Sheet material detection device

A detection device and sheet material technology, applied in the direction of measuring devices, optical devices, transportation and packaging, etc., can solve problems such as difficulty in ensuring the moving speed of the two conveyor belts, damage to the sheet, and different moving speeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In the following, the technical means adopted by the present invention to achieve the intended purpose of the invention will be further described in conjunction with the accompanying drawings and preferred embodiments of the present invention.

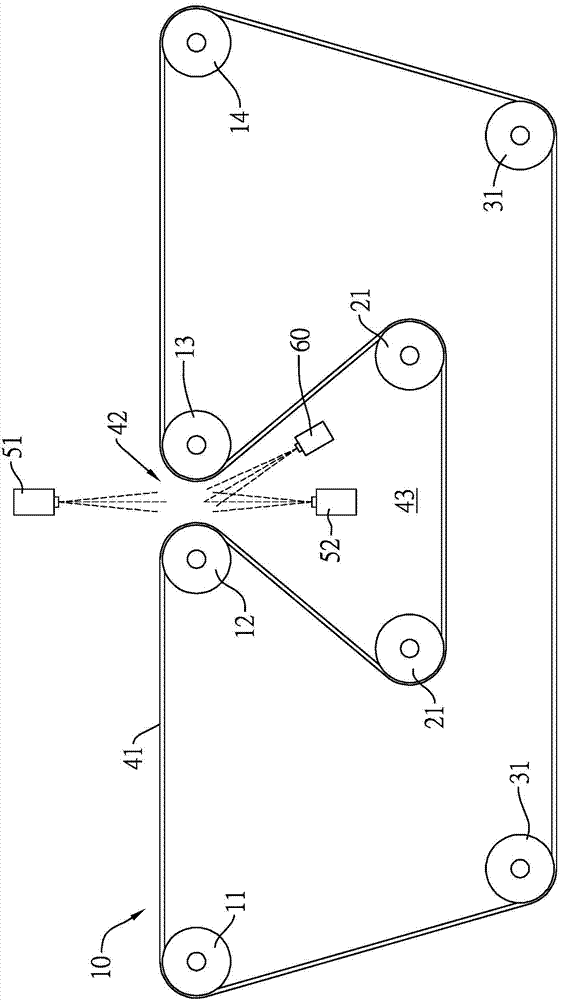

[0036] see figure 1 As shown, the first embodiment of the sheet material detection device of the present invention includes a conveyor belt device 10 , two cameras 51 , 52 and a light source 60 .

[0037] The aforementioned conveyor belt device 10 includes a first upper runner 11, a second upper runner 12, a third upper runner 13, a fourth upper runner 14, two middle runners 21, and two lower runners 31 , a conveyor belt 41 and a power unit; the positions of four upper runners 11, 12, 13, 14 are at the same height, the first upper runner 11, the second upper runner 12, the third upper runner 13 and the third Four upper runners 14 are arranged at intervals in sequence; the positions of these upper runners 11, 12, 13, 14 are hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com