Patents

Literature

56results about How to "Consistent movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

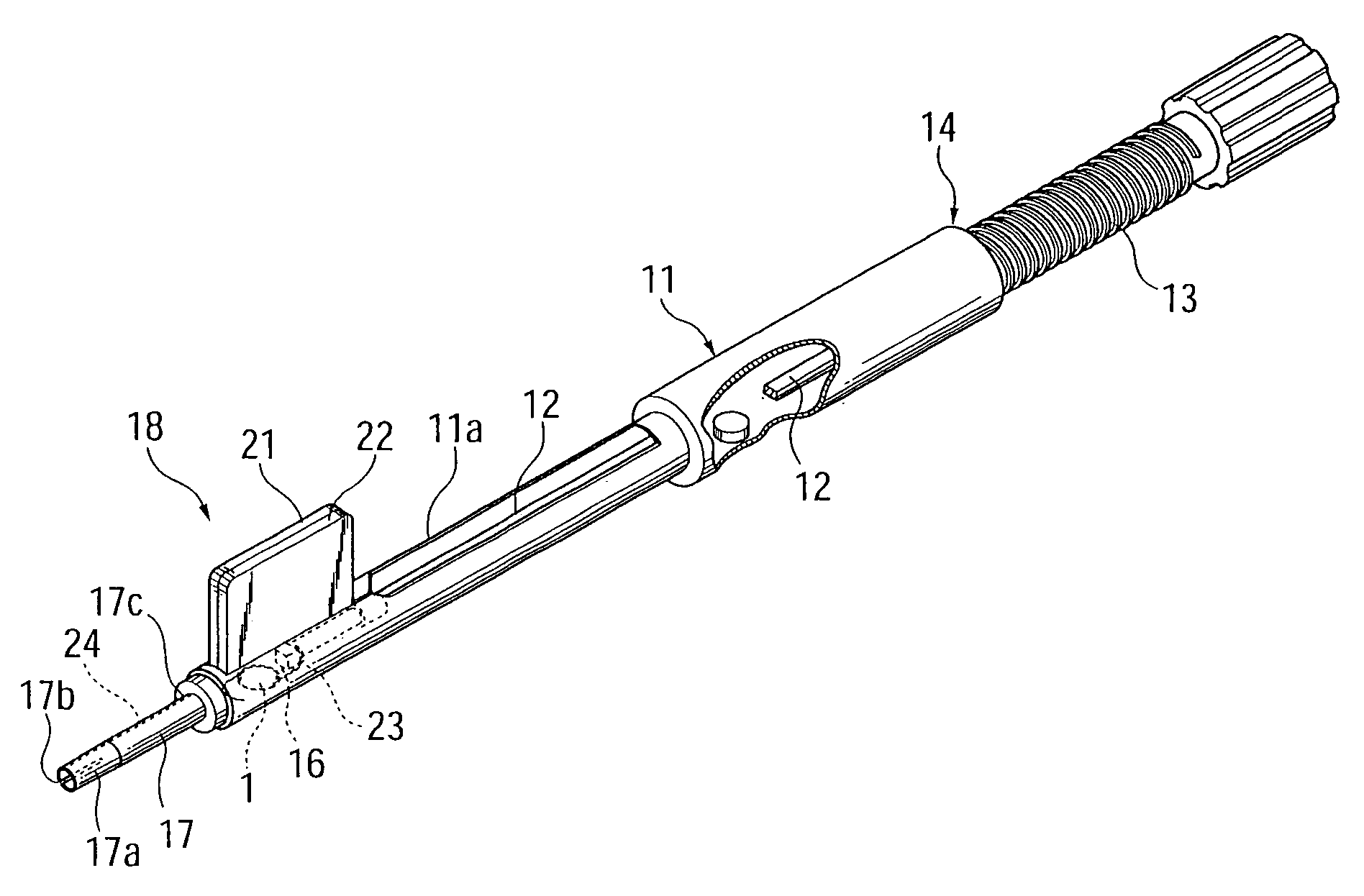

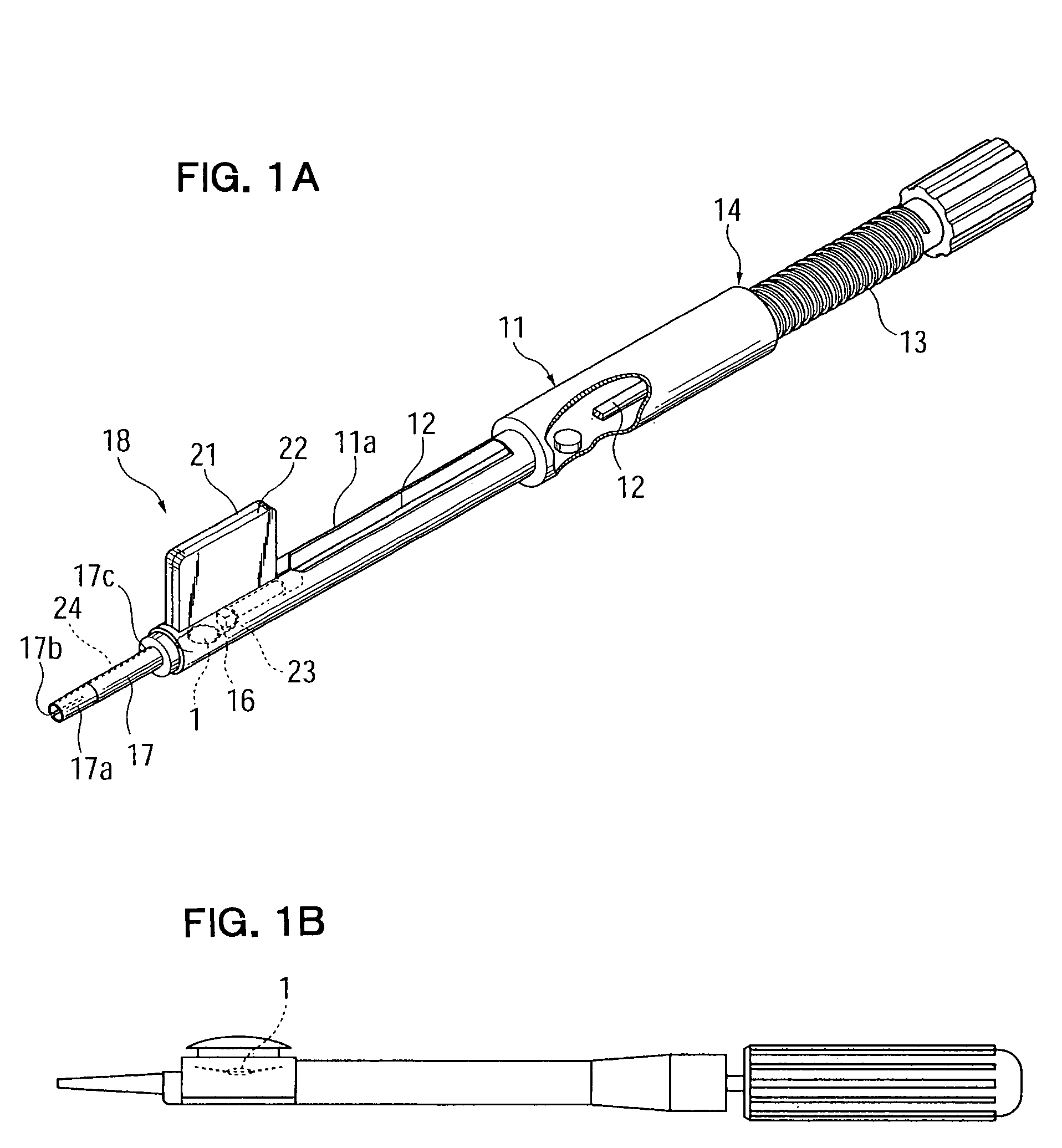

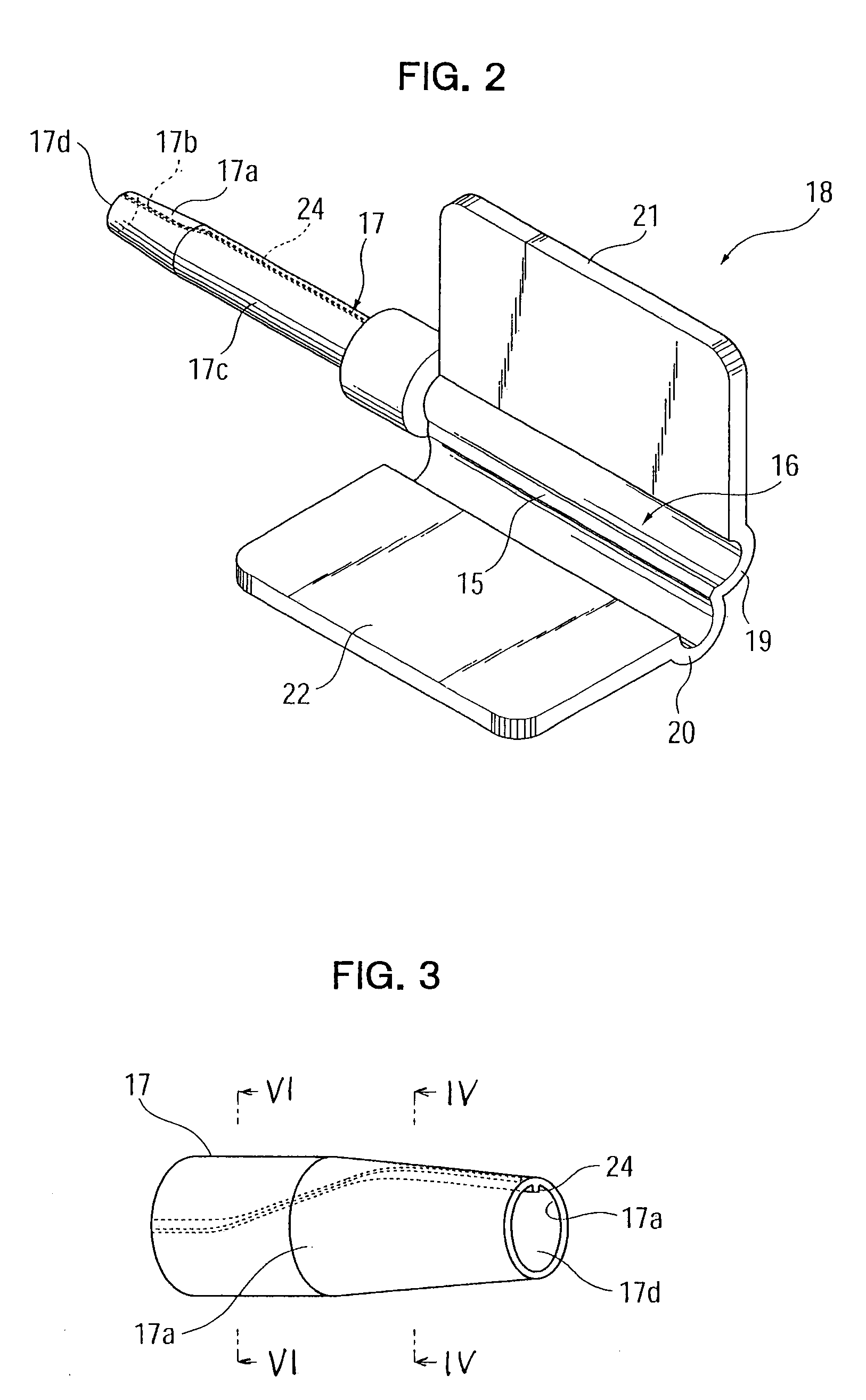

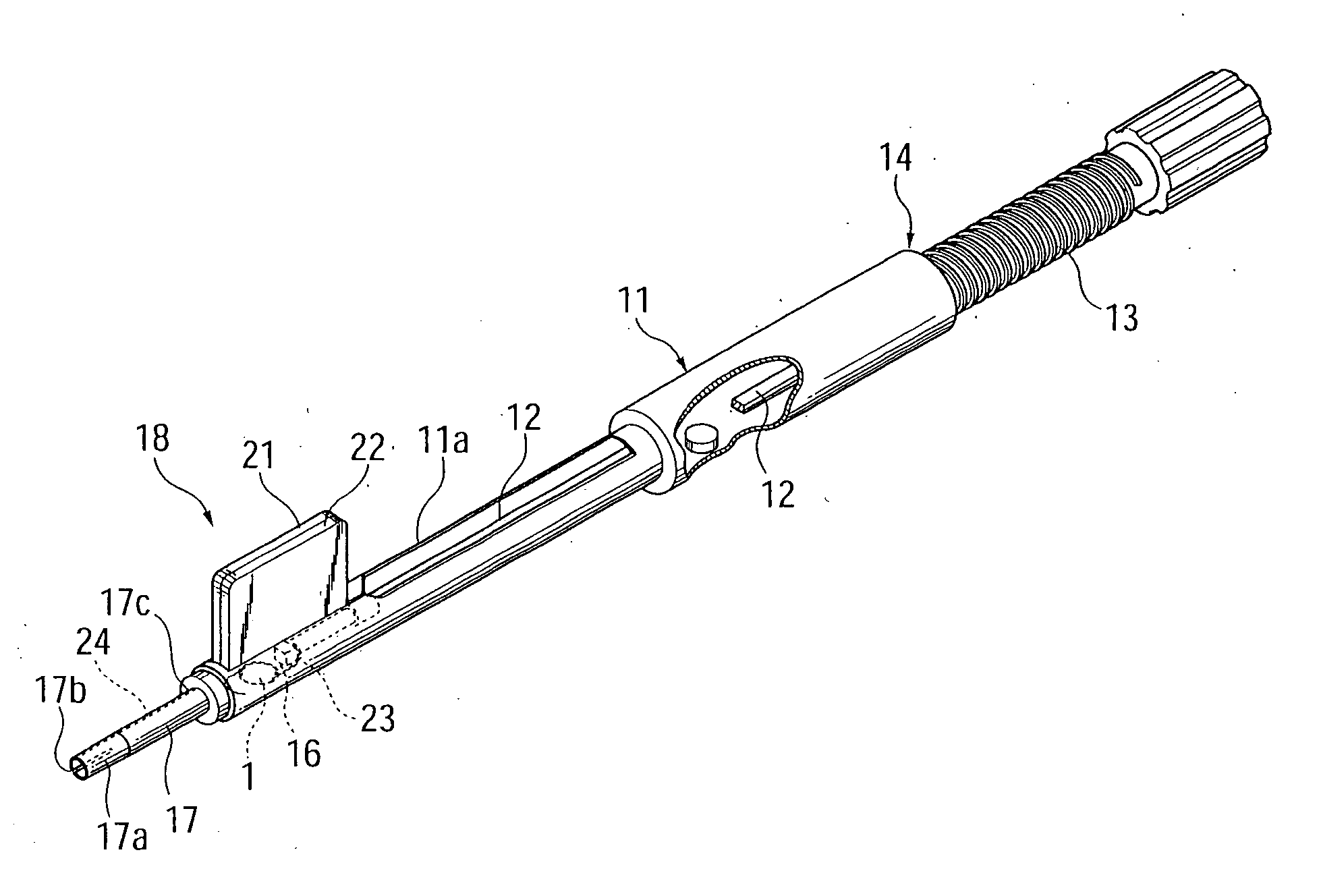

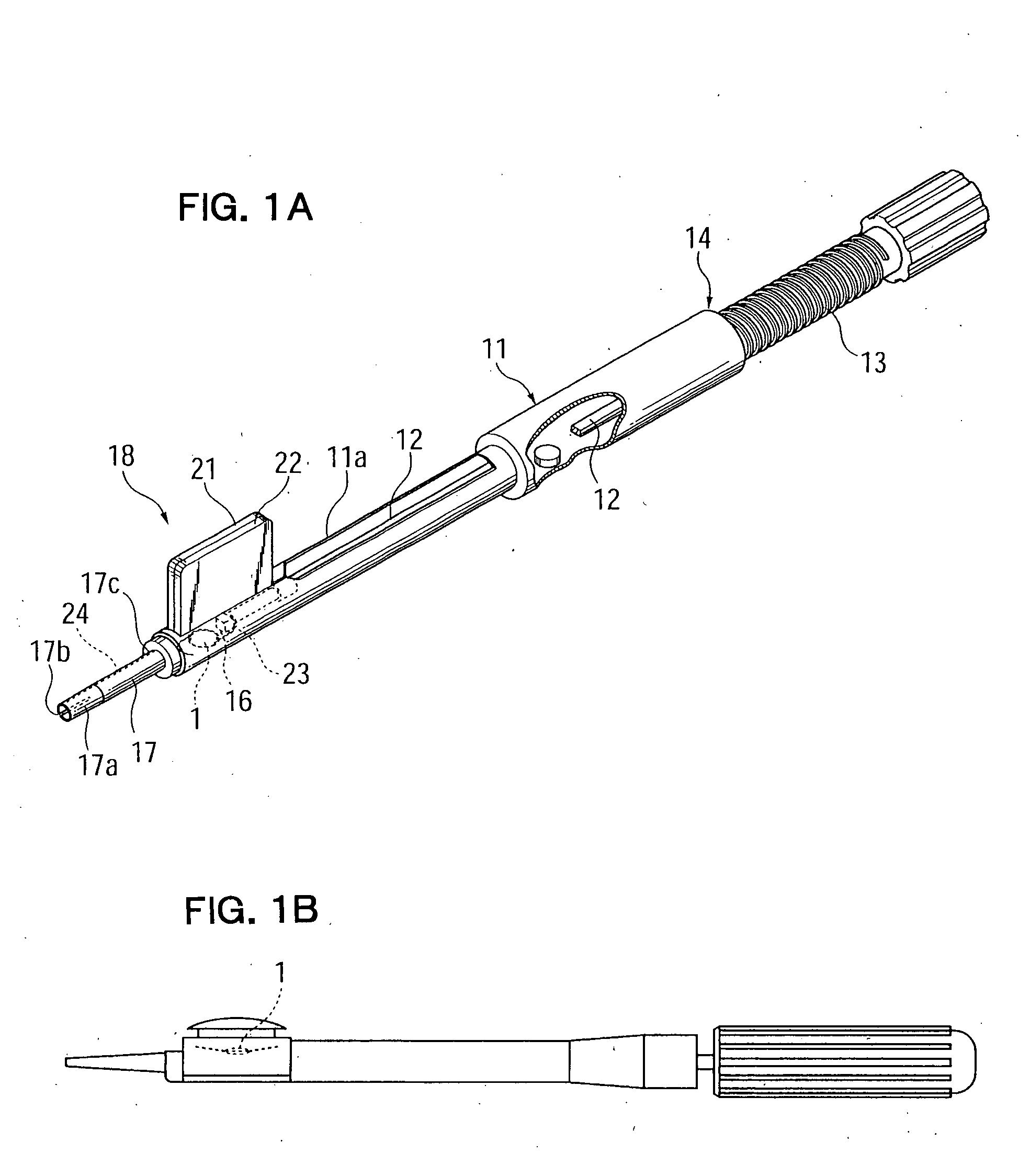

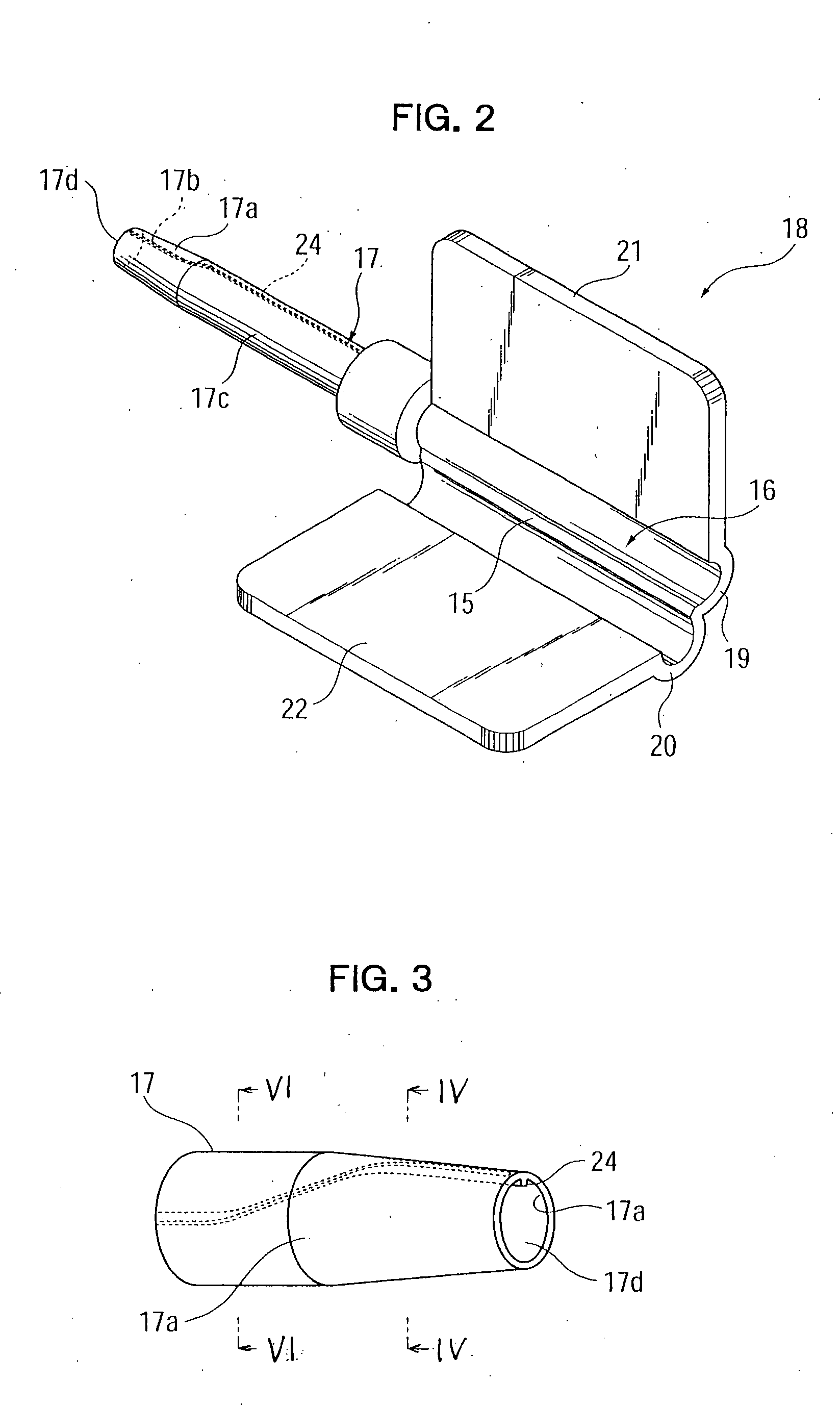

Insertion device for an intraocular lens

ActiveUS7476230B2Guaranteed stable insertionStable supportEye surgeryIntraocular lensMedicineIntraocular lens insertion

In an intraocular-lens insertion device for deforming a deformable intraocular lens to a smaller size and inserting the intraocular lens into an eye via an insertion tube, the insertion tube has such an inner wall shape as to cause the deformable intraocular lens to move rotationally about an insertion tube axis by a predetermined angle in the course of axial movement.

Owner:STAAR JAPAN

Bionic robot arm motion solving and configuration control method

ActiveCN108241339AConsistent movementPreserve the ability to optimizeProgramme controlComputer controlMotor controlJoint spaces

The invention discloses a bionic robot arm motion solving and configuration control method; the method utilizes structure features of the robot arm of said type, solves integral motions of the robot arm on the corresponding human arm, and maps the integral motions back to joint spaces of the robot arm for execution. The motion solving method does not rely on the real joint arrangement of the bionic robot arm, can form consistent motions for the bionic robot arms with different joint arrangements yet same arm lengths of big arms and forearms; the method can keep a motion optimization capability, can simulate human in a task processing mode, thus better forming human-like motions. The configuration control method is proposed according to theories in the motion solving method, can control thecomplete configuration of the bionic robot arm, thus ensuring the consistency of the bionic robot arm from motion planning to motion control.

