Patents

Literature

32results about How to "Realize opening and closing movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

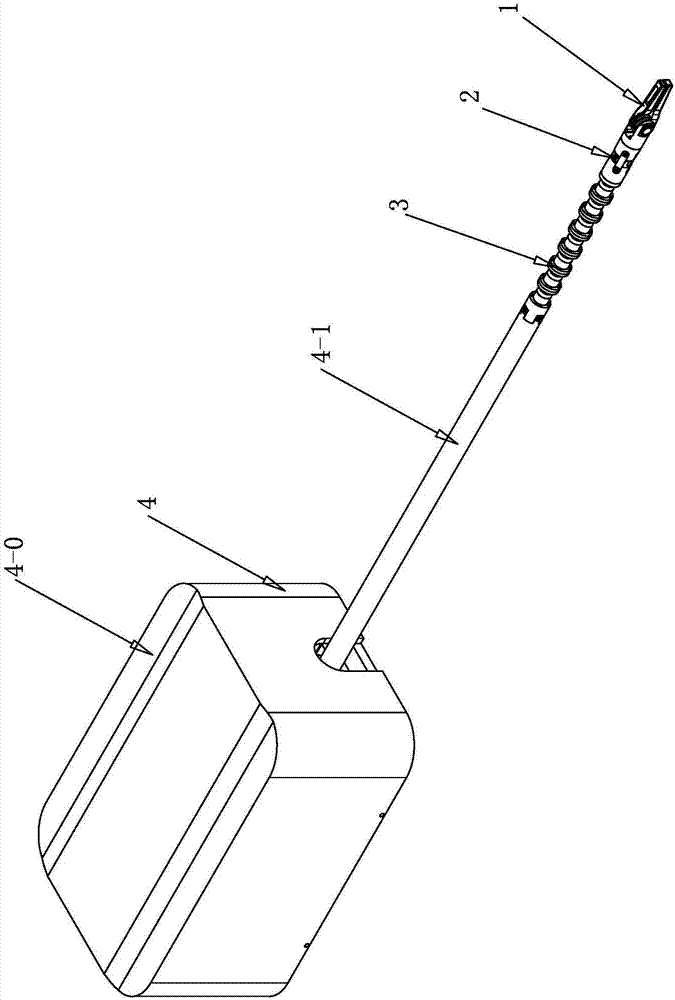

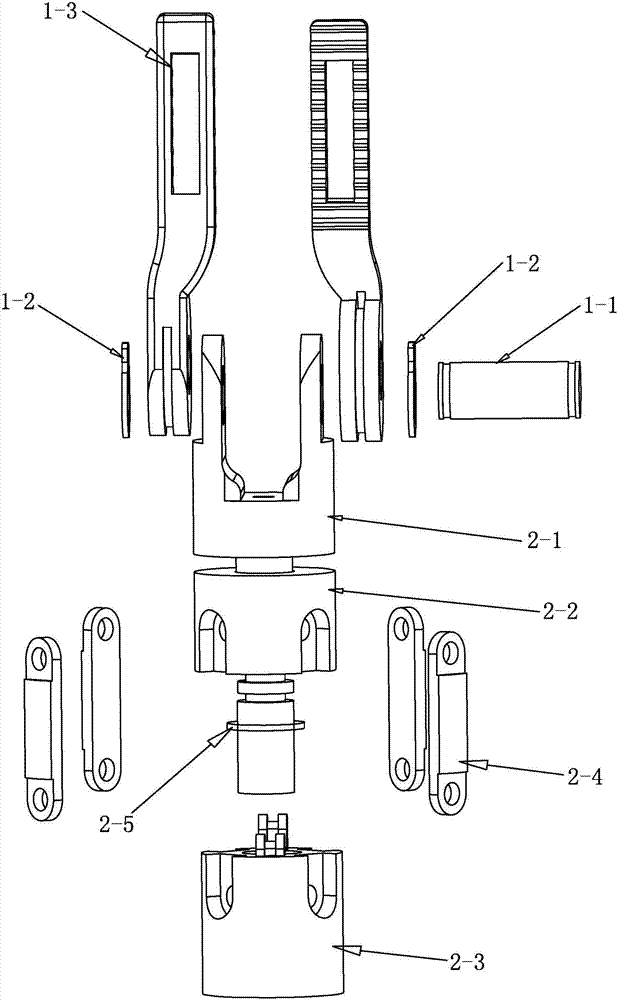

