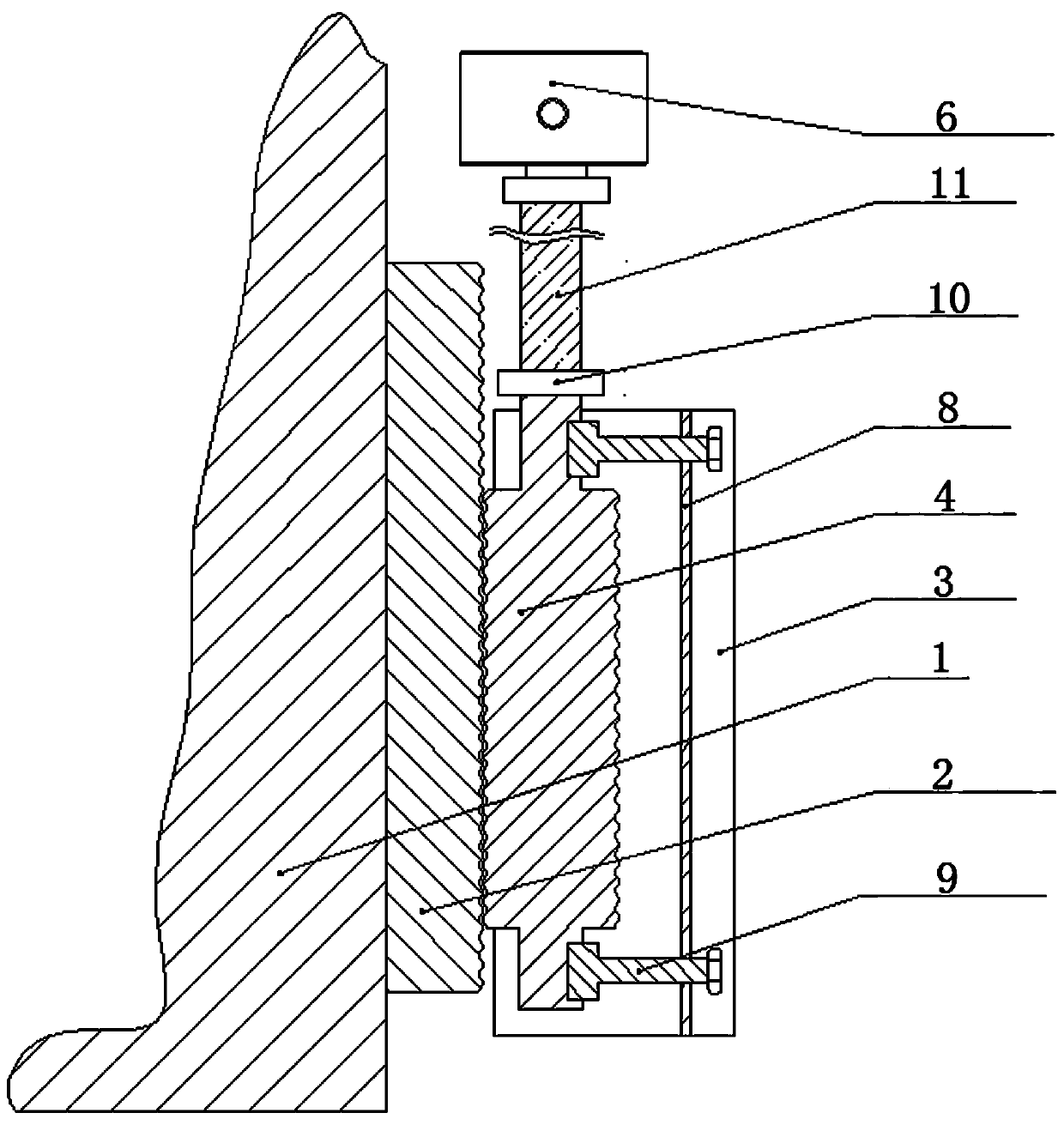

Tile shaped magnet grinding method and device

InactiveCN101508088AMove at the same speedHigh degree of processing automationGrinding machinesEngineeringGrinding wheel

The invention provides a grinding machine and a grinding method for grinding the inner cambered surfaces of tile-shaped magnets and finely grinding the outer cambered surfaces of the tile-shaped magnets synchronously to improve the precision and automation of the machining of the tile-shaped magnets. The tile-shaped magnets sequentially arranged between upper and lower synchronous belts are driven by the upper and lower synchronous belts to move forward along two guide plates arranged on two sides of the tile-shaped magnets, and when the tile-shaped magnets moving along the guide plates pass by an inner circle pressing block contacting with the outer cambered surfaces of the tile-shaped magnets, the inner circle pressing block grinds the inner cambered surfaces of the tile-shaped magnets; and when the tile-shaped magnets moving along the guide plates pass by a supporting rod contacting with the inner cambered surfaces of the tile-shaped magnets, an outer circle finely grinding wheel finely grinds the outer cambered surfaces of the tile-shaped magnets.

Owner:德昌电机(南京)有限公司

Stainless steel plate surface embossing treatment process

InactiveCN112026419ASolve the problem of uneven patternSolve the effect of wasting energyEmbossing decorationsSS - Stainless steelMaterials science

The invention discloses a stainless steel plate surface embossing treatment process, and belongs to the technical field of stainless steel plate surface embossing. The stainless steel plate surface embossing treatment process comprises a frame, an embossing mechanism, a limiting mechanism and a driving mechanism, a sliding rail is fixedly installed at the upper end of the frame, the embossing mechanism is slidably connected to the upper end of the frame through the sliding rail, and the limiting mechanism is slidably connected to the outer wall of the frame; the driving mechanism is slidably connected to the inner wall of the frame, one embossing roller is adopted to cooperate with the two auxiliary rollers, a hydraulic system is used for cooperating with a locking mechanism to adjust embossing depths, thus, the problem that due to adjustment of hand wheels, the feeding amounts of the two hand wheels are not uniform, and consequently the embossing depths are different is solved, and astainless steel plate is embossed through two-way symmetry; and the auxiliary rollers are the same as the embossing roller in linear speed and opposite to the embossing roller in direction through a transmission mechanism, and the problems that the stainless steel embossing plate and the embossing roller slide, the embossing edge is fuzzy, and even the wire drawing phenomenon occurs on the surfaceof the stainless steel plate are solved.

Owner:黄涛

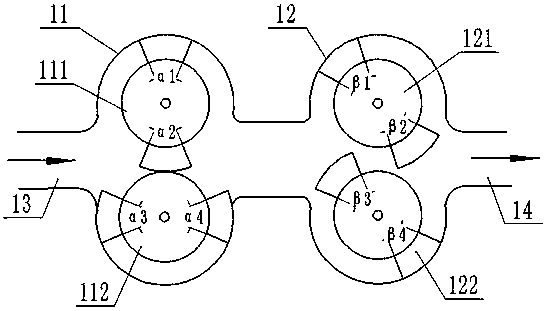

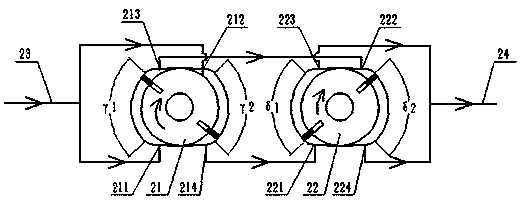

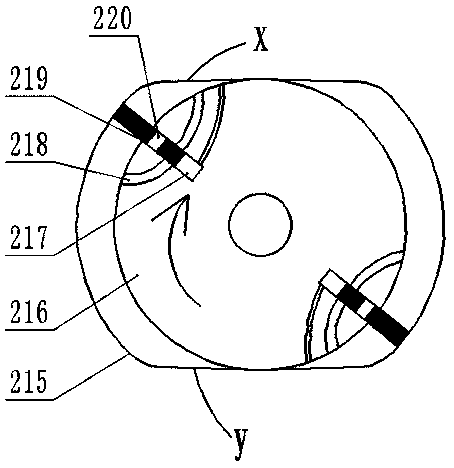

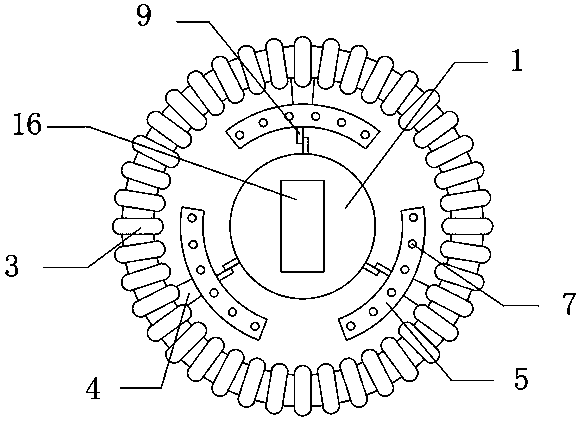

Design method capable of eliminating hydraulic pulsation and device capable of eliminating hydraulic pulsation

ActiveCN108799100ASame instantaneous flow rateConsistent flow changesRotary piston pumpsRotary/oscillating piston combinationsHydraulic pumpControl engineering

The invention discloses a design method capable of eliminating hydraulic pulsation and a device capable of eliminating hydraulic pulsation. The technical scheme of the invention is that a plurality ofsingle hydraulic pumps are connected in series to form a hydraulic pump system to alternate pump fluid, when the single hydraulic pumps act in the respective pump fluid angles, the instantaneous flowrates are kept equal; and the pump fluid angles of all the single hydraulic pumps in the hydraulic pump system add up to at least 360 degrees by setting the angles of the hydraulic pumps. A structural example of applying the method to different types of hydraulic pumps is disclosed, by means of a method alternating pump fluid by the hydraulic pumps connected in series, and the equal instantaneousflow rates of the single hydraulic pumps connected in series, it is ensure that the hydraulic pump system can continuously output hydraulic oil with stable pressure, avoid the problems of system lifereduction, high noise, high cost and unstable rotational speed caused by hydraulic impulse, provide new ideas and schemes to solve the hydraulic impulse problem in the industry, and promote the development of industry technology.

