Stripping device for polarizer

A peeling device and polarizer technology, applied in the field of display screens, can solve the problems of high breakage rate and low efficiency of polarizer glass, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

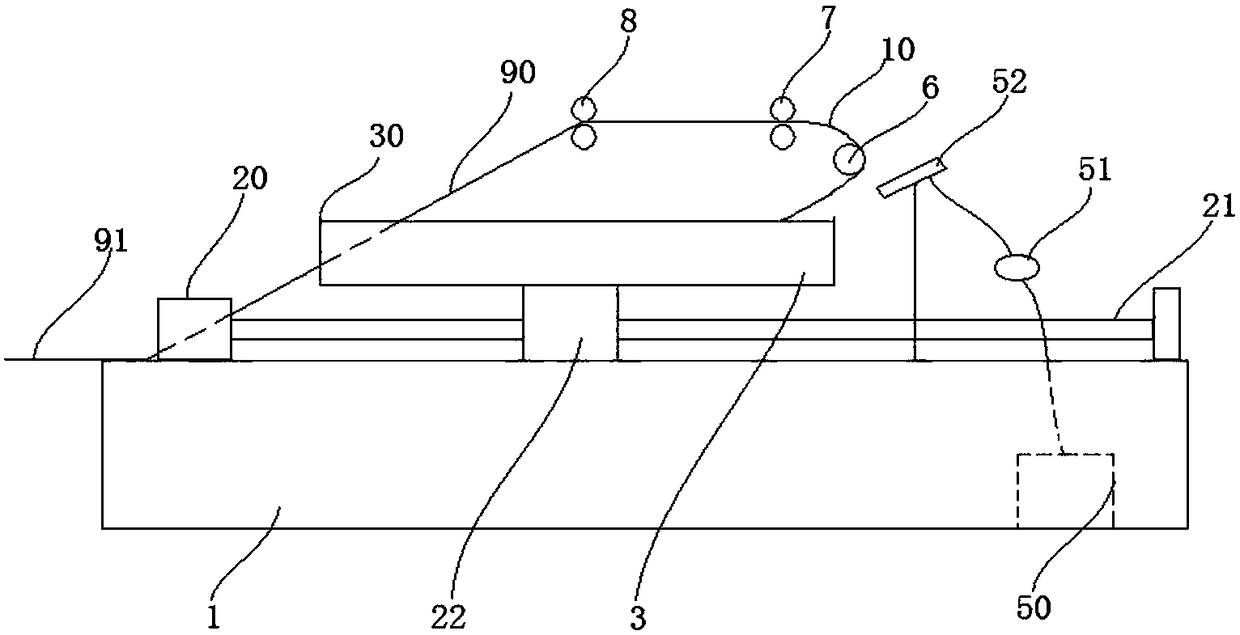

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] See figure 1 , a polarizer peeling device, comprising:

[0025] base1;

[0026] Screw drive mechanism, which is arranged on the base 1, the screw drive mechanism includes a motor 20, a screw rod 21 connected to the output shaft of the motor 20, and a slider 22 sleeved on the screw rod 21 and threaded with the screw rod 21 ;

[0027] The substrate carrying platform 3 is fixed on the top surface of the slide block 22. The four sides of the substrate carrying platform 3 are provided with baffles 30. The substrate carrying platform 3 is also provided with a plurality of suction holes, and the suction holes and the vacuuming device connect;

[0028] The spraying mechanism, which is arranged on the base 1 through the bracket 4, is used to spray the solvent between the substrate and the polarizer. The spraying mechanism includes a solvent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com