Owner:BEIHANG UNIV

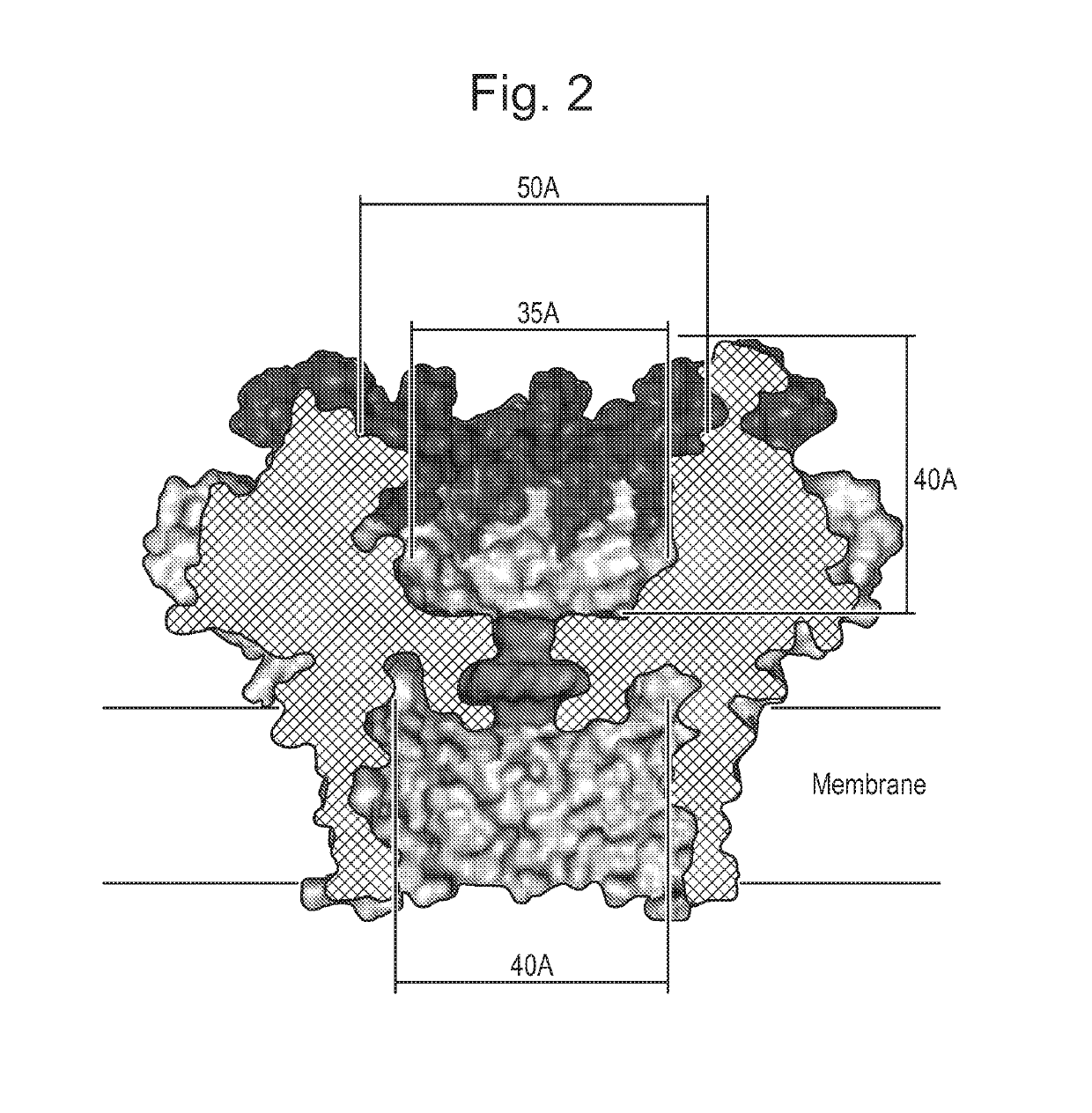

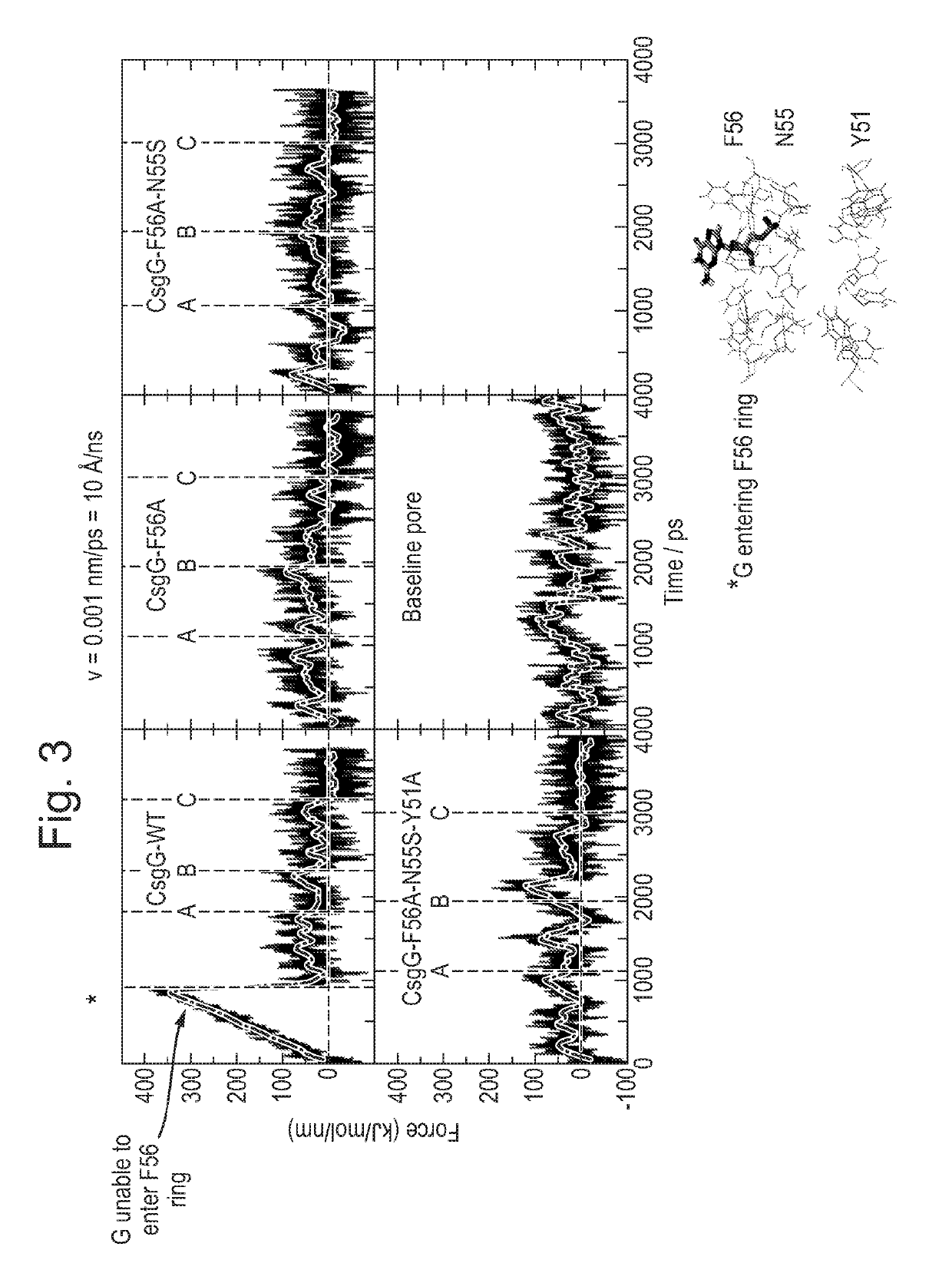

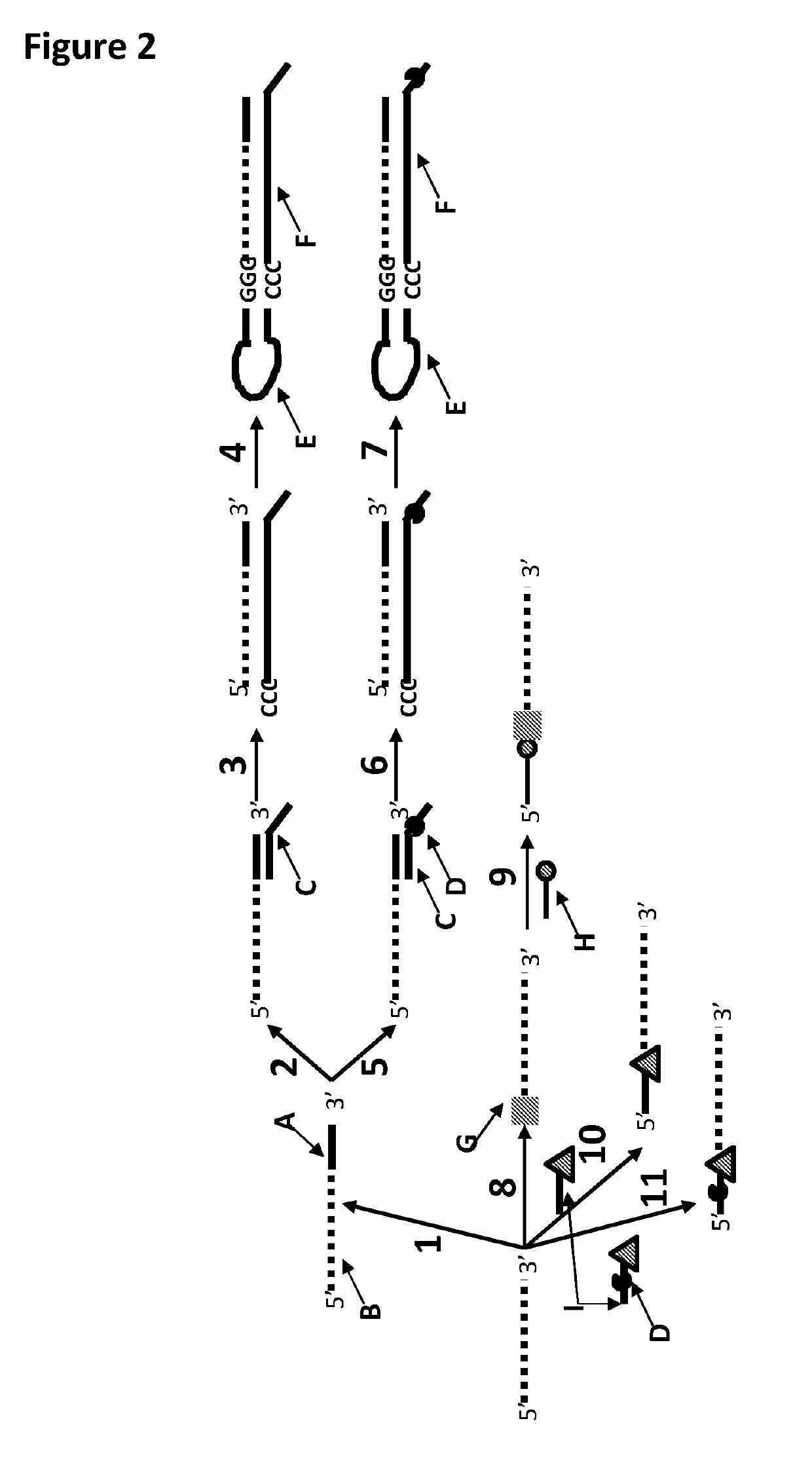

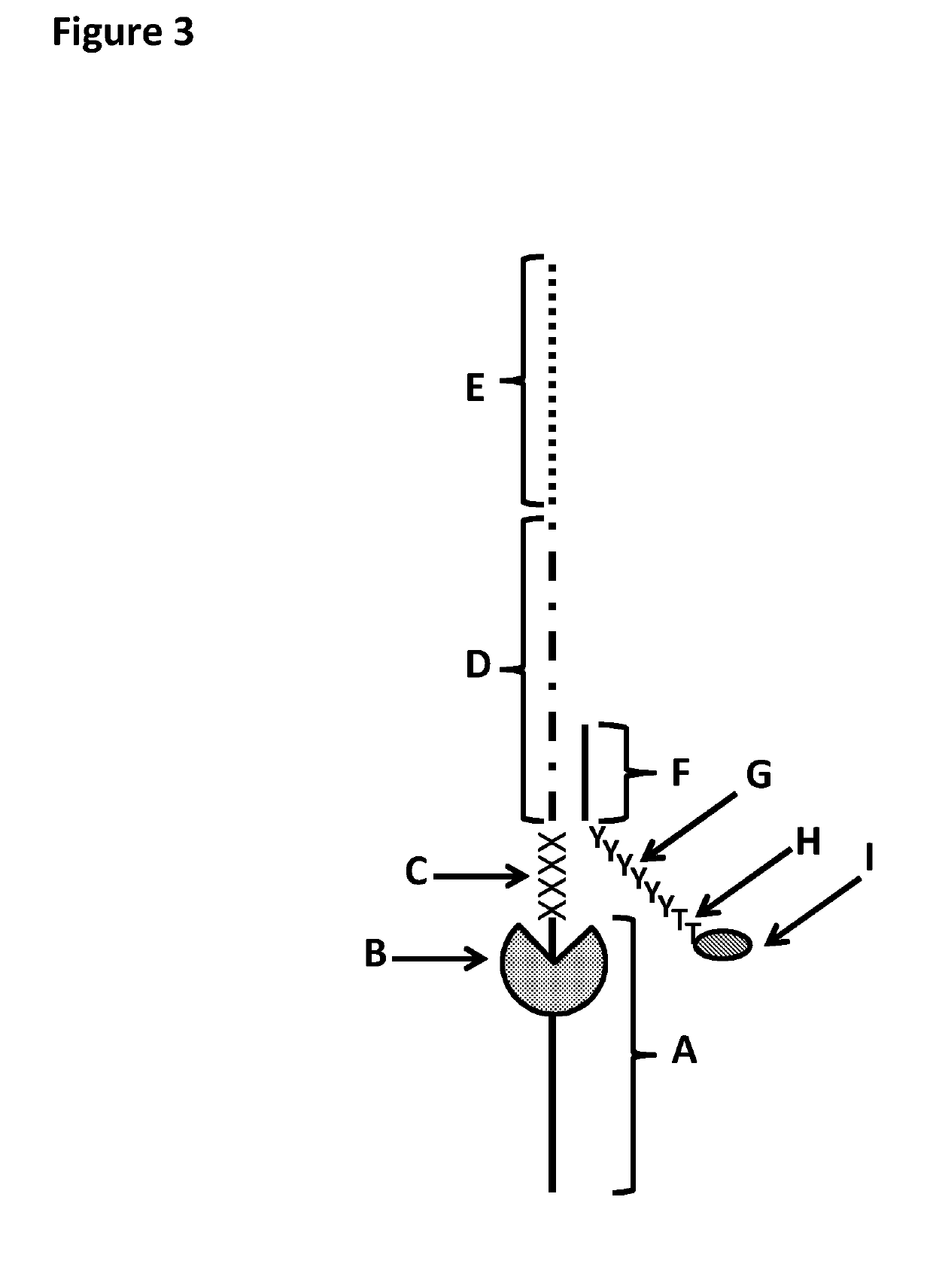

Mutant pores

ActiveUS20190300582A1Enhanced ability to estimate characteristic of analytesEasily discriminatedMicrobiological testing/measurementDepsipeptidesAnalytical chemistryAnalyte

Owner:OXFORD NANOPORE TECH LTD

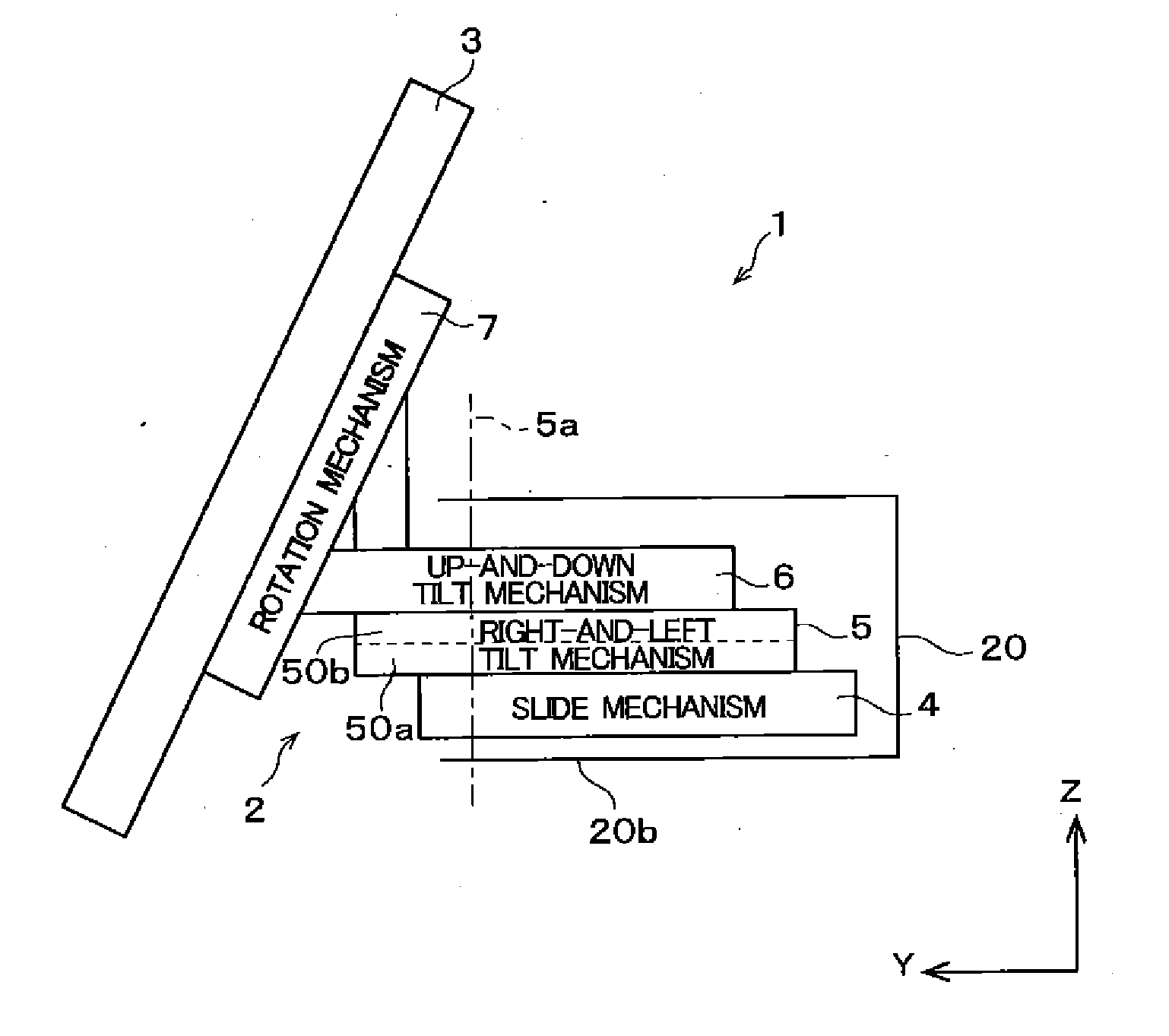

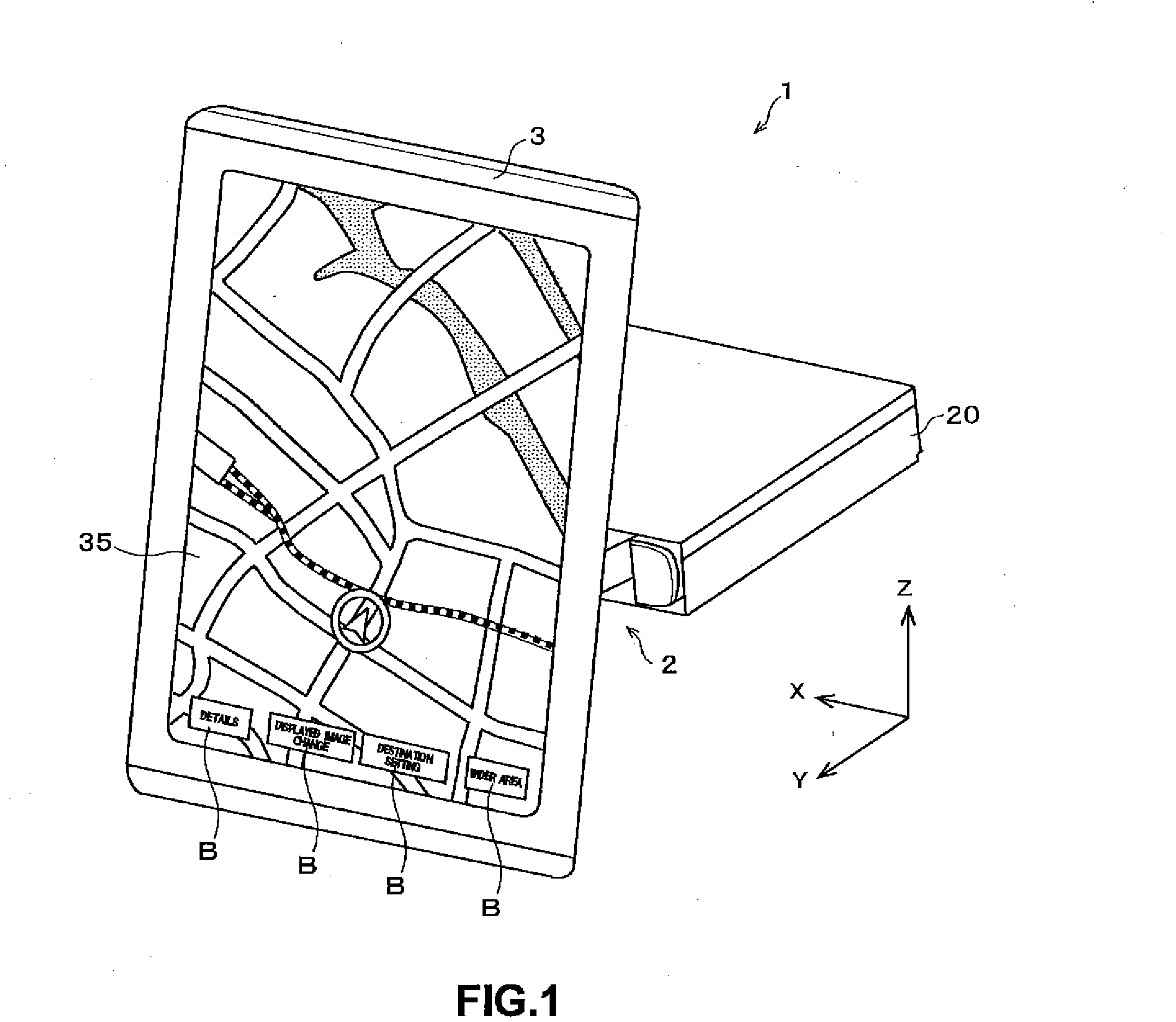

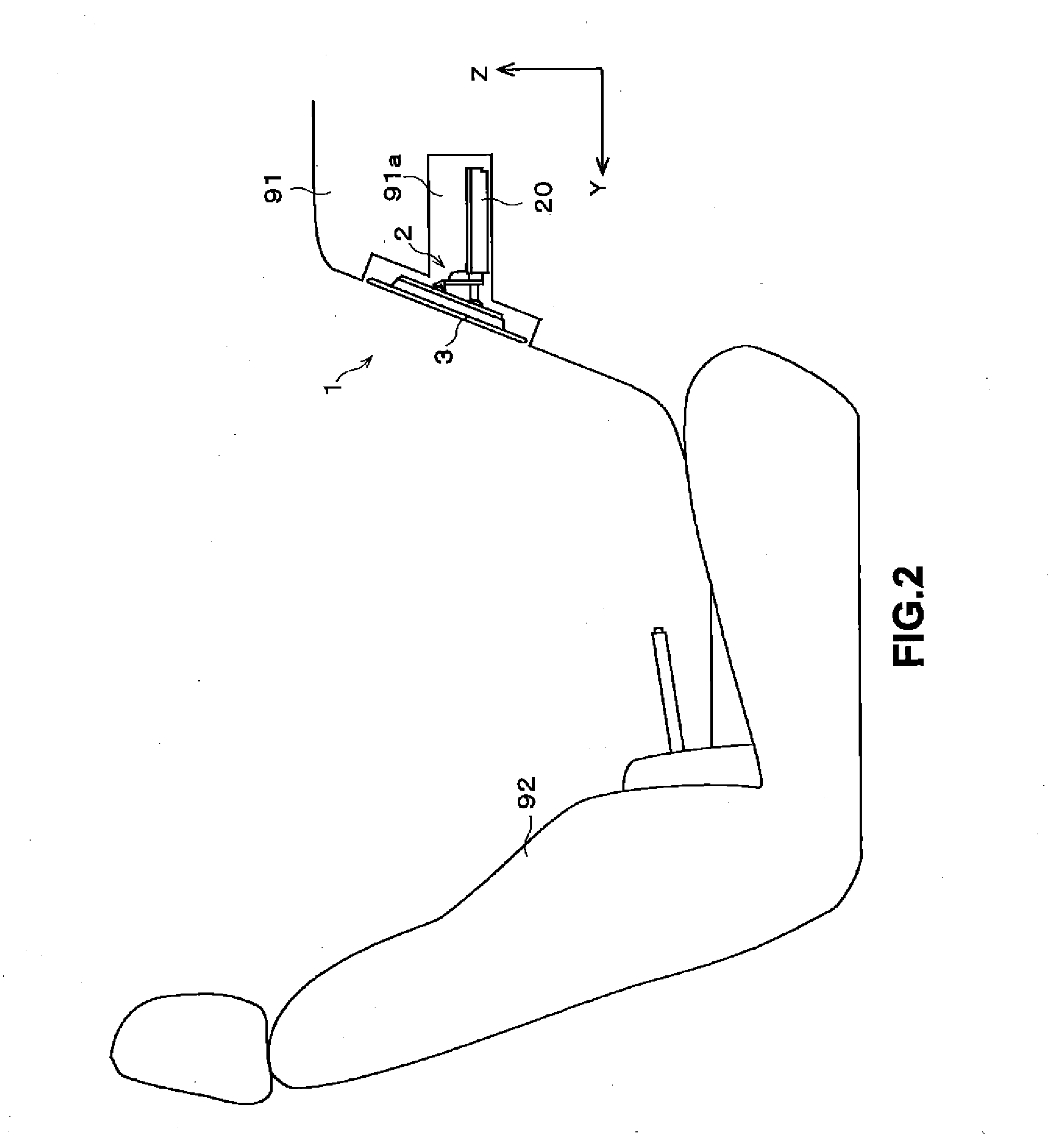

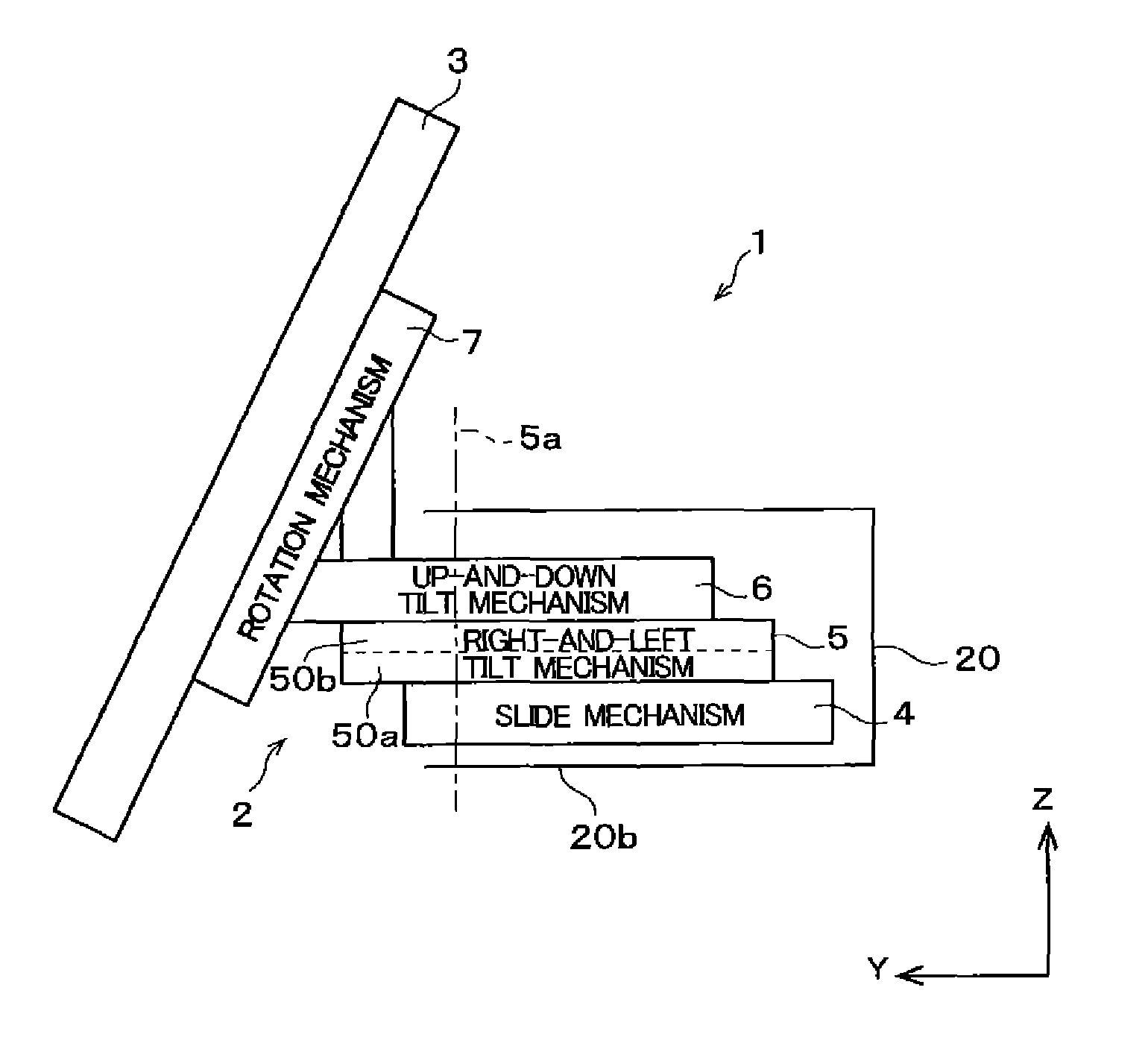

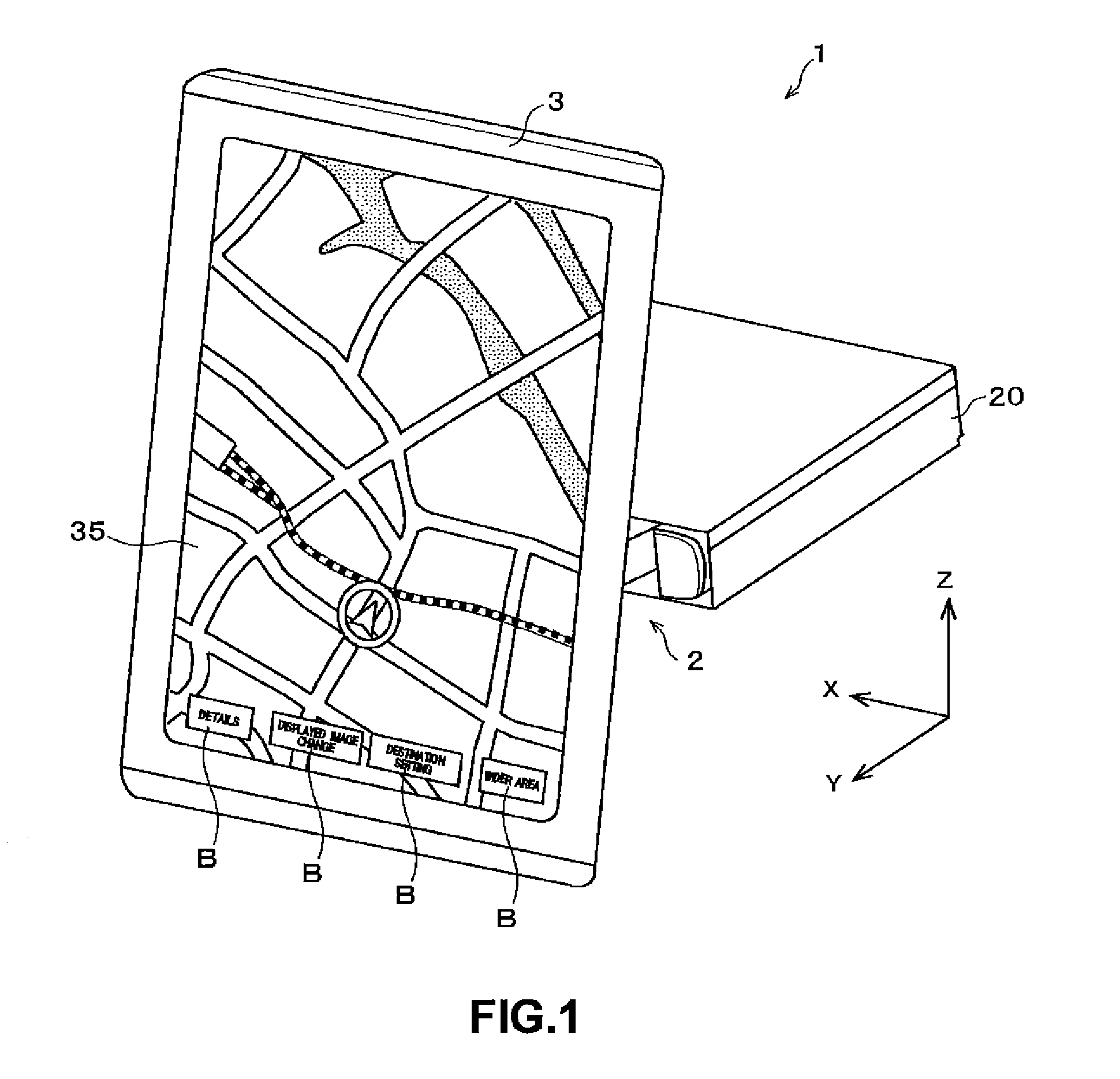

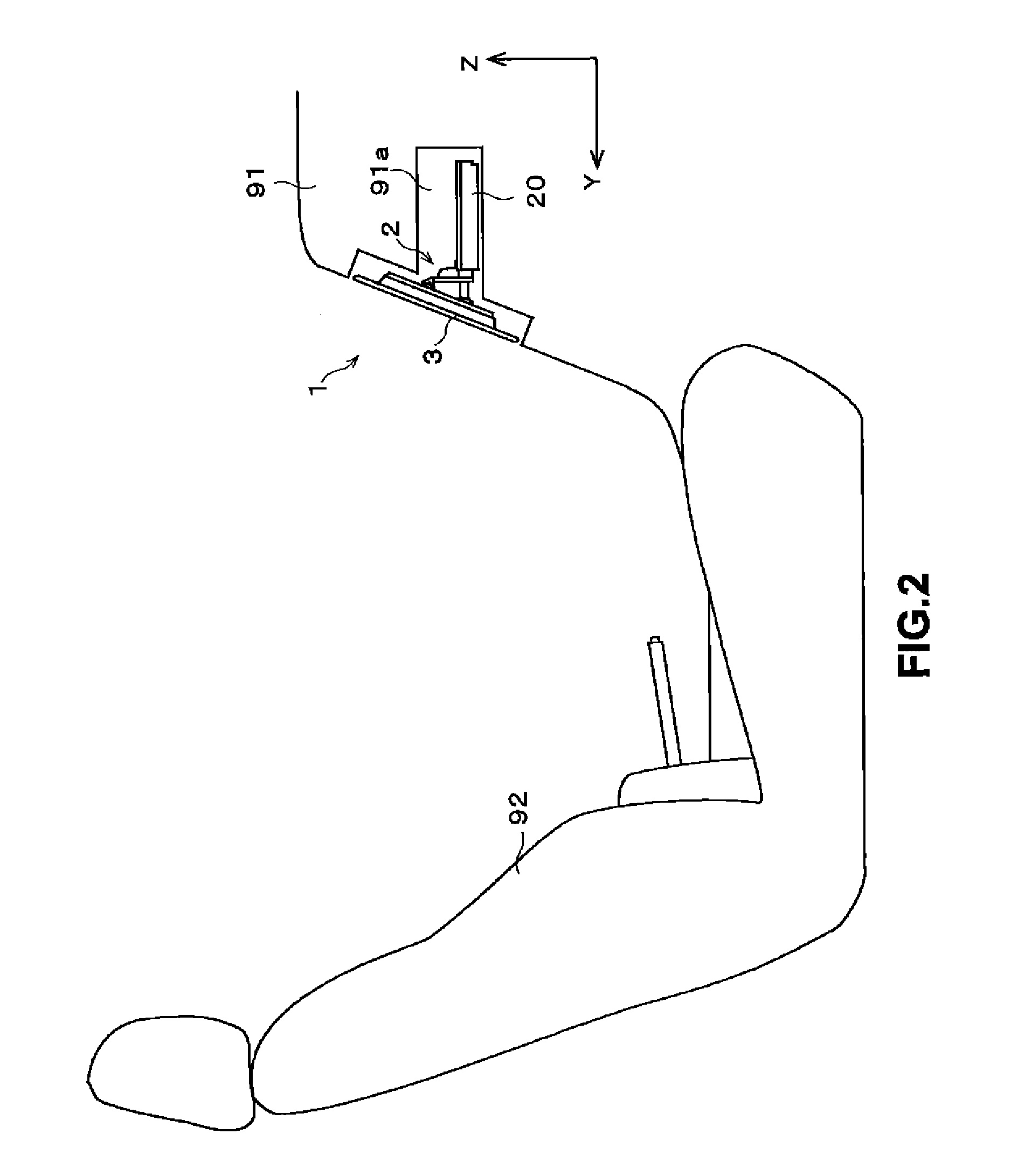

Display system

ActiveUS20140153168A1Consistent movementReduce displayMechanical apparatusJointsLeft directionEngineering

A display system includes a display panel that displays information and a movement apparatus that moves the display panel. The movement apparatus includes: a slide mechanism configured to move the display panel linearly relative to a base chassis; a right-and-left tilt mechanism configured to change an angle of a display surface of the display panel in a right-and-left direction; an up-and-down tilt mechanism configured to change an angle of the display surface of the display panel in an up-and-down direction; and a rotation mechanism configured to rotate the display panel on a rotation axis orthogonal to the display surface of the display panel.