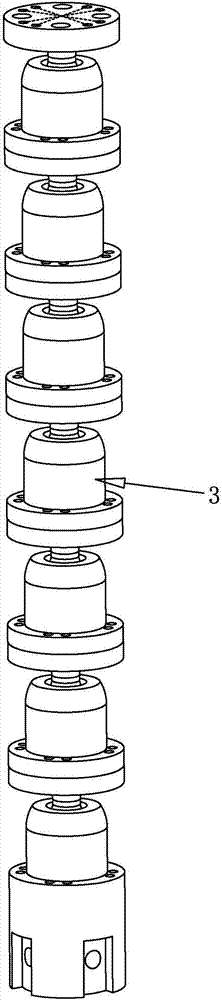

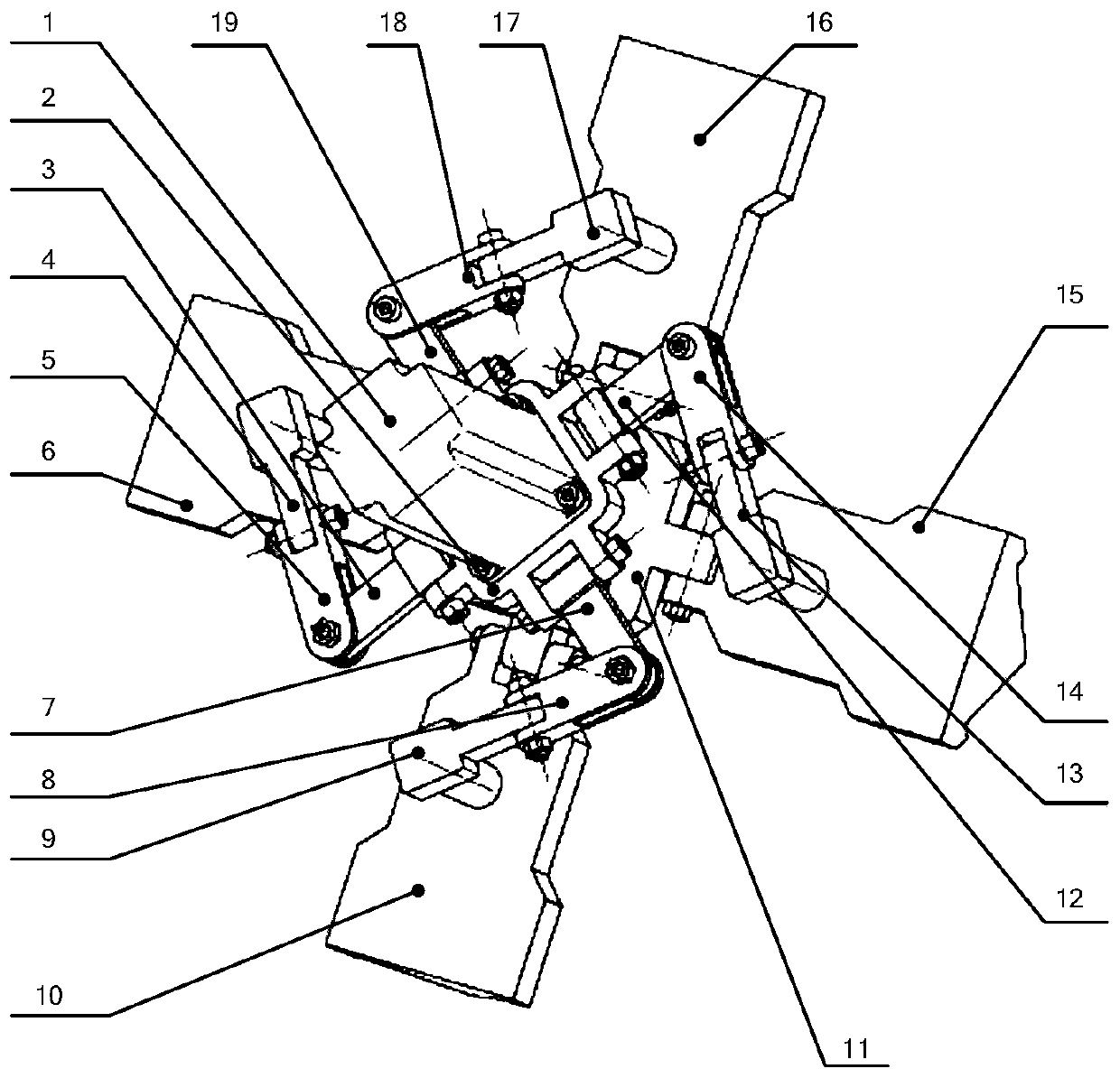

