Device and method for driving anode rod to move

An anode guide rod and anode technology, which is applied in the field of aluminum electrolysis, can solve the problems of increased friction and difficulty in anode descent, complicated structure, etc., and achieves the effects of stable contact voltage drop, high degree of automation and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

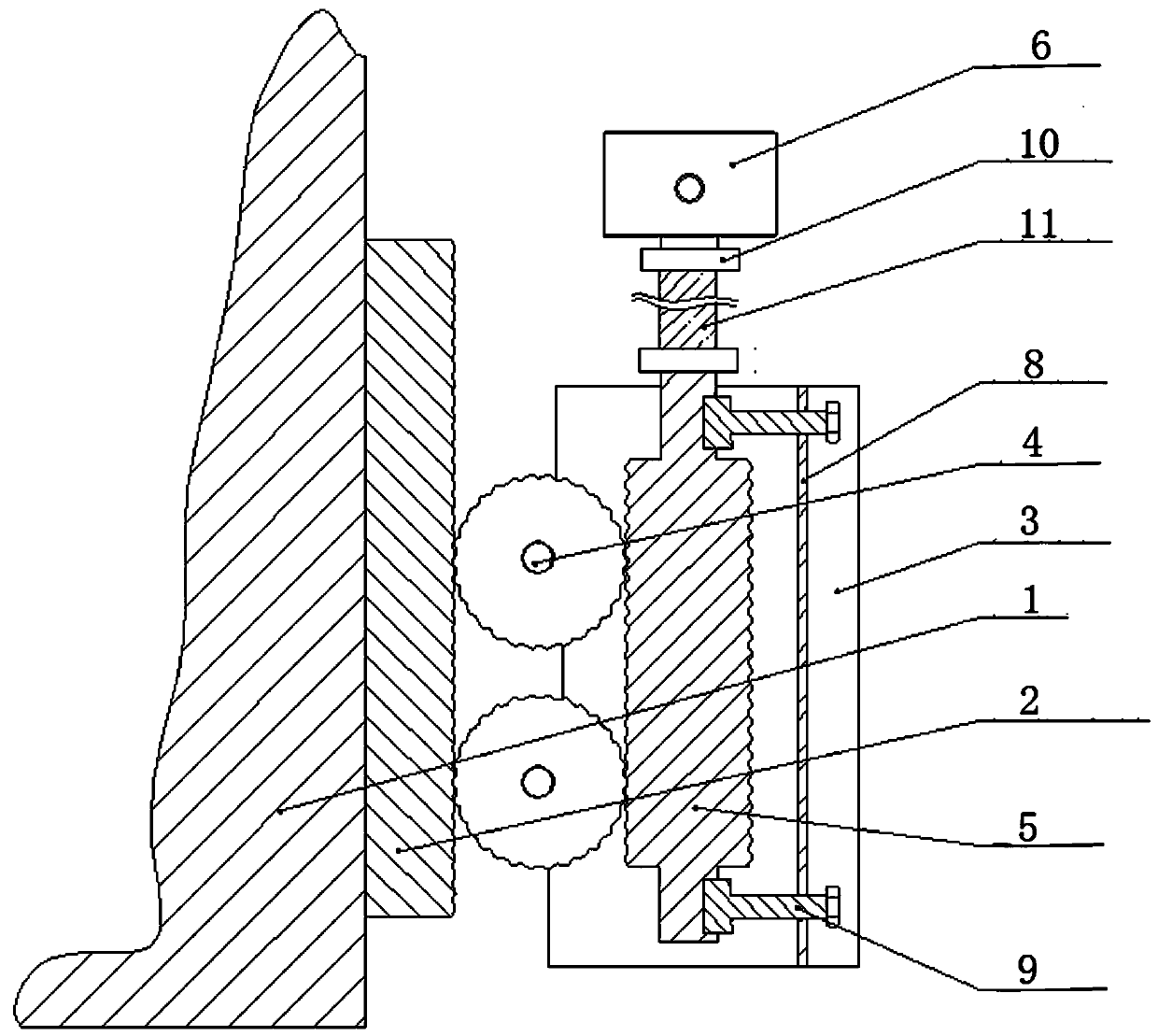

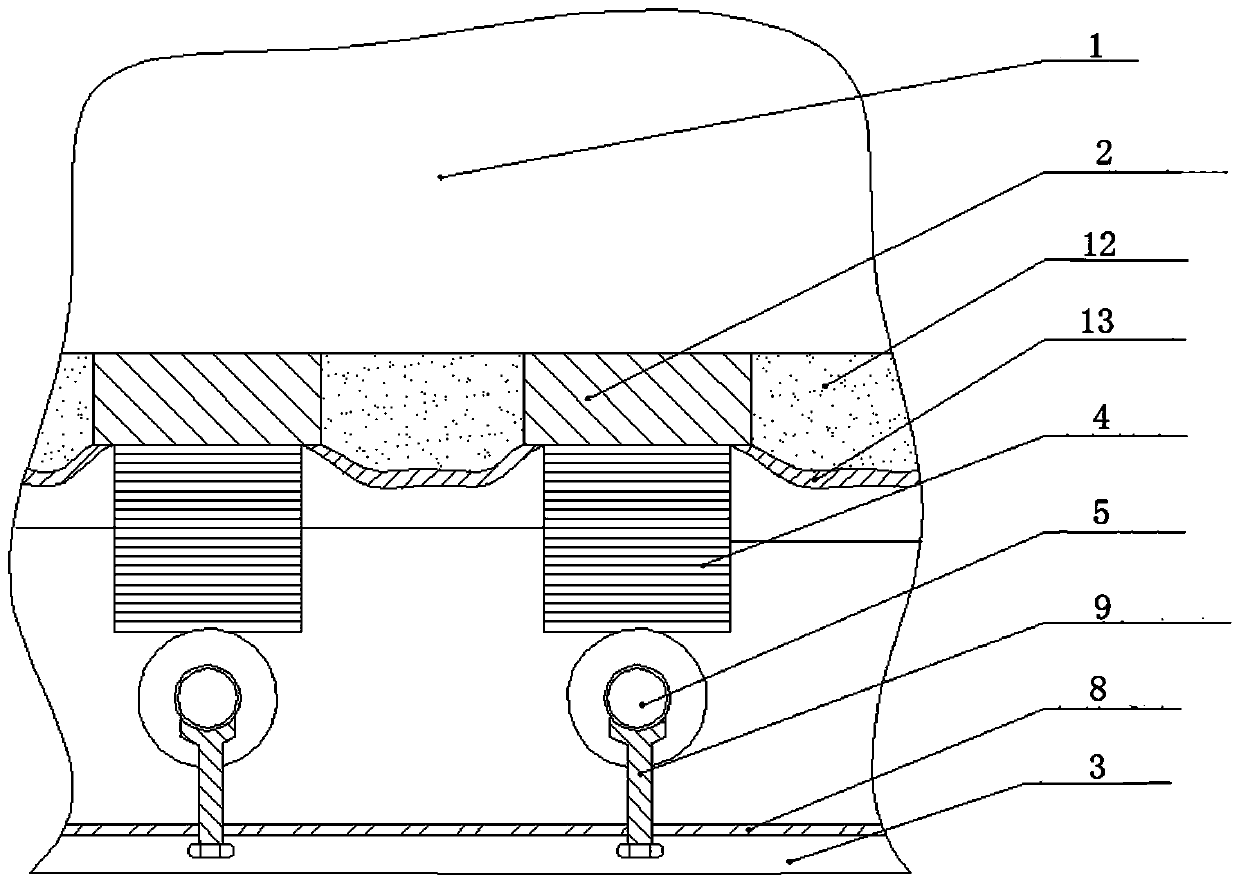

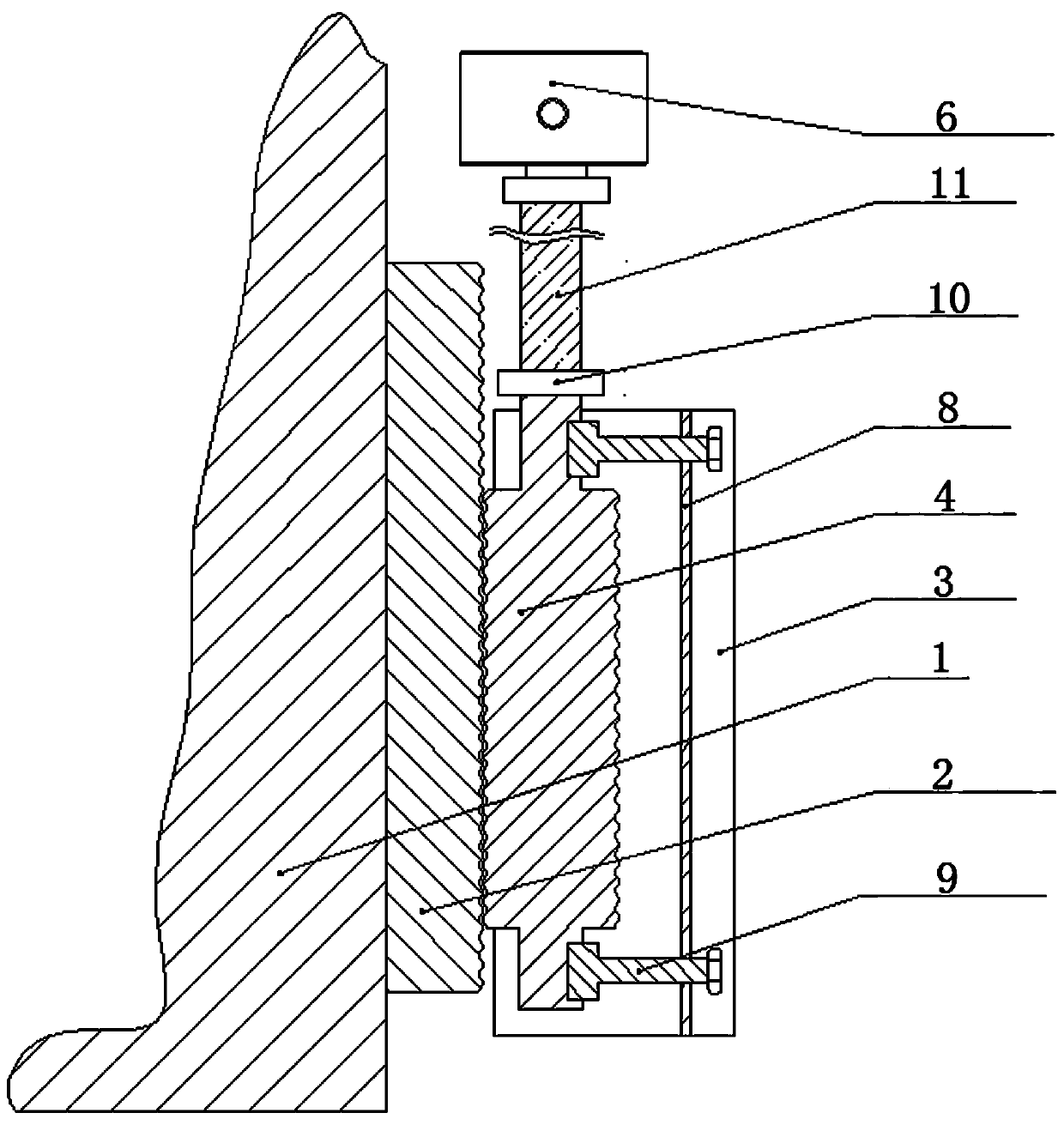

[0033] A device for driving the movement of an anode guide rod, the device relates to an aluminum electrolytic cell assembly comprising at least one upper metal structure, at least one anode busbar frame and / or at least one clamping frame, and also relates to at least one anode and a At least one anode guide rod; the anode is located in the anode bus frame and / or the clamping frame, and the upper metal structure is located above the anode. The anode is described in the patent CN 110484936 A. The drive wheel can be arranged on the front, side or inside of the anode guide rod. Such as figure 1As shown, the surfaces of the transmission wheel, the anode guide rod and the driving wheel are toothed, and the transmission wheel is set on the anode guide rod in meshing contact mode. The pressing mechanism on the fixing frame of the clamping frame presses the anode guide rod on the anode through the driving wheel and the driving wheel. The pressing mechanism is a spring screw mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com