Owner:FUJITSU GENERAL LTD

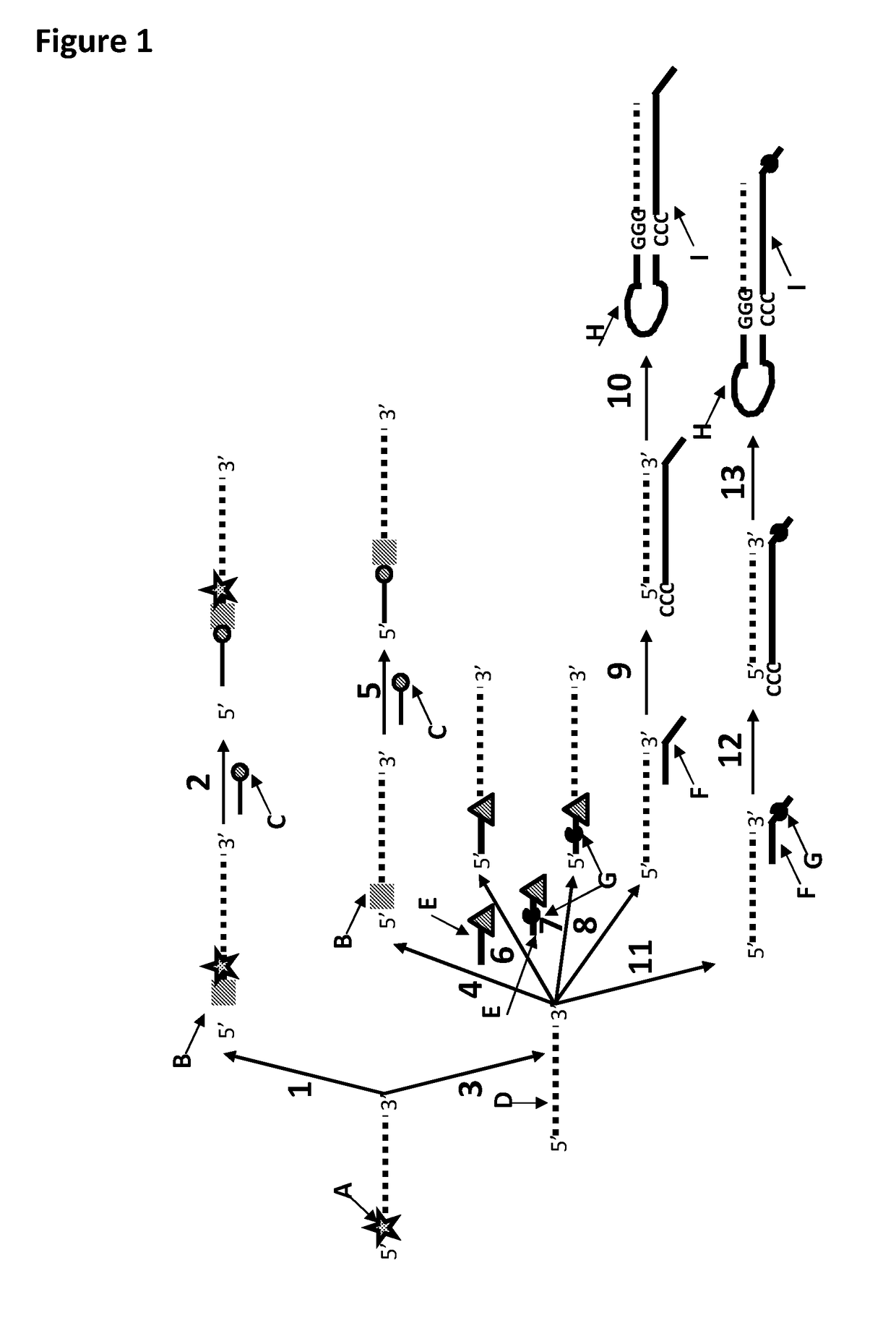

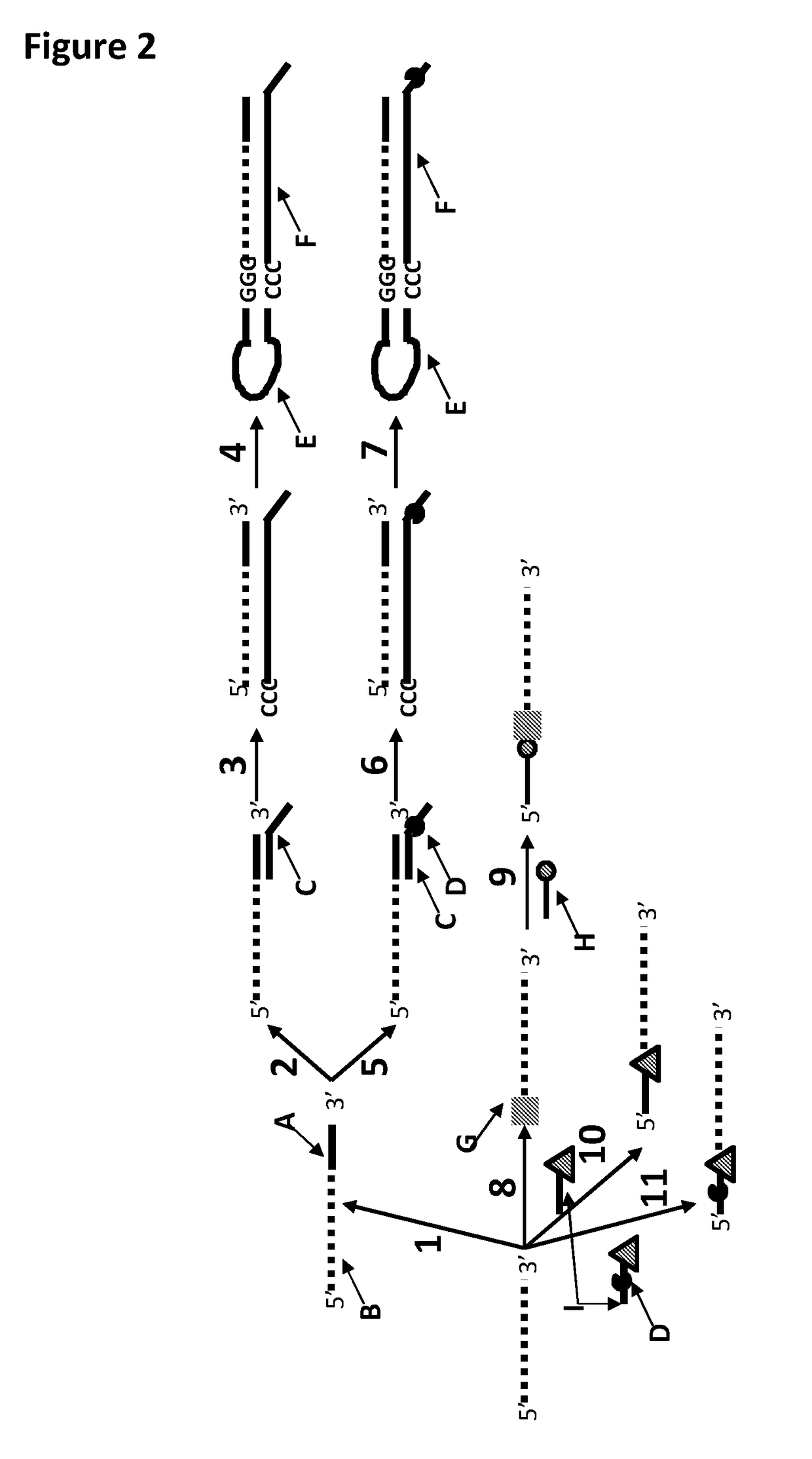

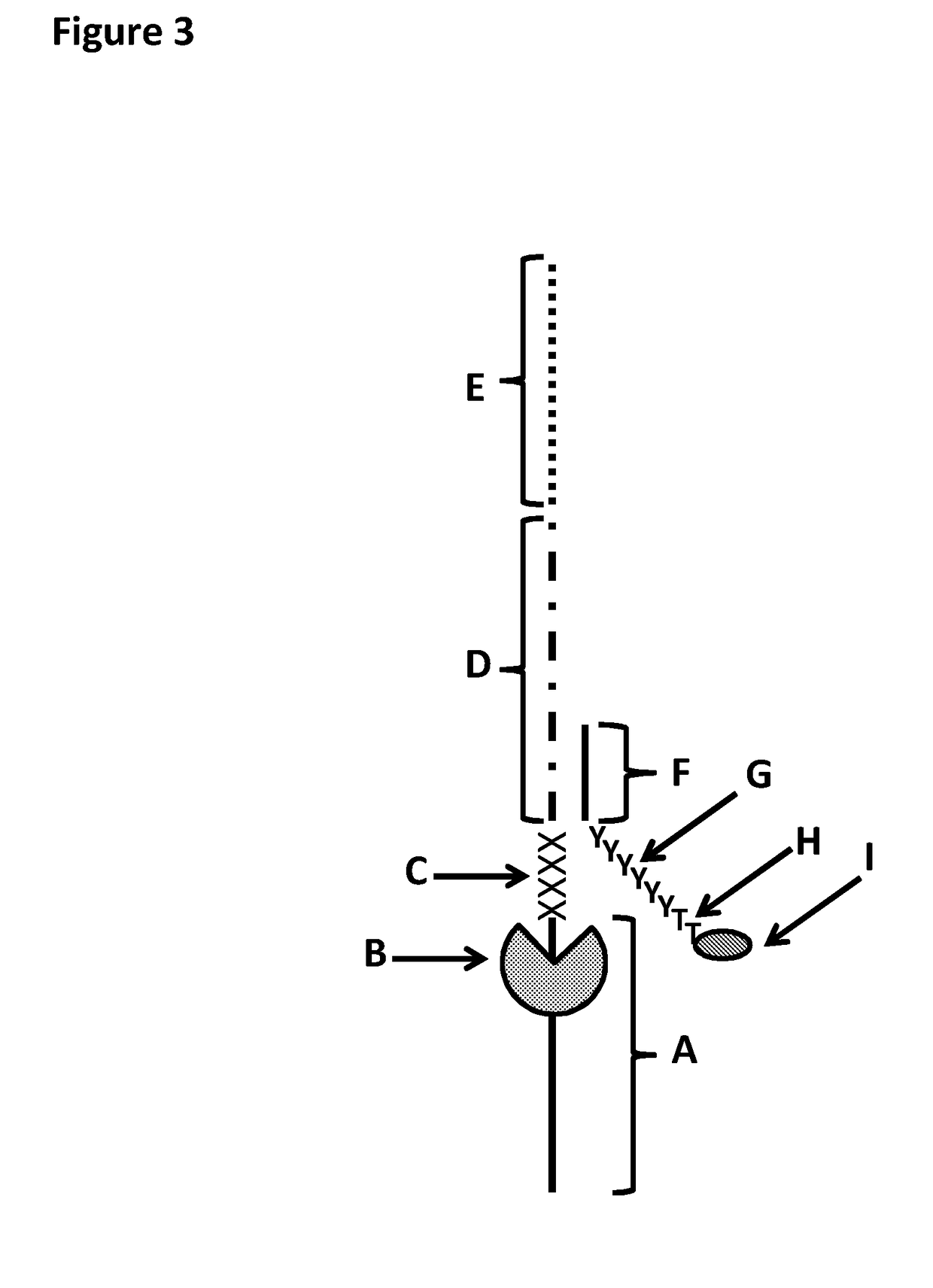

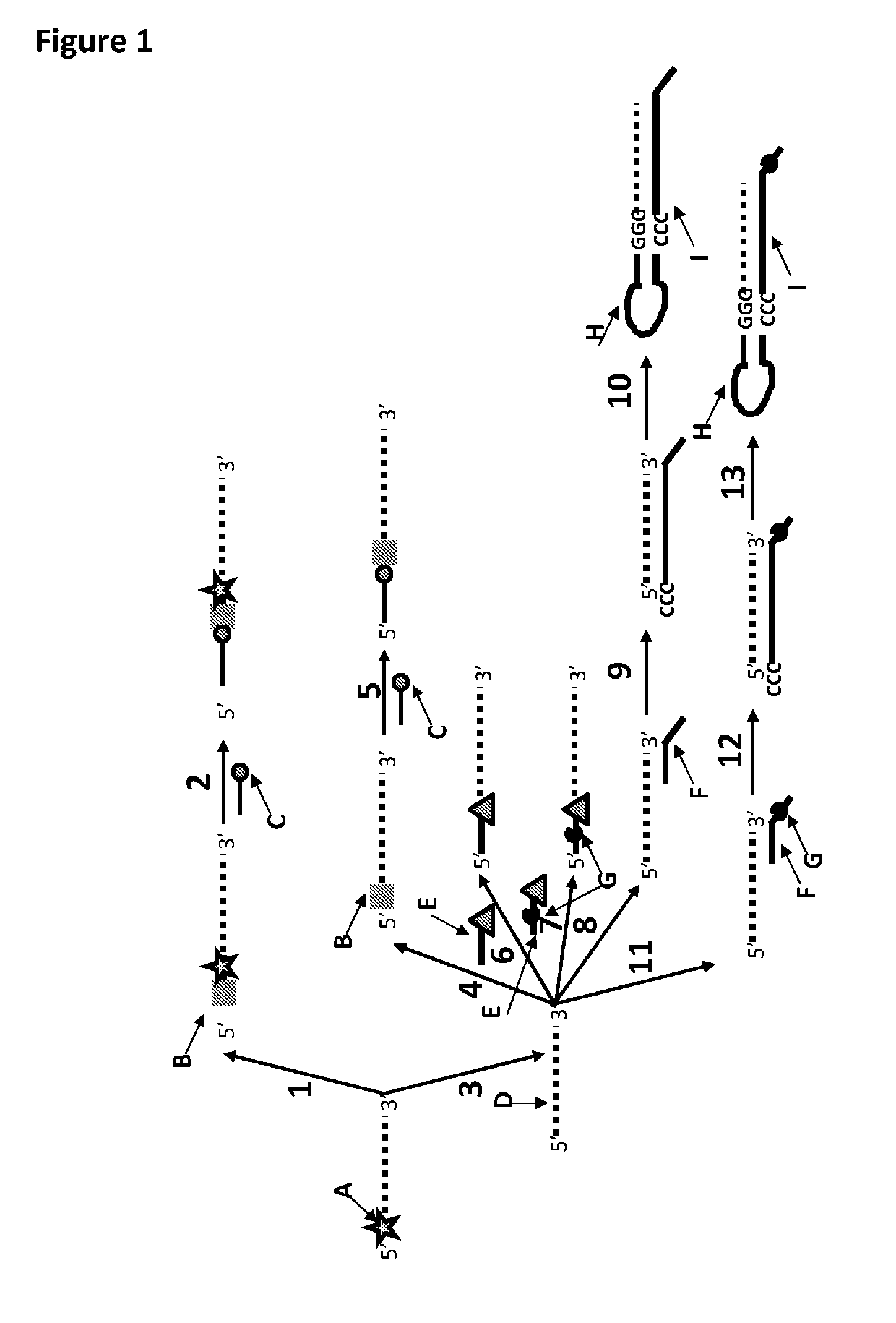

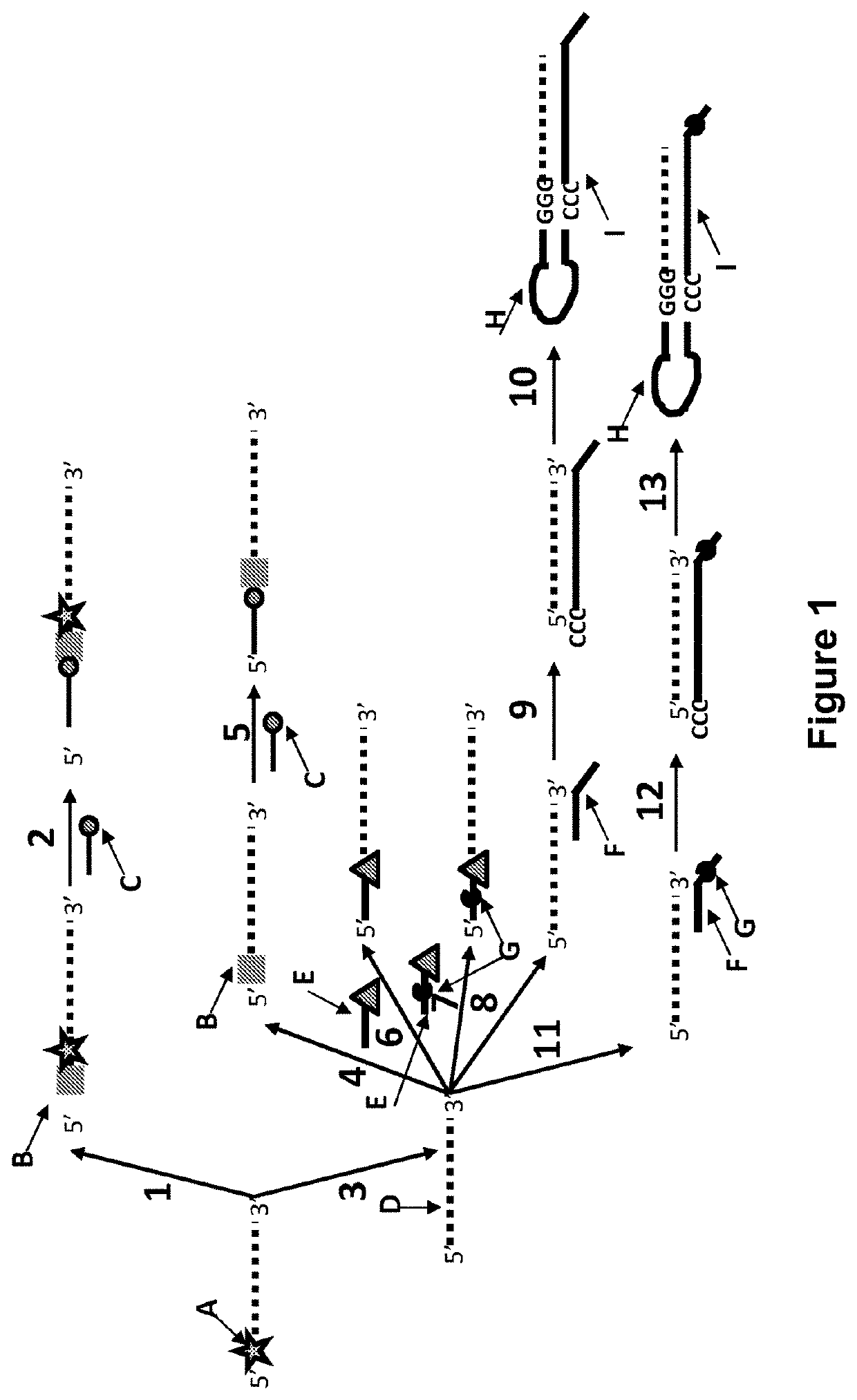

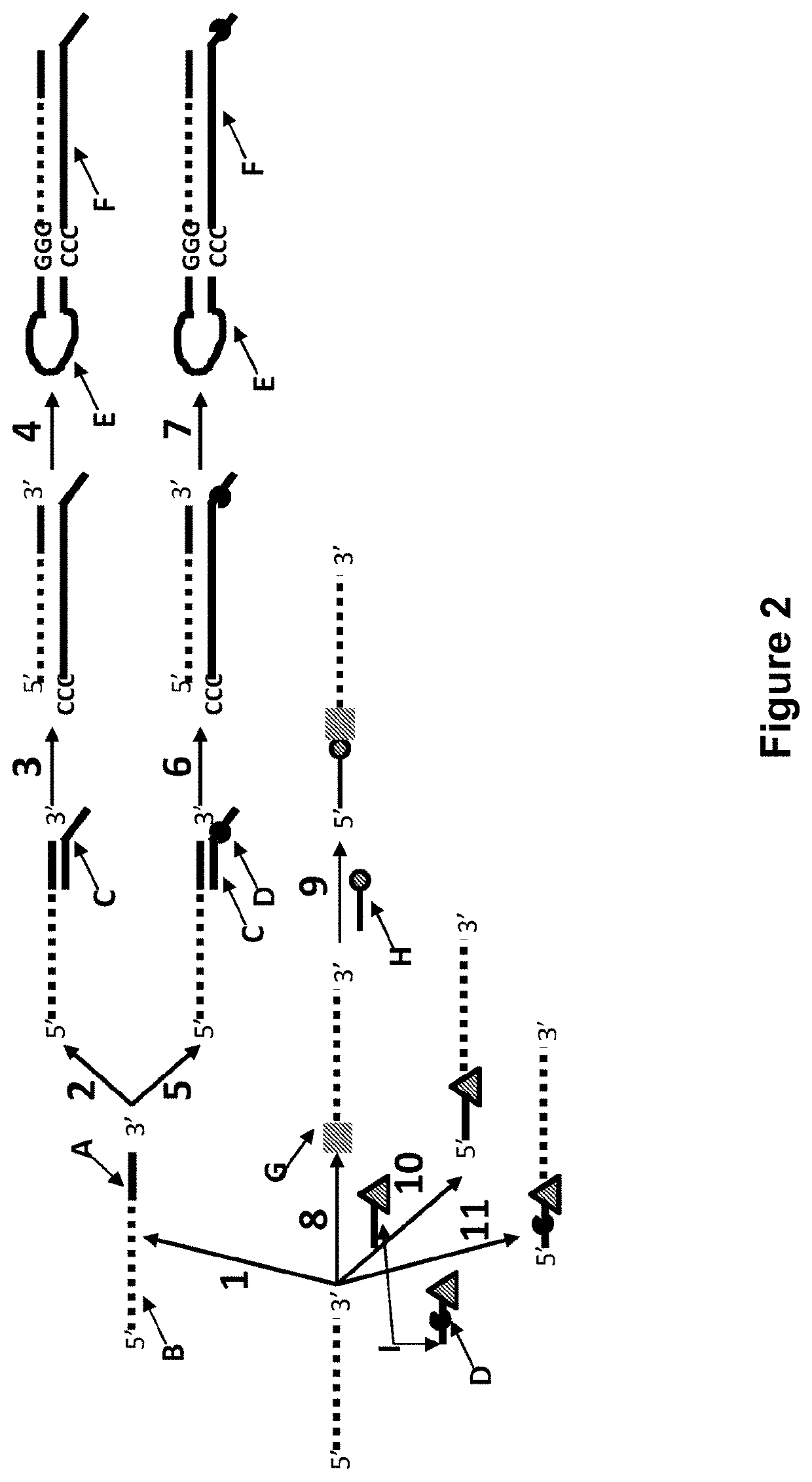

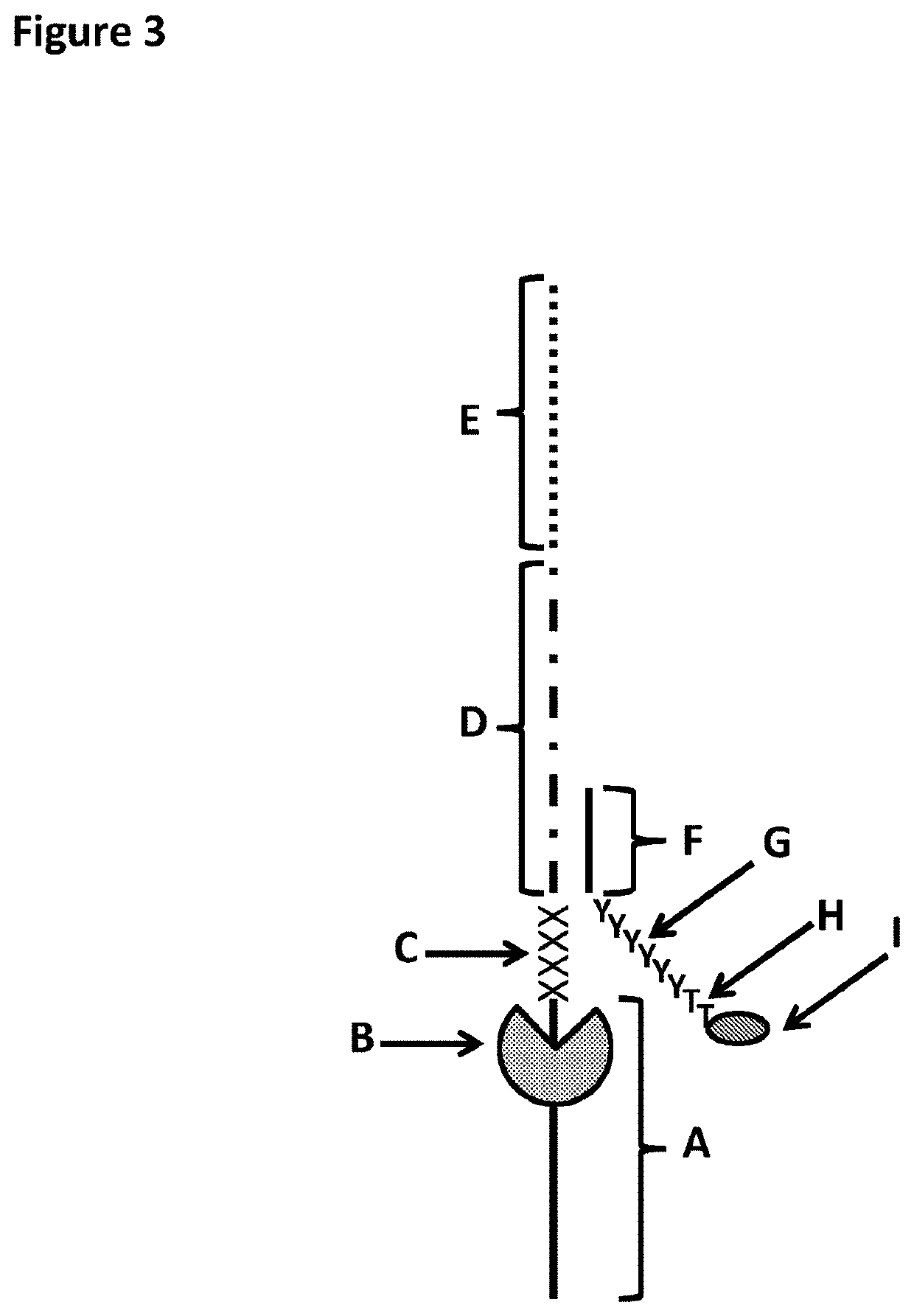

Method for nanopore RNA characterisation

ActiveUS20170253923A1Facilitate movementImprove speed and accuracyHydrolasesMicrobiological testing/measurementNanoporeRNA

The invention relates to a new method of characterising FIG. 3 a target RNA polynucleotide by taking one or more measurements as the target RNA polynucleotide moves with respect to a transmembrane pore. The movement is controlled by a DNA helicase. The invention also relates to a modified RNA construct wherein the RNA polynucleotide has been modified to increase DNA helicase binding thereto.

Owner:OXFORD NANOPORE TECH LTD

Method for nanopore RNA characterisation

ActiveUS10480026B2Improve abilitiesImprove efficiencyHydrolasesMicrobiological testing/measurementNucleotideHelicase

The invention relates to a new method of characterizing a target RNA polynucleotide by taking one or more measurements as the target RNA polynucleotide moves with respect to a transmembrane pore. The movement is controlled by a DNA helicase. The invention also relates to a modified RNA construct wherein the RNA polynucleotide has been modified to increase DNA helicase binding thereto.

Owner:OXFORD NANOPORE TECH LTD

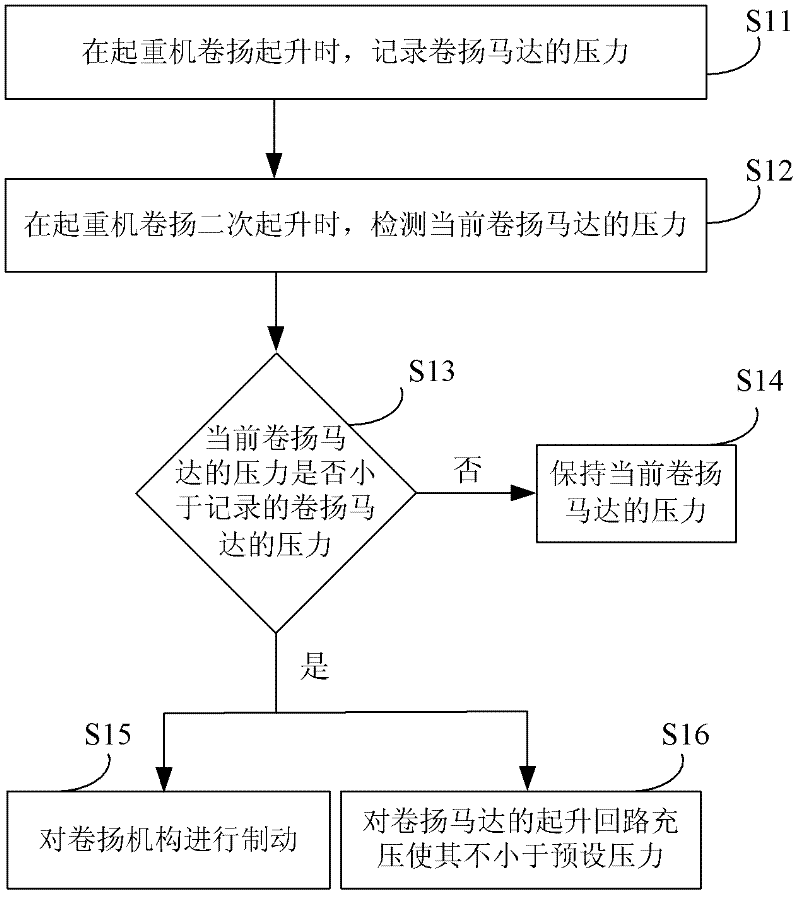

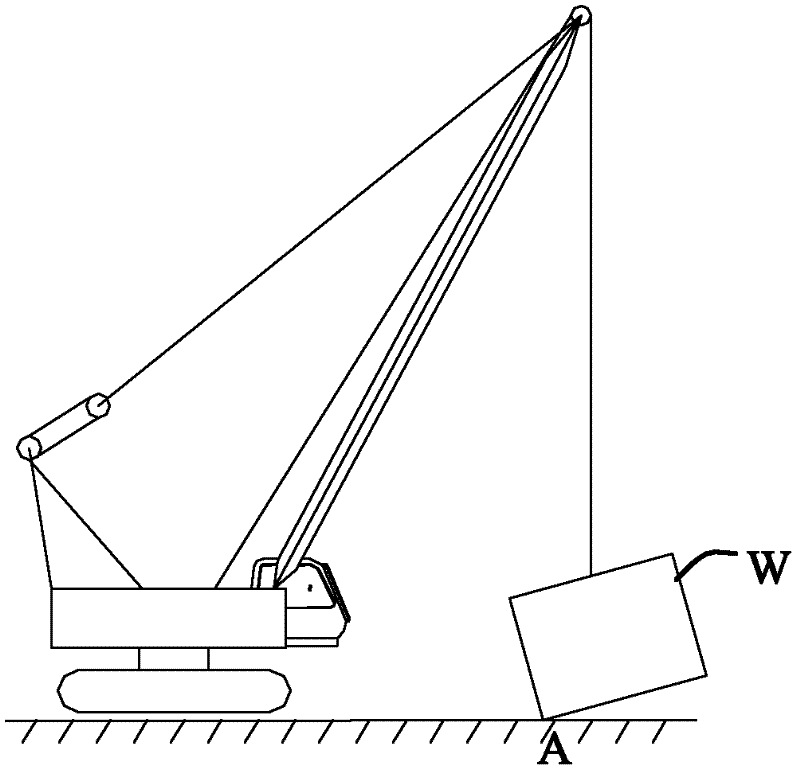

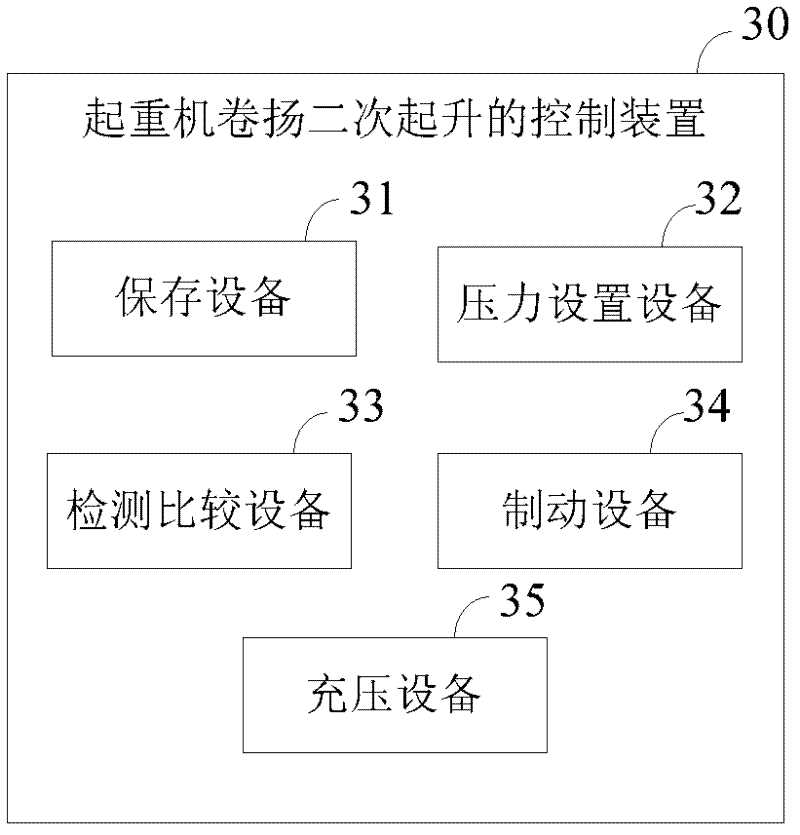

Method and device for controlling secondary hoisting of crane winch

The invention provides a method and a device for controlling secondary hoisting of a crane winch, and the method and device provided by the invention are used for solving the problems of low power utilization efficiency, poor control effect and higher equipment manufacturing cost during control over gliding down of the secondary hoisting of the crane winch. The method comprises the following steps of: recording the pressure of a winch motor when the crane winch performs hoisting; detecting the current pressure of the winch motor when the crane winch performs secondary hoisting, and comparing the current pressure with the recorded pressure of the winch motor; and if the current pressure of the winch motor is less than the recorded pressure of the winch motor, braking a winch mechanism, and pressurizing the hoisting loop of the winch motor to enable the current pressure to be not less than the preset pressure, wherein the preset pressure is determined according to the recorded pressure of the winch motor. By utilizing the technical scheme provided by the invention, the power utilization efficiency and the control effect are improved, and the manufacturing cost of equipment is reduced.