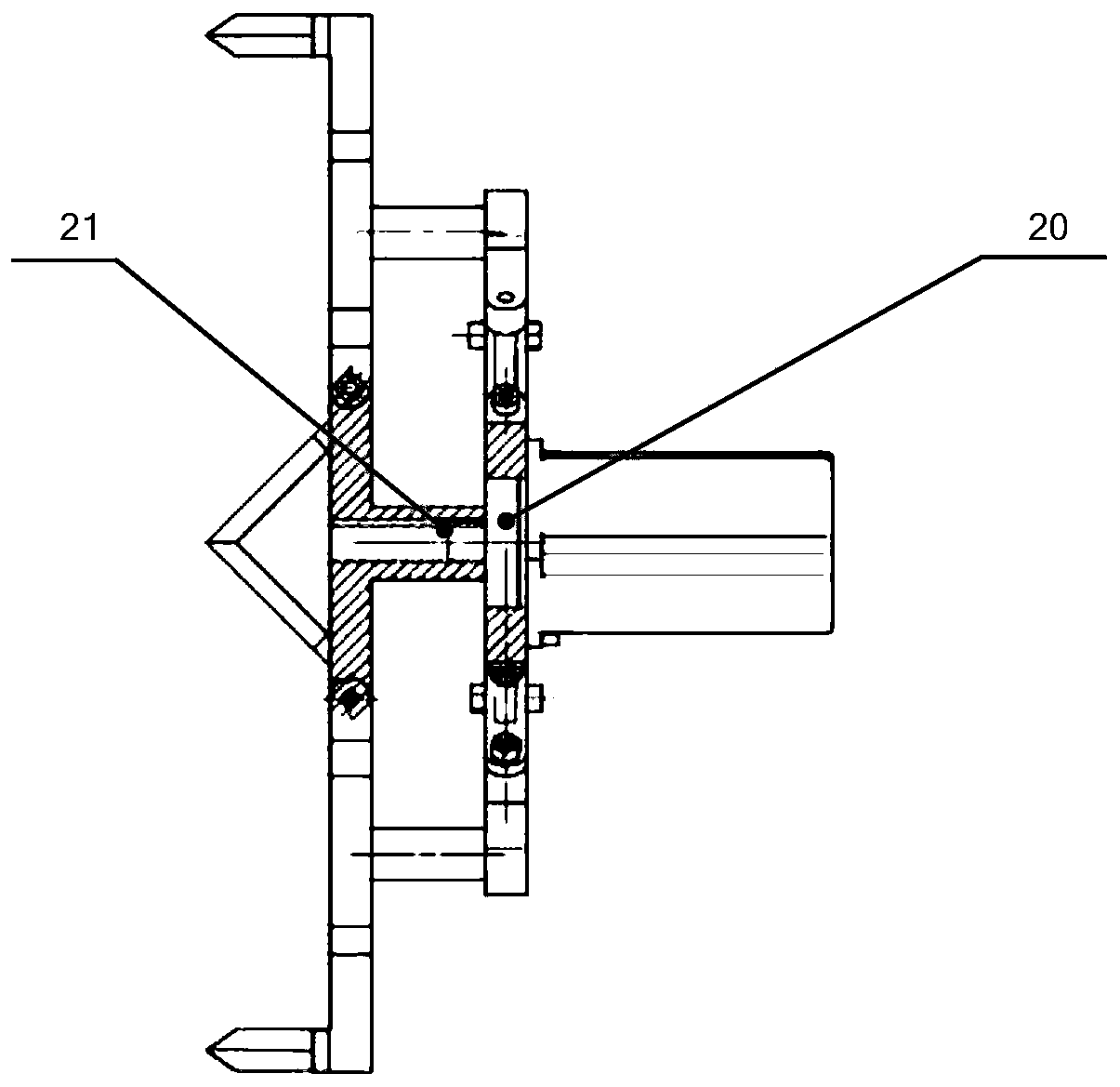

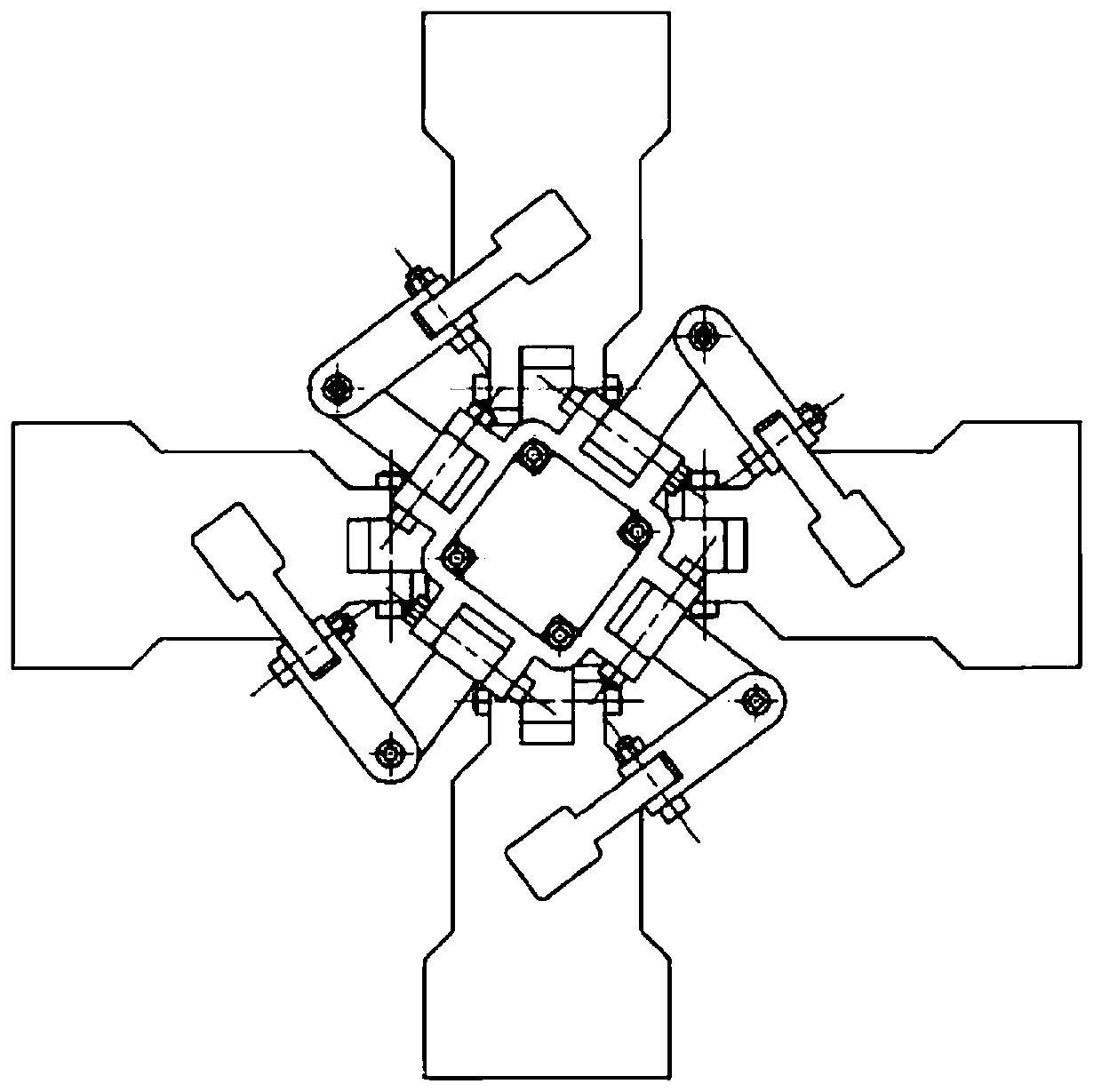

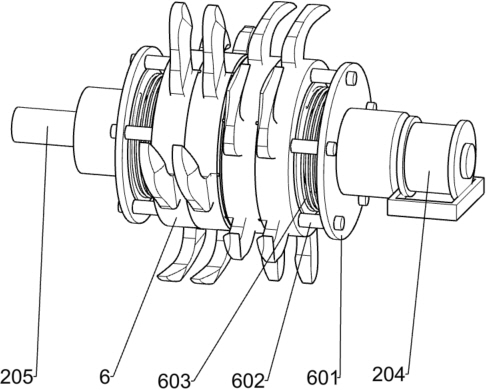