Owner:启东精马液压有限公司

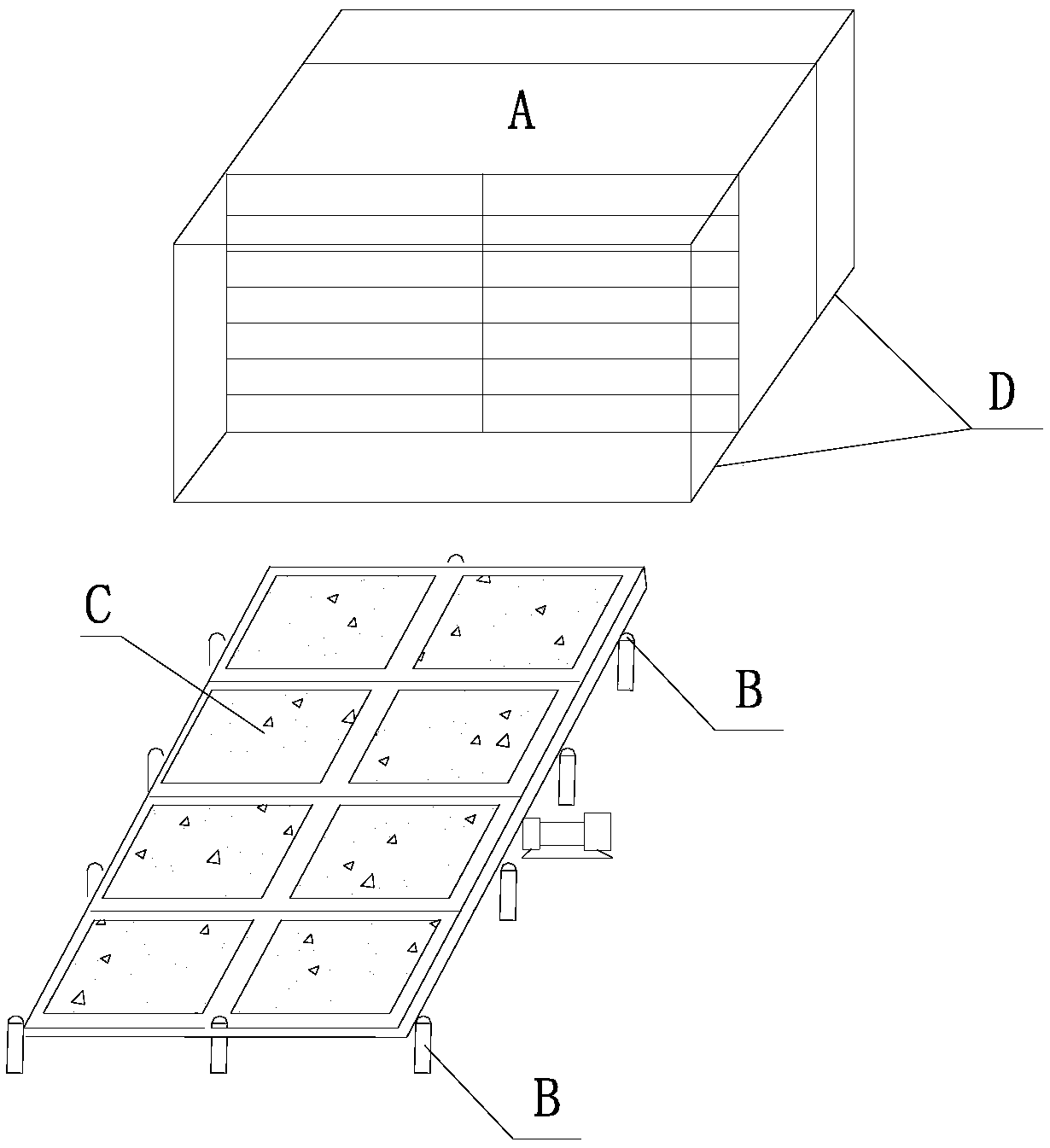

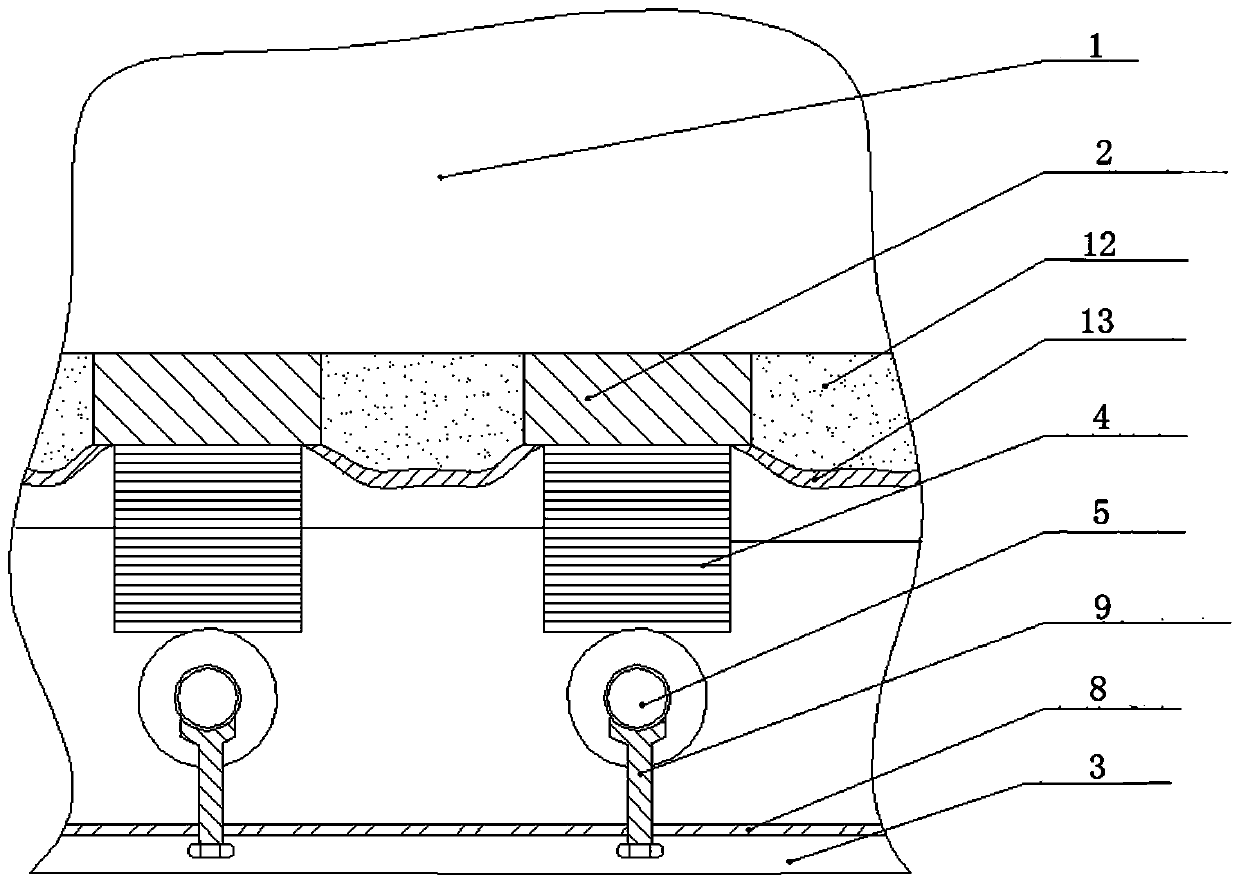

Closed loop type conveying system for building concrete wallboard prefabricated part production line

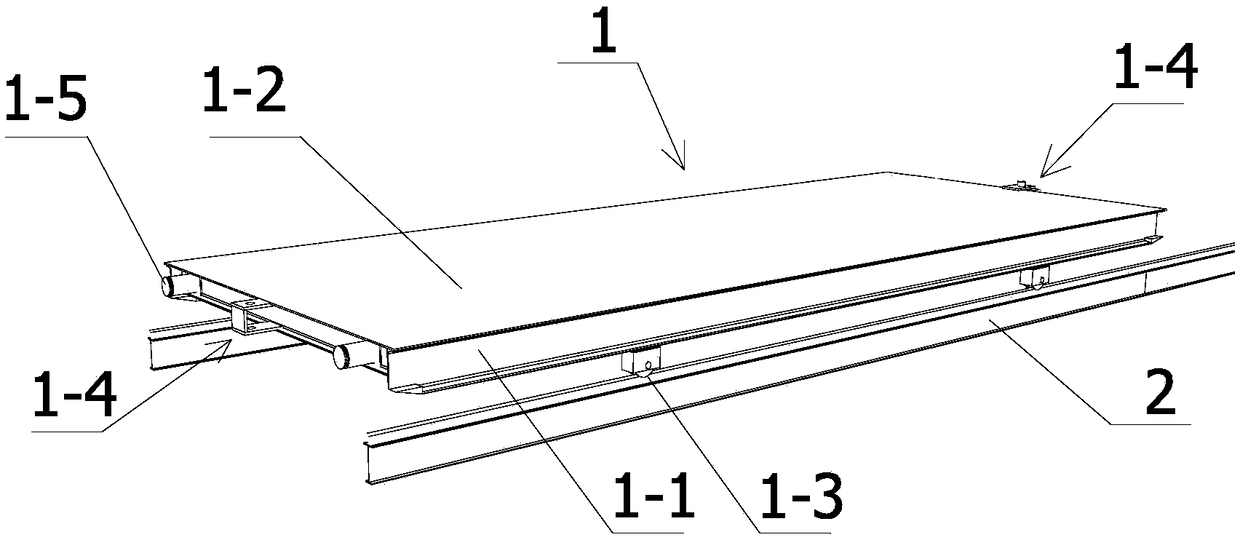

PendingCN108946024AReduce redundant linksReduce or even eliminate redundant linksCeramic shaping plantsAuxillary shaping apparatusProduction lineClosed loop

The invention discloses a closed loop type conveying system for a building concrete wallboard prefabricated part production line. The closed loop type conveying system for the building concrete wallboard prefabricated part production line comprises bench formwork trolleys, traveling tracks, traction devices and ferrying devices. The traveling tracks are divided into multiple sets, one end of eachset of traveling tracks is provided with the corresponding traction device, and the ferrying devices are arranged at the two ends of the sets of traveling tracks correspondingly. The corresponding bench formwork trolleys are sequentially arranged on each set of traveling tracks according to the production processes of prefabricated parts, and the production processes corresponding to the same sideends of the different sets of traveling tracks are linked. According to the closed loop type conveying system, the bench formwork trolleys are moved in the closed loop type conveying system, so thatthe number of the bench formwork trolleys is conveniently matched with the production takt of each process in the production line, the consistency between the number and moving speed of the bench formwork trolleys and the production takt is guaranteed, true streamlined operation is achieved for production of the prefabricated parts, redundant links in the production line are reduced or even omitted, waiting or stagnation time between the working procedures is shortened, the production efficiency of the production line is improved, and the quality of the prefabricated parts is improved.