Owner:ZOOMLION HEAVY IND CO LTD

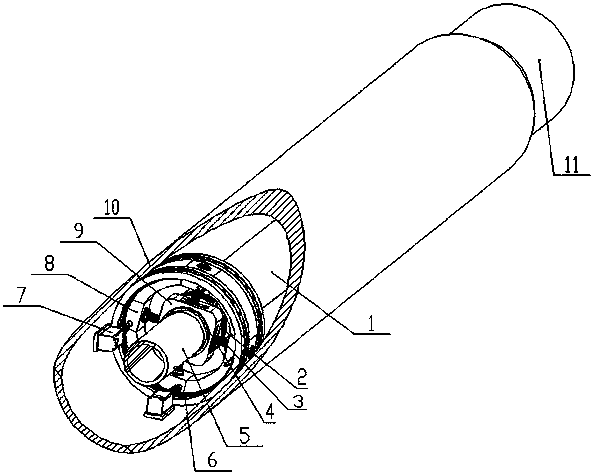

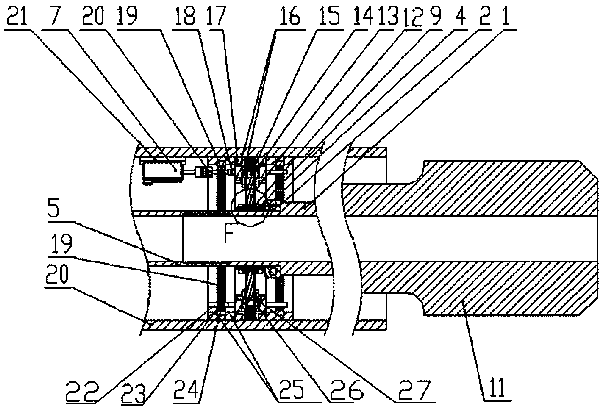

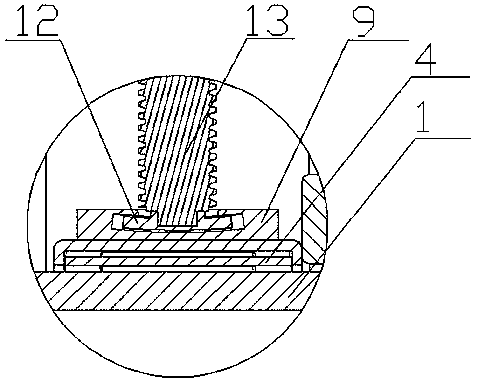

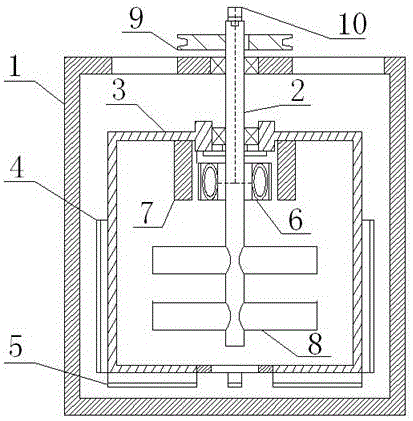

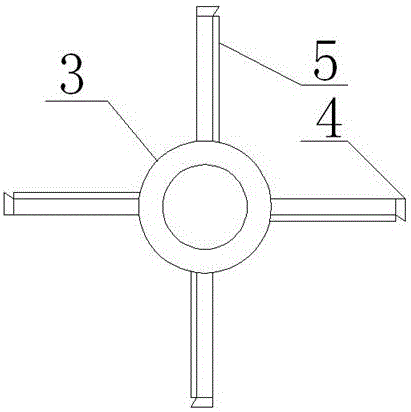

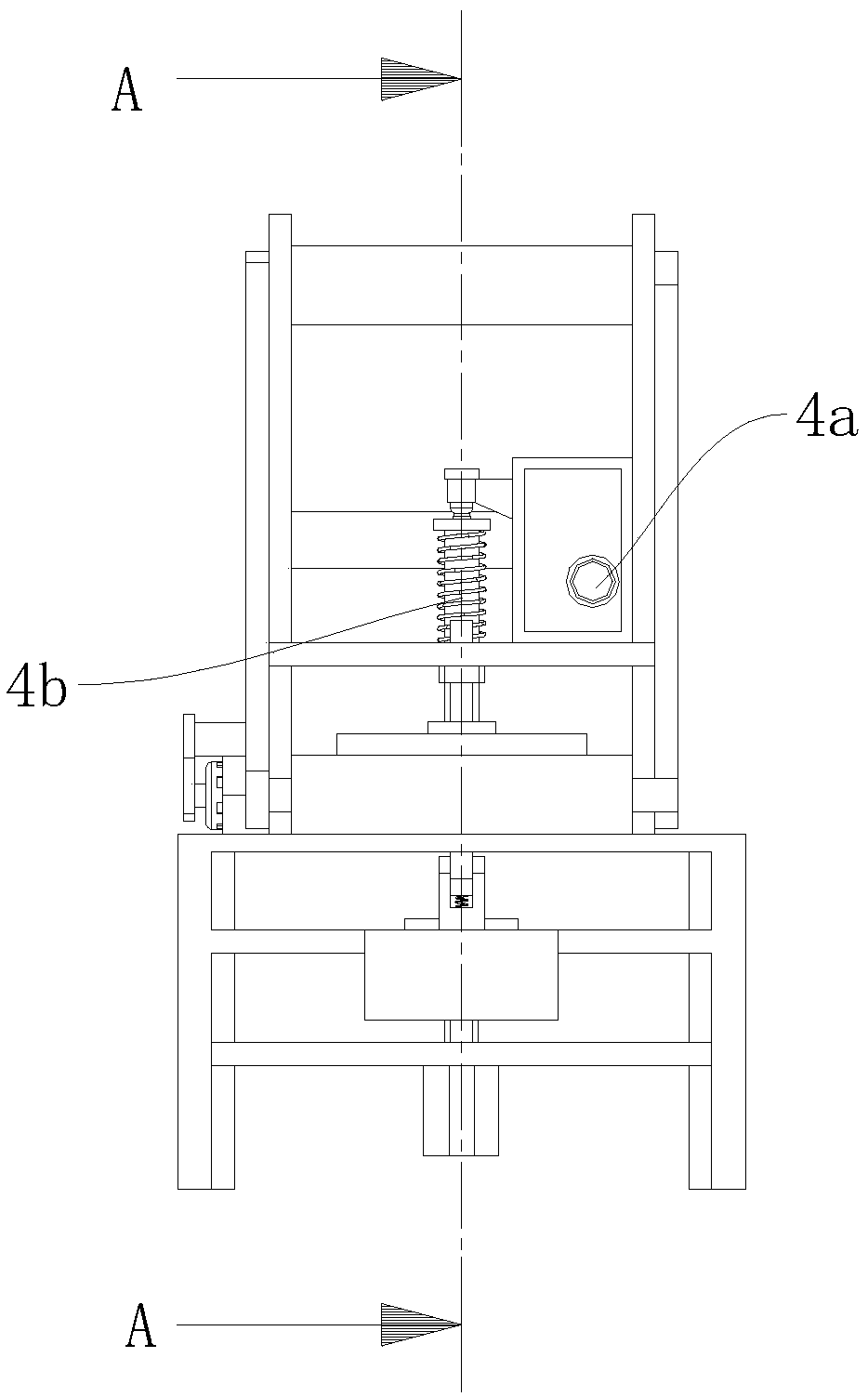

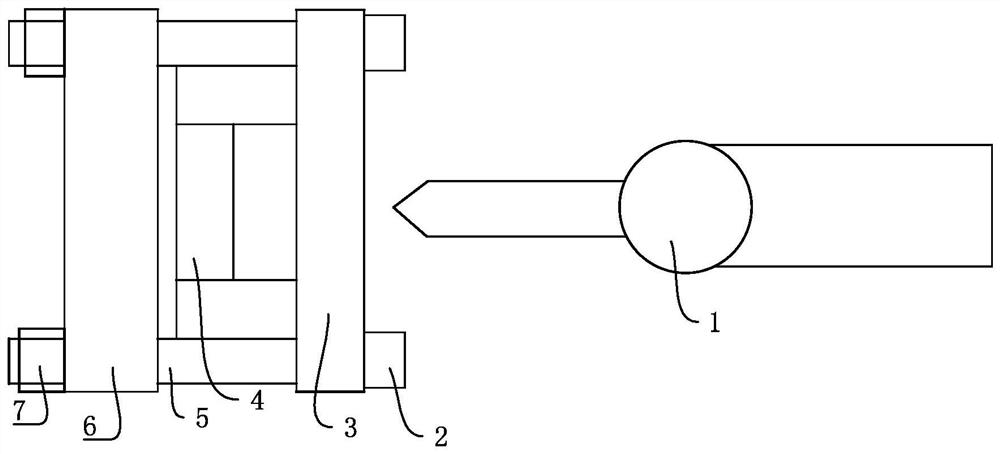

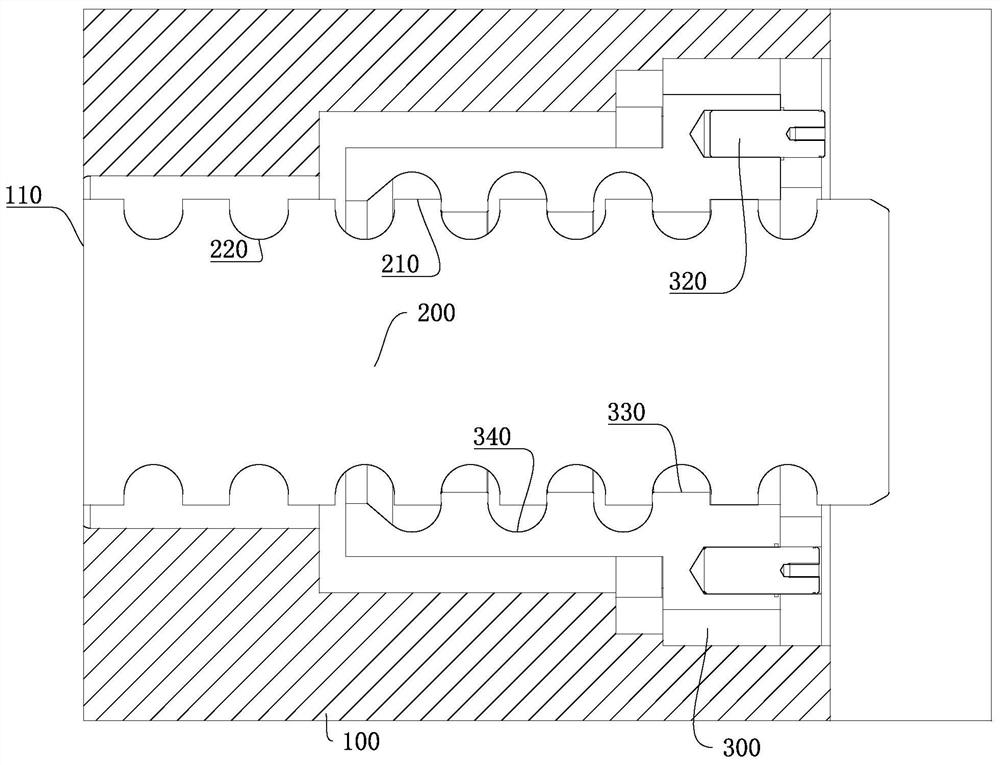

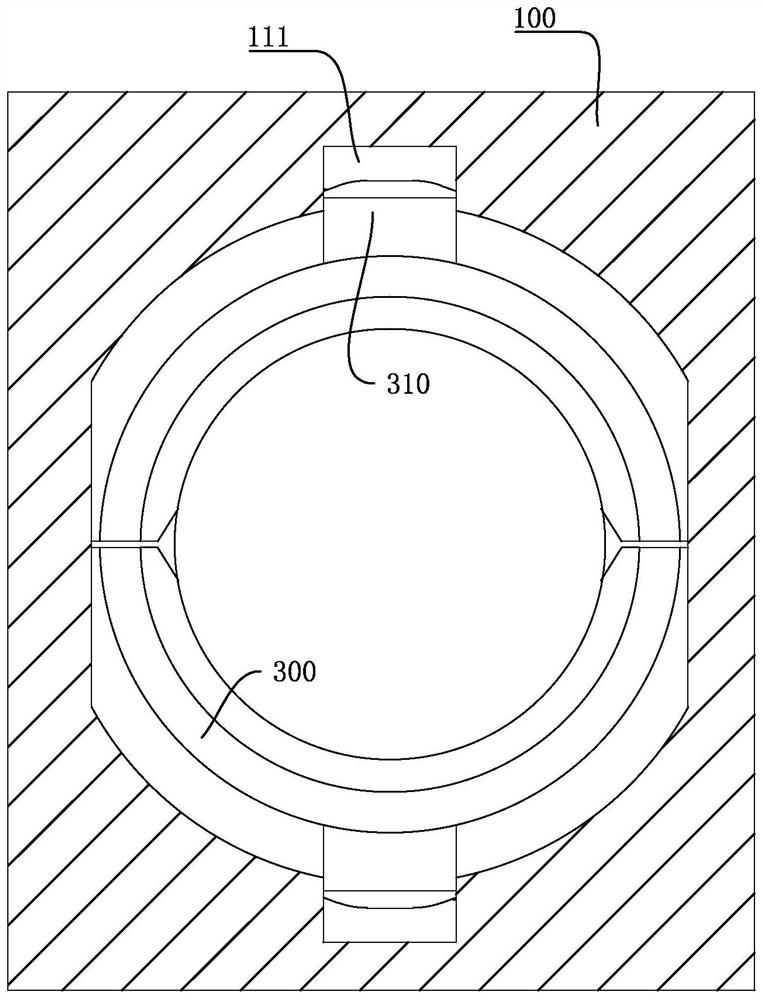

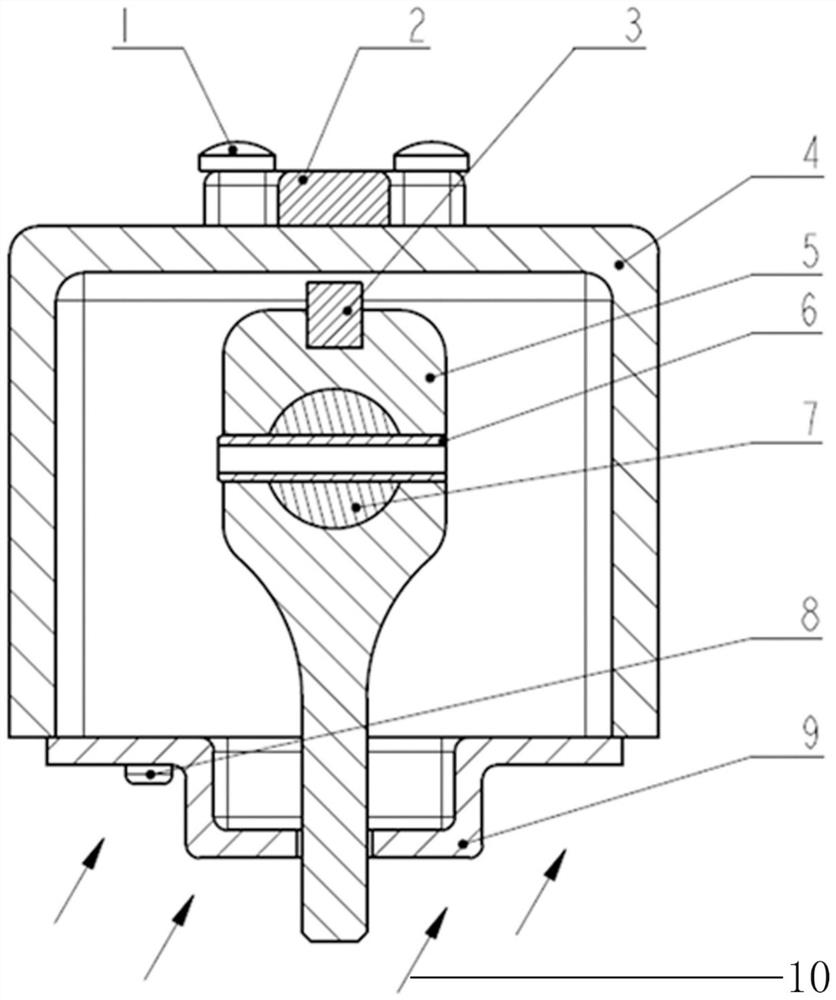

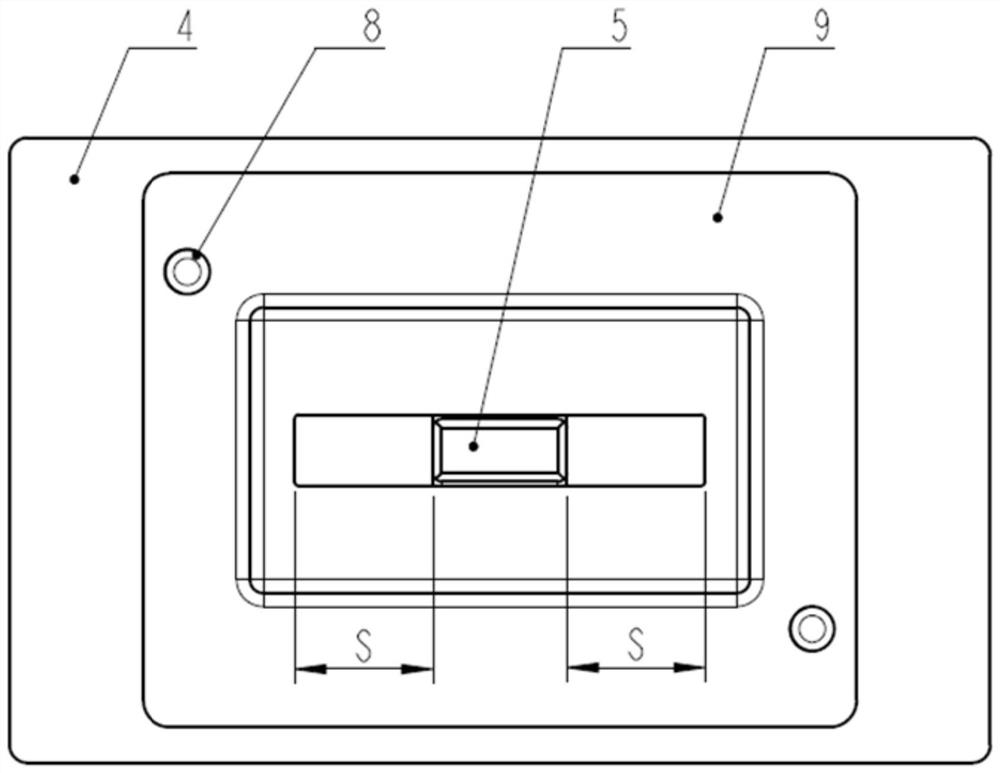

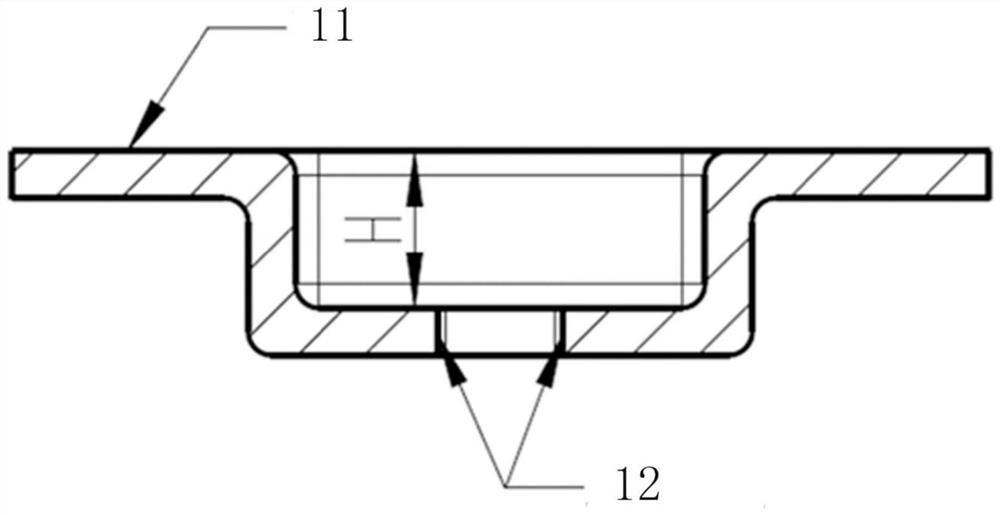

Bias guiding mechanism of static pointing type rotary steering well drilling tool and control method

ActiveCN110043188AReduce the difficulty of orientationSimple implementationDirectional drillingBorehole drivesElectric energyPetroleum

The invention discloses a bias guiding mechanism of a static pointing type rotary steering well drilling tool and a control method, and belongs to the technical field of petroleum and natural gas welldrilling. The bias guiding mechanism of the static pointing type rotary steering well drilling tool comprises a drill bit connecting shaft and a non-rotary outer cylinder, and further comprises a flexible hose, bias mechanisms and a sliding block connecting piece; the flexible hose is connected with the drill bit connecting shaft, and the bias mechanisms are installed in the non-rotary outer cylinder; the bias mechanisms comprise center adjusting sliding blocks, spiral telescopic mechanisms and control motors; the sliding block connecting piece is arranged on the outer part of the drill bit connecting shaft in a sleeving mode; and the center adjusting sliding blocks are connected with the control motors through the spiral telescopic mechanisms and are installed in the sliding block connecting piece, the center adjusting sliding blocks are driven by the control motors to move forward and backward to push the drill bit connecting shaft, and control over structure bend angles and tool face angles is realized. The disturbance and the load applied on the motors are both small and stable in the process of making a connection, the electric energy requirement of a system is reduced obviously, and the service life of the guiding tool is prolonged; and the scheme is simple and easy to operate, and the structure is compact.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

