Stirrer capable preventing material from sedimentation

A technology of agitators and materials, which is applied in the directions of mixer accessories, mixers with rotary mixing devices, chemical instruments and methods, etc., can solve the problems of difficulty in cleaning, increase labor intensity, reduce utilization rate, etc., and achieve lower labor intensity. , improve the effect, avoid the effect of cleaning work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

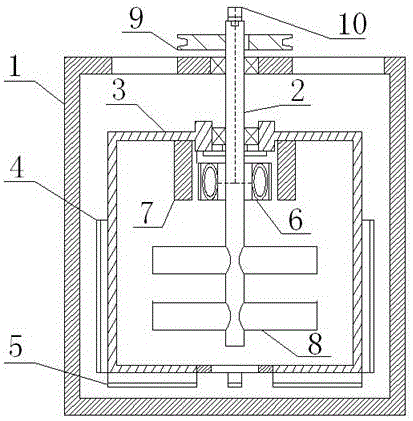

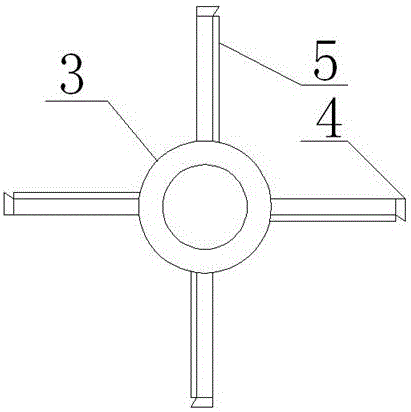

[0019] Such as figure 1 , figure 2 As shown, a stirrer for preventing material deposition, the extension end of the stirring shaft 2 extends into the interior of the barrel body 1, the extension end is located outside the barrel body 1, and the extension end and the extension end of the stirring shaft 2 pass through The bearing is connected to the barrel body 1 in rotation. The vertical scraper 4 and the horizontal scraper 5 are fixedly connected to the scraper frame 3 by bolts. The vertical scraper 4 and the horizontal scraper 5 are strip-shaped scrapers with a trapezoidal cross section. The upper part of the protruding end is rotatably connected by a bearing, and the lower part of the protruding end of the stirring shaft 2 is provided with a stirring paddle 9 . The vertical scraper 4 and the horizontal scraper 5 correspond to the vertical wall of the barrel body 1 and the bottom surface of the barrel body 1 respectively, and are used to scrape off deposited materials depos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com