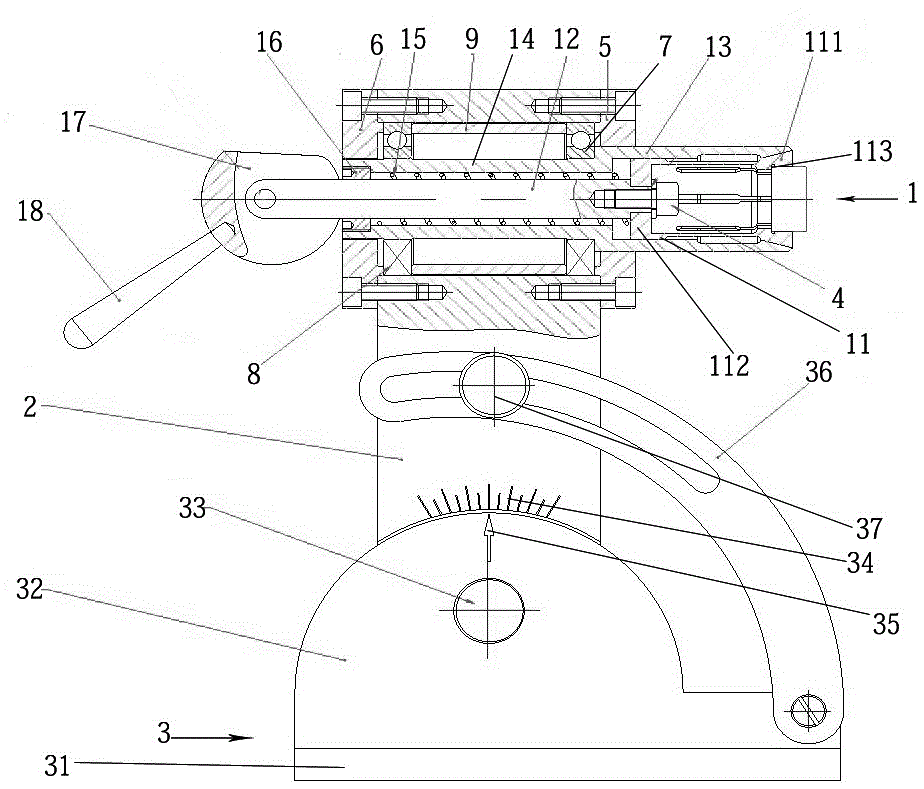

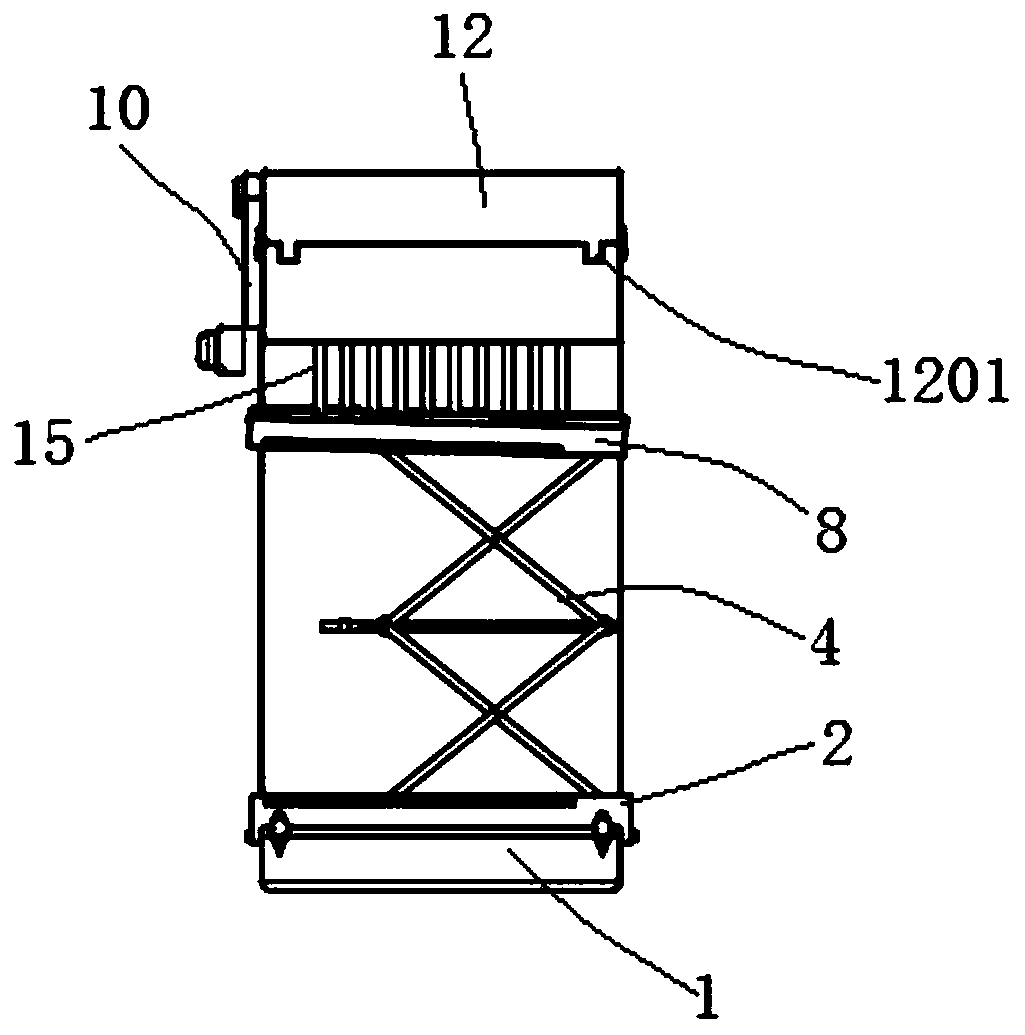