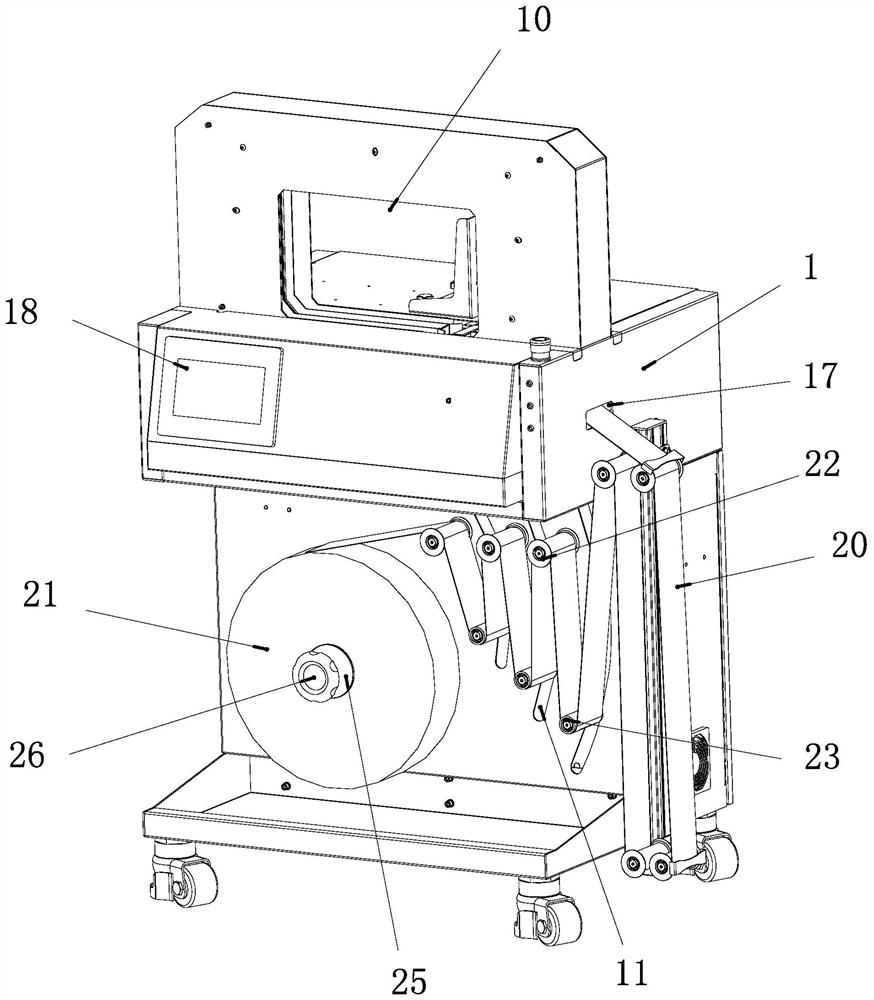

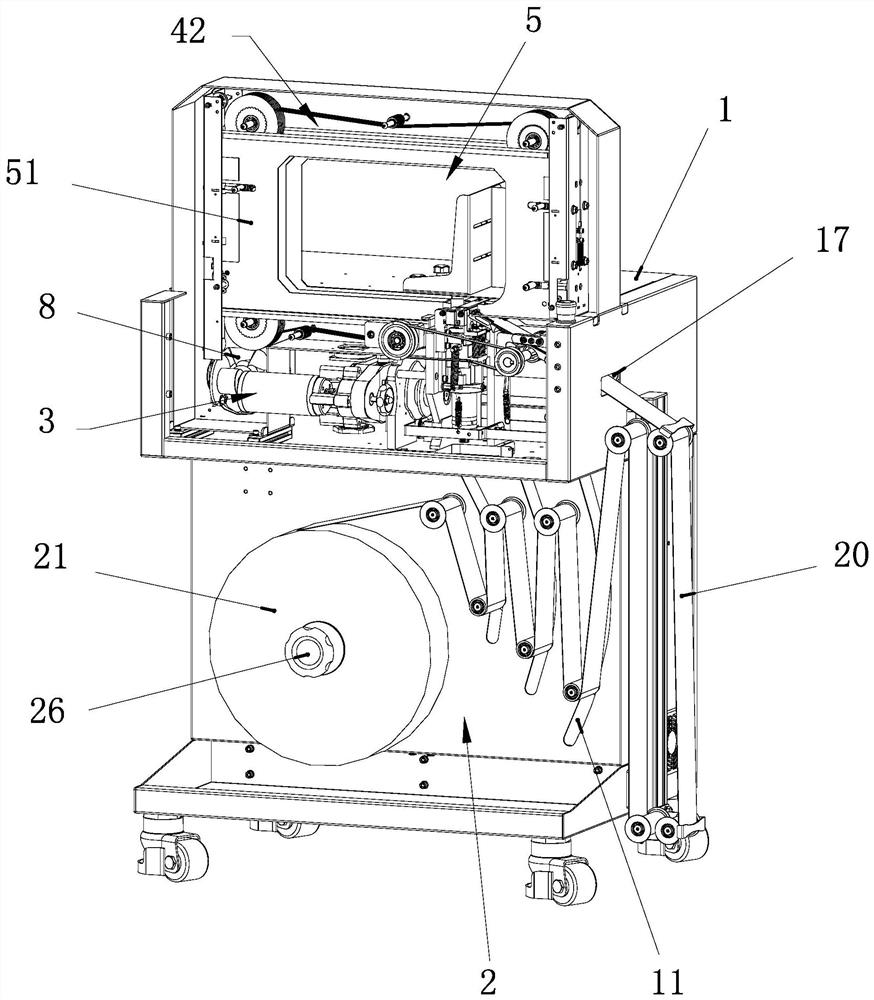

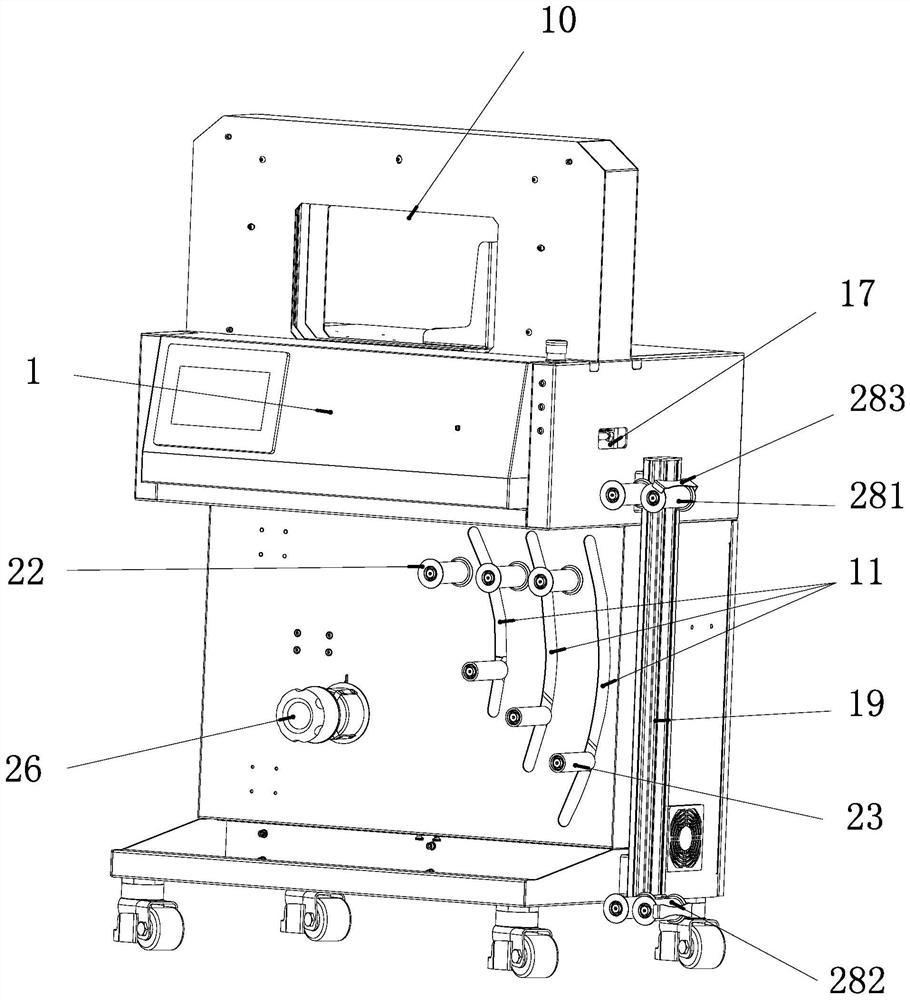

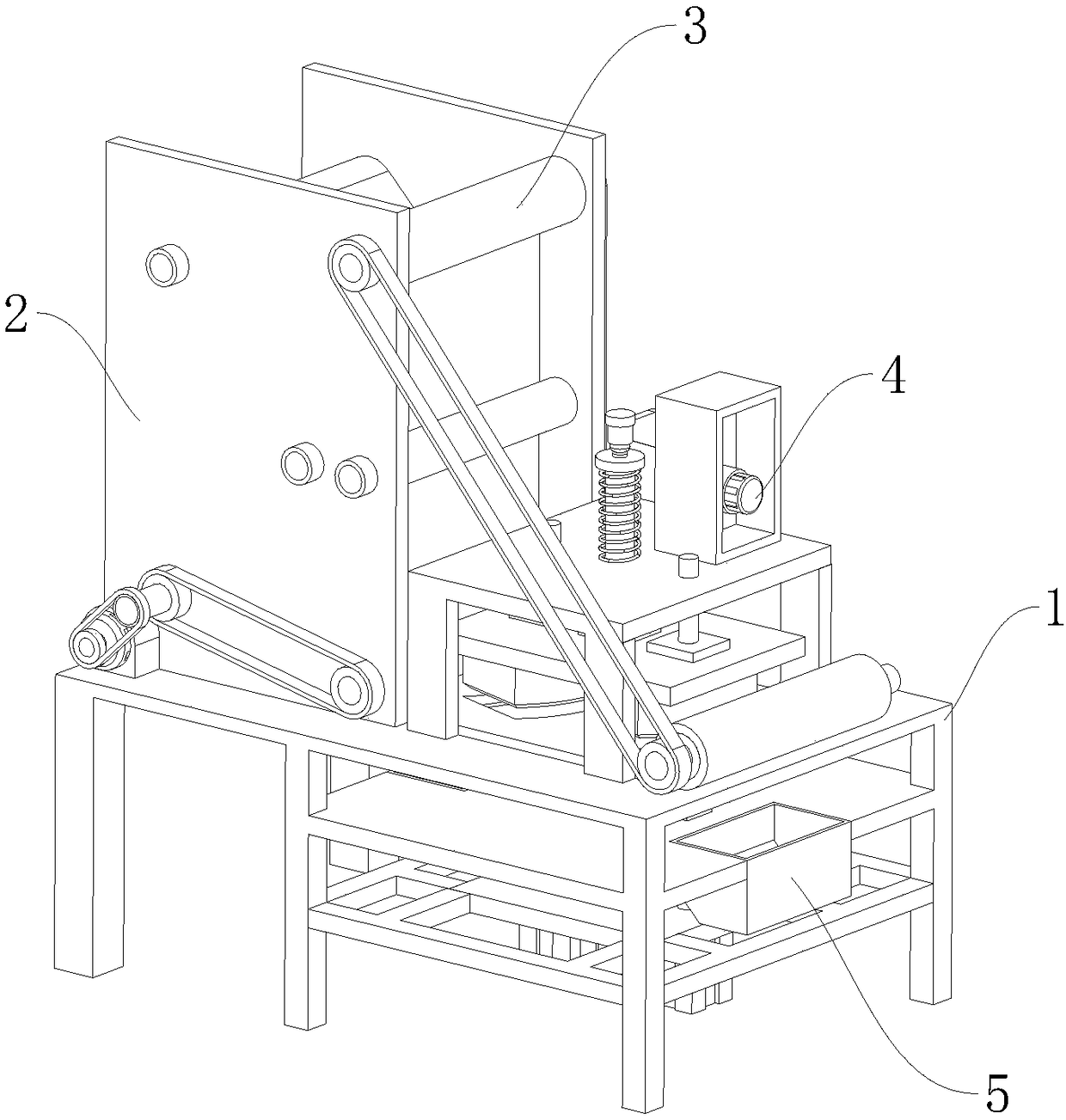

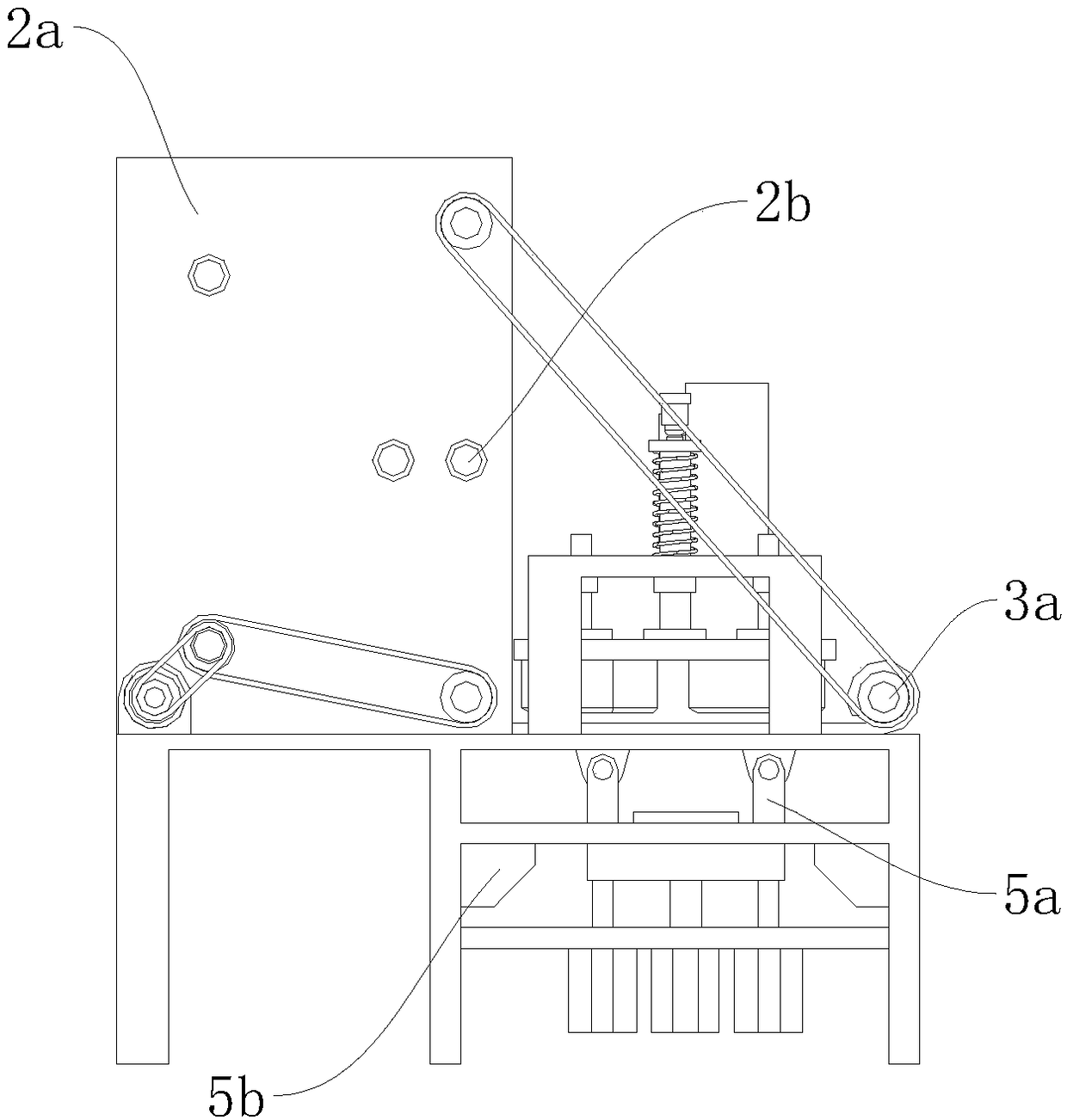

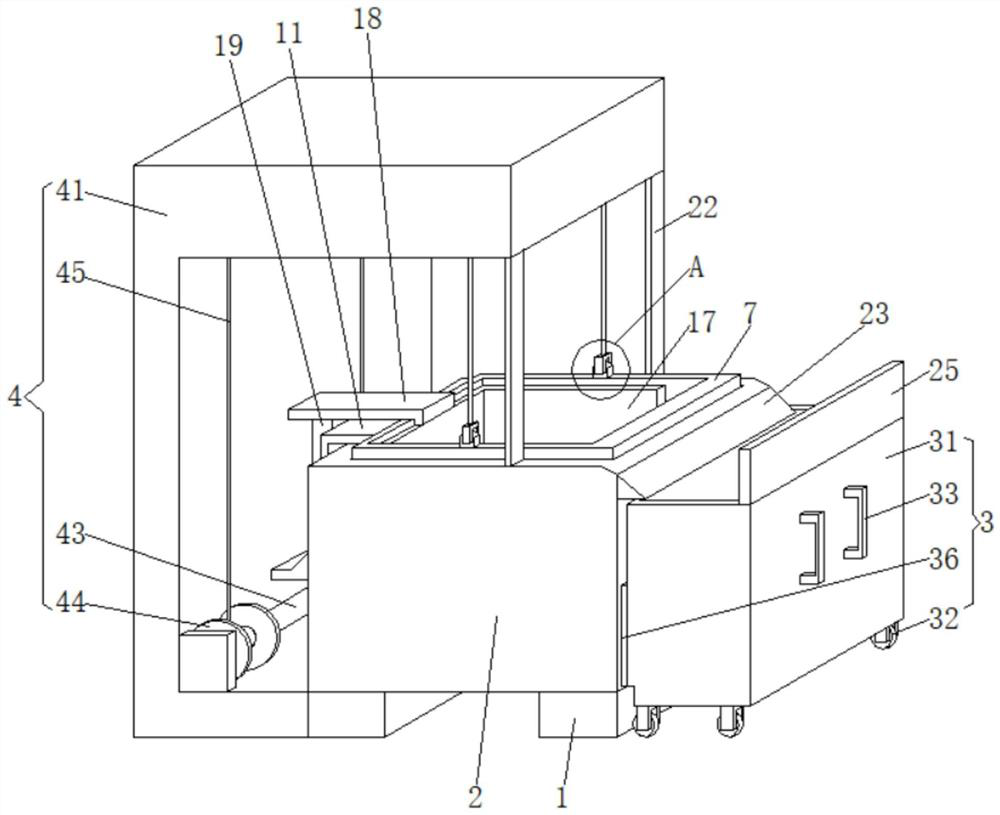

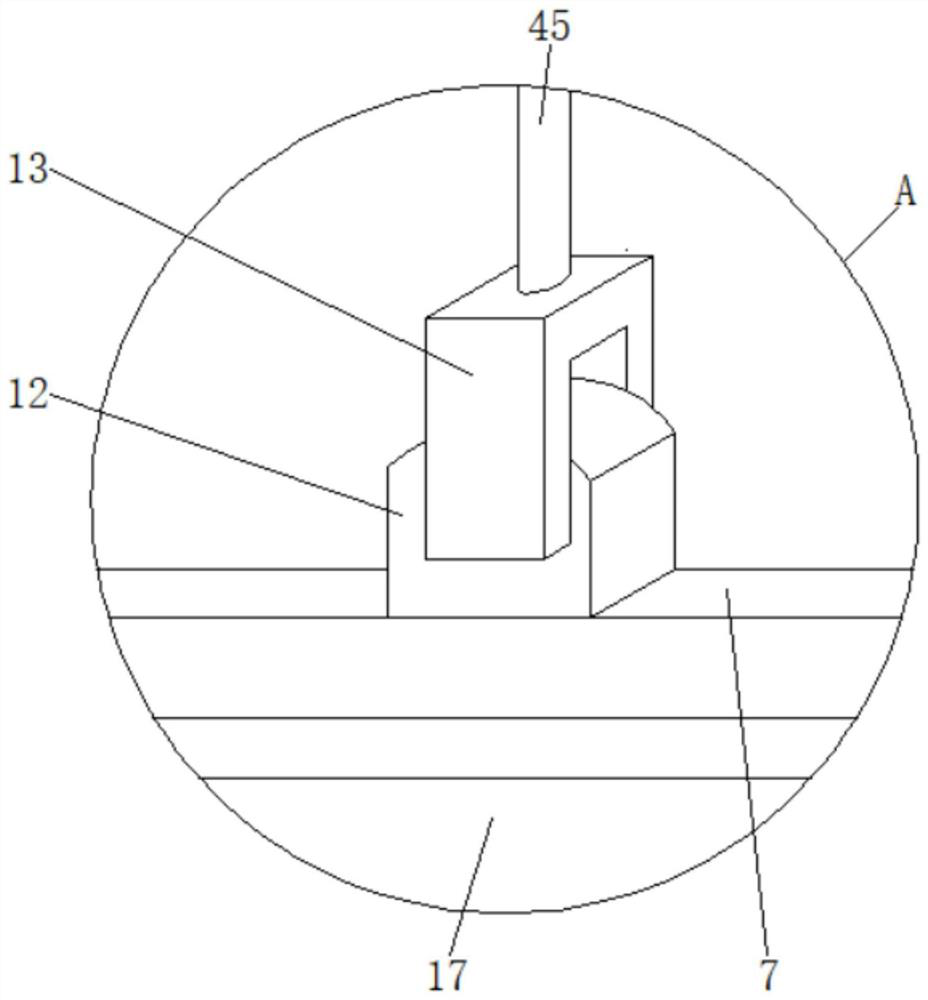

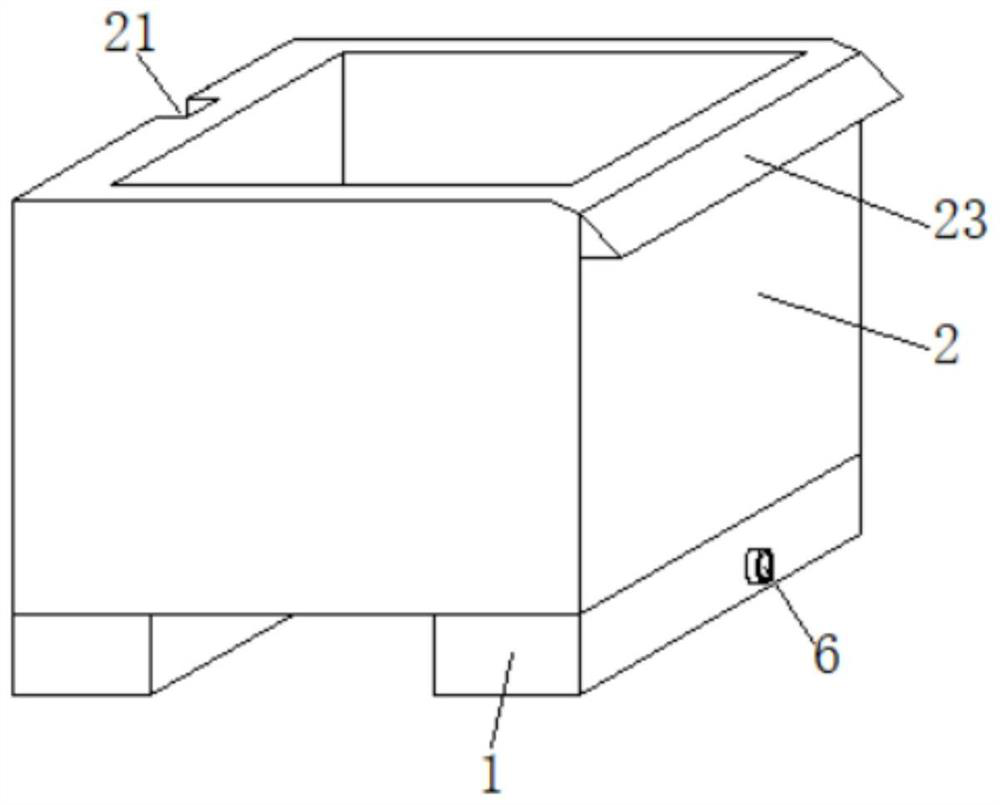

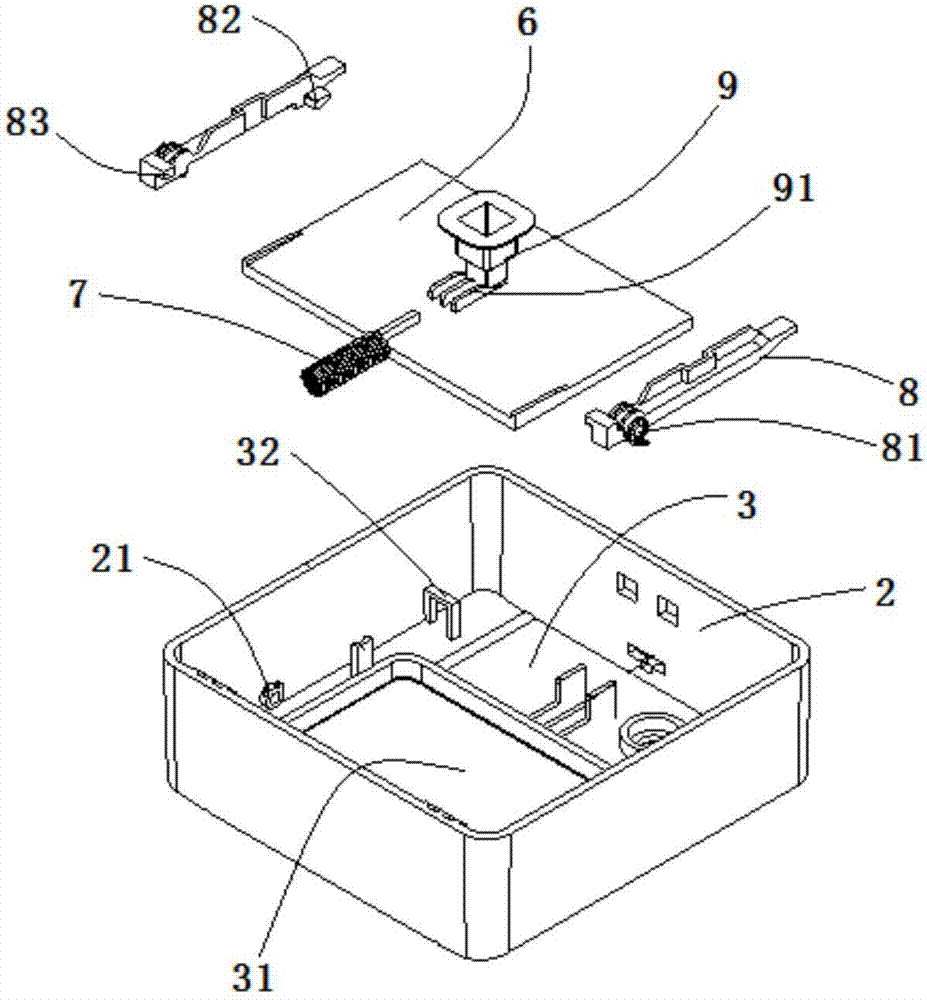

String binding machine

ActiveCN112278965AEasy to transportImprove work efficiencyFinal product manufactureArticle deliveryEngineeringMachine

The invention belongs to the technical field of packing string packing machines, and particularly relates to a string binding machine which comprises a rack, and a string storage mechanism, a loopingmechanism, a tightening mechanism, a fusion welding mechanism and a string shearing mechanism are arranged on the rack. The looping mechanism comprises a plurality of transmission wheels, a belt assembly and a vacuum device, the belt assembly is wound among the transmission wheels and can transfer a binding string, and the vacuum device adsorbs the string on the surface of the belt assembly. The looping mechanism comprises a string guide frame assembly, the string guide frame assembly at least comprises a movable covering part, the covering part has a working position and an opening position,and in the forward conveying process of the string, the covering part is located at the working position and at least covers part of a rail. In the backward tightening process of the string, the covering part is located at the opening position and does not cover the rail so that the string can be separated from the rail. According to the string binding machine, string storage, looping, fusion welding and string cutting are integrated, adaptive adjustment and mechanical control can be carried out on a string conveying channel, the working efficiency is high, the labor cost is reduced, and safety and convenience are achieved.

Owner:TAIZHOU XUTIAN PACKAGING MACHINERY

Insertion device for an intraocular lens

ActiveUS20050075646A1High level of skillConsistent operationEye surgeryIntraocular lensMedicineIntraocular lens insertion

In an intraocular-lens insertion device for deforming a deformable intraocular lens to a smaller size and inserting the intraocular lens into an eye via an insertion tube, the insertion tube has such an inner wall shape as to cause the deformable intraocular lens to move rotationally about an insertion tube axis by a predetermined angle in the course of axial movement.

Owner:STAAR JAPAN

Stirrer capable preventing material from sedimentation

InactiveCN105833765ASimple structureEasy to use and maintainRotary stirring mixersTransportation and packagingPulp and paper industryClutch

The invention discloses a stirrer capable of preventing a material from sedimentation .The stirrer comprises a barrel body, a stirring shaft and a scraper holder .The extending-in end of the stirring shaft extends into the barrel body, and the extending-out end of the stirring shaft is located outside the barrel body .The scraper holder is provided with a vertical scraper and a transverse scraper and rotationally connected with the extending-in end of the stirring shaft, and a stirring paddle is arranged at the extending-in end of the stirring shaft .A clutch is arranged at the extending-in end of the stirring shaft, and the scraper holder is provided with a friction hub used in cooperation with the clutch .A belt wheel is arranged at the extending-out end of the stirring shaft and is in transmission connection with a power source through a belt .A rotation air guide connector is arranged on the end portion of the extending-out end of the stirring shaft, and the rotational air guide connector is connected with an air source .An air channel is formed in the stirring shaft and connected with the rotation air guide connector and the clutch .The vertical scraper and the transverse scraper are strip-shaped scrapers with trapezoidal cross sections .The stirrer solves the problem that the material deposits on a cylinder wall .Compared with the prior art, the stirrer is simple in structure, material sedimentation is avoided, and the stirring efficiency is high.

Owner:CHENGDU AIBIKE BIOTECH

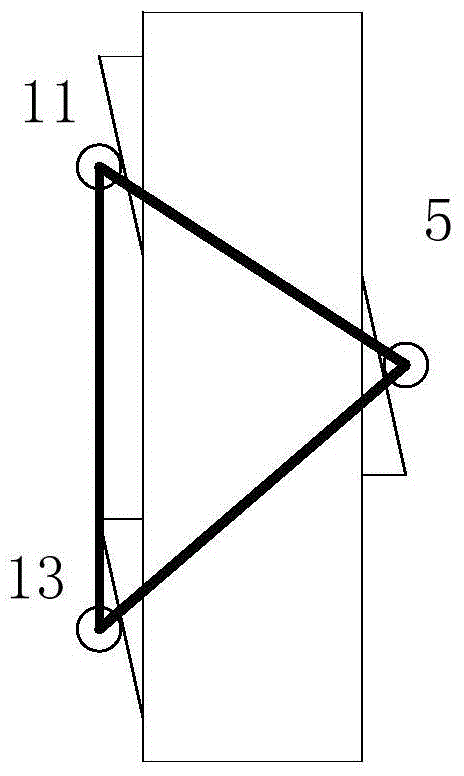

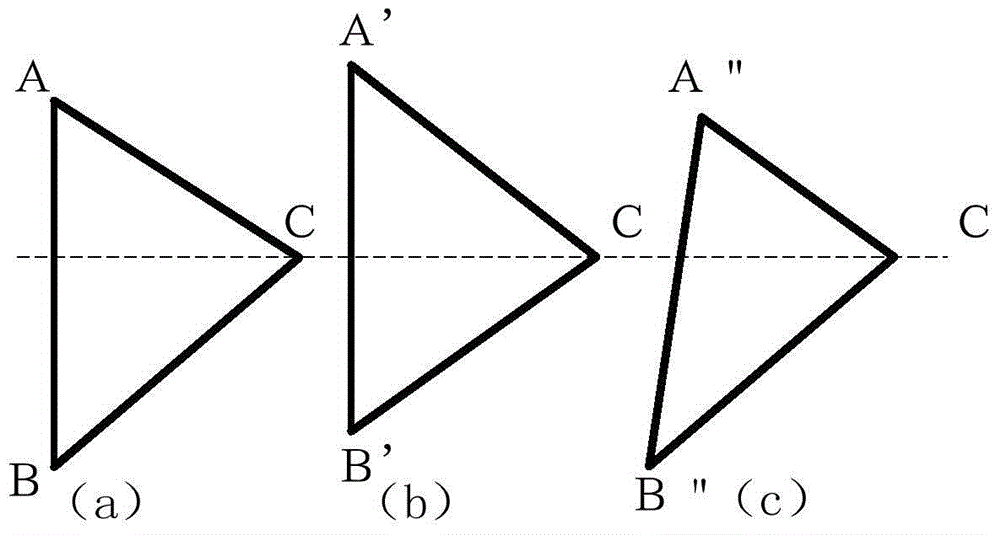

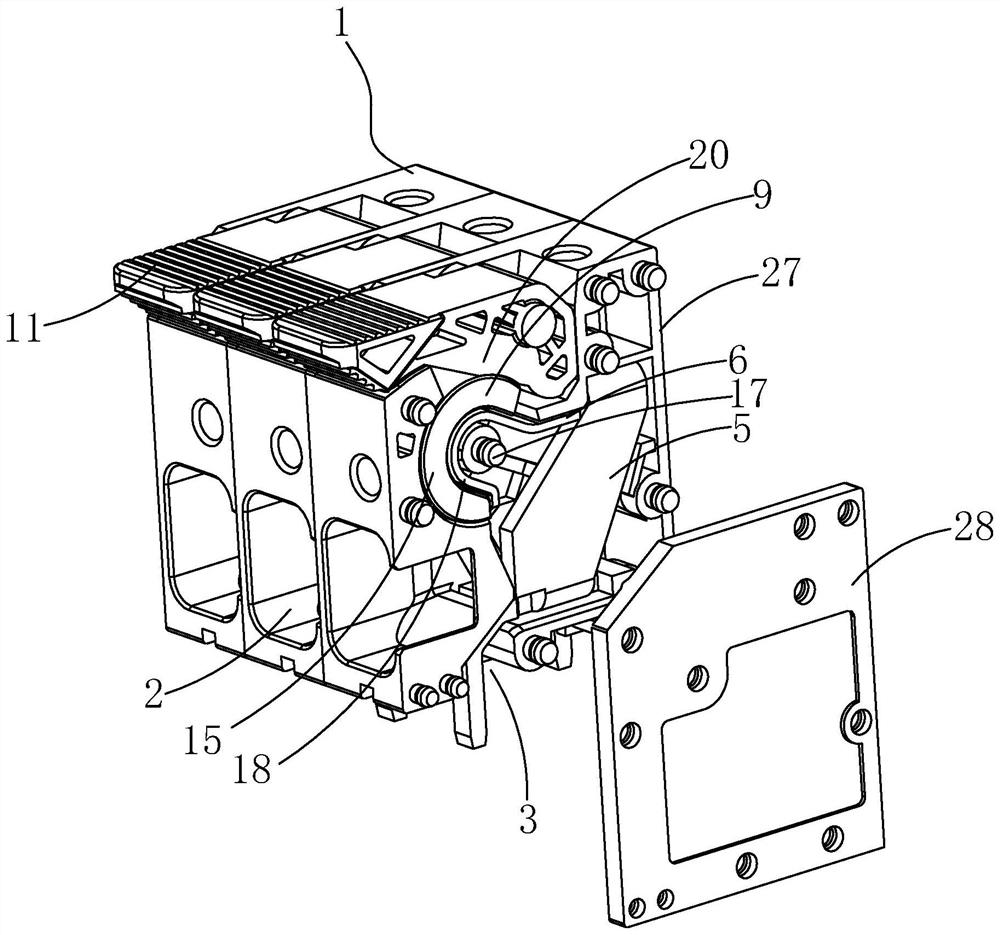

Bevel guide rail plate-shearing machine and shearing method thereof

ActiveCN105817688AConsistent movementNo manual correction requiredShearing machinesShearing toolsEngineeringKnife blades

The invention discloses a bevel guide rail plate-shearing machine and a shearing method thereof and belongs to the field of mechanical manufacturing. The bevel guide rail plate-shearing machine comprises a material pressing beam, an upper knife blade, a lower knife blade, a knife rest and a feeding bracket. The upper knife blade is arranged on the lower portion of the knife rest. The lower knife blade and the feeding bracket are both arranged on a plate-shearing machine platform. A front guide rail is arranged on the right side surface of the knife rest. A back upper guide rail and a back lower guide rail are arranged on the left side surface of the knife rest. The included angle between the guide rail surface of the front guide rail and the knife rest, the included angle between the guide rail surface of the back upper guide rail and the knife rest and the included angle between the guide rail surface of the back lower guide rail and the knife rest are angles alpha, controlled by a controller and adjustable. The slope range of the guide rail surfaces is 0.06-0.08 mm. The front guide rail is connected with a front rolling wheel arranged on the left side surface of the material pressing beam. A back upper rolling wheel and a back lower rolling wheel move simultaneously and are both eccentric wheels. According to the bevel guide rail plate-shearing machine and the shearing method thereof, the perpendicularity and gap value between an upper knife and a lower knife can be automatically adjusted, and machining errors are small.

Owner:马鞍山市中亚机床制造有限公司

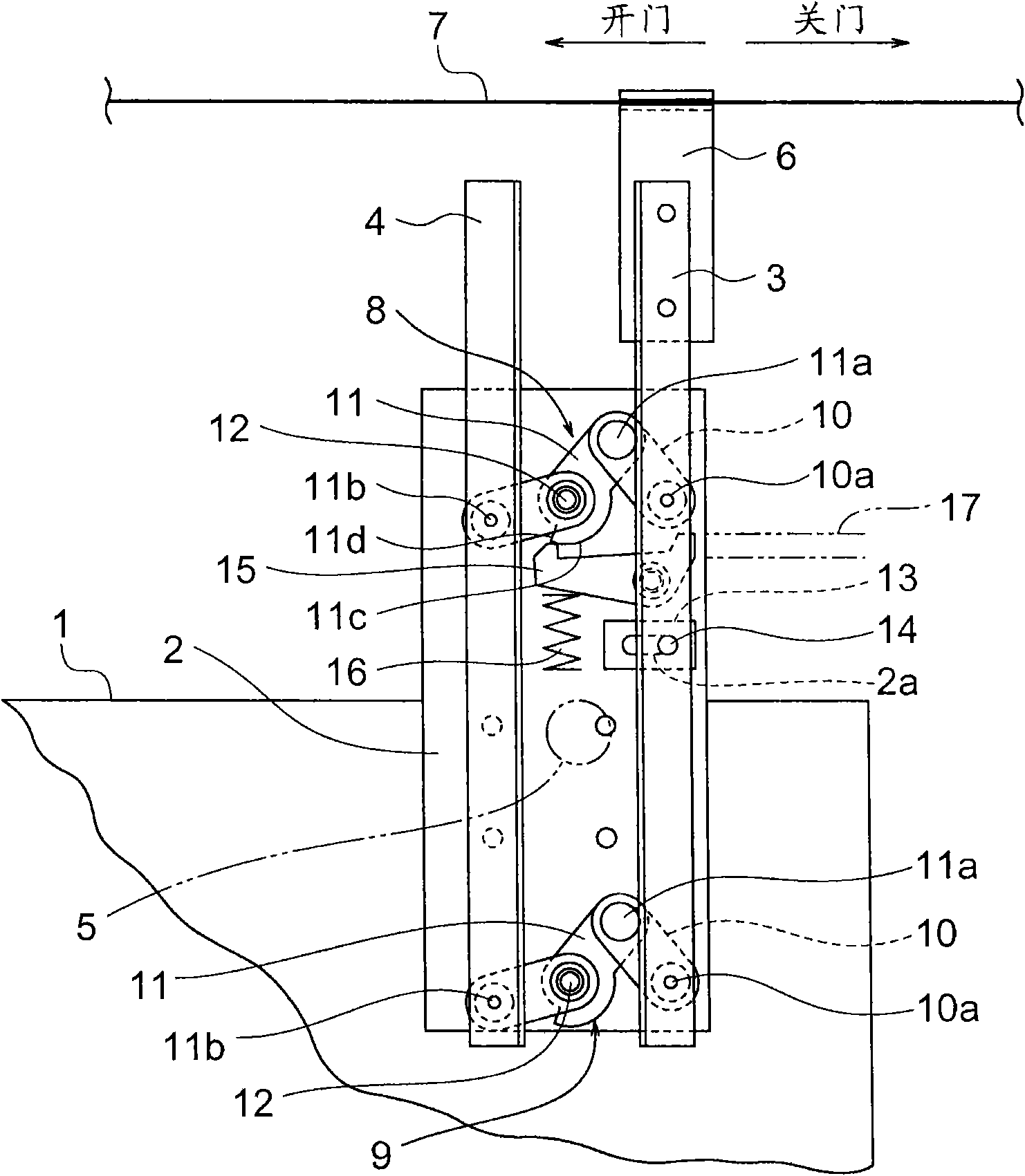

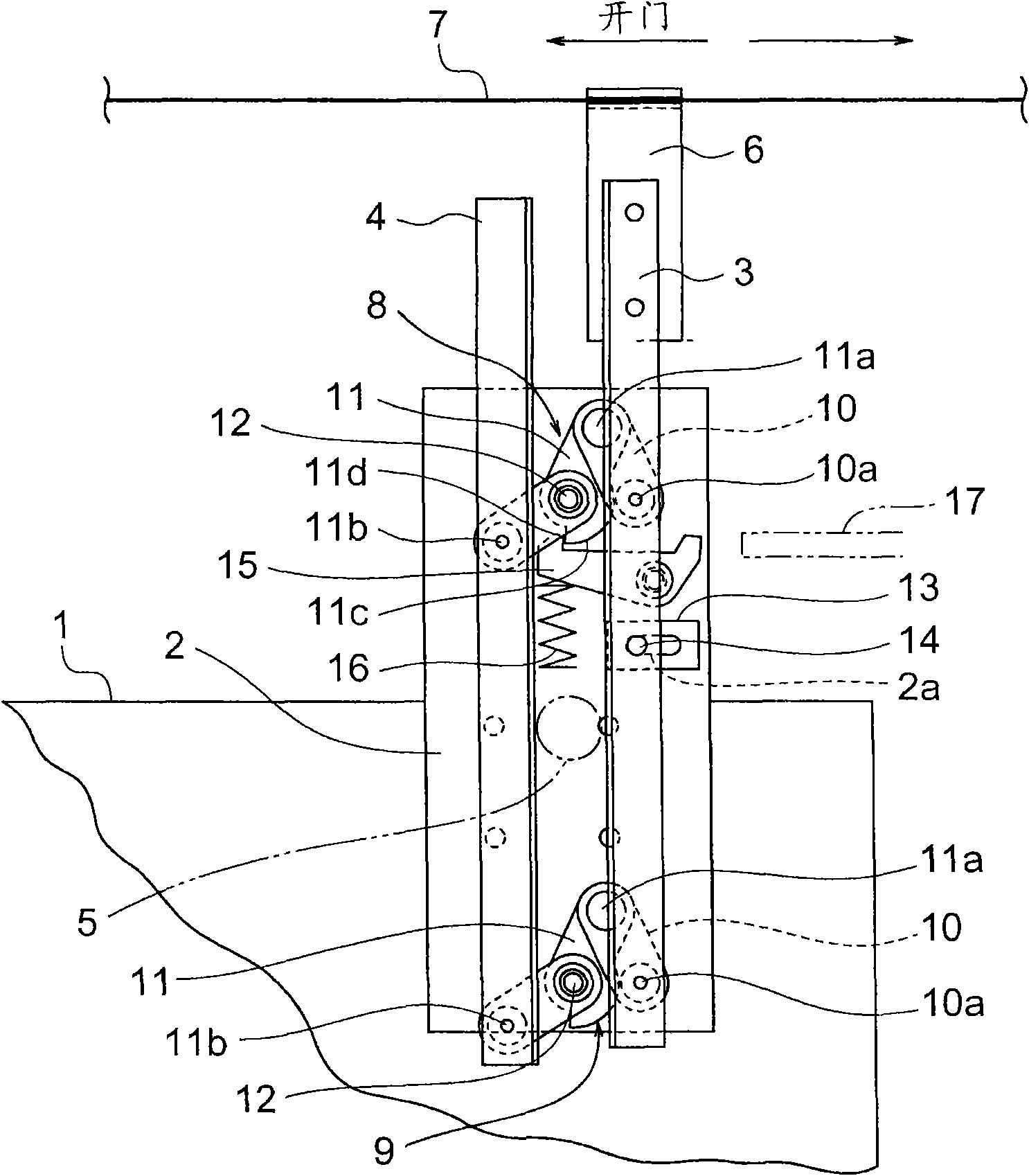

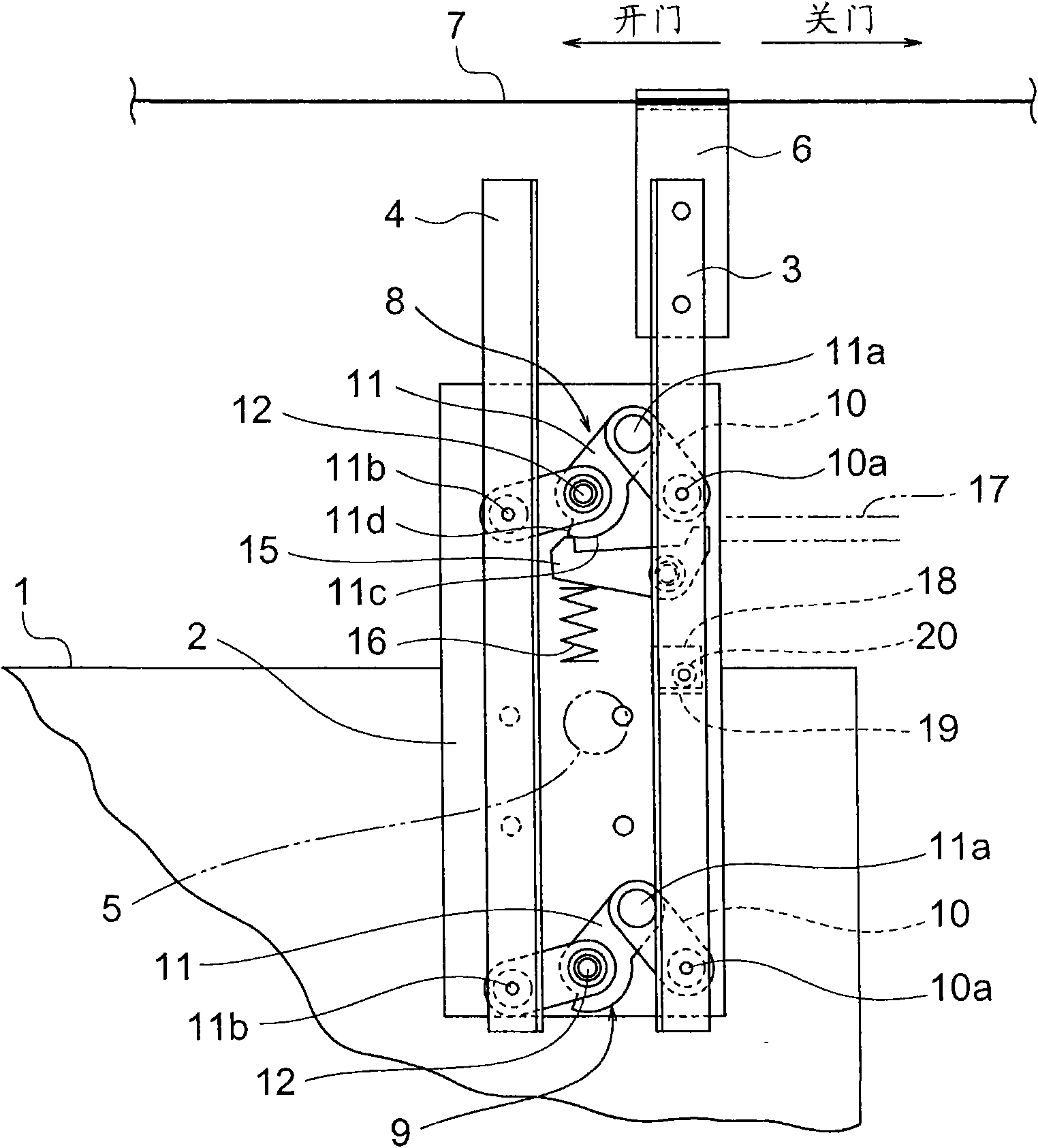

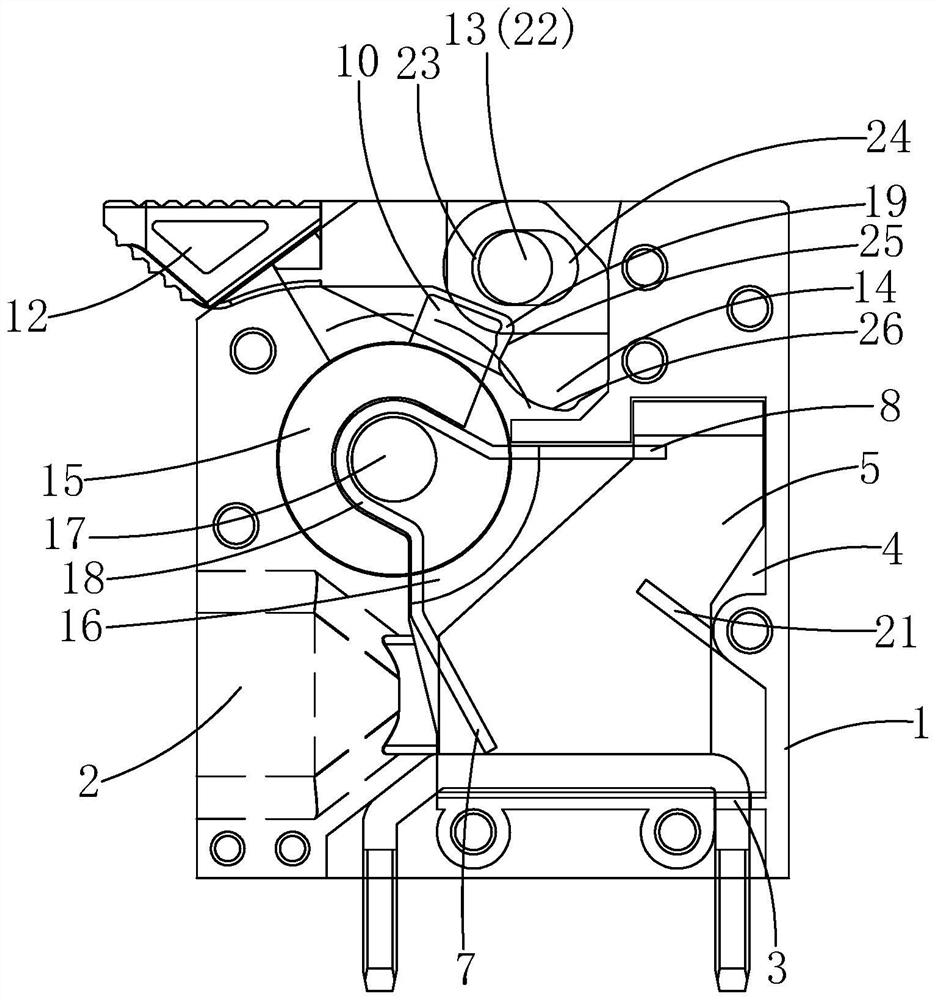

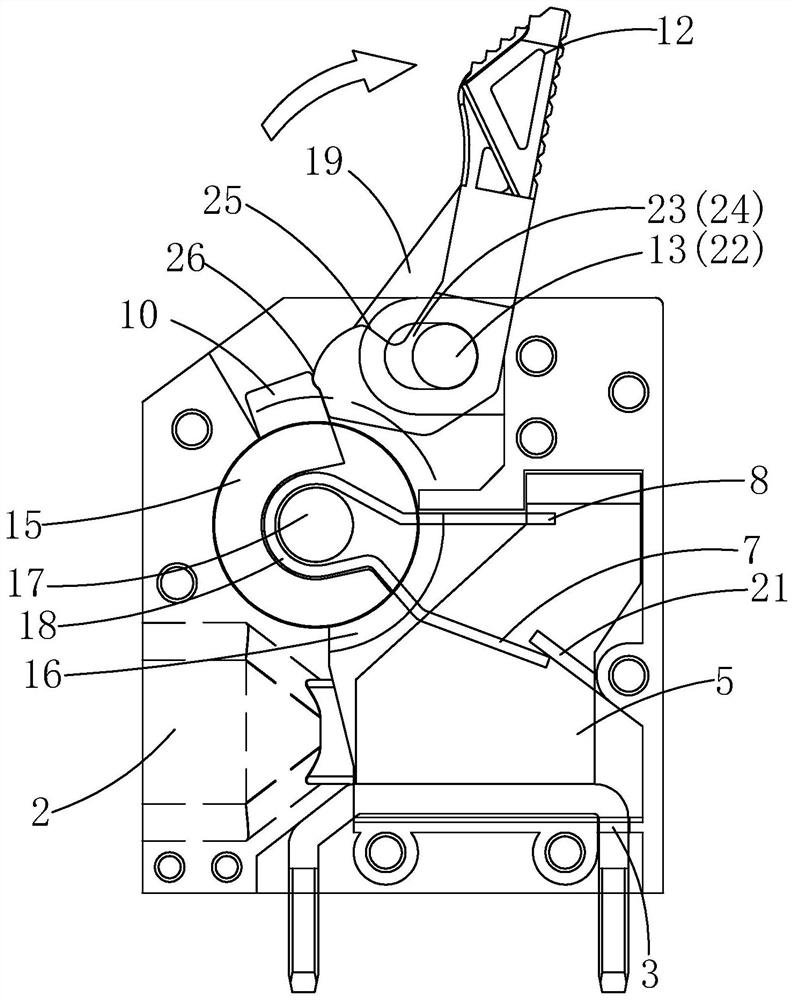

Door engagement device for elevator

InactiveCN101679005AReduce the amount of shiftConsistent movementBuilding liftsDrive motorEngineering