Owner:正方利民(天镇)建筑工业化有限公司 +2

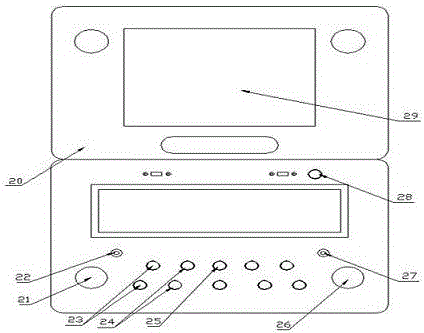

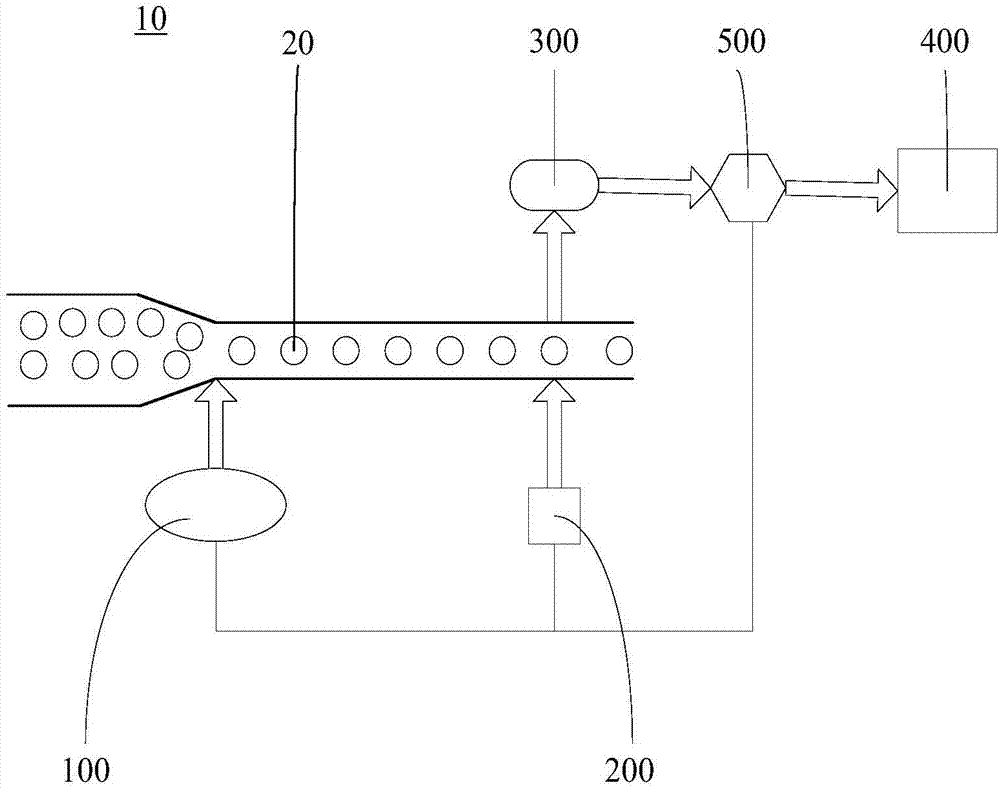

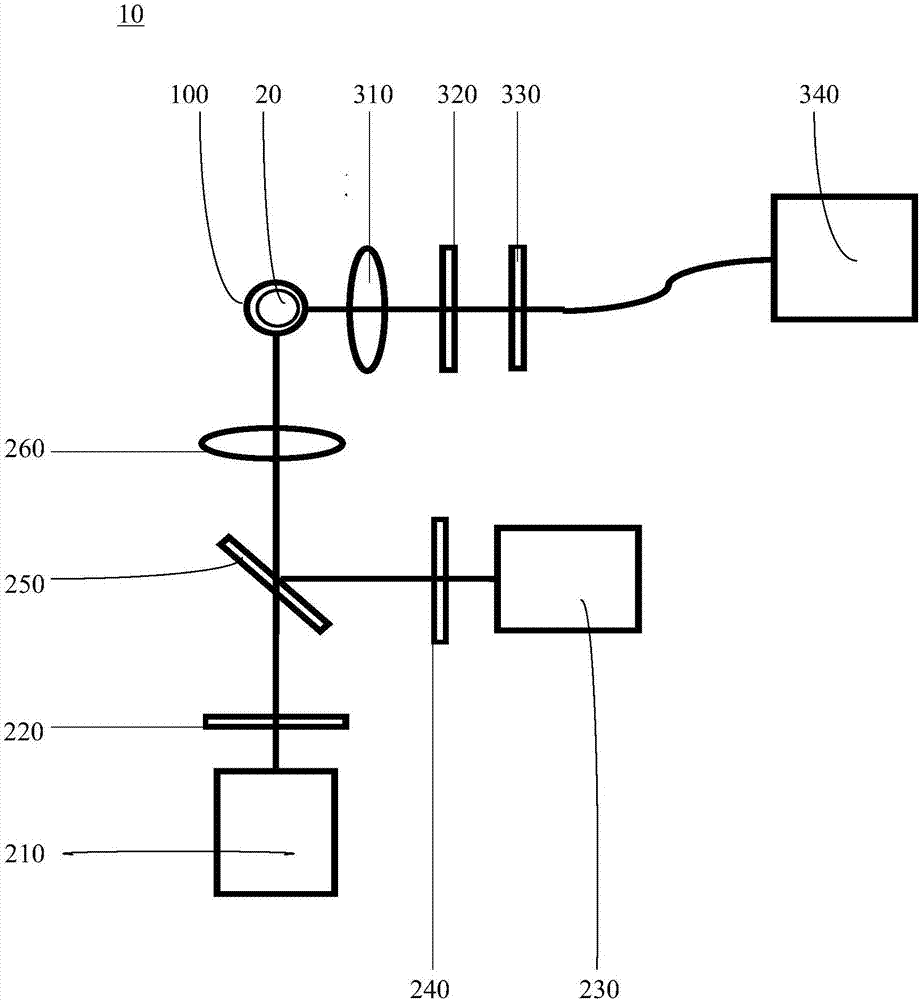

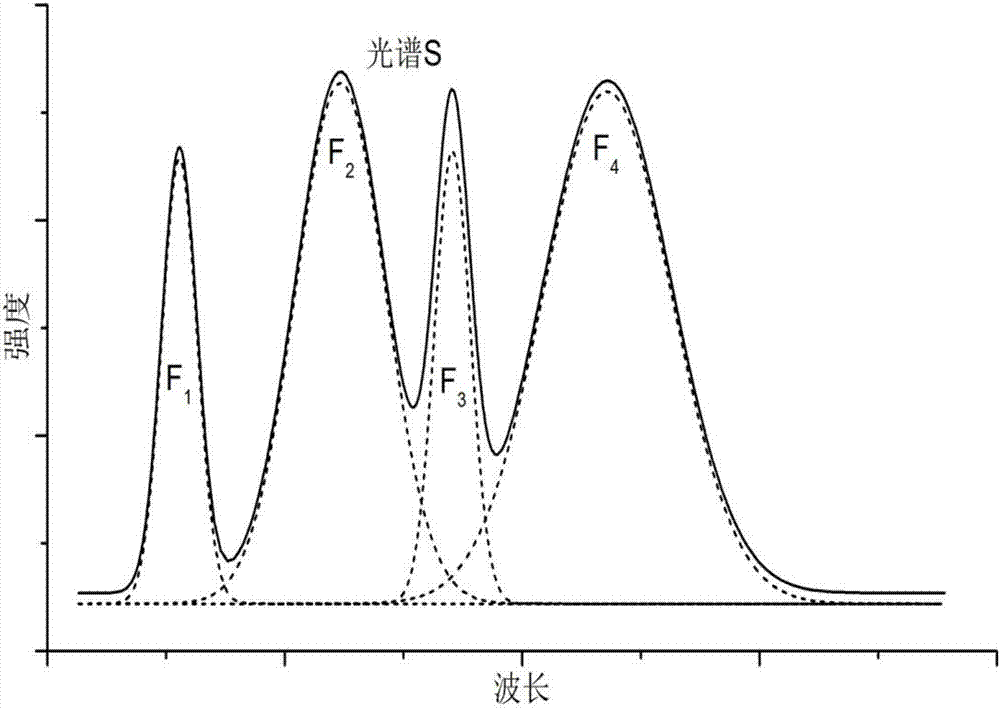

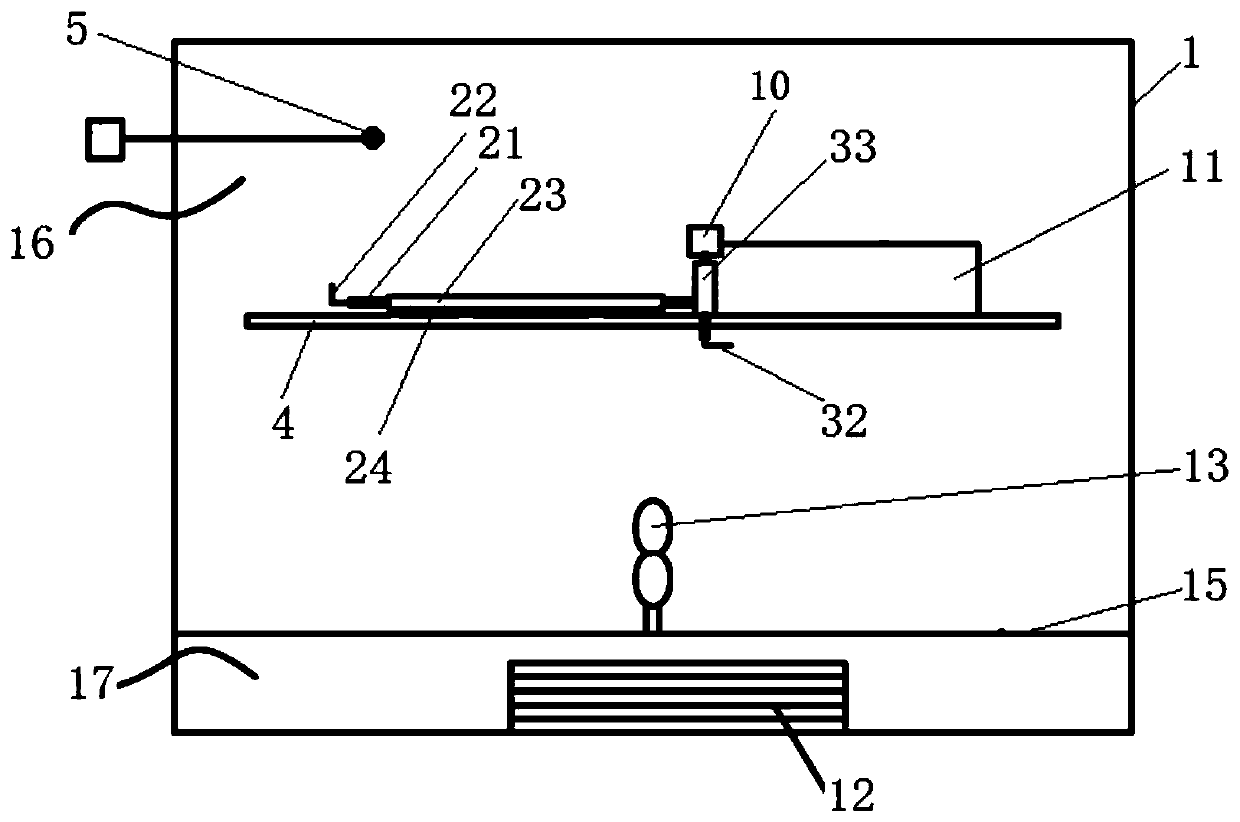

Digital polymerase chain reaction optical detection device and method

ActiveCN106906132ASimple structureImprove stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsPhysicsLight source

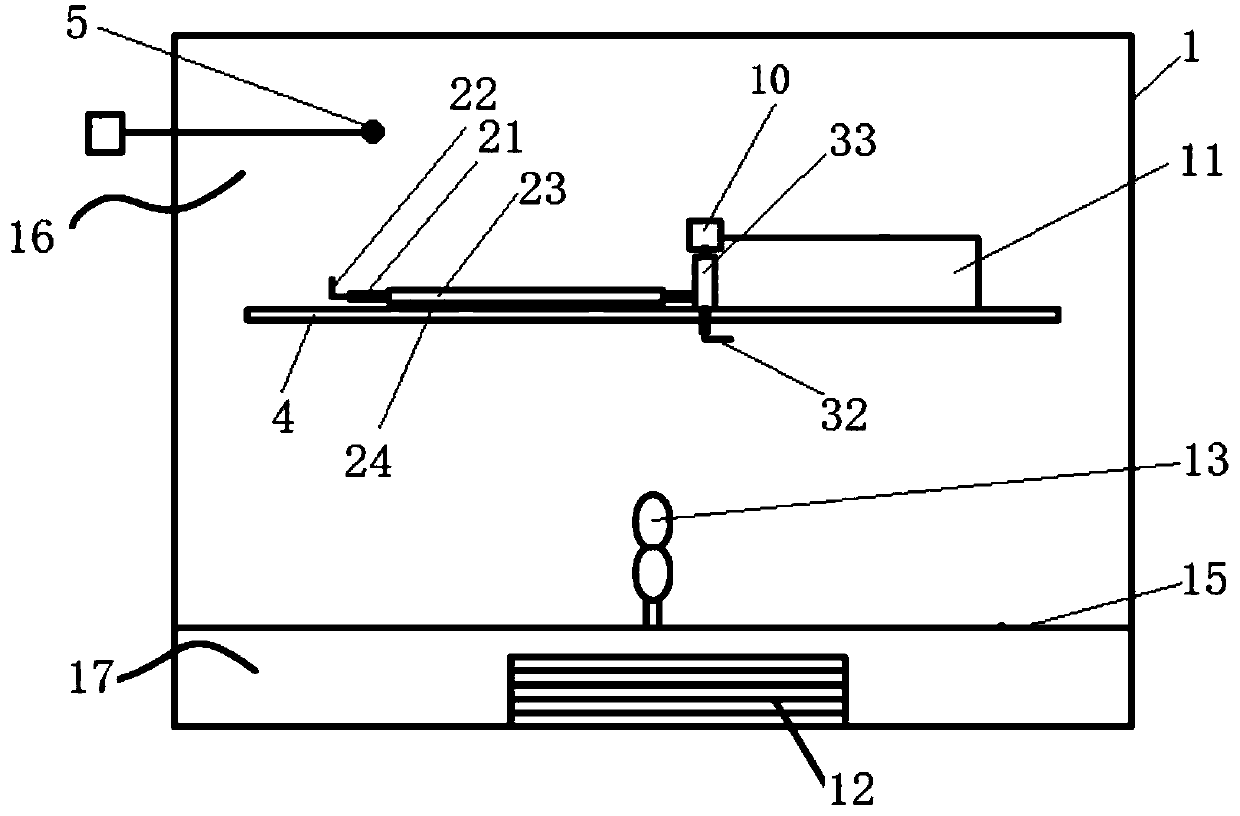

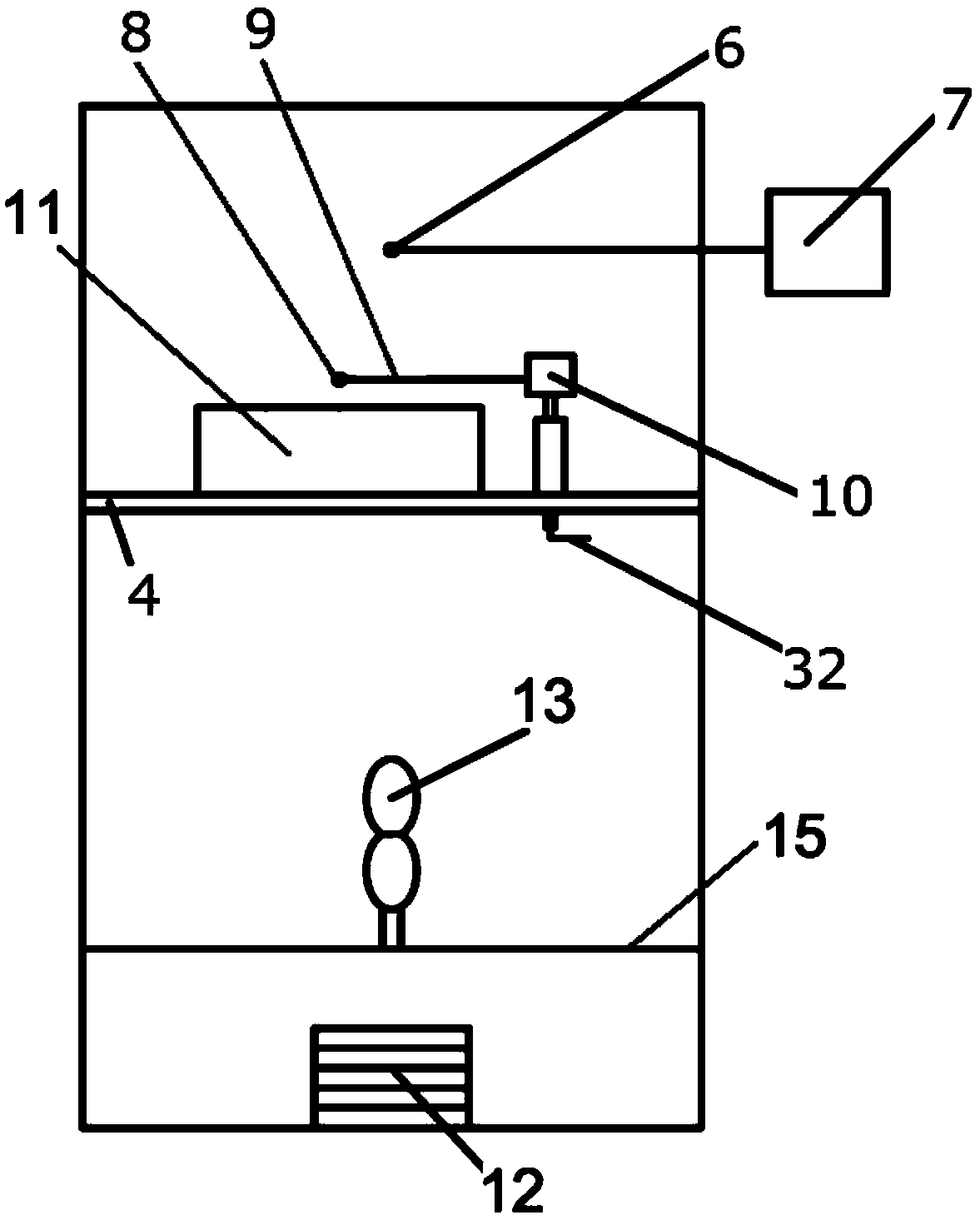

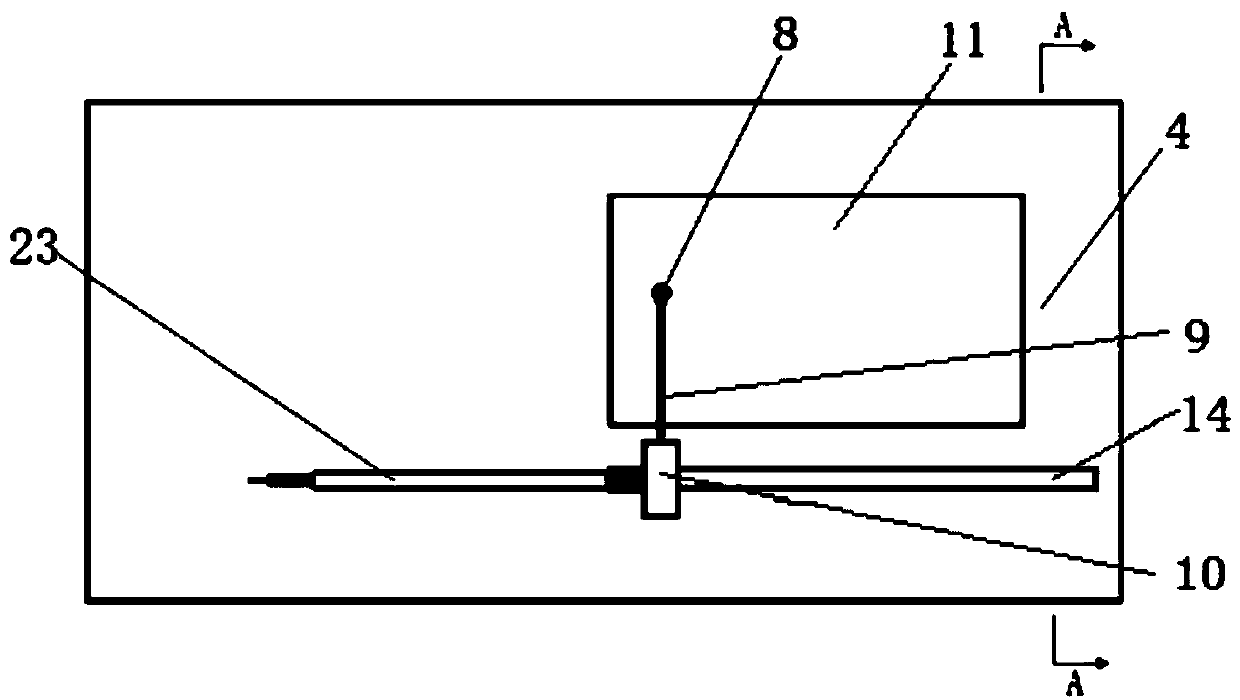

The invention relates to a digital polymerase chain reaction optical detection device and method. The device for detecting sample microdroplets comprises a sample transmission mechanism, an excitation light source mechanism, an optical detection mechanism, an input display mechanism and a control mechanism; the sample transmission mechanism is provided with a transmission micro channel for transmitting the sample microdroplets and a detection micro channel, and the detection micro channel is arranged at one end of the transmission micro channel and is only used for single row of the sample microdroplets to pass through; the excitation light source mechanism is provided with an excitation light source for exciting the sample microdroplets to generate an optical signal; the optical detection mechanism is provided with an optical fiber spectrometer for collecting and converting the optical signal of the sample microdroplets; the input display mechanism is used for setting or displaying the passing speed of the sample microdroplets in the sample transmission mechanism, the luminous intensity of the excitation light source and the spectral data of the sample microdroplets; the control mechanism is used for controlling the passing speed of the sample microdroplets in the sample transmission mechanism and the luminous intensity of the excitation light source. The device has the advantages of simple structure and high detection accuracy.