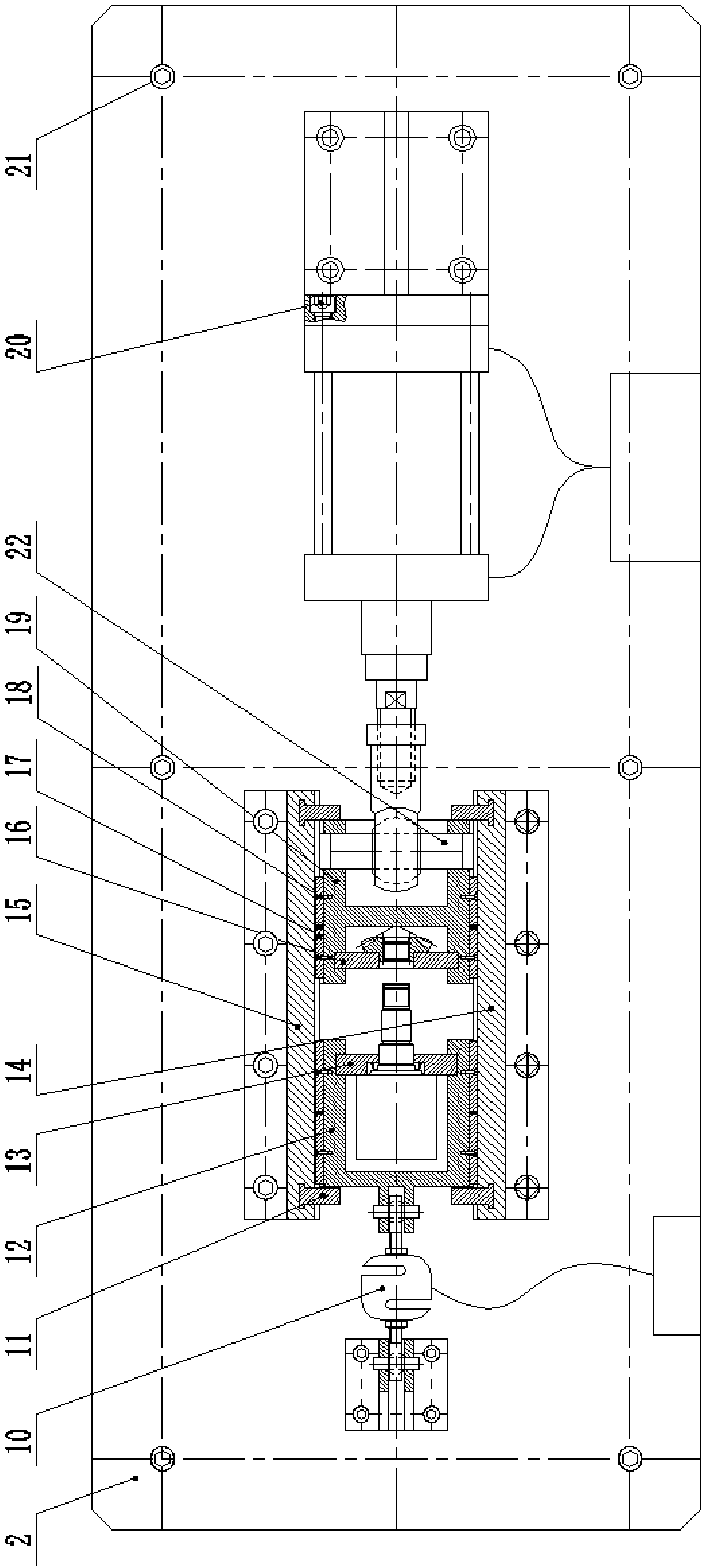

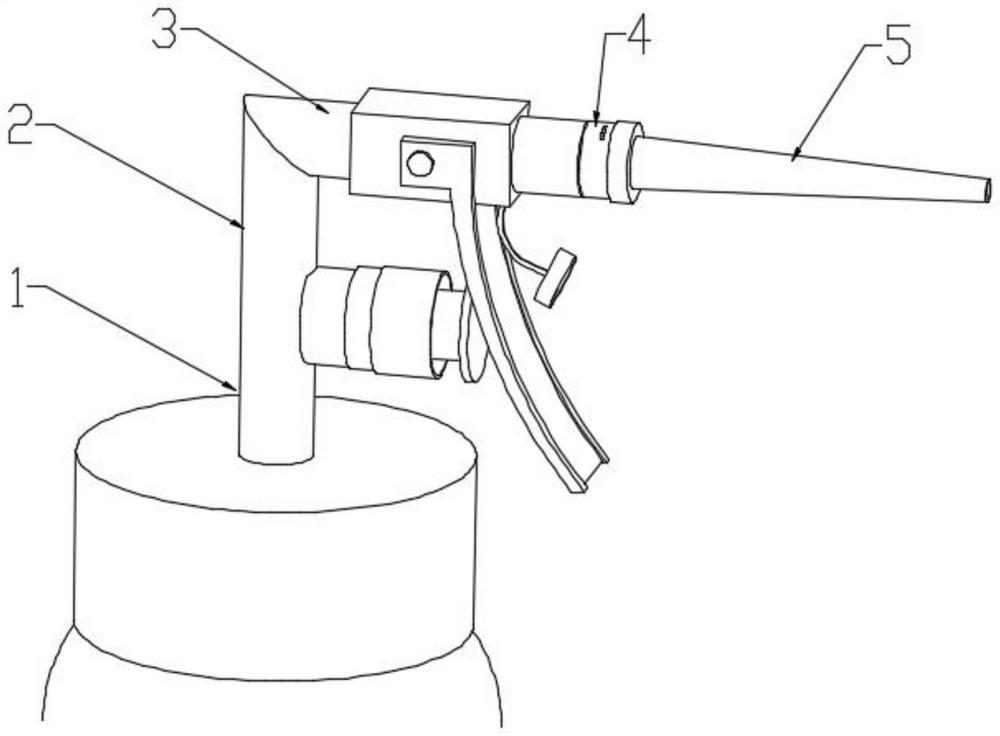

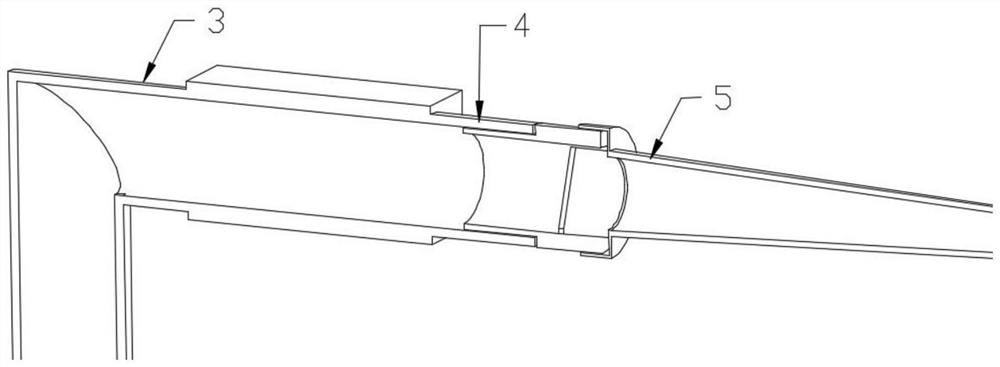