The invention provides a door engaging device for an elevator, first and second engagement members are provided to a car door through an intermediation of a plurality of interlocking link mechanisms.The interlocking link mechanisms displace the first and second engagement members in an interlocked manner to change a distance between the first and second engagement members. A power transmission body is moved in a direction in which the car door opens and closes by a drive motor for opening and closing the car door. A transmission body connecting portion connected to the power transmission bodyis provided on the first engagement member. The interlocking link mechanisms displace the first engagement member in parallel to the direction in which the car door opens and closes by movement of the power transmission body.

Owner:MITSUBISHI ELECTRIC CORP

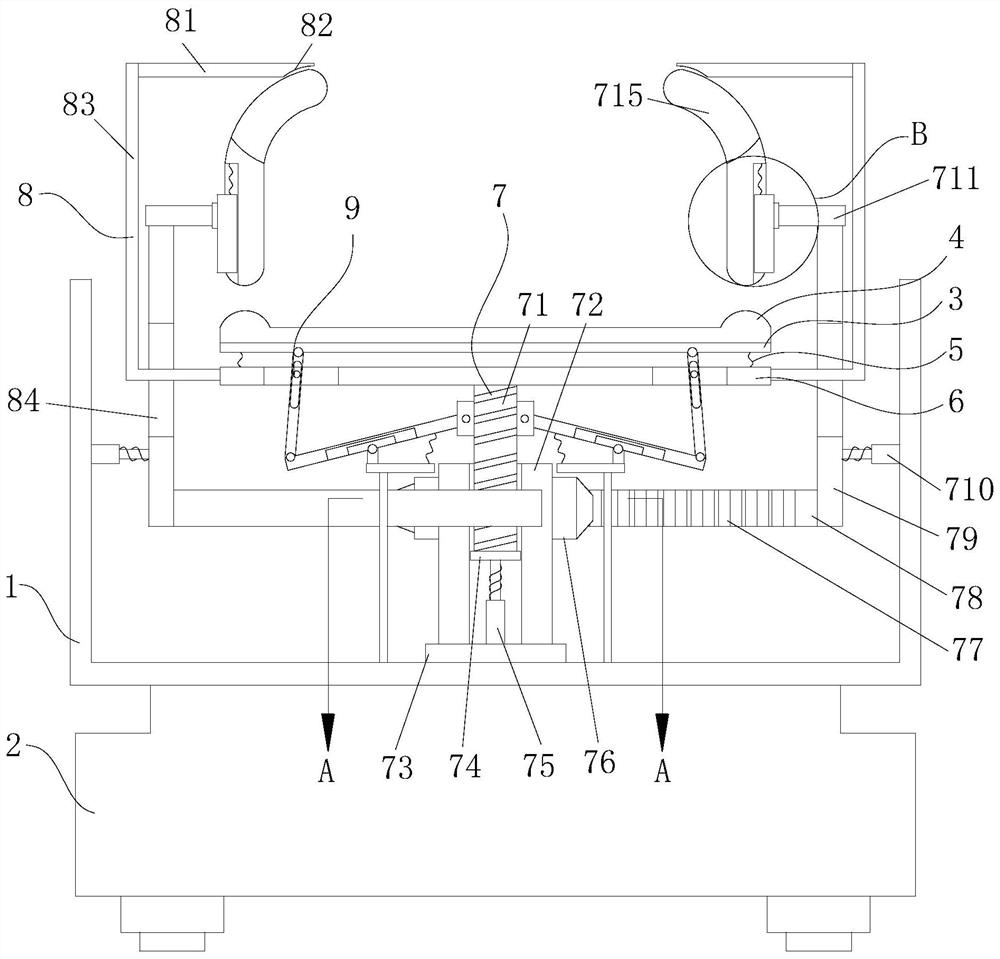

Drying, cutting and stacking integration device for paper cup production

ActiveCN109367120AConsistent movementImprove efficiencyPaper-makingBox making operationsPaperboardPulp and paper industry

The invention relates to the field of paper cup production and manufacturing, in particular to a drying, cutting and stacking integration device for paper cup production. The drying, cutting and stacking integration device for paper cup production comprises a working table, a supporting device, a conveying device, a cutting device and a stacking device, wherein the supporting device comprises a supporting assembly and a heating assembly; the conveying device comprises a drive assembly, a first feeding assembly and a second feeding assembly; the cutting device comprises a power assembly and a cutting assembly; and the stacking device comprises a lifting assembly and a stacking assembly. According to the drying, cutting and stacking integration device for paper cup production provided by theinvention, when drying, cutting and stacking operations need to be carried out during the paper cup primary processing process, the second feeding assembly is used for feeding a paperboard of a papercup body, the first feeding assembly is used for feeding patterns on the outer side wall of the paper cup, the heating assembly is used for heating and pasting the paper cup and the patterns, the power assembly is used for driving the cutting assembly to accurately cut the paperboard, and cut paper sheets are stacked through the stacking assembly after cutting, so that the whole process is automatically carried out, and the efficiency is greatly improved.

Owner:江西盛峰日用品有限公司

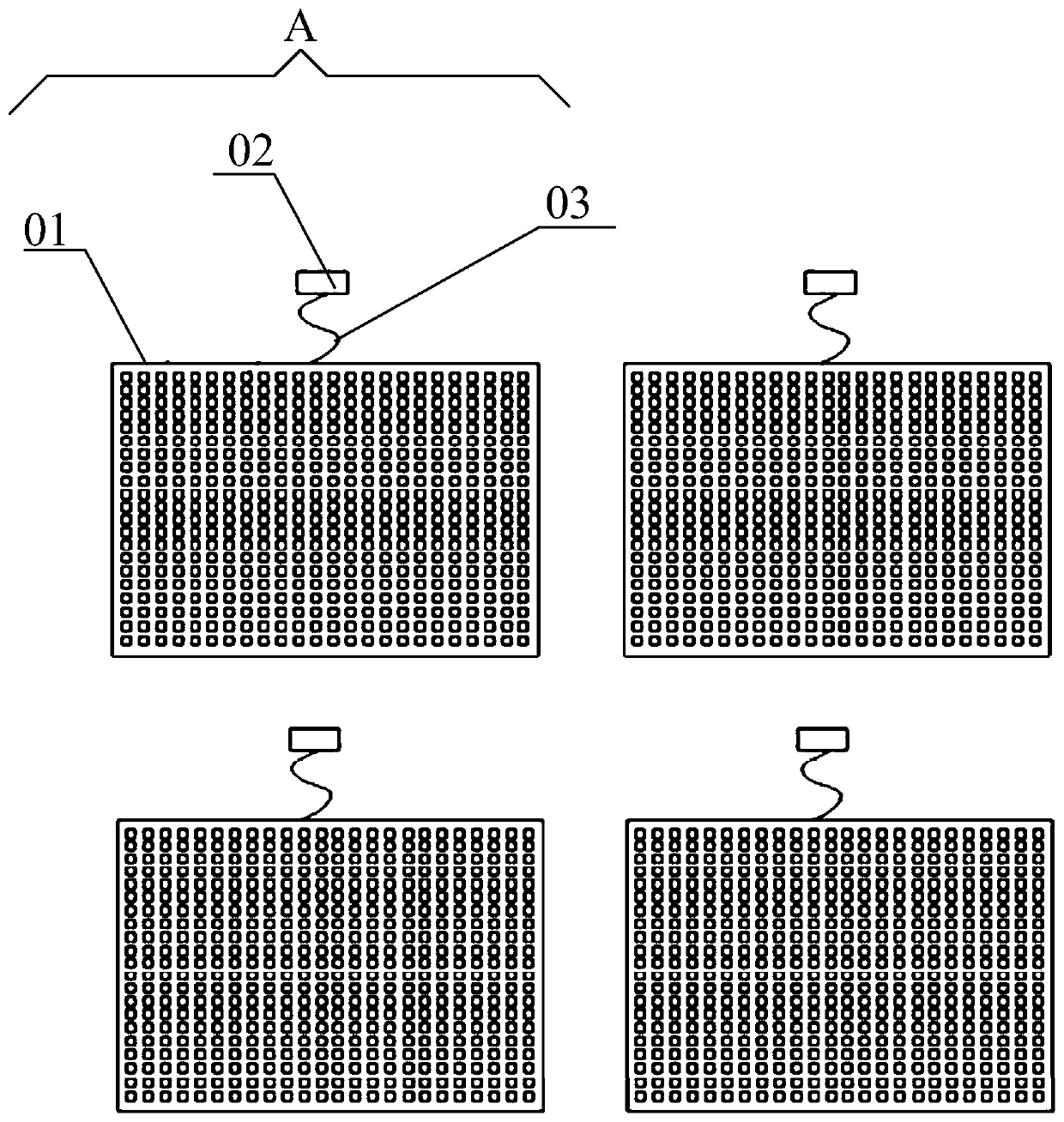

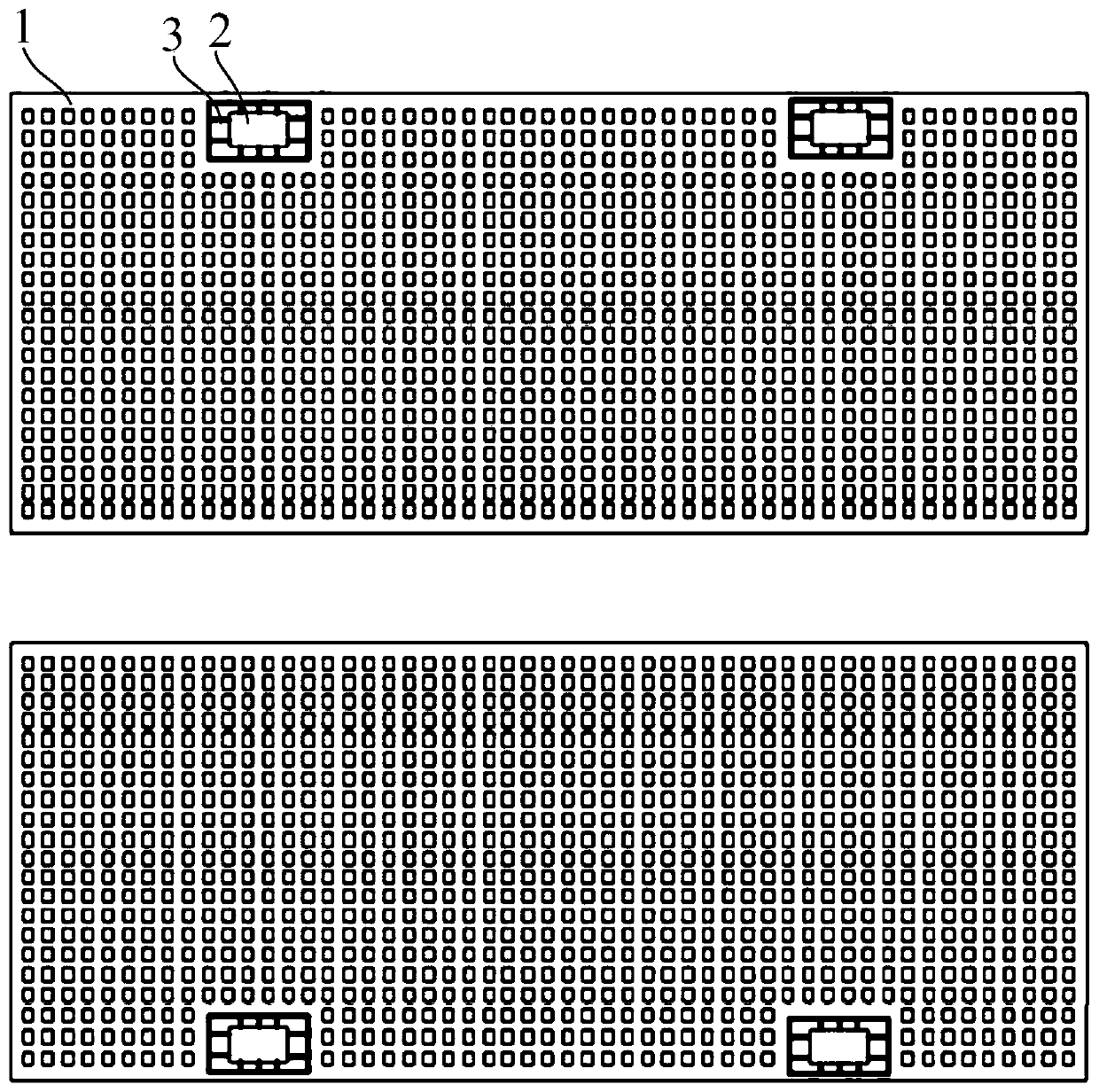

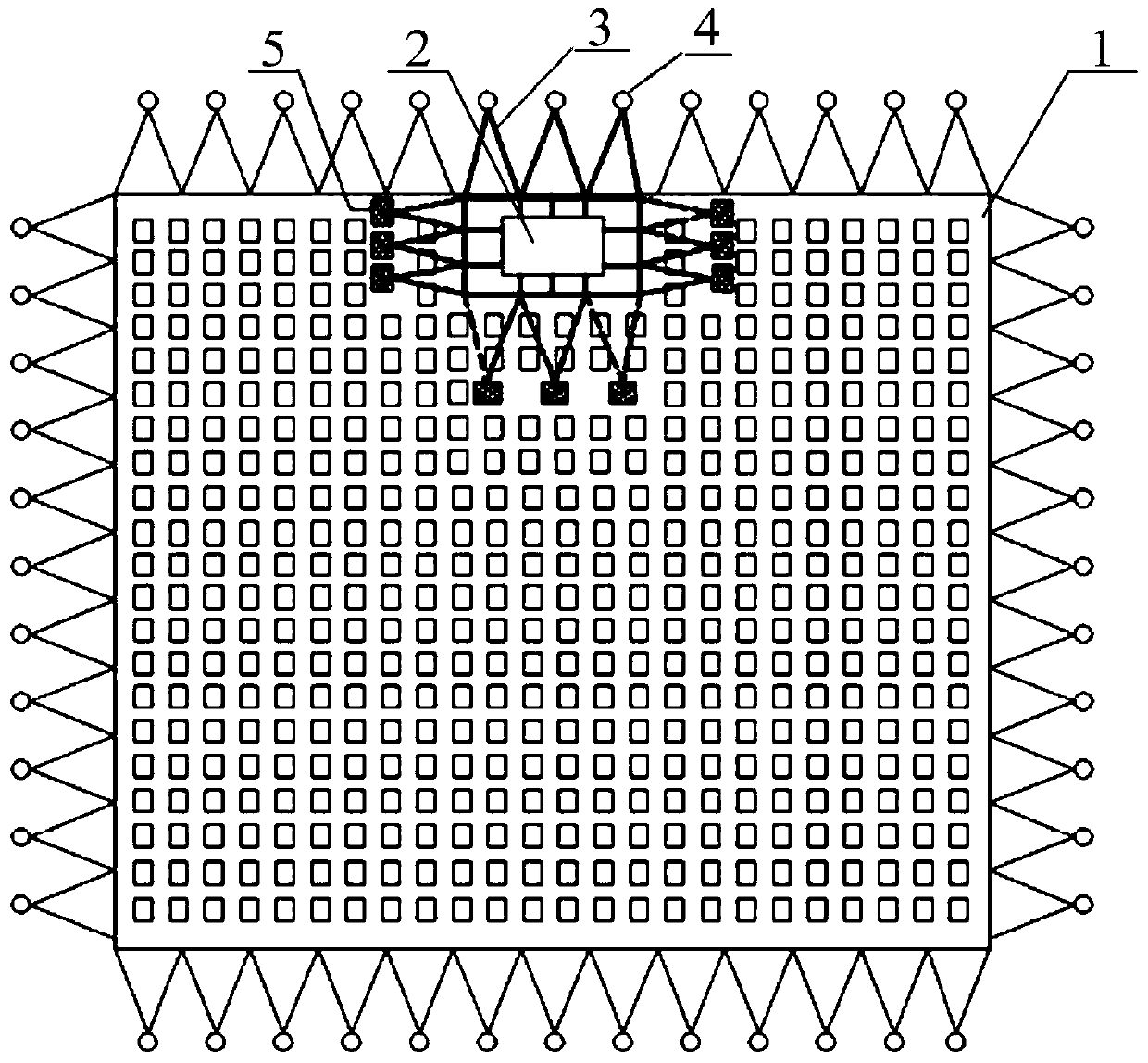

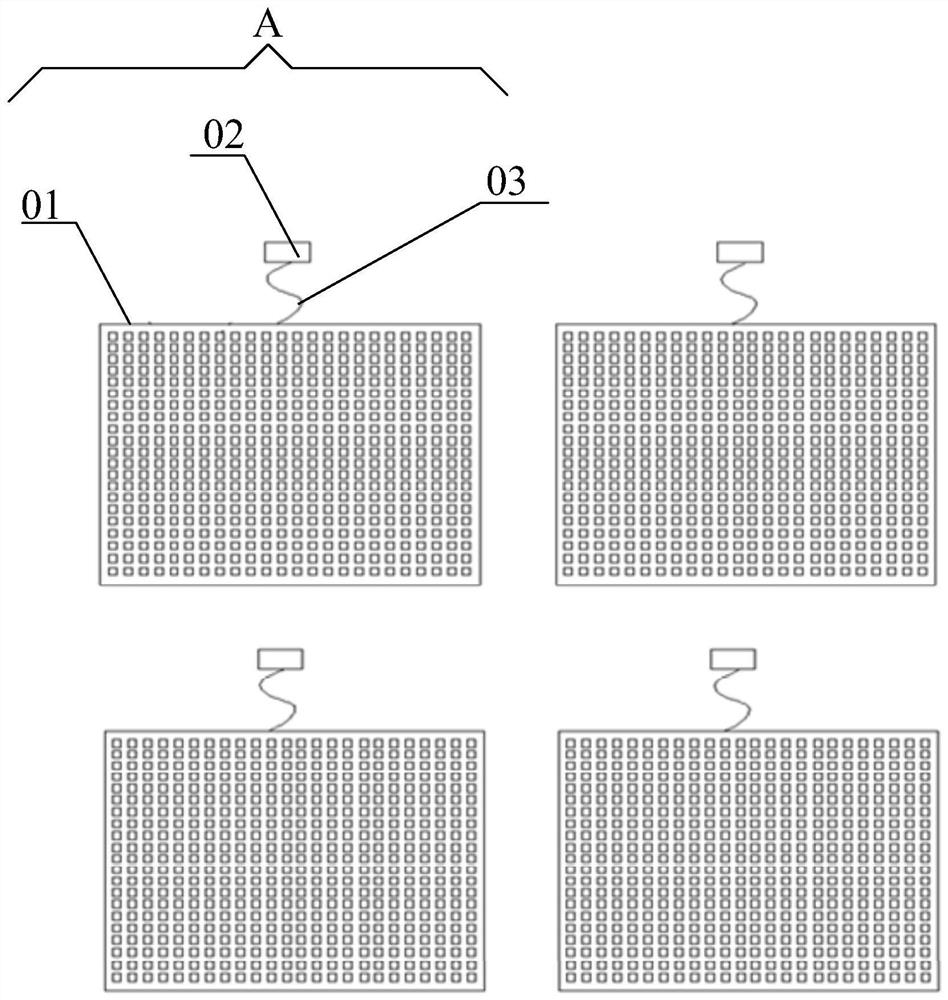

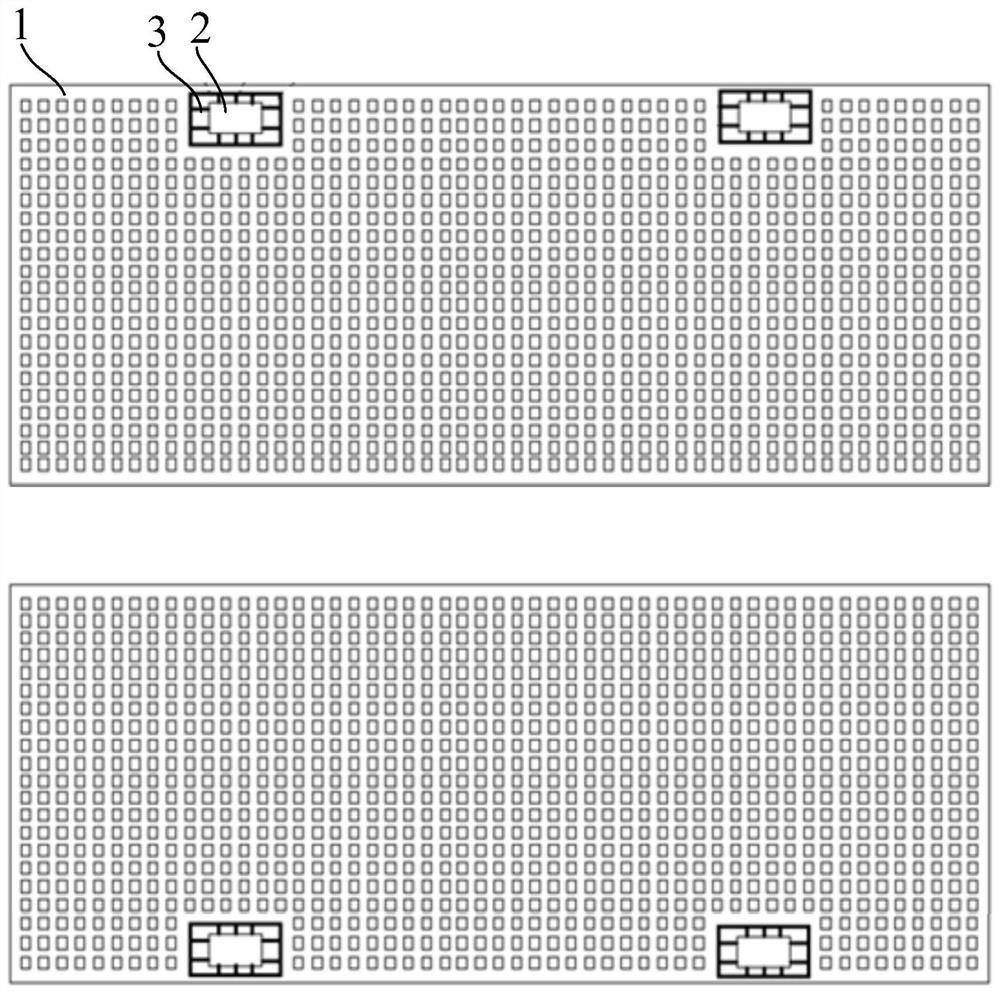

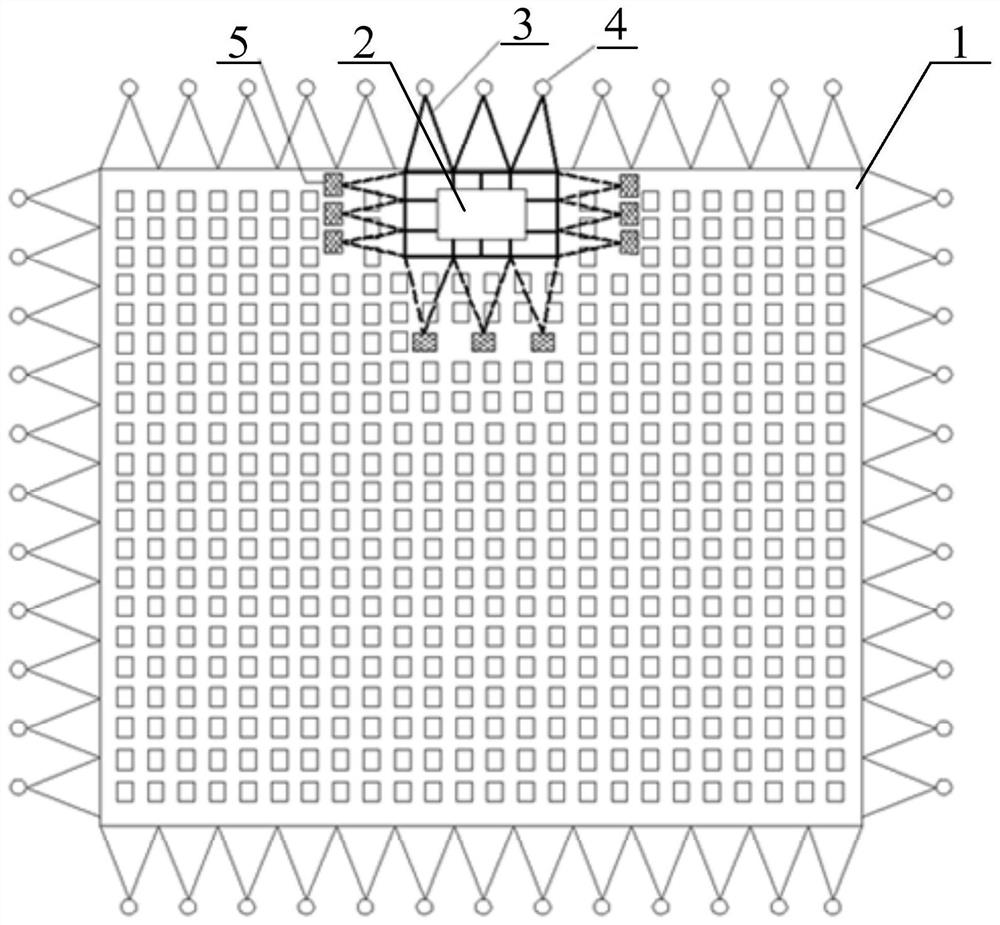

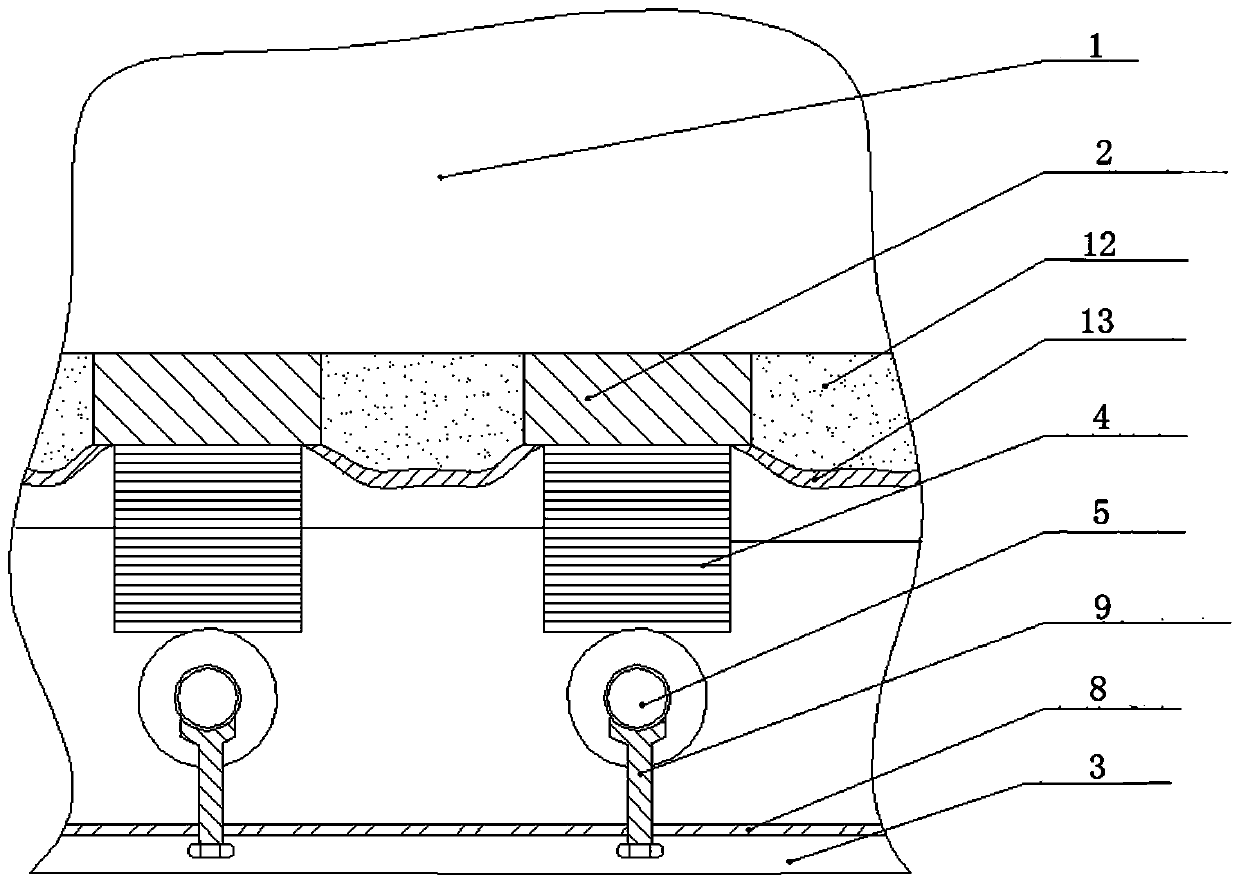

Floating type photovoltaic power station and position adjusting method of floating platform and photovoltaic floating body square array of floating type photovoltaic power station

ActiveCN110304210AGuaranteed to be relatively fixedIncrease profitFloating buildingsAnchoring arrangementsSquare arrayPhotovoltaic power station

The invention relates to a floating type photovoltaic power station. The floating type photovoltaic power station comprises a photovoltaic floating body square matrix used for installing a photovoltaic module and a floating platform used for installing an inverter boosting device, wherein the floating platform is arranged in the photovoltaic floating body square matrix, the floating platform and the photovoltaic floating body square matrix are correspondingly and independently arranged on the water bottom through mooring cables, or the floating platform and the photovoltaic floating body square matrix are connected to form a combination body through mooring cables, and the combined system is arranged on the water bottom. According to the floating type photovoltaic power station, the relative fixation between the floating platform and the photovoltaic floating body square matrix is guaranteed, and mutual collision between the floating platform and the photovoltaic floating body square matrix is avoided; and on the other hand, the distance between two adjacent photovoltaic floating body matrixes in the same water area can be effectively reduced, so that the water utilization rate iseffectively improved.