Owner:广东永诺医疗科技有限公司

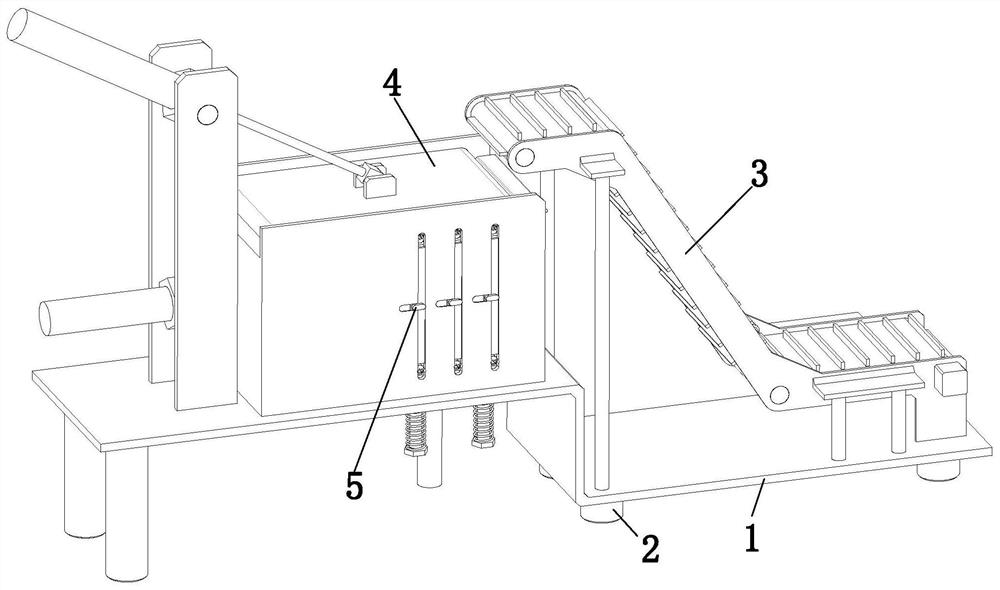

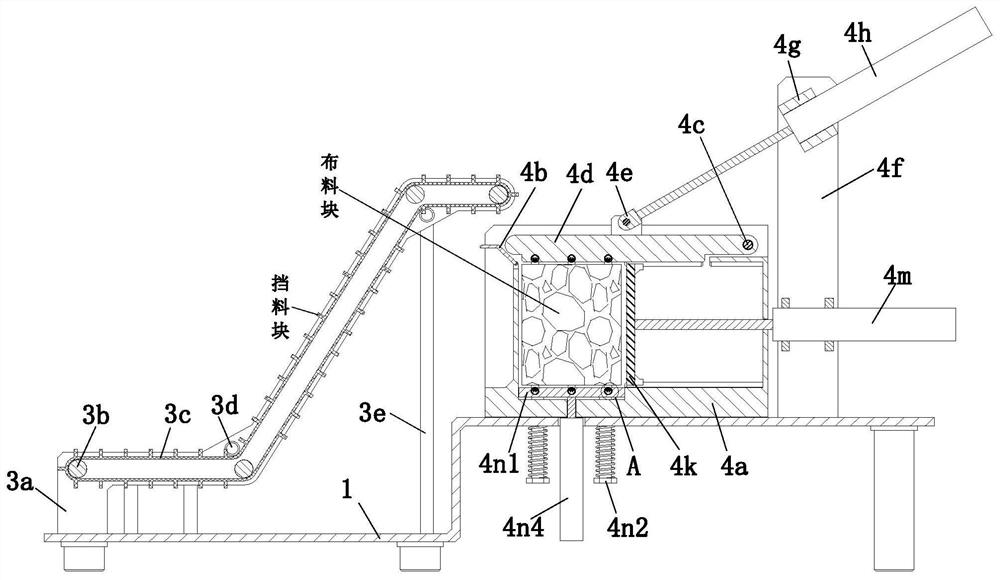

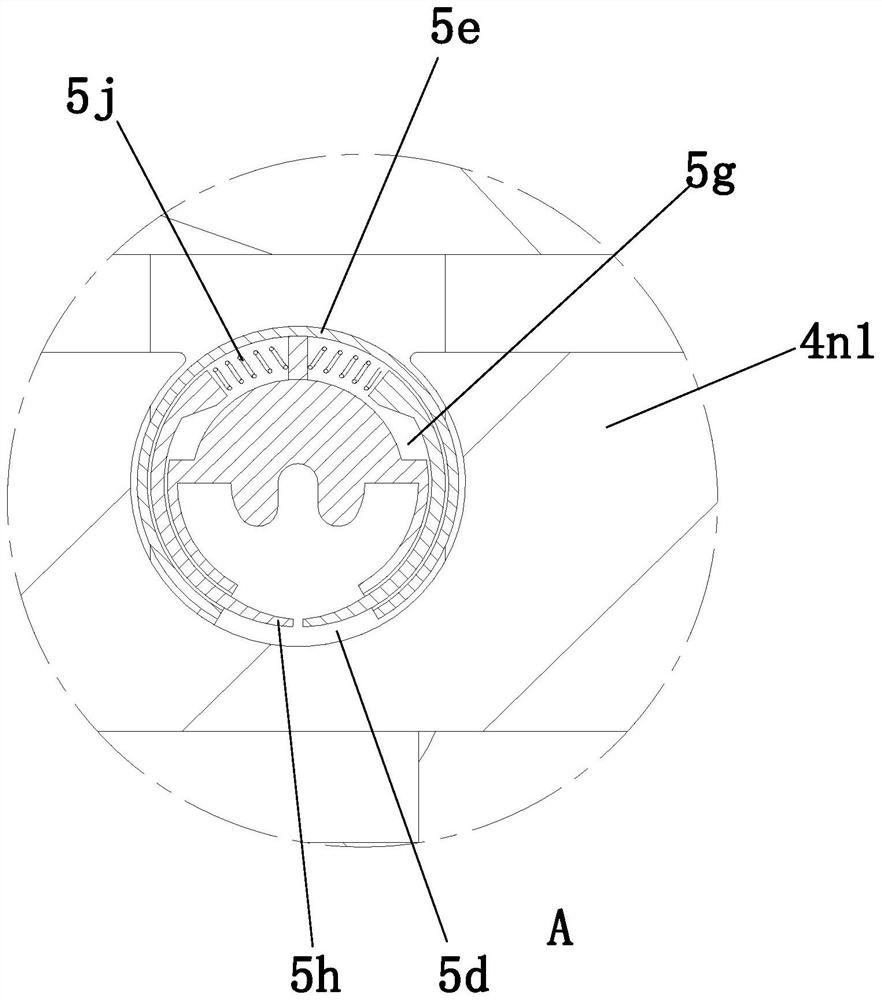

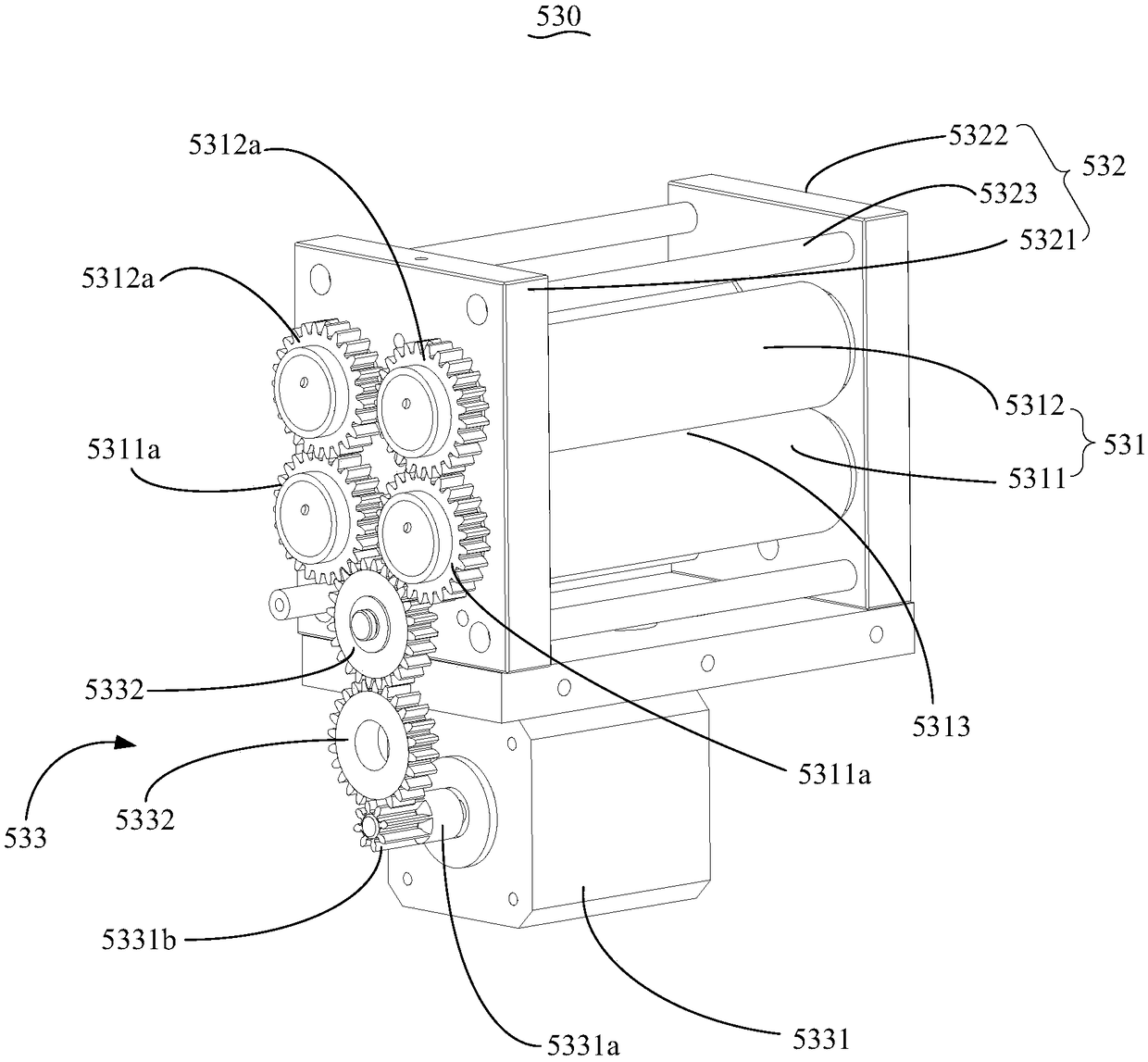

Industrial solid waste comprehensive treatment system and treatment method

ActiveCN113401440AReduce labor intensityReduce contact timePackagingPressesProcess engineeringTreatment system

The invention provides an industrial solid waste comprehensive treatment system and a treatment method. The industrial solid waste comprehensive treatment system comprises a mounting bottom plate, supporting legs, a conveying mechanism, a compressing mechanism and a packaging mechanism, and can solve the problems that during waste cloth treatment operation, cloth needs to be manually bundled through a packaging rope, the labor intensity of workers is increased due to a large amount of repeated operation, moreover, the cloth is difficult to be effectively compressed by manual packaging, so that the density of the cloth in each area in a cloth compression block is kept consistent, the probability of loosening of the cloth compression block is increased, and the packaged cloth compression block is difficult to eject out of the equipment, and the cloth is loosened and falls off due to excessive scraping between the cloth compression block and the side wall of a compression box when the cloth is taken out manually is solved.