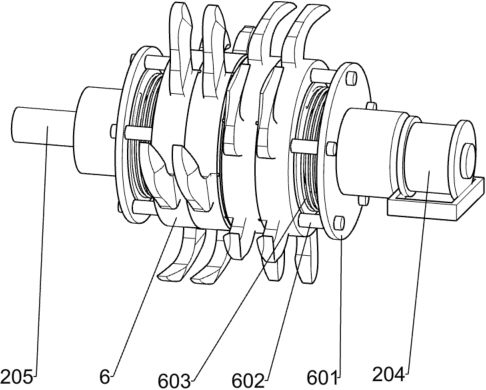

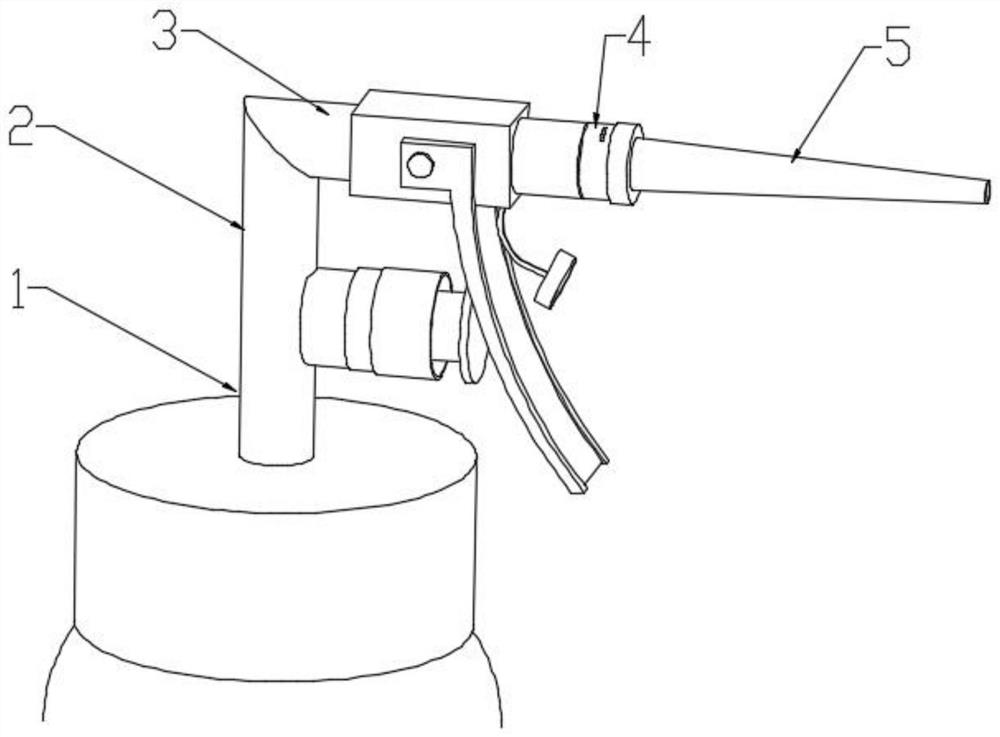