Owner:HEFEI SUNGROW RENEWABLE ENERGY SCI & TECH CO LTD

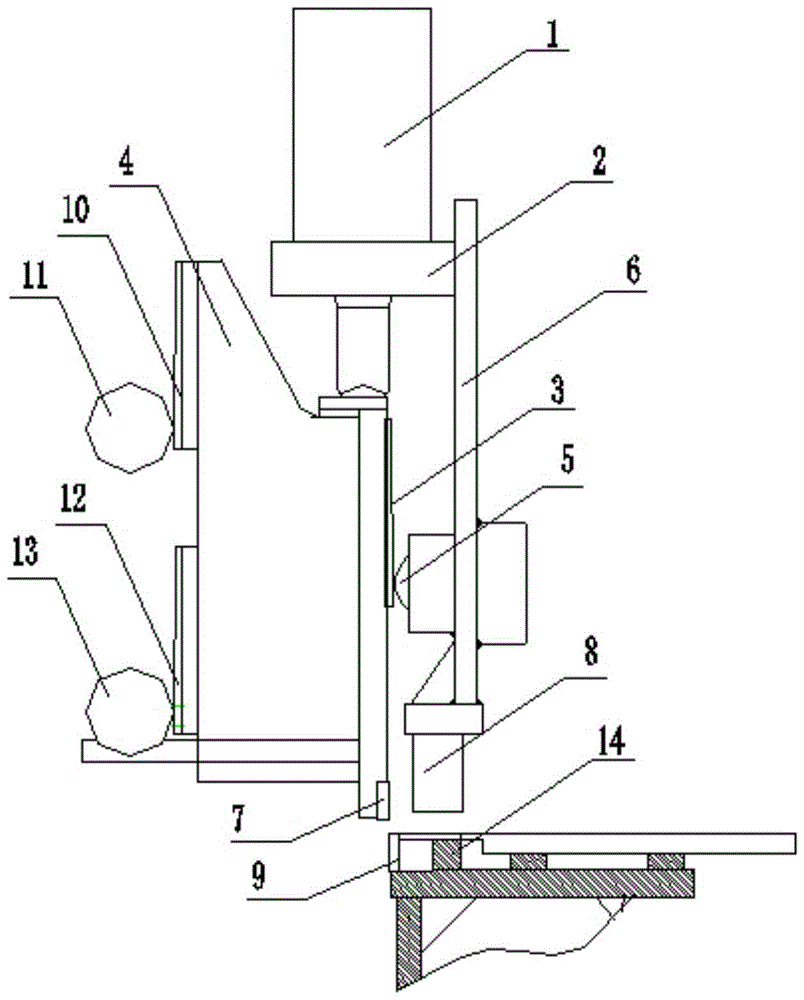

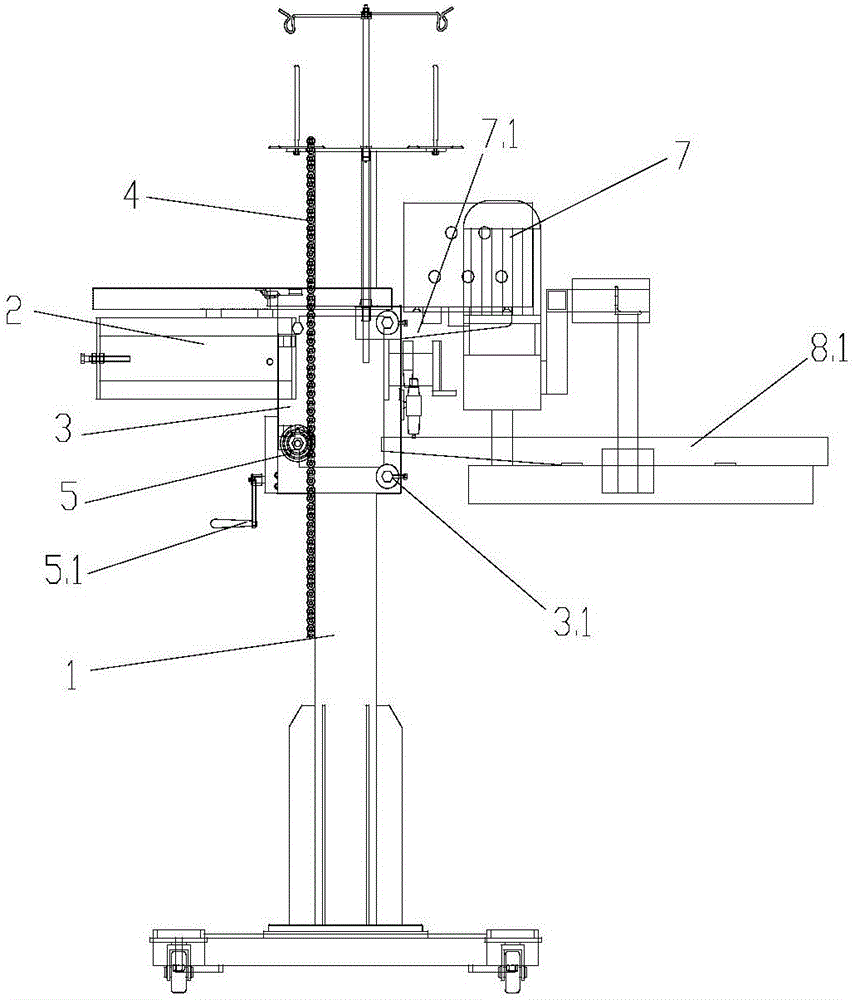

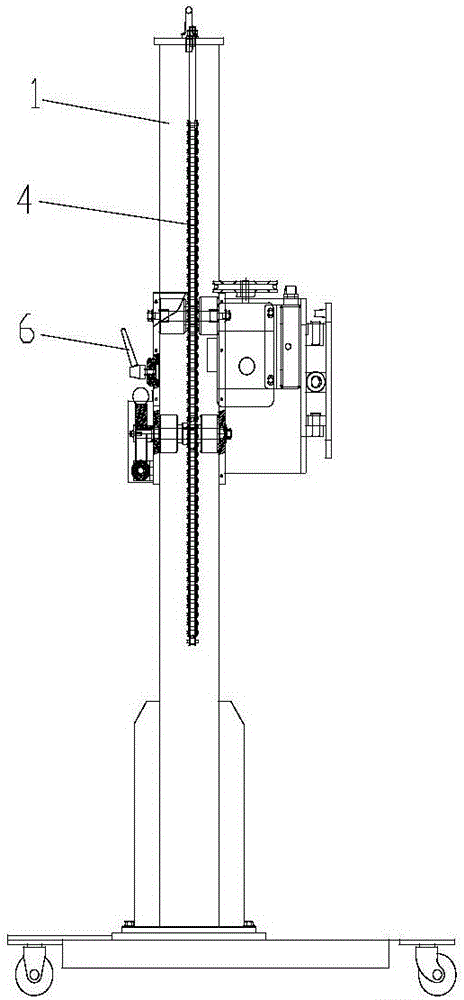

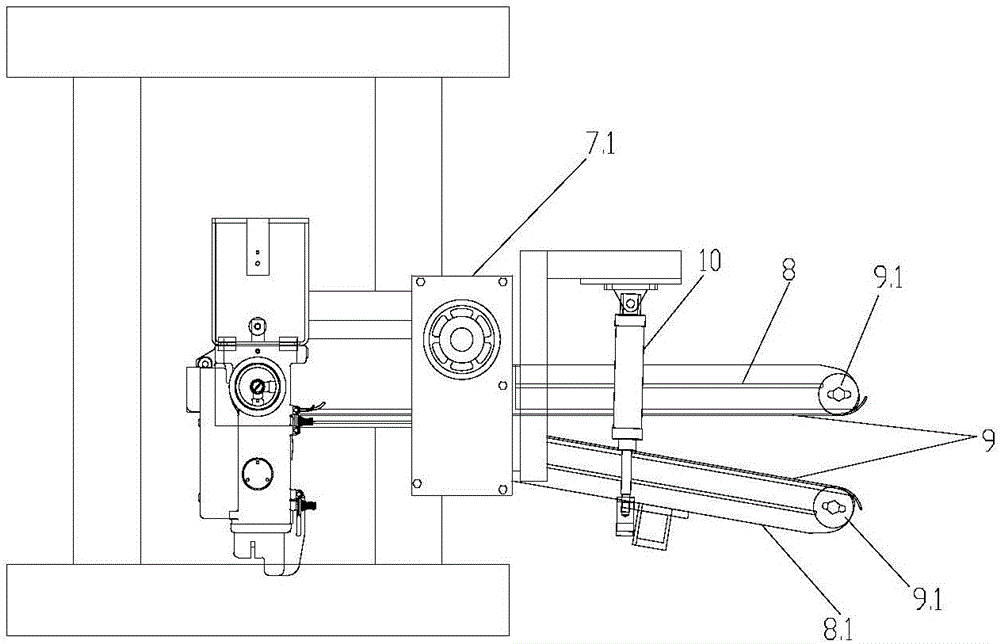

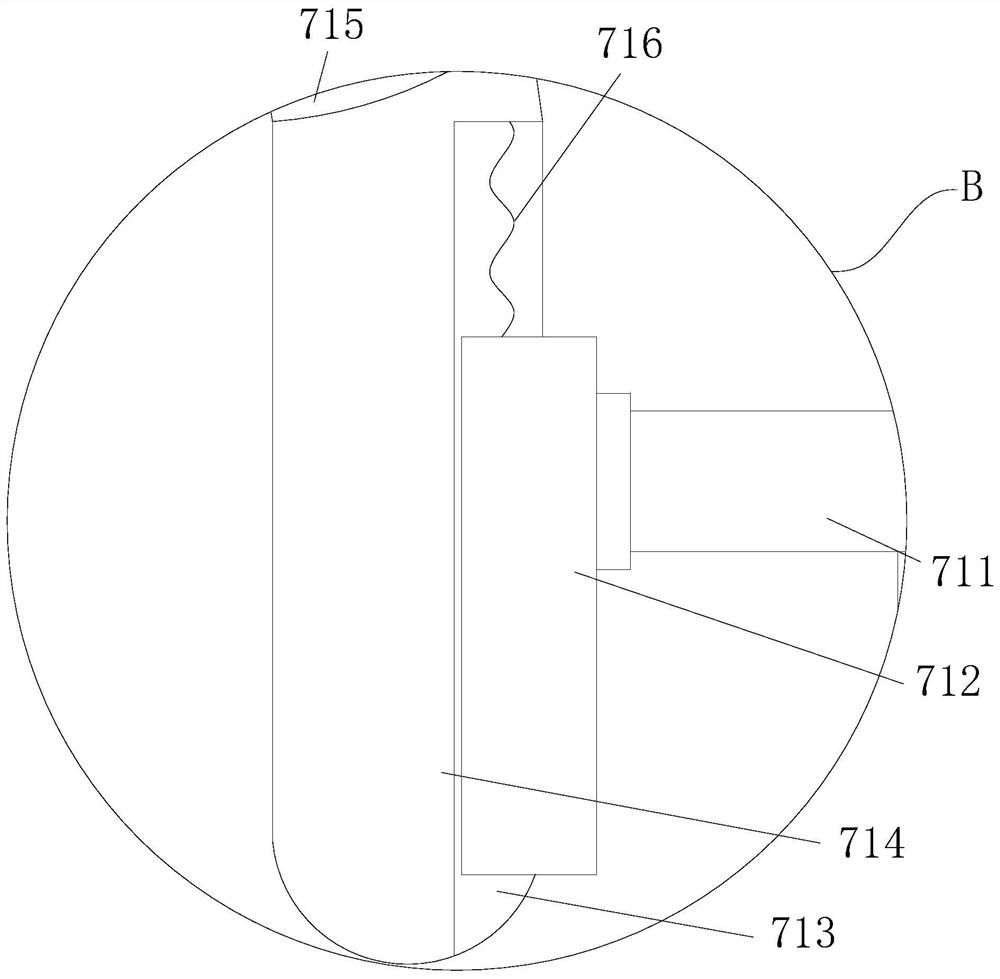

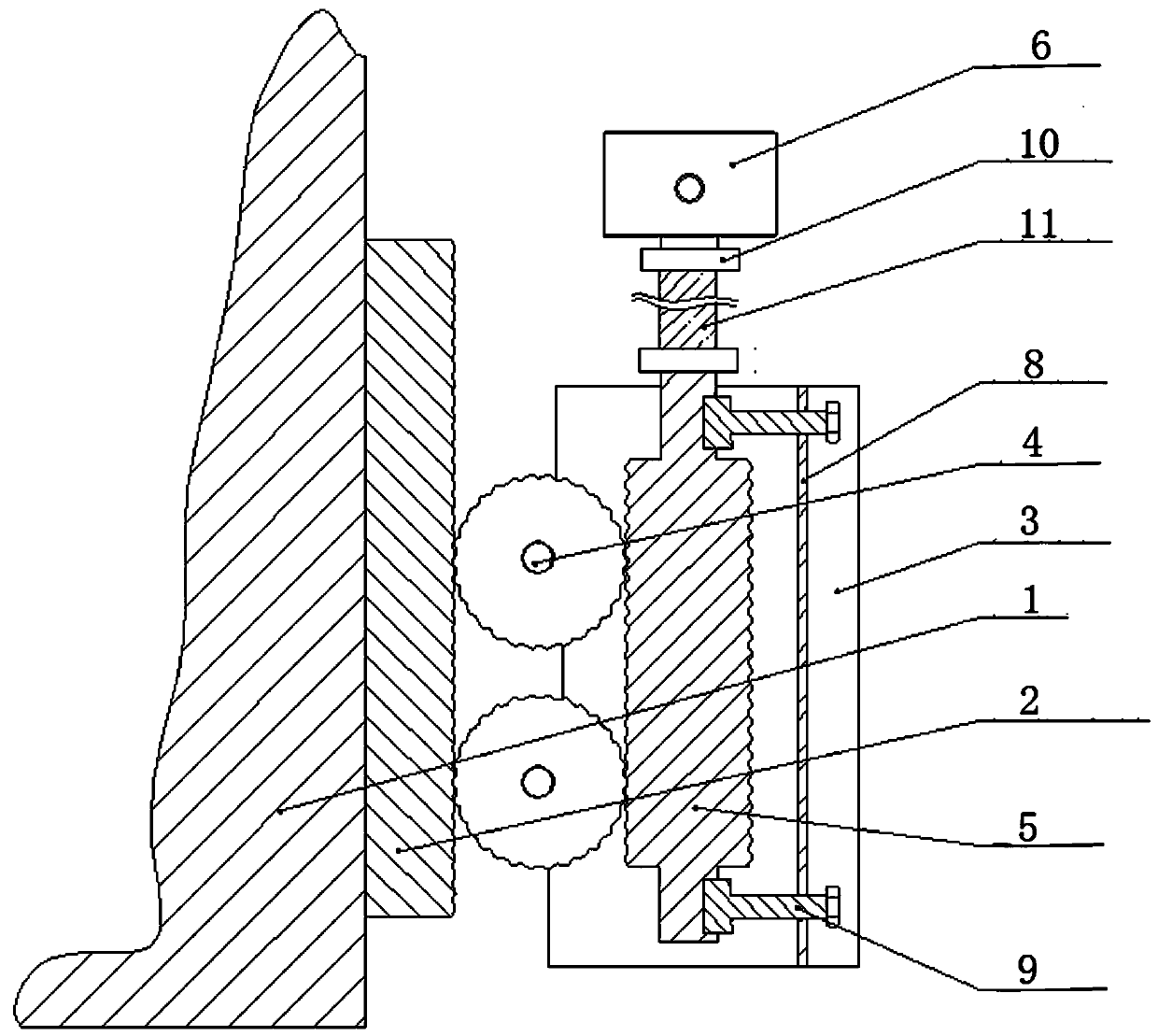

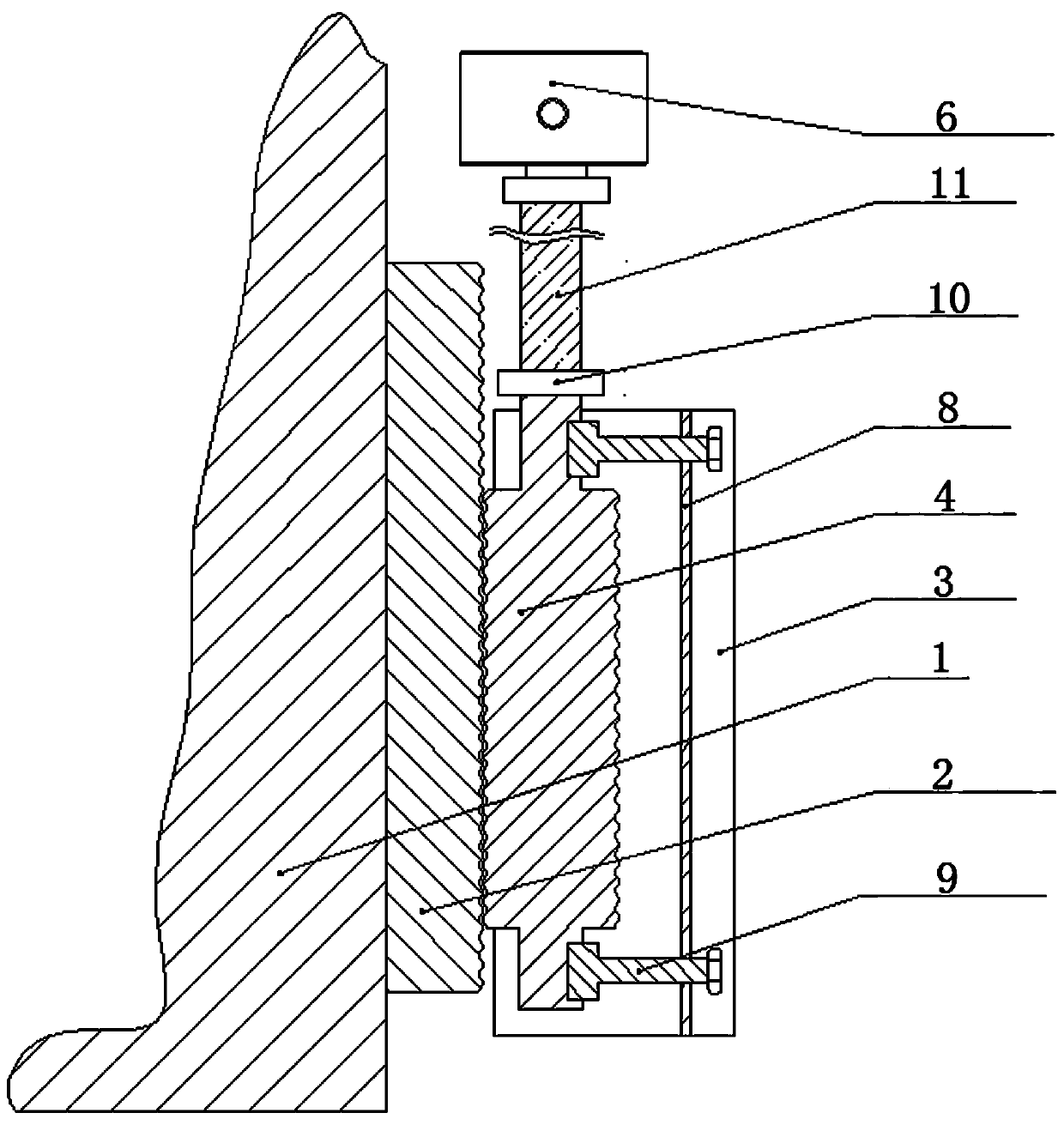

Automatic traction bag-sewing machine with adjustable height

InactiveCN106428804AEasy height adjustmentGood effectWrapper twisting/gatheringLocking mechanismEngineering

The invention belongs to the technical field of bag-sewing machine and particularly relates to an automatic traction bag-sewing machine with adjustable height. The automatic traction bag-sewing machine with adjustable height comprises a column and a bag-sewing machine which is arranged on the column. The bag-sewing machine is movably connected with the column by a fixing part. The column is sleeved with the fixing part. Both sides of the fixing part are provided with rollers which have contact with the side of the column. The up and down directions of the column are provided with chains. The corresponding fixing part is provided with a chain wheel which is engaged with the chain. The fixing part is provided with a rocking handle. The rocking handle is connected with the chain wheel by a transmission mechanism. A locking mechanism is arranged between the fixing part and the column. A traction mechanism is arranged at the front end of the bag-sewing machine, which facilitates the adjustment of the bag-sewing machine height. The automatic traction bag-sewing machine with adjustable height is simple in structure and automatic traction woven bags can greatly improve the quality of sewing bags.

Owner:常州新峰农业发展有限公司

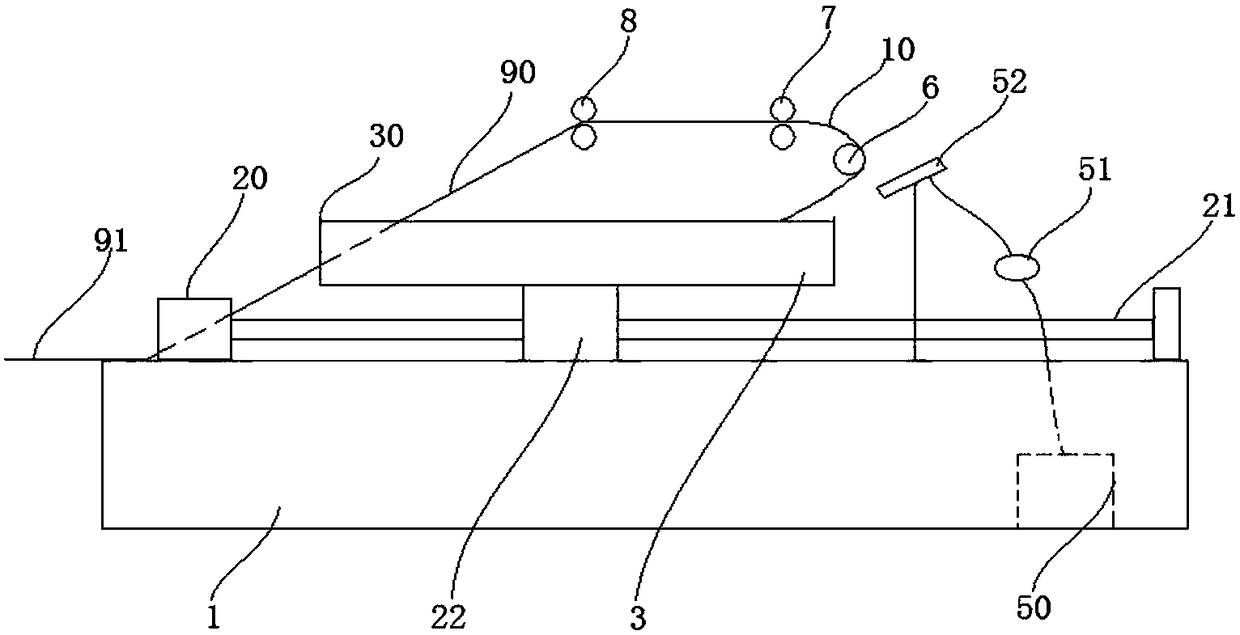

Stripping device for polarizer

PendingCN108248192AReduce damageFacilitate strippingLamination ancillary operationsLaminationSolventPolarizer

The invention provides a stripping device for a polarizer. The device comprises a base seat, a screw rod drive mechanism, a base plate carrying platform, a spraying mechanism, a guiding roller, a first roller assembly, a second roller assembly and a material falling platform; the screw rod drive mechanism is arranged on the base seat, and the screw rod drive mechanism comprises a motor, a screw rod connected to the output shaft of the motor, and a slide block which sleeves the screw rod and is in threaded connection with the screw rod; the base plate carrying platform is fixed on the top surface of the slide block; the spraying mechanism is arranged on the base seat through a support; the guiding roller is arranged on the base seat; the first roller assembly is arranged on the base seat through a first supporting frame; the second roller assembly is arranged on the base seat through a second supporting frame; and the material falling platform comprises an inclined section and a horizontal section arranged at the lower end of the inclined section, and the top of the inclined section is flush with the tangent place of two rollers of the second roller assembly. According to the device provided by the invention, in the process of stripping the polarizer by the first roller assembly, the base plate carrying platform performs synchronous motion, so that damage to the polarizer and abase plate is reduced to the minimum extent; and spraying of a solvent facilitates stripping of the polarizer in the stripping process.

Owner:CHONGQING ZHONGGUANGDIAN DISPLAY TECH CO LTD

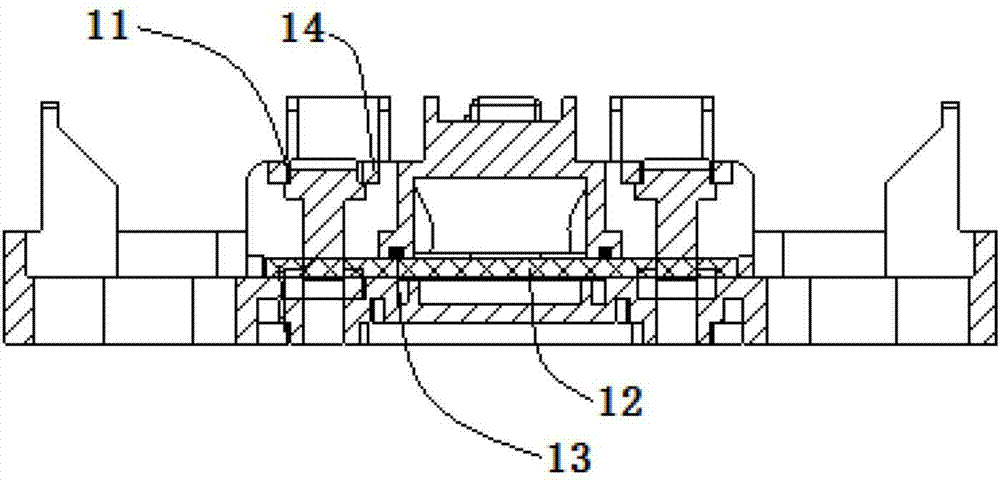

Bearing fixing device for children detection in radiology department

InactiveCN112089435AAvoid shakingDetection process impactPatient positioning for diagnosticsEngineeringMechanical engineering

The invention relates to a bearing fixing device for children detection in radiology department. The device comprises a supporting frame and a supporting base, the supporting frame is fixedly arrangedon the upper end face of the supporting base, an upper bearing plate is arranged in the supporting frame, a rubber pad is fixedly arranged on the upper end face of the upper bearing plate, and a plurality of first supporting springs are fixedly connected to the lower end face of the upper bearing plate. According to the device, combined structures of rectangular clamping fixing plates and arc-shaped clamping fixing plates are arranged on the two sides of the upper bearing plate, and the combined structures are used for fixing a baby from the two sides as much as possible so that the baby canbe prevented from shaking in the detection process; and when the fixing assembly is arranged, the baby is fixed from the two sides, so that the position right above the baby is not blocked, and the detection process cannot be influenced.

Owner:刘贵芳

Method for nanopore RNA characterisation

ActiveUS20200063199A1Improve abilitiesImprove efficiencyHydrolasesMicrobiological testing/measurementNucleotideHelicase

The invention relates to a new method of characterising a target RNA polynucleotide by taking one or more measurements as the target RNA polynucleotide moves with respect to a transmembrane pore. The movement is controlled by a DNA helicase. The invention also relates to a modified RNA construct wherein the RNA polynucleotide has been modified to increase DNA helicase binding thereto.

Owner:OXFORD NANOPORE TECH LTD

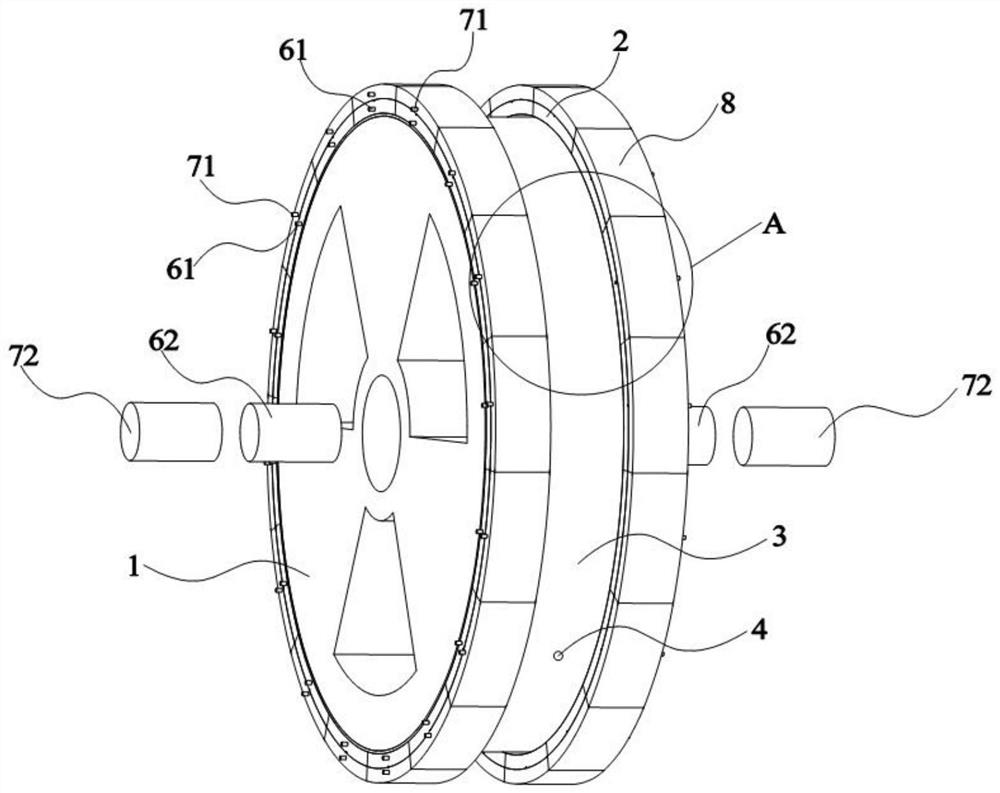

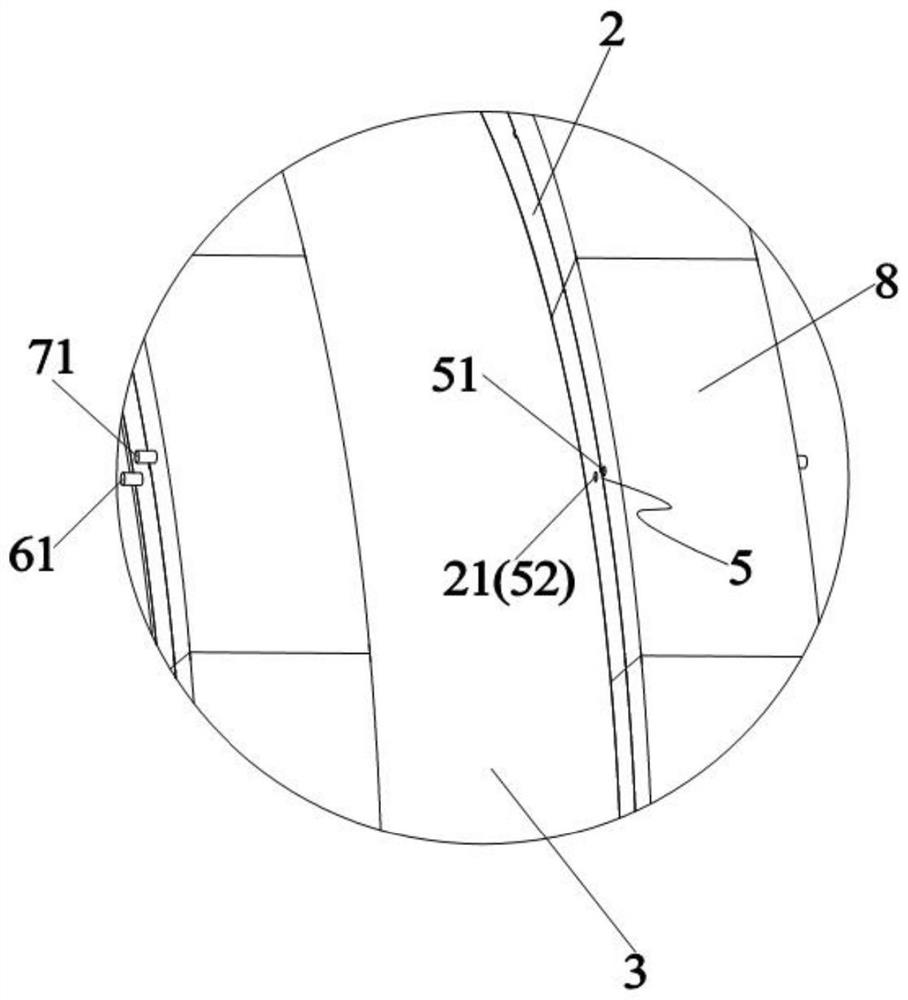

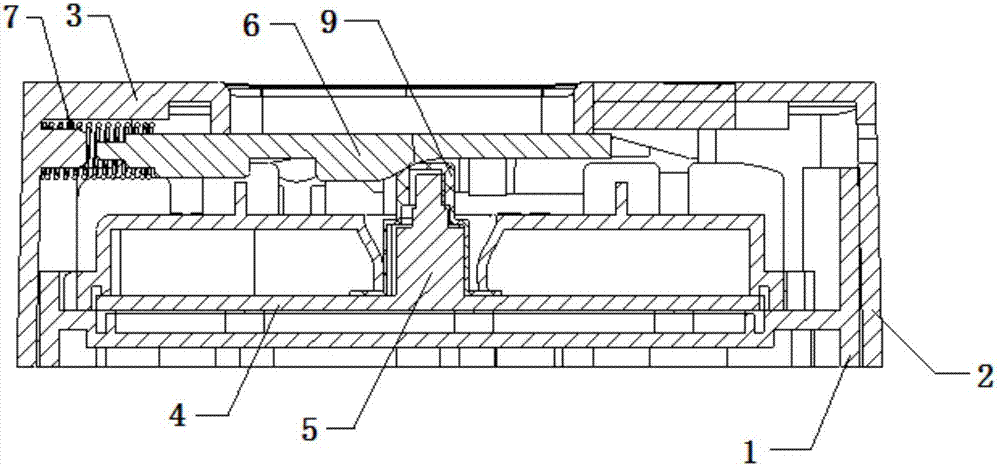

Control system and control method for die wheel

ActiveCN112245114AAvoid disassemblyPrevent overflowAbsorbent padsBaby linensControl systemControl engineering

The invention discloses a control system and control method for a die wheel. Two sides of the die wheel are each provided with a plurality of die shoes; a forming cavity for a cotton core is formed between the die shoes at the two sides; the control system comprises a width detecting device, a depth detecting device, a width adjusting device and a depth adjusting device, wherein the width detecting device detects the forming width of the cotton core; the depth detecting device detects the forming depth of the cotton core in the forming cavity; the width adjusting device correspondingly adjuststhe die shoes according to the detection signal of the width detecting device so as to adjust the width of the forming cavity; and the depth adjusting device correspondingly adjusts the die shoes according to the detection signal of the depth detecting device so as to adjust the depth of the forming cavity to further adjust the forming thickness of the cotton core. According to the control system, the width of the forming cavity is automatically adjusted by detecting the forming width of the cotton core so as to adapt to forming of cotton cores different in width, so that the die wheel is prevented from being disassembled; the depth of the forming cavity is adjusted by adjusting the die shoes so as to adapt to forming of the cotton cores different in thickness, and the depth of the forming cavity is automatically adjusted by detecting the forming thickness of the cotton core, so that not only is the die wheel prevented from being disassembled, but also overflowing of filler of the cotton core is avoided.