Owner:西安旭旌再生资源有限公司

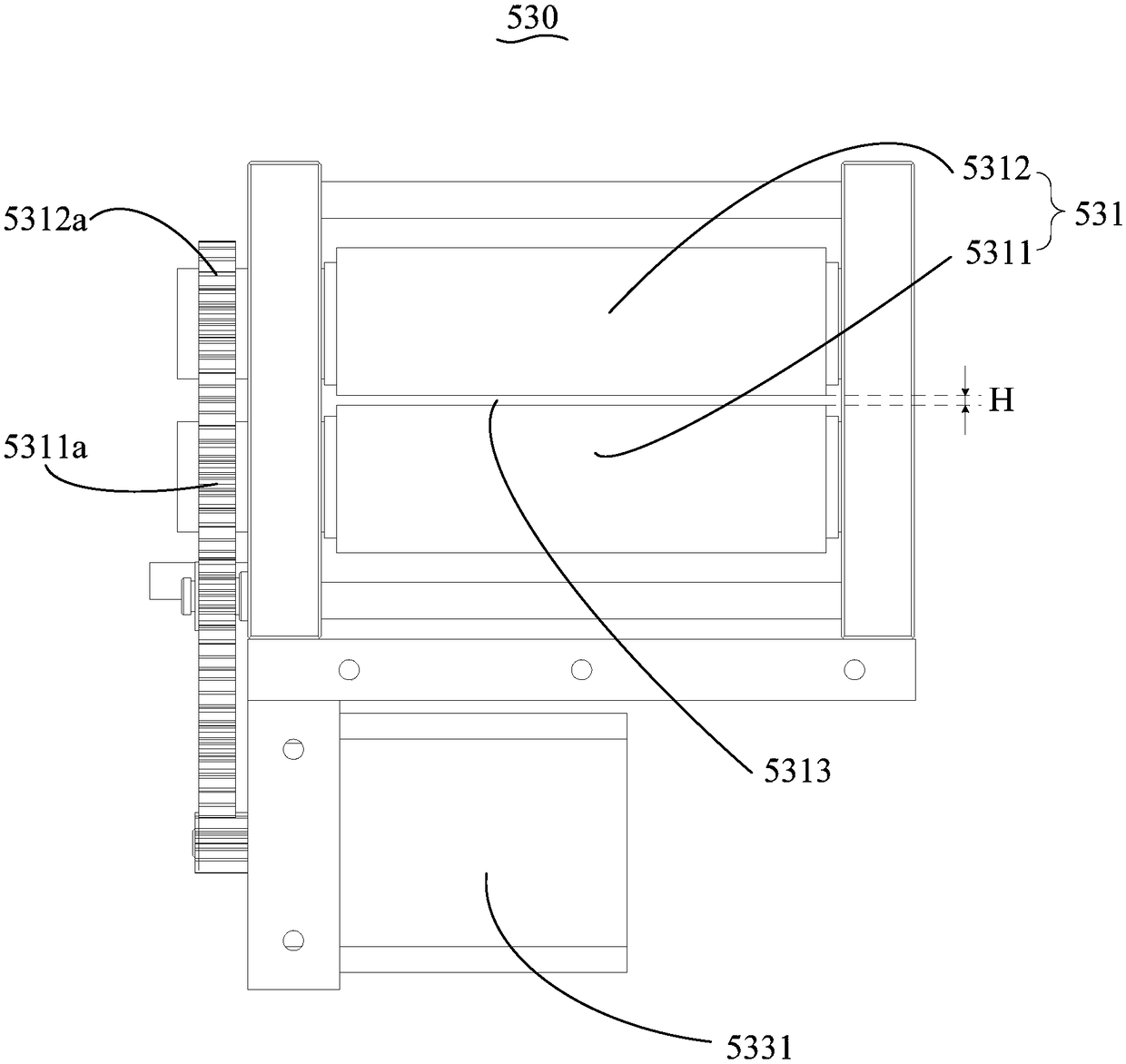

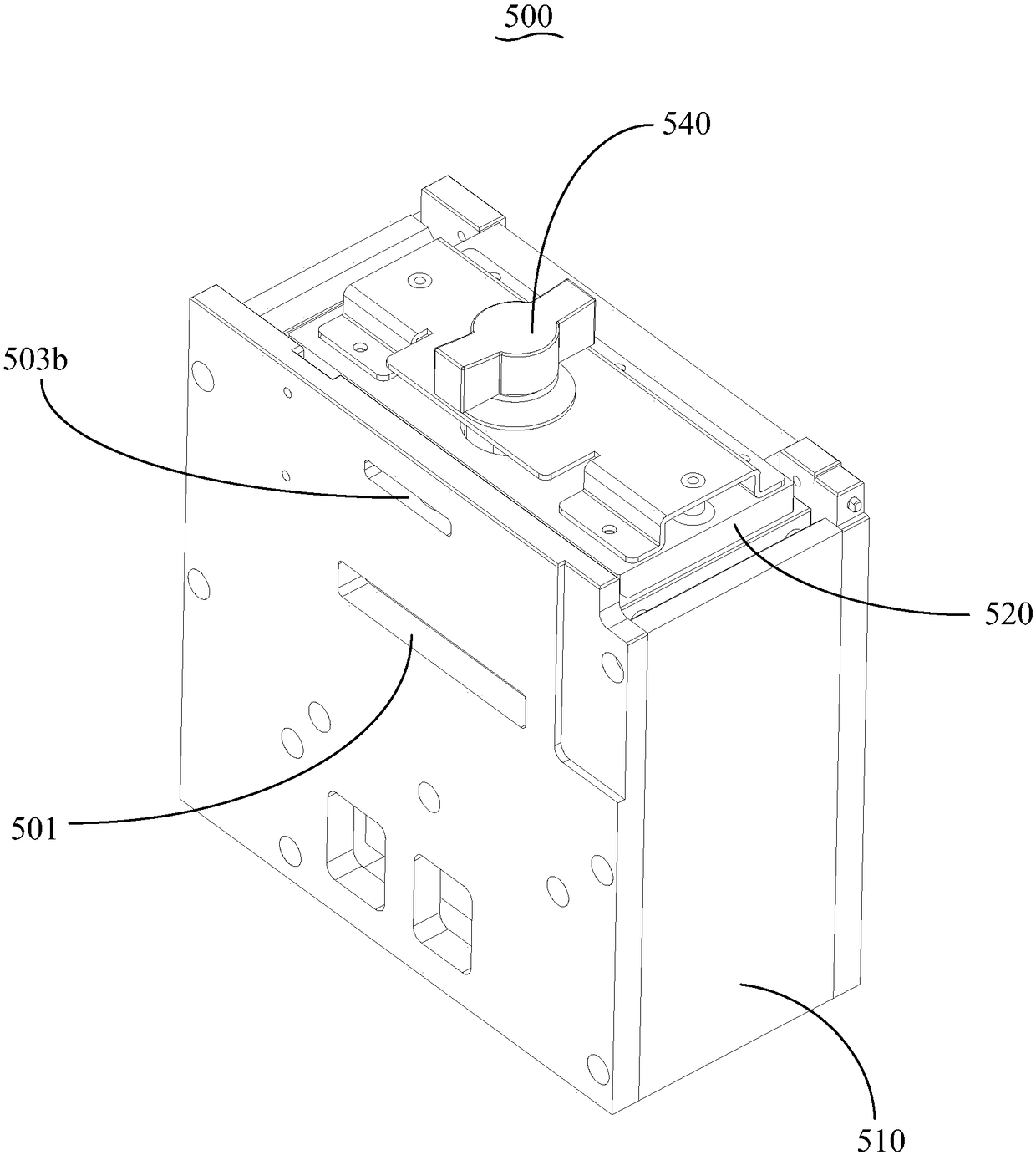

Film laminating mechanism and device and certificate making machine

ActiveCN109291421AMove at the same speedAvoid misalignmentInformation cardsMechanical engineeringEngineering

The invention discloses a film laminating mechanism and device a certificate making machine. The film laminating mechanism comprises a first driving assembly and at least one rolling wheel set arranged side by side. Each rolling wheel set comprises a first rolling wheel and a second rolling wheel which are oppositely arranged, and a film laminating passage is formed between the first rolling wheeland the second rolling wheel. Each first rolling wheel is connected with a first gear, and each second rolling wheel is connected with a second gear. Each first gear is in engagement connection withthe corresponding second gear. The first gears are in driving connection with the first driving assembly.. the distance of the gap between the first rolling wheels and the second rolling wheels is defined as the height H of the film laminating passage. The height H is greater than or equal to 0.5 mm and less than or equal to 0.7 mm. The film laminating mechanism can prevent certificates and filmsfrom get dislocated.

Owner:SHENZHEN ADVANCE CARD TECH

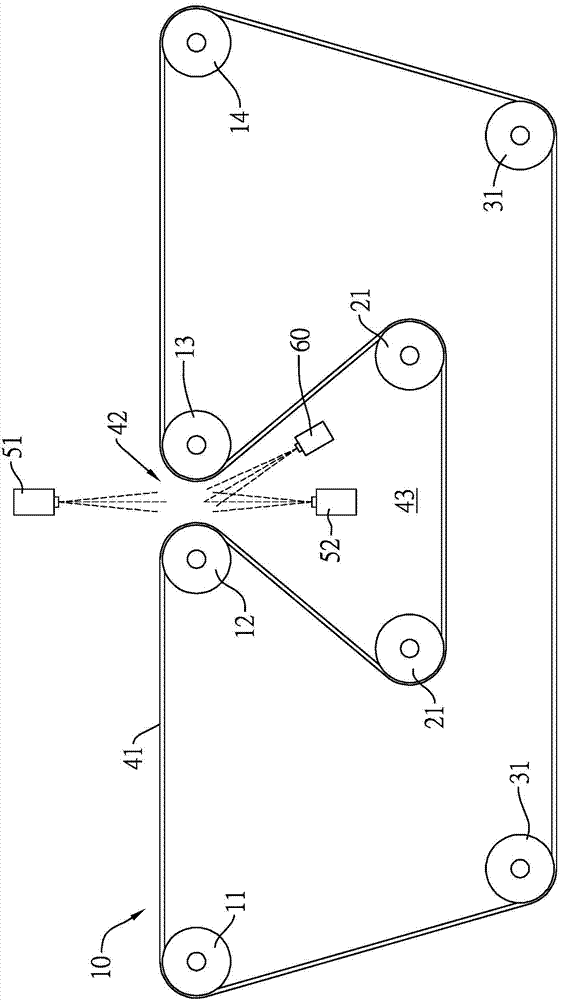

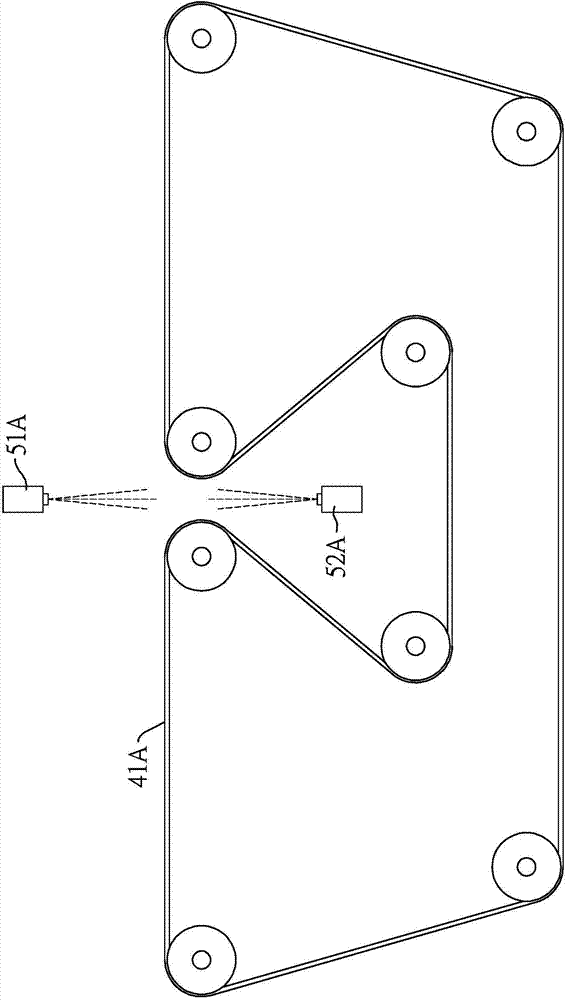

Sheet material detection device

InactiveCN104749188AMove at the same speedAvoid damageConveyorsOptically investigating flaws/contaminationShape objectLight source

The invention discloses a sheet material detection device. The sheet material detection device comprises a conveyer belt device and at least one camera, wherein the conveyer belt device comprises four upper rotating wheels, at least one middle rotating wheel, at least one lower rotating wheel and a conveying belt; the conveying belt forms a gap between the second upper rotating wheel and the third rotating wheel and forms a containing space between the second and the third upper rotating wheels and the middle rotating wheel, the containing space is communicated with the gap, and a light source or the camera used for shooting the bottom surface of a sheet-shaped object is arranged in the containing space; and as the conveyer belt device only adopts single conveying belt, the moving speeds of the conveying belt at two sides of the gap are enabled to be consistent, and a phenomenon that the sheet-like object is damaged due to friction with the conveying belt owning to inconsistent speeds of the conveying belt at two sides of the gap when the sheet-like object passes through the gap is avoided.

Owner:欧壹科技股份有限公司

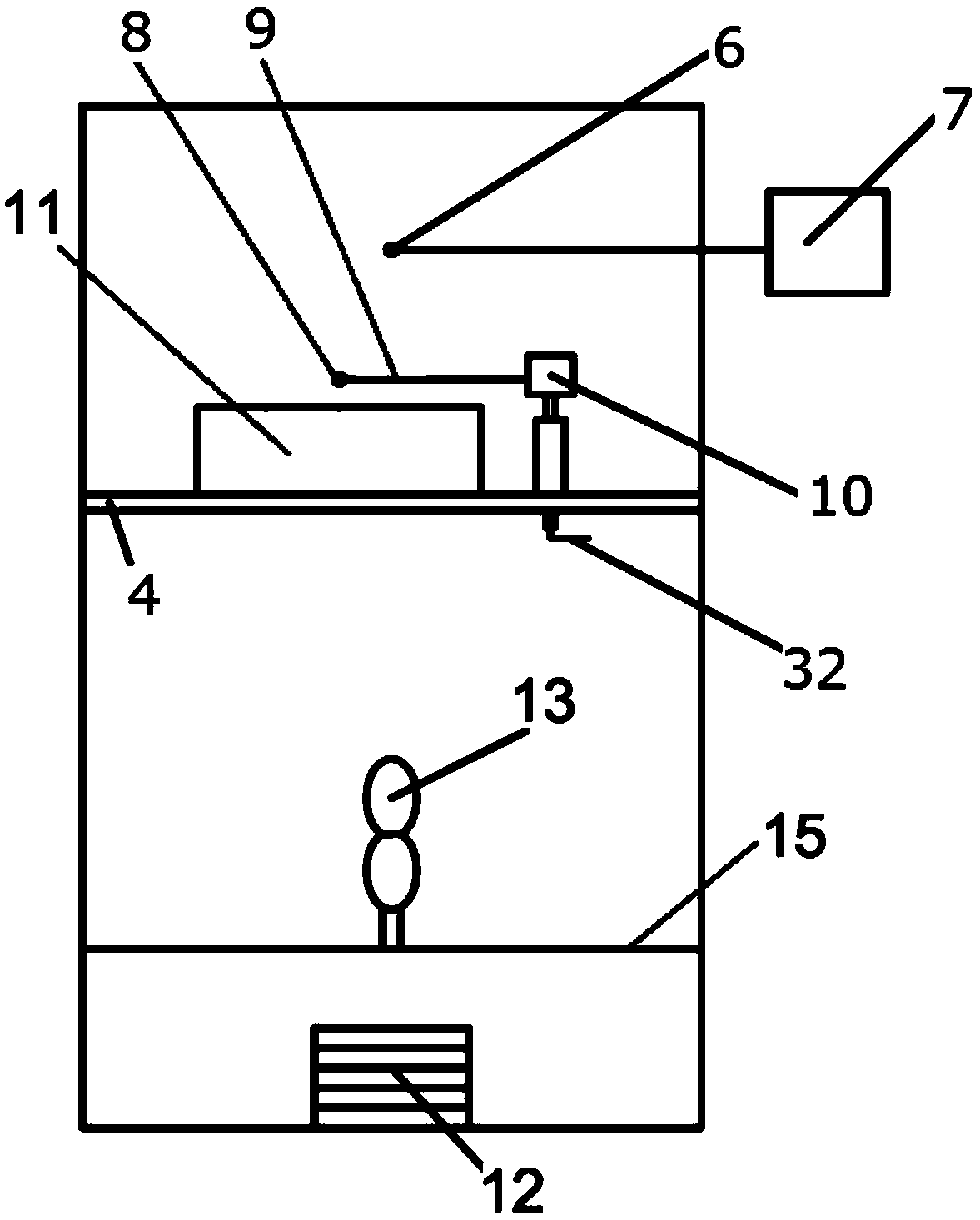

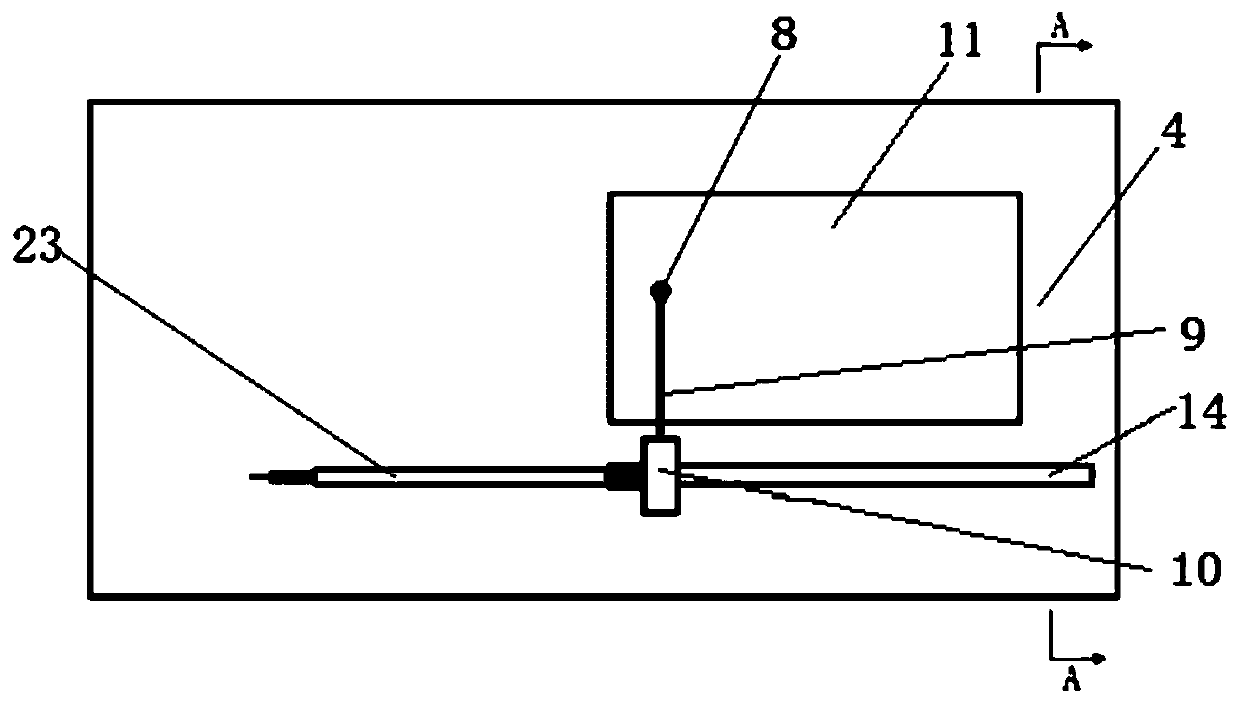

Equipment for measuring thickness of heat and mass transfer thin layer on wood surface in drying process

ActiveCN109682339AImprove drying qualityHigh measurement accuracyDrying gas arrangementsDrying chambers/containersMeasurement deviceHeat mass transfer

The invention discloses equipment for measuring the thickness of a heat and mass transfer thin layer on the wood surface in the drying process. The equipment comprises a wood drying chamber, a first feeding device, a second feeding device and a measuring device, wherein the first feeding device, the second feeding device and the measuring device are arranged in the drying chamber, and the drying chamber is internally and horizontally provided with a bracket used for placing to-be-dried wood; the first feeding device is perpendicular to the second feeding device, the second feeding device is fixed at the front end of the first feeding device, and the first feeding device pushes the second feeding device to move horizontally in the longitudinal direction or horizontal direction of the dryingchamber. The equipment for measuring the thickness of the heat and mass transfer thin layer on the wood surface in the drying process has the advantages that the collected data volume is large, measured results are accurate, the precision is high, the heat and mass transfer thin layer in the drying process of wood is improved, data support is provided for the wood drying quality, and good theoretical guidance is provided for strengthening heat and moisture transfer on the wood surface and increasing the wood drying rate.

Owner:BEIJING FORESTRY UNIVERSITY

Mechanical part surface sand blasting device

ActiveCN112171522AIncrease linkageMove at the same speedAbrasive machine appurtenancesMagnetic separationMechanical componentsSand blasting

The invention relates to the technical field of mechanical parts, and discloses a mechanical part surface sand blasting device. The device comprises a shell, and a collecting bin is fixedly connectedto the interior of the shell. According to the device, automatic linear moving sand blasting is conducted, so that the moving speed is kept consistent, two hands are liberated, and the situation thatduring manual operation, the moving speed is not constant, and consequently the scrap removing degree is not uniform is avoided; by means of the capacitance principle, the magnetic state of an attraction tool is controlled, so that the scrap removing operation is conveniently conducted, the linkage between structures is improved, and the high automation degree is achieved; a mixture of sandstone and scrap iron is stored and turned over, so that the scrap iron in the mixture is conveniently attracted by the attraction tool, the sandstone is separated from the scrap iron, and the sandstone can be conveniently recycled; and the attraction tool attracting the scrap iron is automatically moved out of the collecting bin, by means of the property of an electromagnet, the attraction tool losing magnetism does not attract the scrap iron any more, the scrap iron automatically falls off under the action of the gravity of the scrap iron, and the scrap iron is intensively collected.