Owner:福建亿发卫生用品有限公司

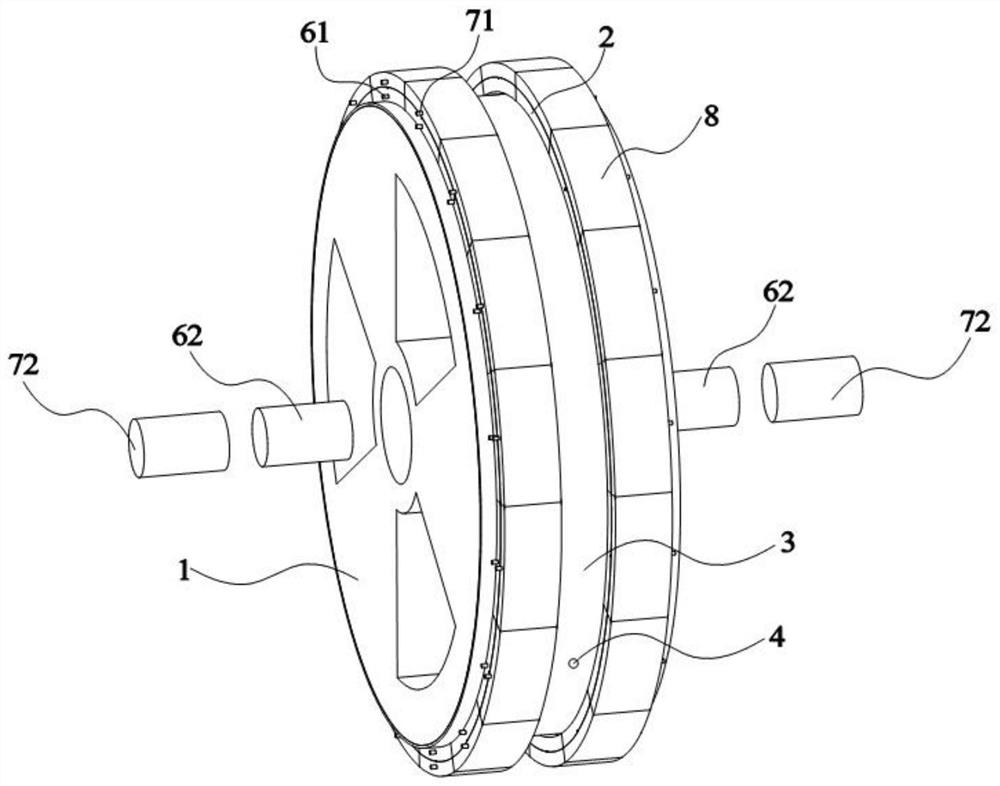

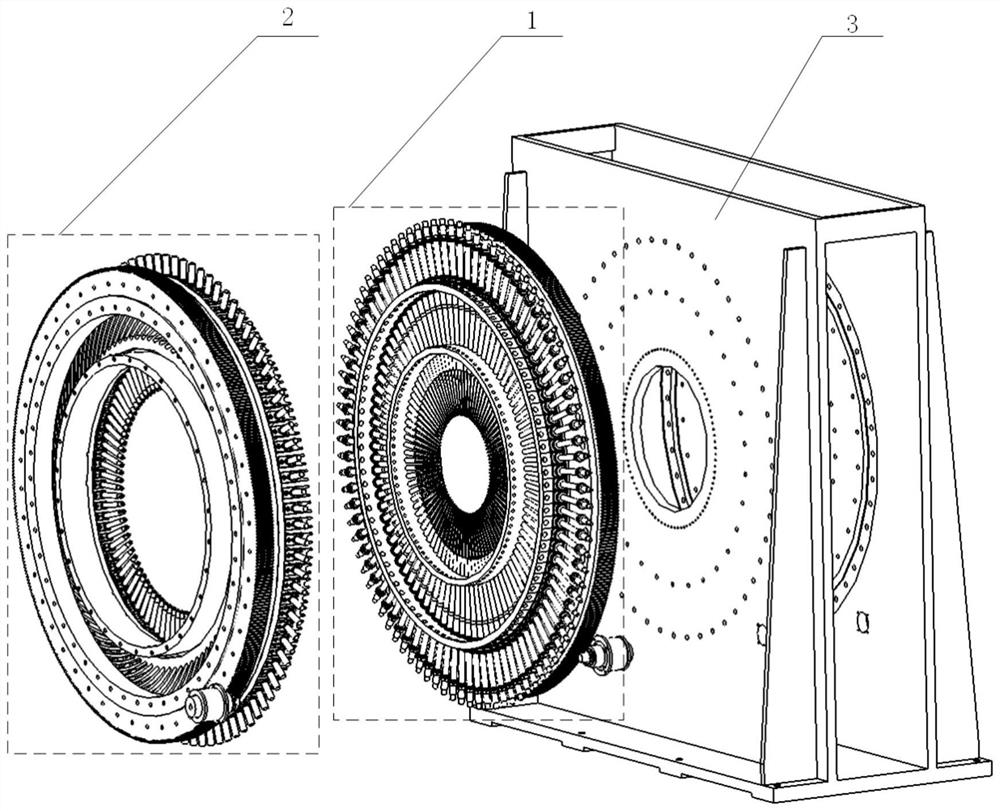

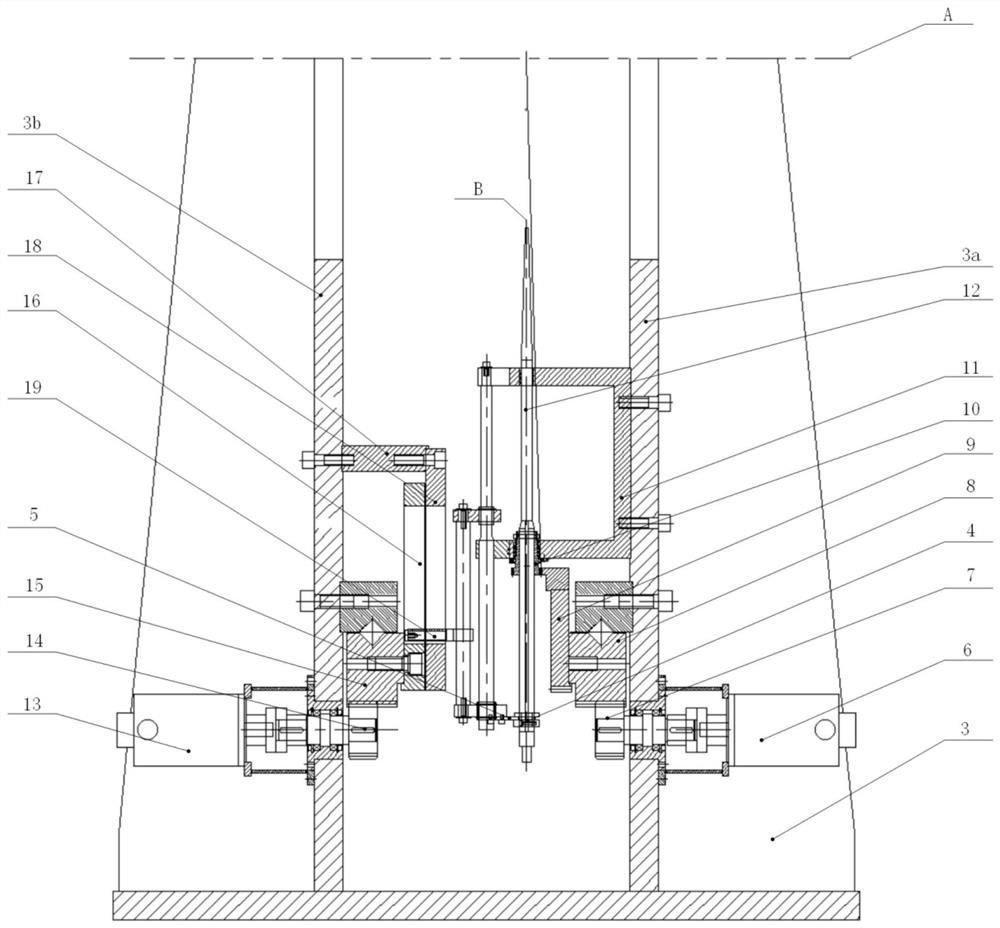

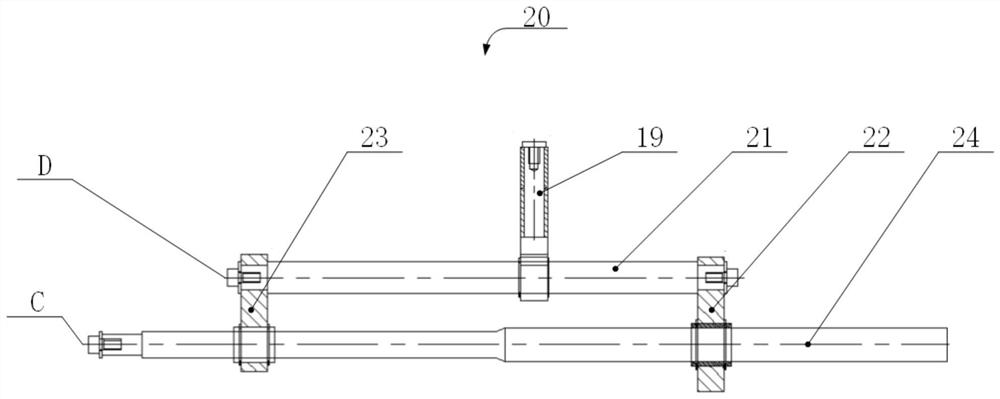

Novel multi-bundle fiber spiral winding equipment

The invention belongs to the technical field of fiber winding equipment, and particularly relates to novel multi-bundle fiber spiral winding equipment. A rotating system is mounted on the outer side of a right rack through a bolt, a radial moving system is mounted on the outer side of a left rack through a bolt, and the rotating system is connected with a shifting fork of the radial moving system through a notch of a hoop. According to the novel multi-bundle fiber spiral winding equipment, bevel gears, which are evenly distributed on the circumference, are driven through a gear disc in a meshed mode, so as to guarantee that rotating angles transmitted to a yarn guide pipe are synchronous; a spiral disc notch and a guide disc notch are combined, a spiral disc is rotated, and therefore, it is guaranteed that the yarn guide pipes conduct radial movement synchronously at the same time; through joint control of a rotary driving system and the radial moving system, it is guaranteed that the yarn guide pipes evenly distributed in the circumferential direction move consistently. The existing single-bundle or few-bundle fiber winding process is broken through, single-layer synchronous winding is realized, and the winding efficiency is improved; and the phenomenon of fiber crossing caused by single-bundle winding is avoided, so that the phenomenon of stress concentration is greatly reduced.

Owner:TAIYUAN UNIV OF TECH

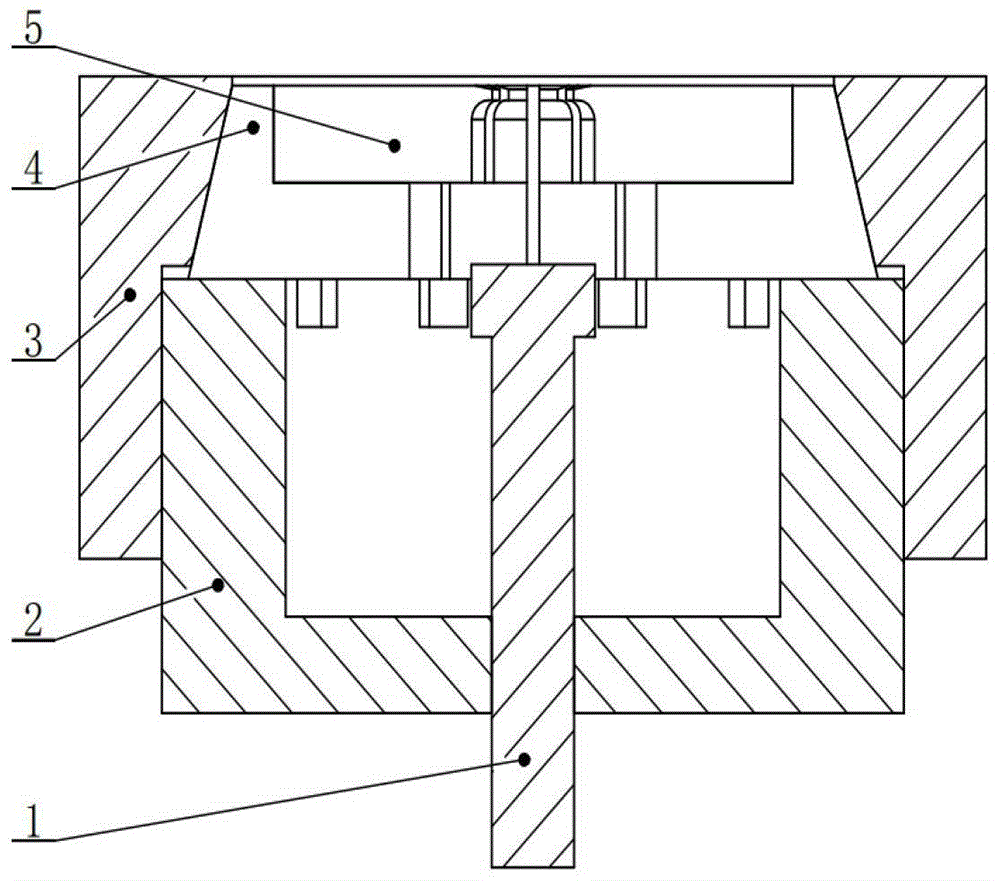

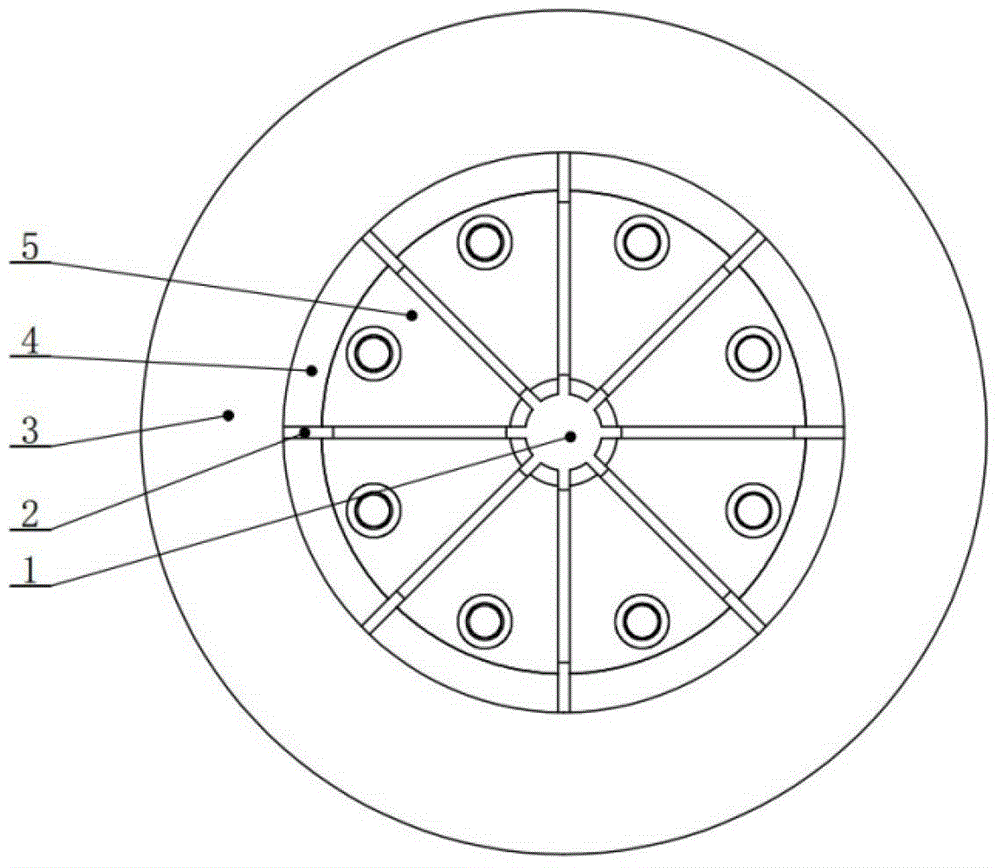

Novel fastening connection method and device for sacrificial anode assembly

The invention relates to a novel fastening connection method and device for sacrificial anode assembly. According to the novel fastening connection method and the novel fastening connection device, a sacrificial anode to be assembled is placed on a location block, a support block is fixed on an equipment base, a slide sleeve sleeves the support block and is capable of moving up and down, the slide sleeve moves up and down so that a die sleeve performs a tightening movement or a releasing movement along a radial direction, and a die is driven to perform a tightening movement or a releasing movement along the radial direction, so as to fasten the sacrificial anode placed on the location block. According to the novel fastening connection method and the novel fastening connection device disclosed by the invention, a hydraulic pressure or an air pressure is used as a power for pushing the die sleeve to move up and down, and thus the movements of eight petals of fastening dies with the same structure are the same, the fastening forces are the same, the deformations of the fastened elements are uniform, and the connection is firm; adjustments for a fastening tightening amount and a fastening releasing amount are realized through the stroke changes of the slide sleeve, the fastening dies are replaceable, and various fastening connection requirements on the anode bar of the sacrificial anode, and a screw, a nut as well as other forms of connection shafts can be realized.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

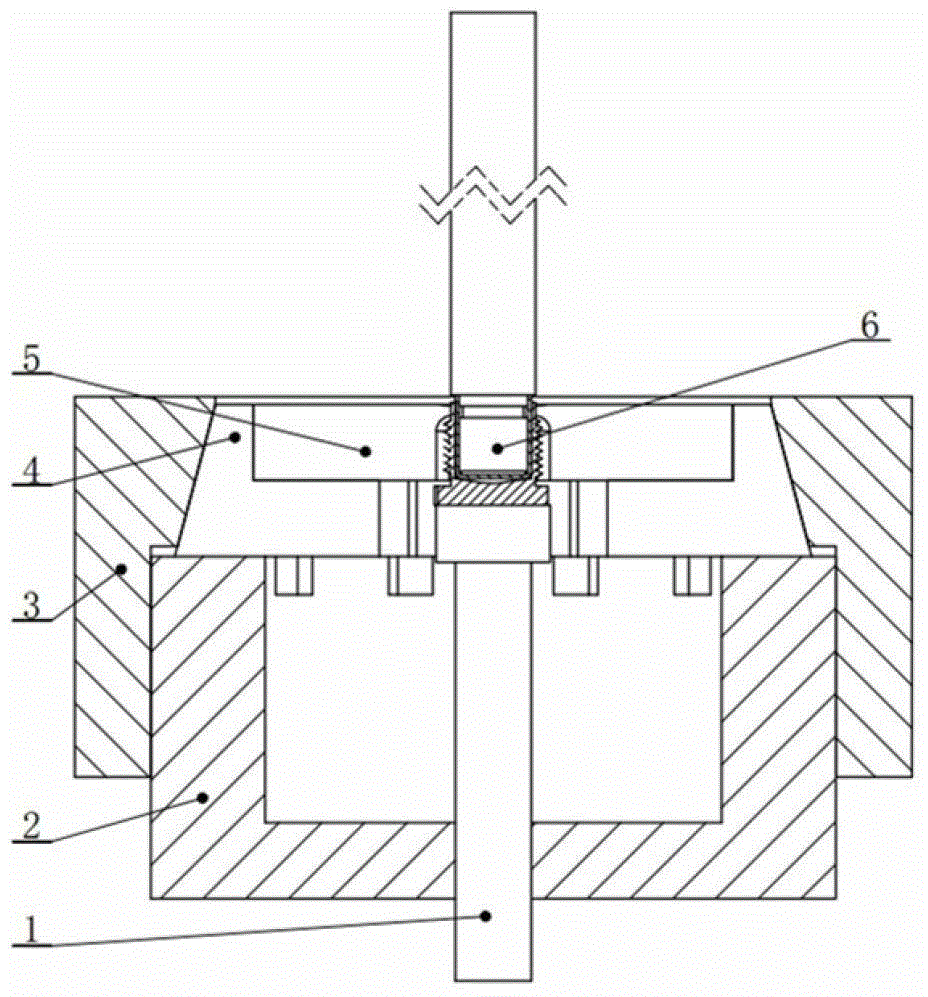

Novel direct opening type injection molding machine synchronous hooping device

PendingCN111993650ARealize opening and closing movementConsistent movementStructural engineeringMachine

The invention discloses a novel direct opening type injection molding machine synchronous hooping device. The problems that in the prior art, a hooping device in an injection molding machine cannot besynchronous, consequently, a die is damaged and noise is generated are solved. The novel direct opening type injection molding machine synchronous hooping device comprises a movable die plate, a pullrod, a hooping device and a synchronous device. Due to the fact that sliding grooves are formed in the inner side of a pull rod hole, two semi-hooping nuts can only move in the opening direction of the sliding grooves due to sliding blocks, meanwhile, a synchronous rotary disc is arranged so that the two semi-hooping nuts can be driven to move synchronously, various kinds of damage and noise generated when synchronization is not conducted are prevented, the two semi-hooping nuts are arranged in the pull rod hole, the length of a pull rod can be shortened, and therefore the length of the wholemachine is shortened; and when the two semi-hooping nuts are used for hooping the pull rod, the two semi-hooping nuts are fixed to the pull rod under the cooperation of protrusions and grooves, and the hooping effect of the two semi-hooping nuts is better.

Owner:HAITIAN PLASTICS MACHINERY GRP

Display system

ActiveUS9220177B2Reduce displayReduce weightMechanical apparatusDashboard fitting arrangementsLeft directionEngineering

A display system includes a display panel that displays information and a movement apparatus that moves the display panel. The movement apparatus includes: a slide mechanism configured to move the display panel linearly relative to a base chassis; a right-and-left tilt mechanism configured to change an angle of a display surface of the display panel in a right-and-left direction; an up-and-down tilt mechanism configured to change an angle of the display surface of the display panel in an up-and-down direction; and a rotation mechanism configured to rotate the display panel on a rotation axis orthogonal to the display surface of the display panel.

Owner:FUJITSU GENERAL LTD

Position adjustment method of floating photovoltaic power station and its floating platform and photovoltaic floating body square array

ActiveCN110304210BGuaranteed to be relatively fixedIncrease profitFloating buildingsAnchoring arrangementsSquare arrayPhotovoltaic power station

The invention relates to a floating photovoltaic power station, comprising a photovoltaic floating body square array for installing photovoltaic components, and a floating platform for installing inverter boosting equipment, the floating platform is arranged inside the photovoltaic floating body square array, and the The floating platform and the photovoltaic floating body square array are independently moored to the bottom of the water through mooring cables, or the floating platform and the photovoltaic floating body square array are connected by mooring cables to form a combination, and the combined system is moored at the bottom of the water. On the one hand, the floating photovoltaic power station ensures the relative fixed position between the floating platform and the photovoltaic floating body square array, and avoids the collision between the two; on the other hand, it can also make two adjacent photovoltaic floating body squares in the same water area. The distance between the arrays is effectively reduced, thereby effectively improving the water surface utilization rate.

Owner:HEFEI SUNGROW RENEWABLE ENERGY SCI & TECH CO LTD

Fishing device for soaking kidney-tonifying Chinese herbal medicine preparation and preparation method

InactiveCN112545893AConsistent movementRise steadilyPharmaceutical product form changeBiotechnologyHerbal preparations

The invention discloses a fishing device for soaking a kidney-tonifying Chinese herbal medicine preparation and a preparation method, and relates to the technical field of Chinese herbal medicine preparation devices. The fishing device for soaking the kidney-tonifying Chinese herbal medicine preparation comprises a supporting base, a pool body, a collecting mechanism and a lifting mechanism, through two steel ropes, a square box is stressed evenly and cannot deflect in the ascending process, ascending of the square box is more stable, the two steel ropes are pulled through one motor, each steel rope does not need to be provided with one motor, and electric energy is saved; in the salvaging process, workers do not need to salvage manually in batches through tools, a large number of Chineseherbal medicines can be salvaged at a time in the preparation process, salvaging efficiency can be improved, salvaging is complete, the electric push rod is arranged between the supporting plate and the L-shaped plate and located outside the pool body, and work of the electric push rod is not affected by water; and the electric push rod works more stably, and the collecting mechanism can collect the fished Chinese herbal medicines and transfer the Chinese herbal medicines to the decocting equipment, so that subsequent decocting of the Chinese herbal medicines is facilitated.

Owner:合肥坤全生物科技有限公司

Double-lever manual fire alarm button

ActiveCN107393263AAvoid enteringAvoid damageCasings/cabinets/drawers detailsAlarmsTorsion springPush-button

The invention discloses a double-lever manual fire alarm button, comprising a box, a circuit board seat fixed in the box, a circuit board fixed on the circuit board seat, a trigger switch arranged on the circuit board and an operating panel capable of controlling the trigger switch to be turned off or on, wherein the box is composed of a base, side vertical plates and an upper cover with an opening; the operating panel is of a flat plate structure, the edge of the upper surface of the operating panel is plied-up to the edge of the opening of the upper cover, one end of the operating panel presses against and is connected with the side vertical plates via compression springs, the other end of the operating panel is separated from the side vertical plates, levers are arranged on two sides of the operating panel in the length direction, one end, close to the compression spring, of each lever is connected with the side vertical plate via a torsion spring, a lug extends out of each lever, the lugs are limited to the bottom of the operating panel, and the other end of each lug is limited to the top of the operating panel. The fire alarm button has the characteristics of dust prevention, fast alarm, high safety, high reliability and the like.

Owner:JADE BIRD FIRE CO LTD

Wiring terminal convenient to operate

PendingCN114566812AQuick Wiring ActionEasy Wiring ActionCoupling device detailsClamped/spring connectionsStructural engineeringMechanical engineering

A wiring terminal convenient to operate comprises an insulating shell which is provided with an accommodating cavity; the conductive piece is arranged in the accommodating cavity, and at least part of the conductive piece extends out of the insulating shell; the elastic clamping piece is arranged in the accommodating cavity and is provided with a movable end and a fixed end; the driving guide wheel is rotationally arranged in the containing cavity, one end of the driving guide wheel abuts against the movable end of the elastic clamping piece, the other end of the driving guide wheel abuts against the fixed end of the elastic clamping piece, and a transmission part is arranged on the driving guide wheel; and the operating piece is sequentially provided with an operating end, a connecting end and a driving end, the operating end extends out of the insulating shell, and the connecting end is rotationally connected with the insulating shell. According to the invention, without the help of external tools such as a screwdriver, the insertion gap for the lead to penetrate in / out can be formed between the elastic clamping piece and the conductive piece through the operating piece and the driving guide wheel, so that the wiring action is quicker and easier, the operation difficulty is effectively reduced, and a large amount of time is saved.

Owner:慈溪市万捷电子有限公司

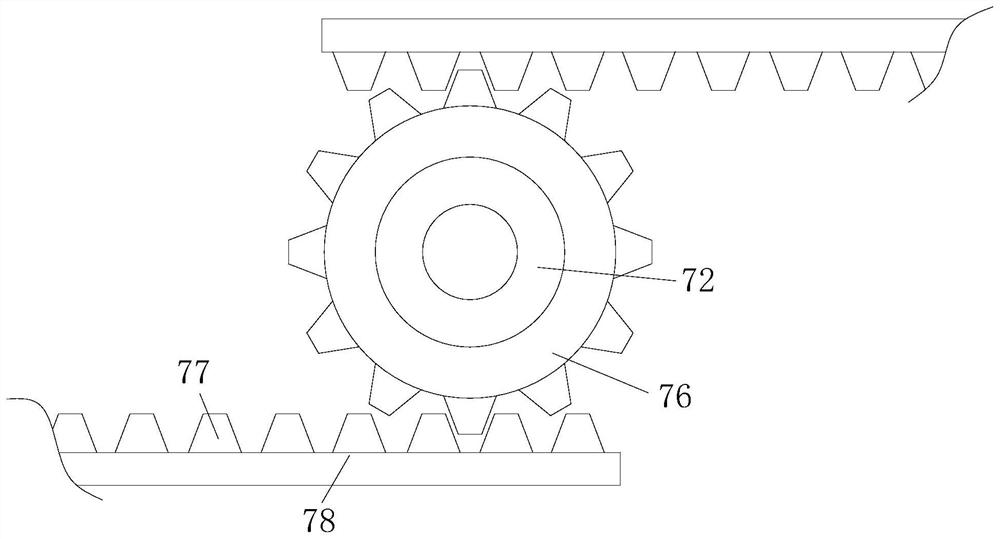

Device and method for driving anode rod to move

ActiveCN111472023AEasy to adjust individual liftingEffective adjustment and locking forceAluminium electrolysisMechanical engineering

The invention relates to the technical field of aluminium electrolysis, in particular to a device and a method for driving an anode rod to move. The device comprises at least one positive bar rack and / or at least one clamping frame; and at least one driving wheel enabling the anode rod to move up and down is arranged on any one, or any two or three of the anode rod, the clamping frame and the positive bar rack and is connected with a power mechanism to drive the anode rod and the anode to move to a designated position or to drive the anode rod to a designated position. The device enables all to-be-moved anode rods and anodes to move synchronously, so that the problem that the sparkover problem generated between the anode rods and the anodes is avoided; and when a single or part of anode rods and the anode have relative displacement, the sparkover problem generated between the anode rods and the anodes is also avoided.

Owner:党星培

Limiting structure of gear shifting pulling head

PendingCN113958706AShift positioning is clearEasy shift positioningGear lubrication/coolingGearing controlEngineeringPiston rod

The invention discloses a limiting structure of a gear shifting pulling head. The limiting structure comprises a magnet, a gear shifting shell, the gear shifting pulling head, a piston rod and a limiting partition plate, wherein the limiting partition plate is additionally arranged at the lower end of the gear shifting shell, a hollowed-out structure used for limiting is formed in the limiting partition plate, and the lower portion of the gear shifting pulling head penetrates through the hollowed-out structure. The pulling head acts stably in the gear shifting process, the pulling head is prevented from rotating and shaking, and the gear shifting function failure of a gear shifting executing mechanism is avoided. The limiting partition plate is convenient to disassemble and high in adaptability, adaptive development can be made according to the shapes and the number of the gear shifting pulling heads, and meanwhile normal work of the pulling heads of different shapes and numbers is met. The limiting partition plate separates splashing lubricating oil liquid from the magnet on the pulling head, so that the magnet is prevented from adsorbing scrap iron in the oil liquid, the measurement precision is guaranteed, and the problems that gear shifting is not accurate enough, the measurement precision is reduced or even fails due to the fact that the magnet on the pulling head adsorbs the scrap iron in the oil liquid due to magnetism, and a sensor breaks down are solved.

Owner:SHAANXI FAST GEAR CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com