Owner:山西衡兴盛机械设备股份有限公司

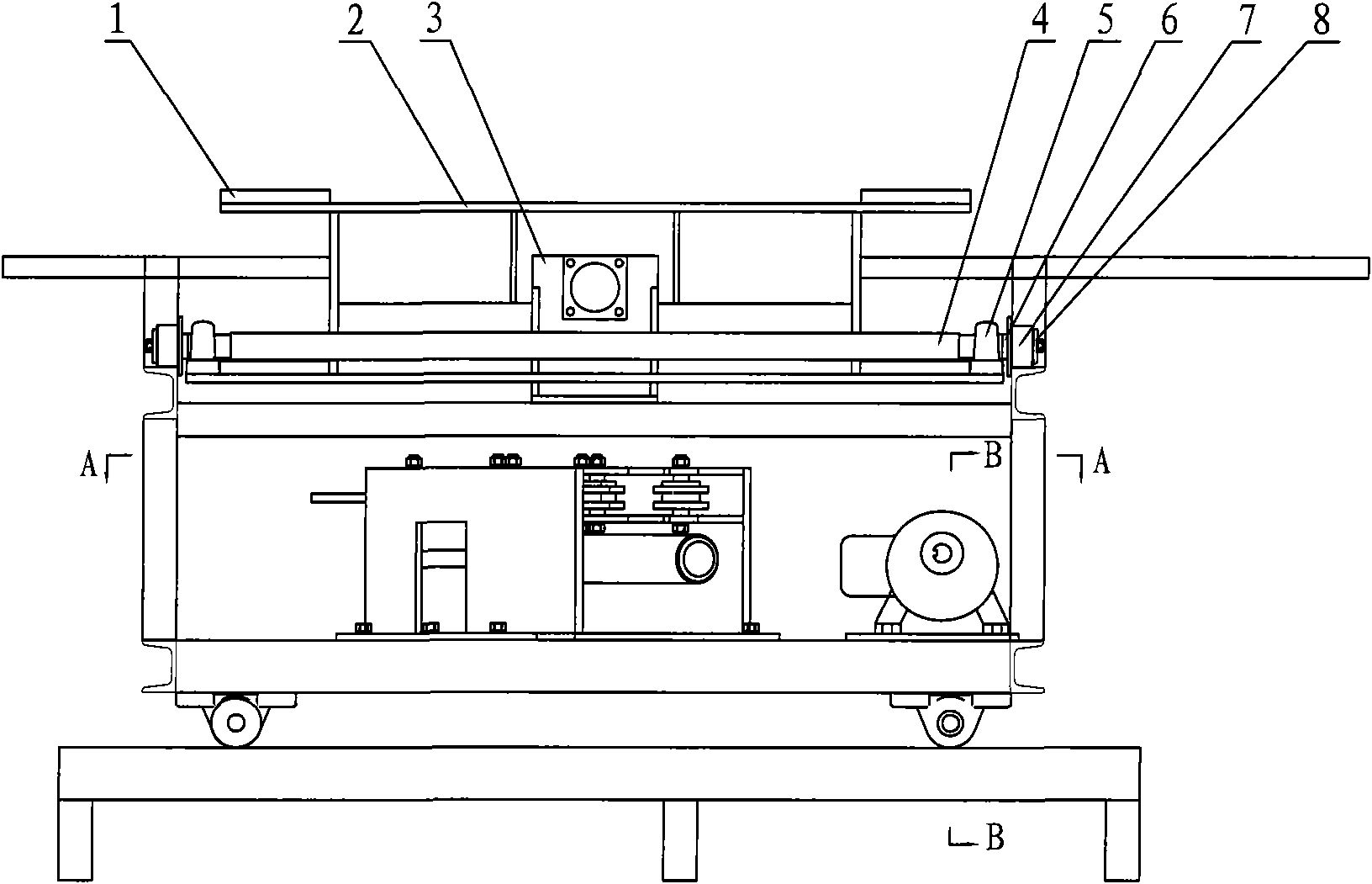

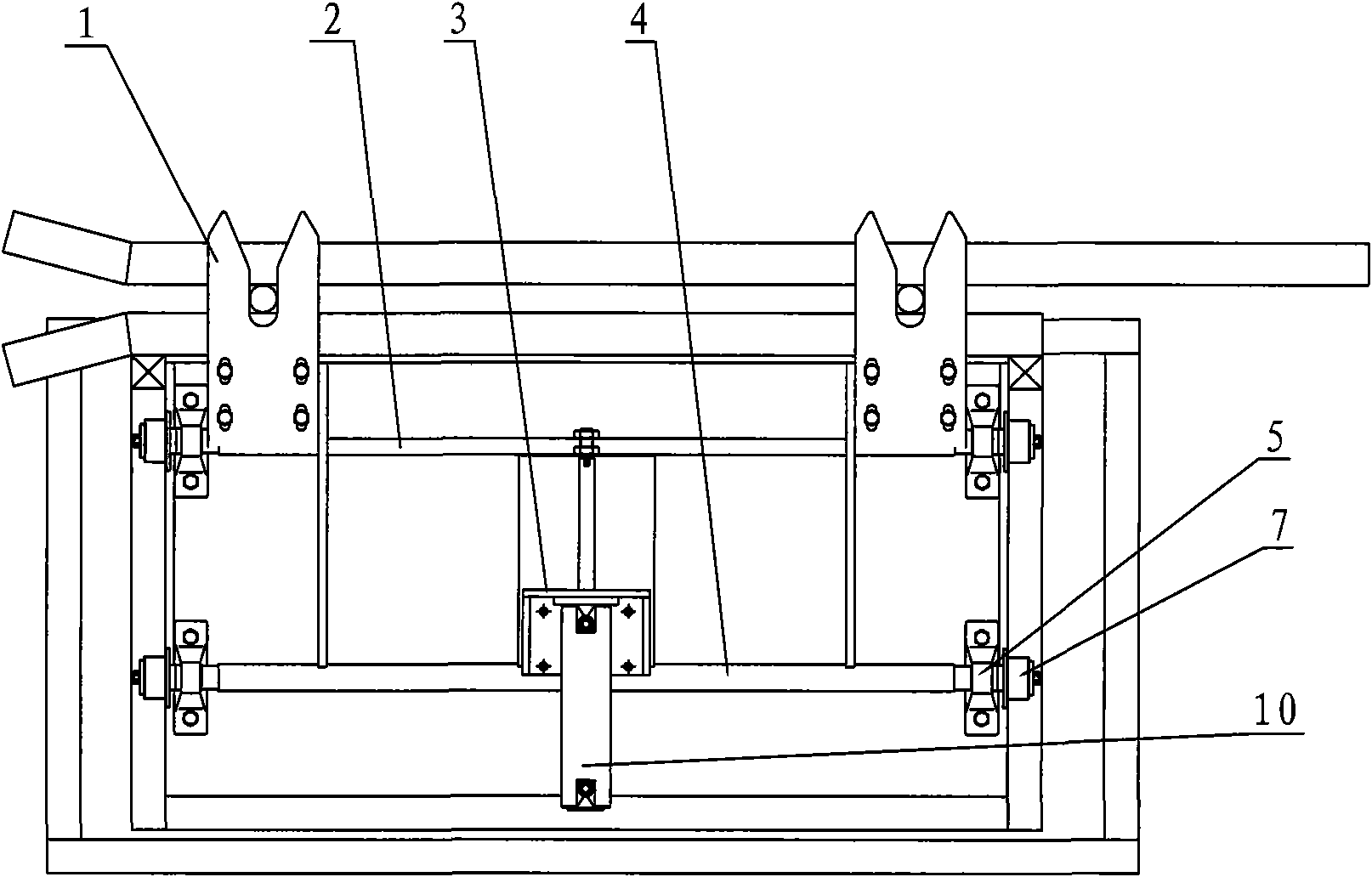

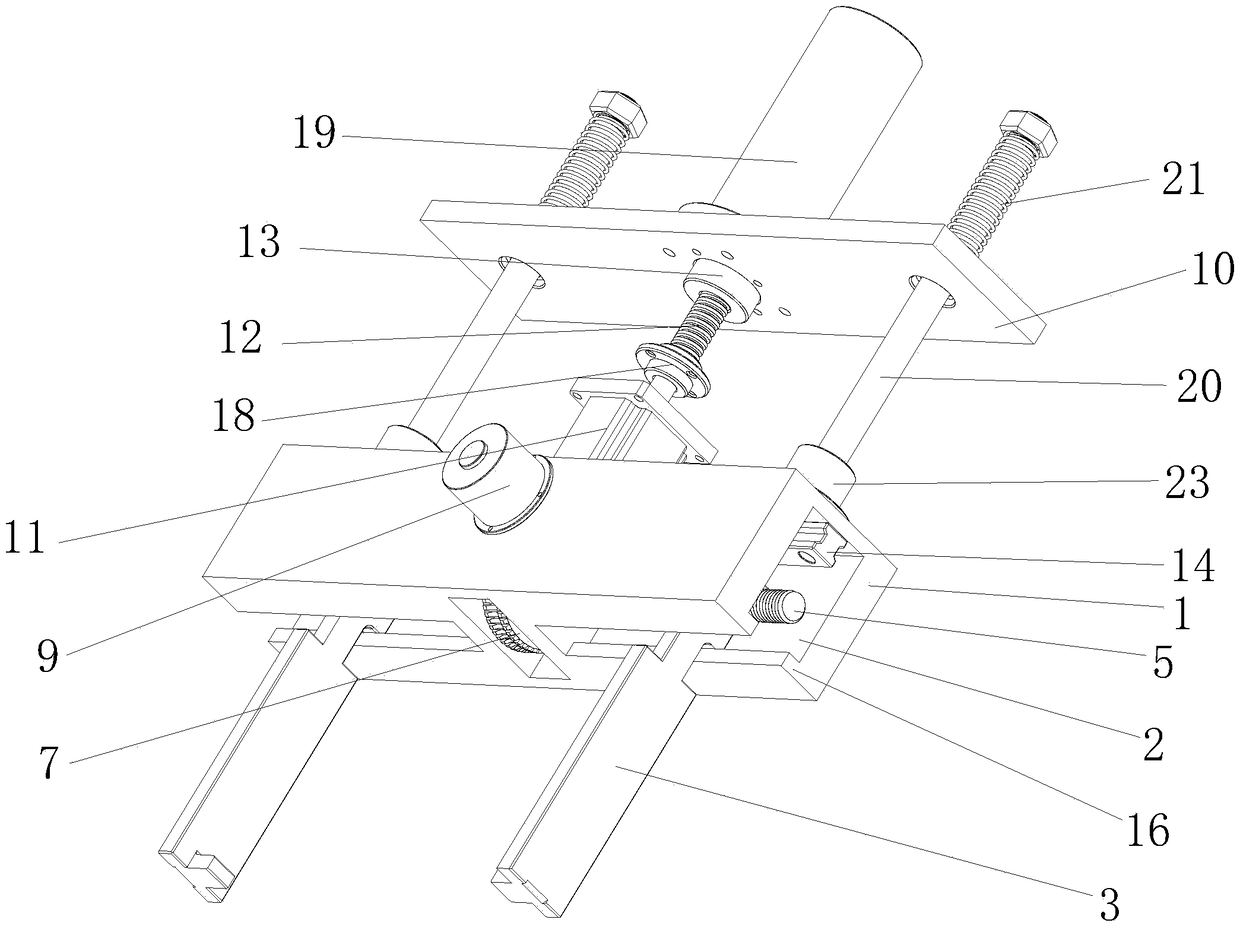

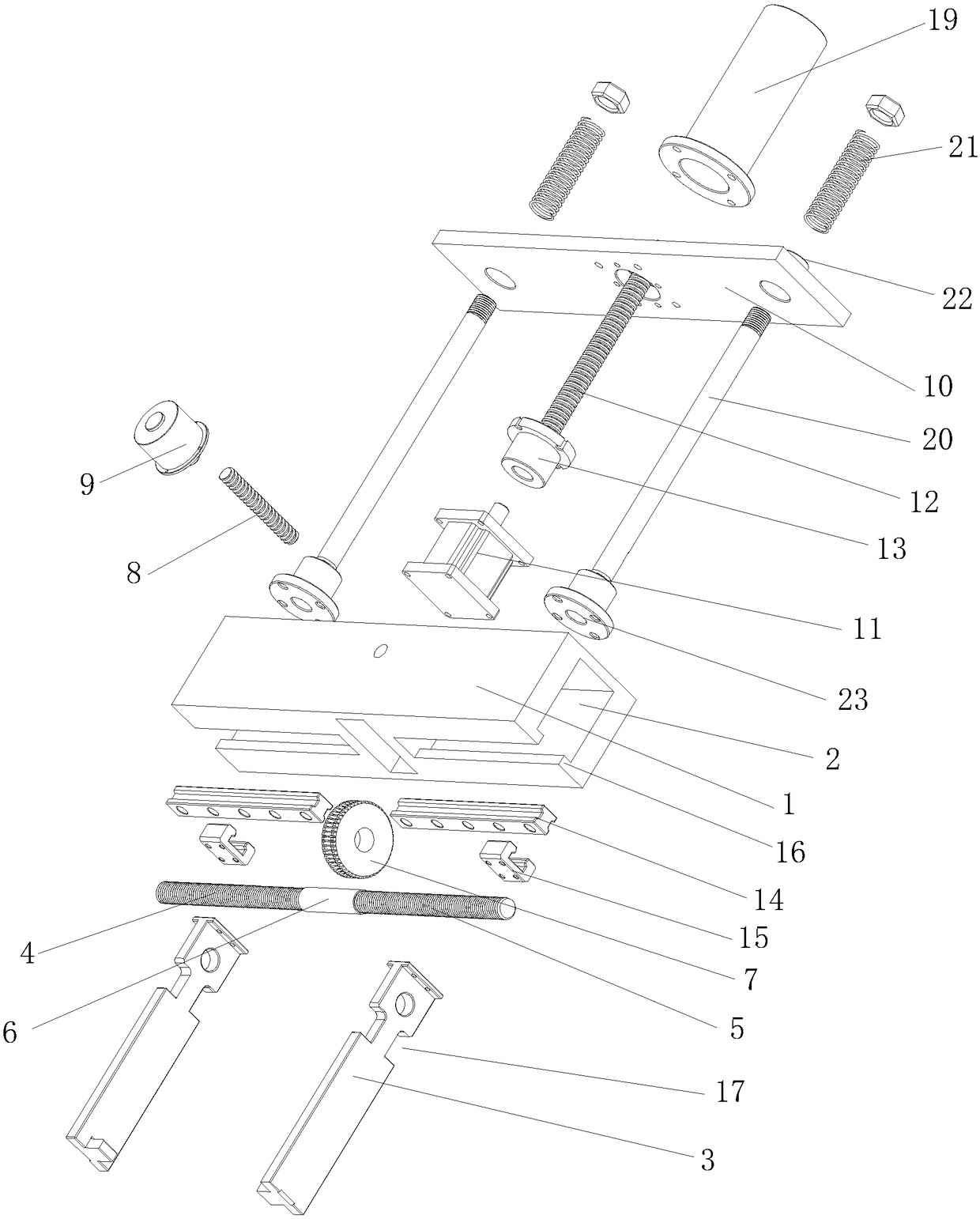

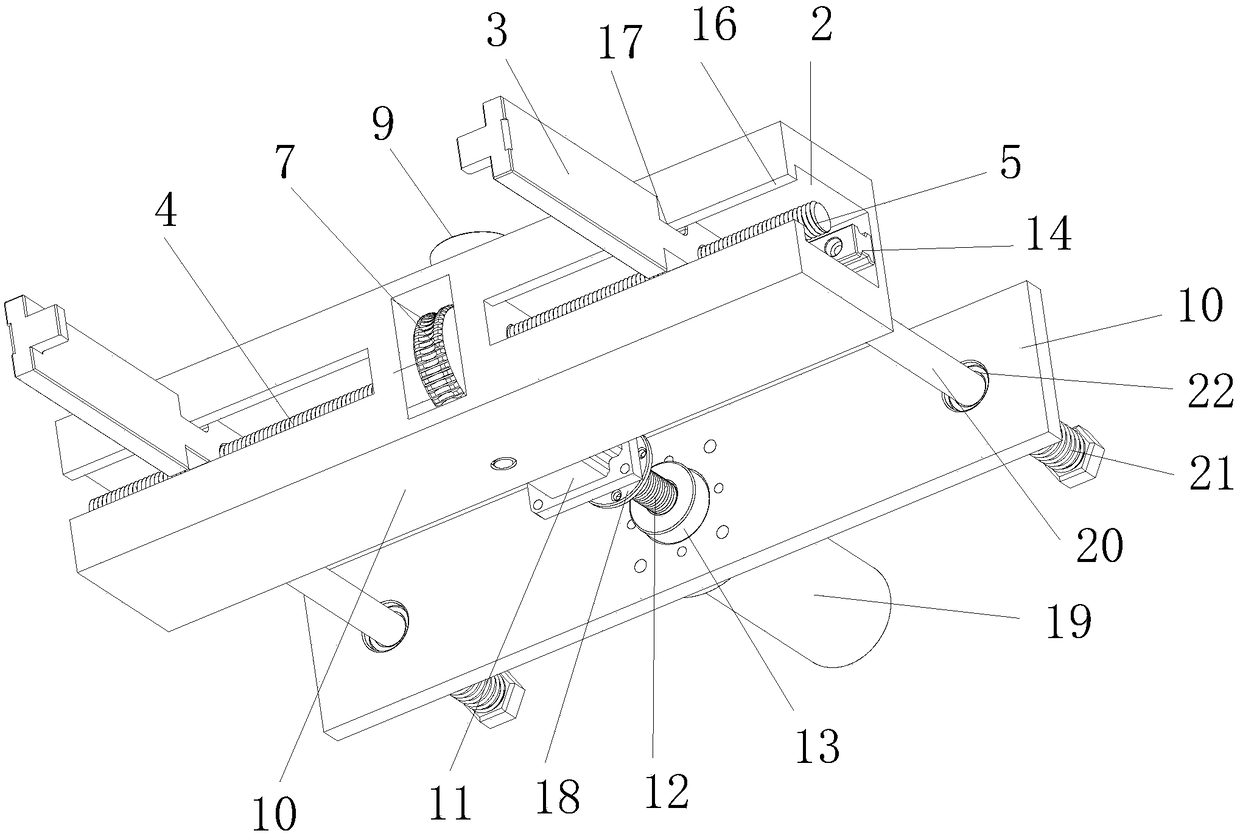

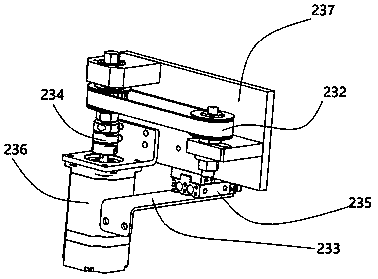

Gearbox shell grabbing manipulator for new-energy automobiles

The invention relates to the technical field of gearbox production equipment for new-energy automobiles, in particular to a gearbox shell grabbing manipulator for the new-energy automobiles. The gearbox shell grabbing manipulator comprises a clamping jaw seat, clamping jaws, a threaded shaft, a worm gear, a worm, a worm driving motor, a connecting plate, a servo motor, a ball screw and a screw nut, wherein the clamping jaw seat is provided with a sliding groove, and the clamping jaws slide in the sliding groove; and when the threaded shaft rotates, the two clamping jaws are driven to move oppositely, and the worm gear is engaged with the worm. According to the gearbox shell grabbing manipulator, each clamping jaw is arranged on the clamping jaw seat through a sliding part, so that the resistance is reduced to the minimum when the clamping jaws slide, and quick clamping is achieved; the clamping jaws are arranged to move oppositely after being driven by the threaded shaft, and due to the fact that the threaded engagement force of threaded connection is large, a gearbox shell with a large weight can be clamped; and the driving mode of the threaded shaft enables the moving speed and the stroke of the two clamping jaws to be consistent, so that the clamped gearbox shell is in a balanced state, and the situation that assembly is affected due to shake cannot occur.

Owner:安徽航科自动化设备有限公司

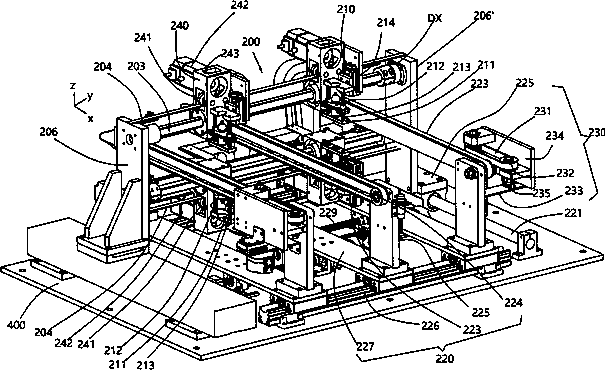

PCB surface copper thickness measuring machine and measuring method

PendingCN110487234AImprove measurement efficiencyMove at the same speedMeasurement devicesCharge manipulationEngineeringCopper

The invention discloses a PCB surface copper thickness measuring machine, which comprises measuring heads for measuring the thickness of copper on the surface of a PCB; a conveying device for conveying the PCB; and a computer control system connected with the a conveying device drive device and a copper thickness measuring instrument. The copper thickness measuring heads are arranged above and under the PCB conveying device; the copper thickness measuring heads are mounted on a drive device that can move synchronously with the PCB and keeps the copper thickness measuring heads static relativeto the PCB; and copper thickness measuring head drive devices are connected with the computer control system for controlling the copper thickness measuring head drive devices. According to the method,whole plate devices move synchronously with the PCB during material input of the PCB surface copper thickness measuring machine; during measuring, the copper thickness measuring heads move synchronously with the PCB, and in the measuring process, the PCB does not stop; and meanwhile, since the copper thickness measuring heads are arranged above and under the PCB conveying device, the thickness ofthe copper on the upper and lower surfaces of the PCB at the same position can be measured synchronously, thereby improving work efficiency of the PCB surface copper thickness measuring machine.

Owner:昆山盈达科机电科技有限公司

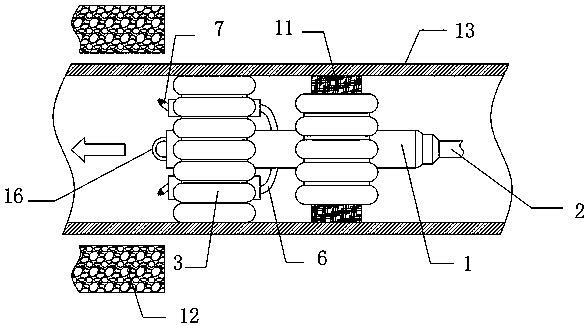

Pipe degreasing equipment based on ultrasonic cleaning technology and using method thereof

ActiveCN111589806AEasy to operateSimple structureHollow article cleaningCleaning using liquidsActivated carbonMegasonic cleaning

The invention discloses pipe degreasing equipment based on an ultrasonic cleaning technology and a using method thereof, and belongs to the field of stainless steel pipe treatment equipment. The pipedegreasing equipment based on the ultrasonic cleaning technology comprises a moving pipe and a pipe, one end of the moving pipe communicates with a water pipe, the end, away from the water pipe, of the moving pipe is sleeved with a contraction body, and the contraction body comprises a stretching pipe which is filled with magnetic fluid. The pipe degreasing equipment can achieve ultrasonic degreasing treatment of an ultra-long pipe, and can be suitable for pipes with different calibers, the degreasing equipment can make adaptive changes according to the calibers of the pipes through the adsorption effect of a magnetic field on the magnetic fluid, and the degreasing equipment in the pipe can move along with the attraction force, so that the operation is simple, rapid and convenient, and thetreatment efficiency is high; and an activated carbon attraction net capable of wiping grease is further arranged behind a sprayed degreasing agent so that grease failing to fall off can be further cleared, the degreasing effect is improved, and the whole equipment is simple in structure, low in cost and easy to operate.

Owner:新机金属(深圳)有限公司

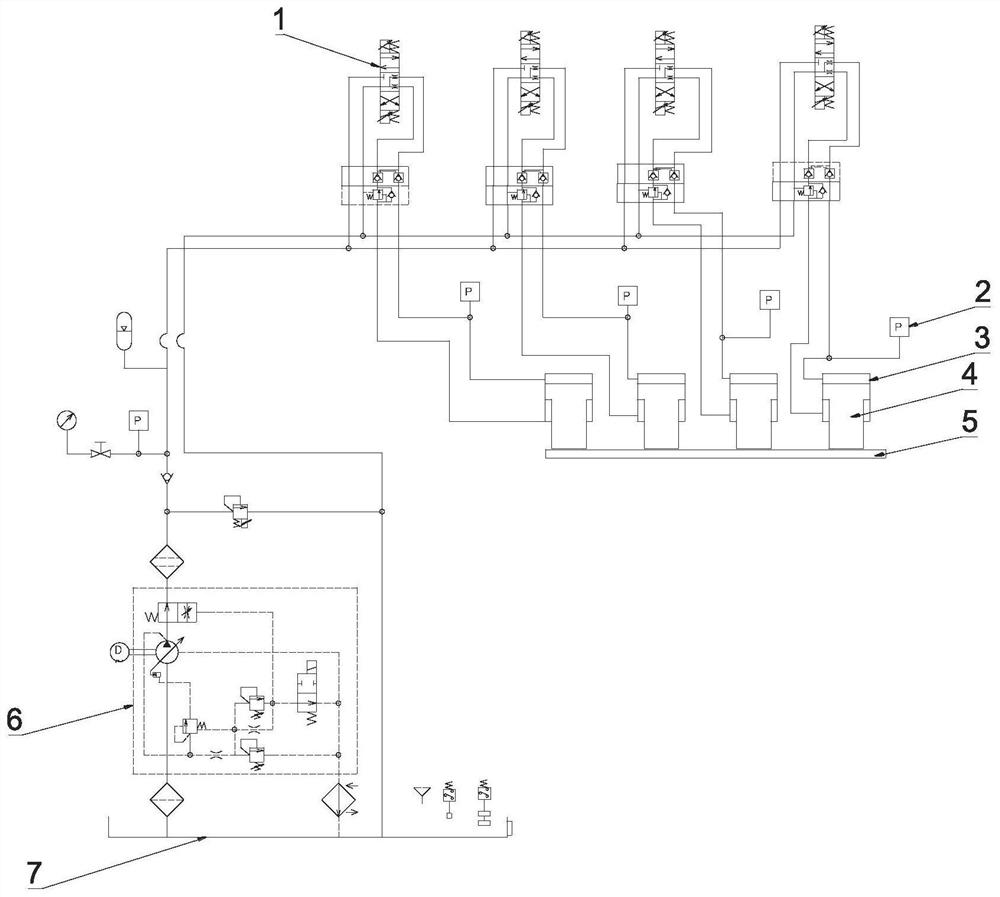

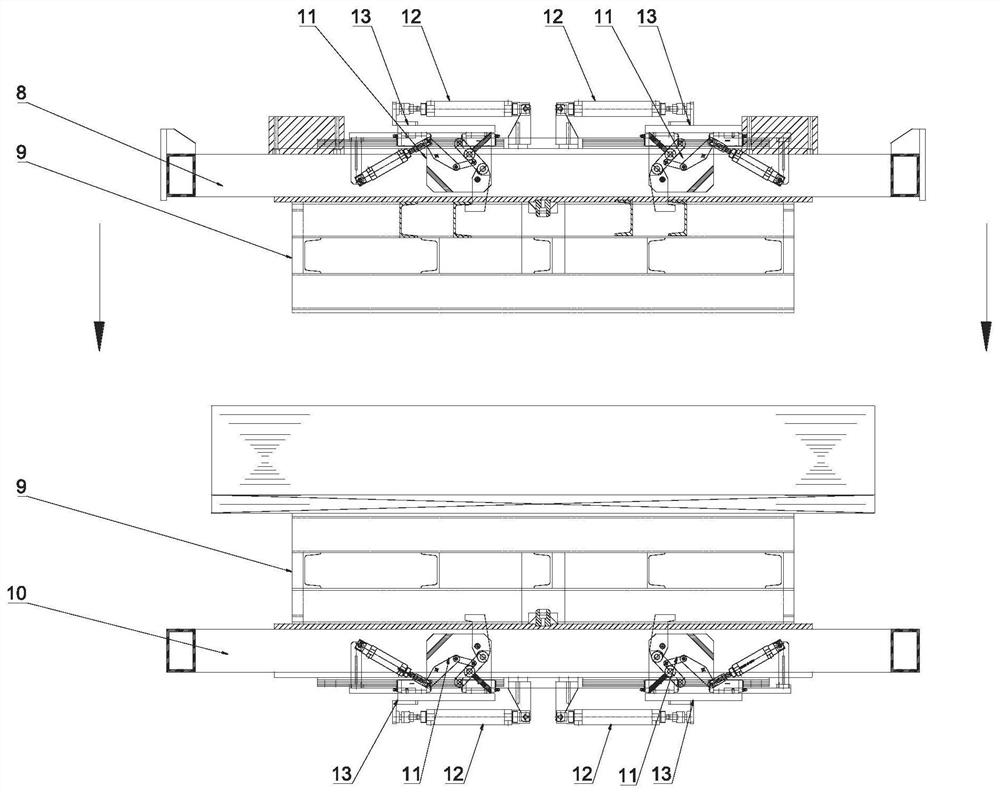

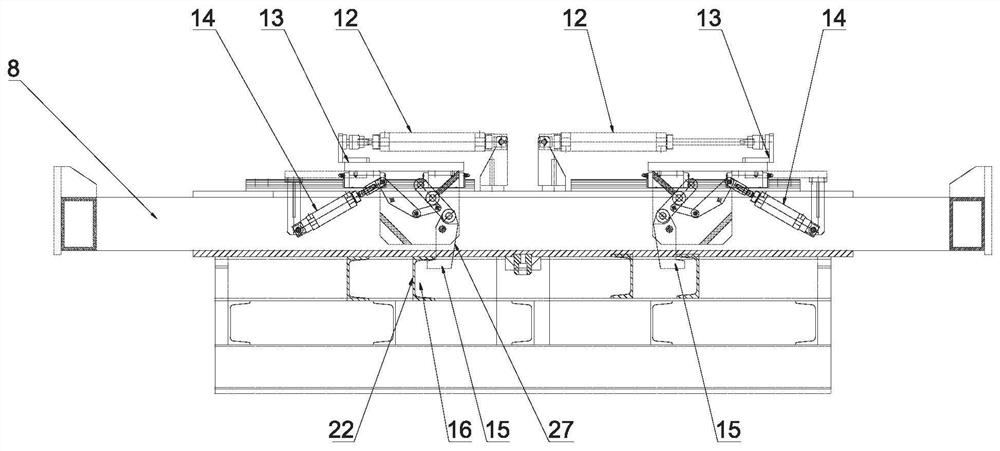

High-synchronization pressing system and method for automatic sheet stack upender

ActiveCN112357636AAvoid stuck phenomenonMove at the same speedOverturning articlesFinal product manufactureControl engineeringControl theory

The invention discloses a high-synchronization pressing system and method for an automatic sheet stack upender. The high-synchronization pressing system comprises a pressing plate, a plurality of oilcylinders and a hydraulic system, wherein in the hydraulic system, a hydraulic pipeline of each oil cylinder is provided with an electro-hydraulic proportional valve used for controlling the working speed of the corresponding oil cylinder; speed detection modules and a control module are further included; the signal input end of the control module is connected with each speed detection module, andthe signal output end of the control module is connected with each electro-hydraulic proportional valve; and the control module is used for controlling the electro-hydraulic proportional valves to adjust the flow according to the moving speeds, detected by the speed detection modules, of piston rods of the multiple oil cylinders, so that the moving speeds of the piston rods of all the oil cylinders are consistent. According to the system, the synchronous movement of the piston rods of the multiple oil cylinders can be accurately controlled, the pressing effect of the pressing plate on a sheetstack is improved, the sheet stack is prevented from loosening or being extruded to deform in the overturning process, and meanwhile the phenomenon that the oil cylinders are stuck due to unbalancedstress is avoided.

Owner:GUANGZHOU YUEYAN INTELLIGENT EQUIP CO LTD

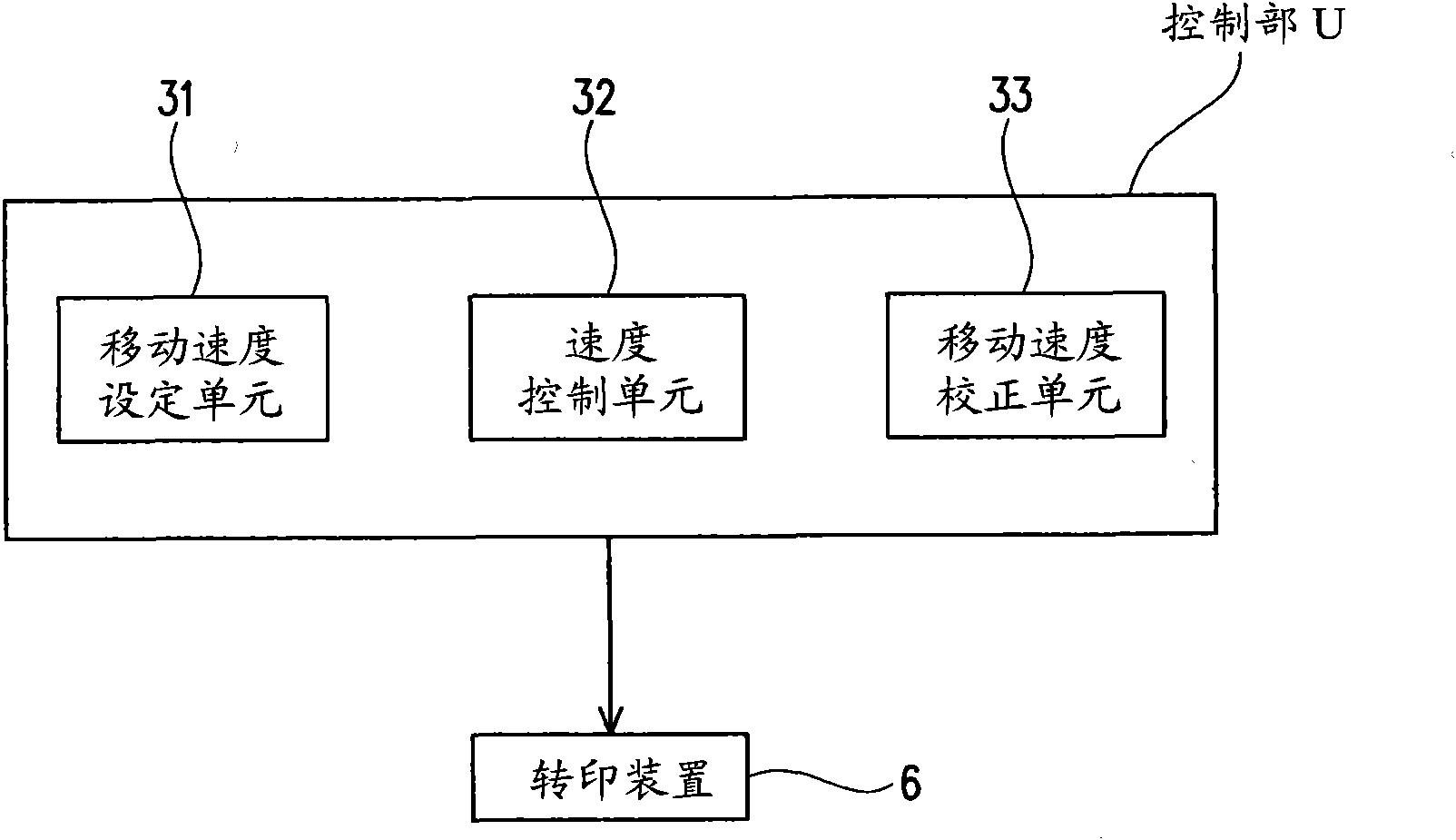

Transfer device and transfer method for printed sheets of paper

InactiveCN101837673AMove at the same speedConsistent delivery speedTransfer printingAdhesivesEngineeringElectrical and Electronics engineering

Owner:RYOBI MHI GRAPHIC TECH

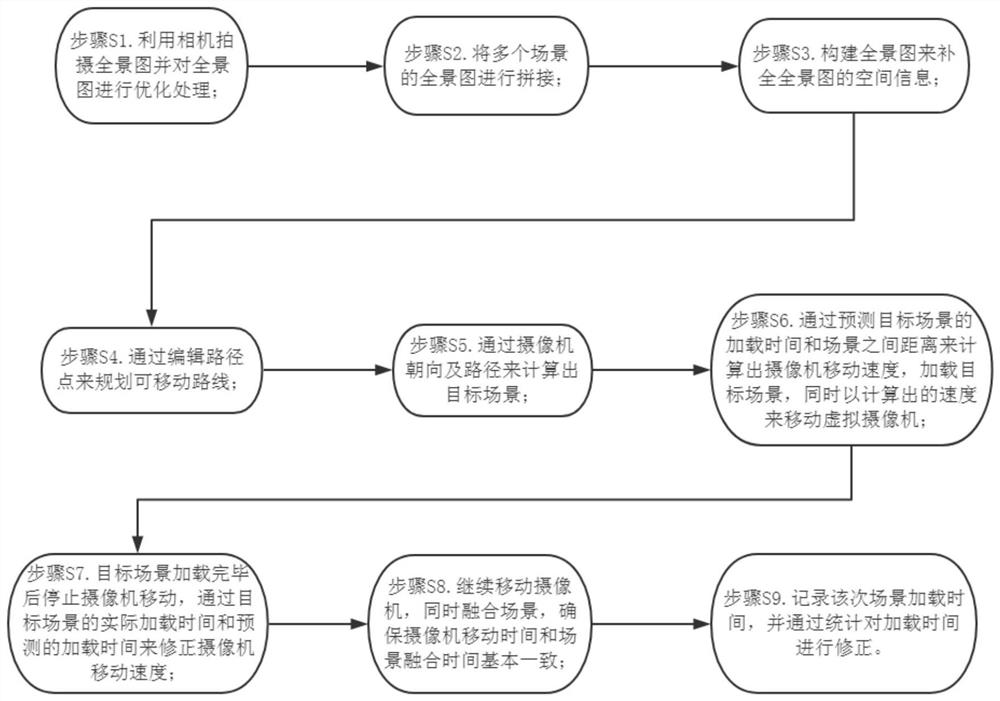

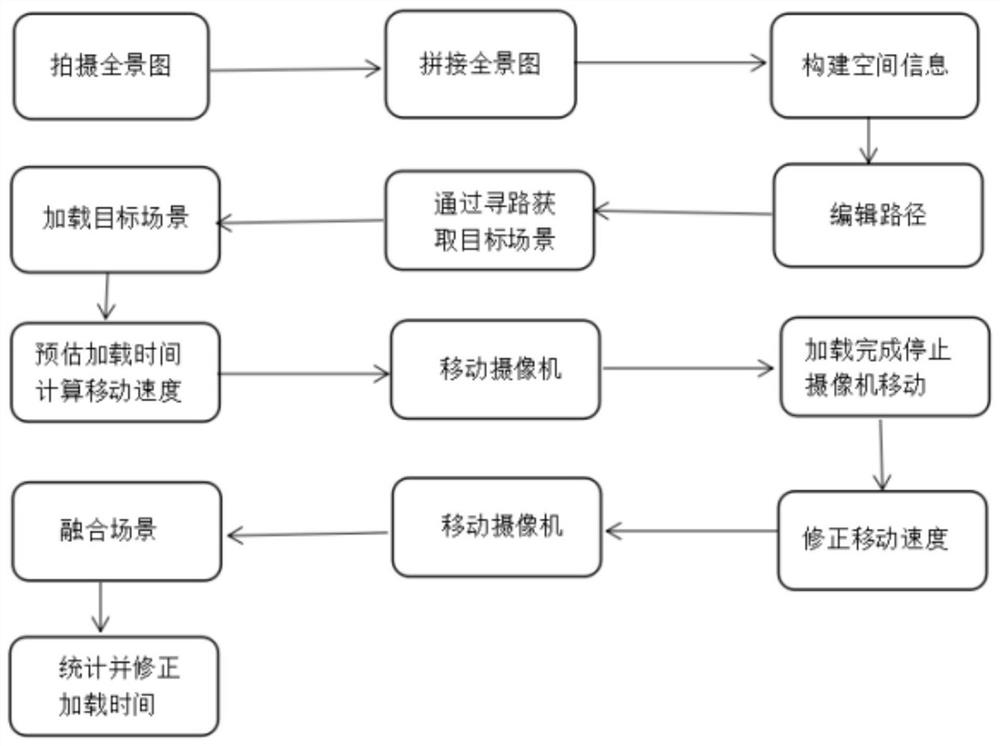

Method for realizing real scene roaming technology coherence

ActiveCN111698425AMove at the same speedAchieve smooth switchingImage enhancementTelevision system detailsEngineeringVirtual cinematography

The invention provides a method for realizing real scene roaming technology coherence. The method comprises the following steps: S1, shooting a panorama by using a camera and optimizing the panorama;S2, splicing the panoramas of the plurality of scenes; S3, constructing a panorama to complement the space information of the panorama; S4, planning a movable route by editing the route points; S5, calculating a target scene through the orientation and the path of the camera; S6, calculating the moving speed of the camera, and moving the virtual camera at the calculated speed; S7, stopping the movement of the camera after the target scene is loaded, and correcting the movement speed of the camera according to the actual loading time of the target scene and the predicted loading time; S8, continuing to move the camera, and fusing the scene to ensure that the moving time of the camera is basically consistent with the scene fusion time; and S9, recording the scene loading time, and correctingthe loading time through statistics. According to the invention, the problem of inconsistency of switching between scenes is solved.

Owner:四川可易世界科技有限公司

Device and method for driving anode rod to move

ActiveCN111472023AEasy to adjust individual liftingEffective adjustment and locking forceAluminium electrolysisMechanical engineering

The invention relates to the technical field of aluminium electrolysis, in particular to a device and a method for driving an anode rod to move. The device comprises at least one positive bar rack and / or at least one clamping frame; and at least one driving wheel enabling the anode rod to move up and down is arranged on any one, or any two or three of the anode rod, the clamping frame and the positive bar rack and is connected with a power mechanism to drive the anode rod and the anode to move to a designated position or to drive the anode rod to a designated position. The device enables all to-be-moved anode rods and anodes to move synchronously, so that the problem that the sparkover problem generated between the anode rods and the anodes is avoided; and when a single or part of anode rods and the anode have relative displacement, the sparkover problem generated between the anode rods and the anodes is also avoided.

Owner:党星培

A device for measuring the thickness of the thin layer of heat and mass transfer on the surface of wood during the drying process

ActiveCN109682339BImprove drying qualityHigh measurement accuracyDrying gas arrangementsDrying chambers/containersHeat mass transferEngineering

Owner:BEIJING FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com