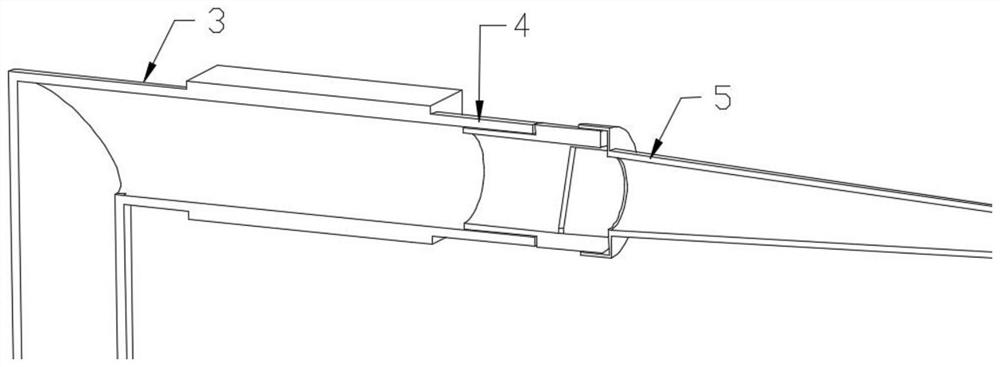

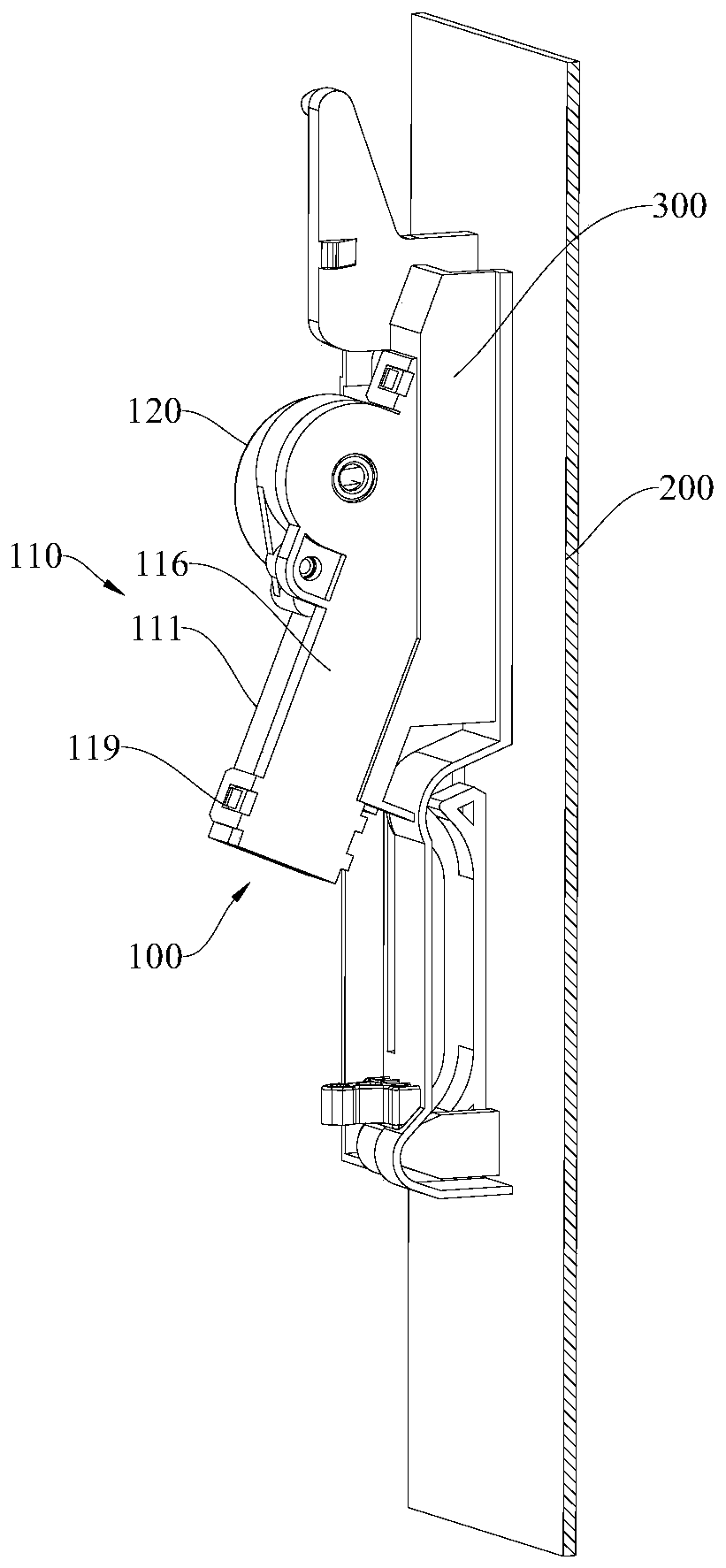

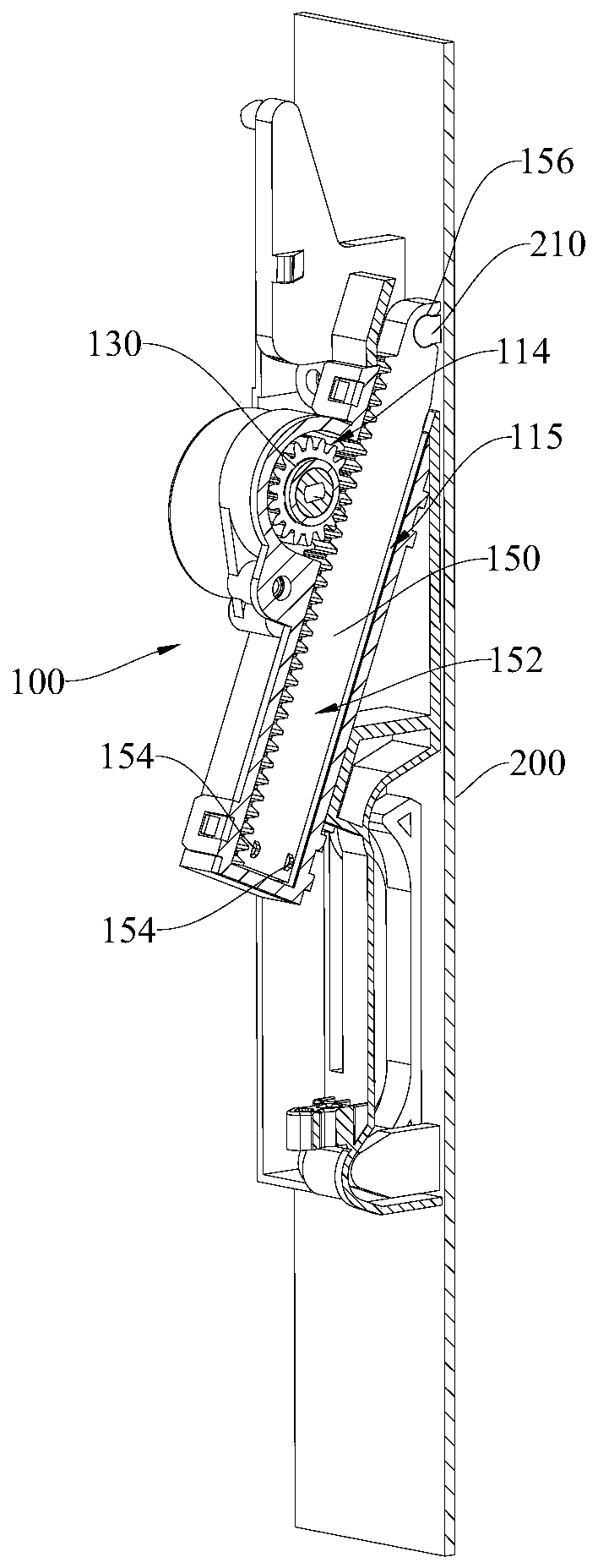

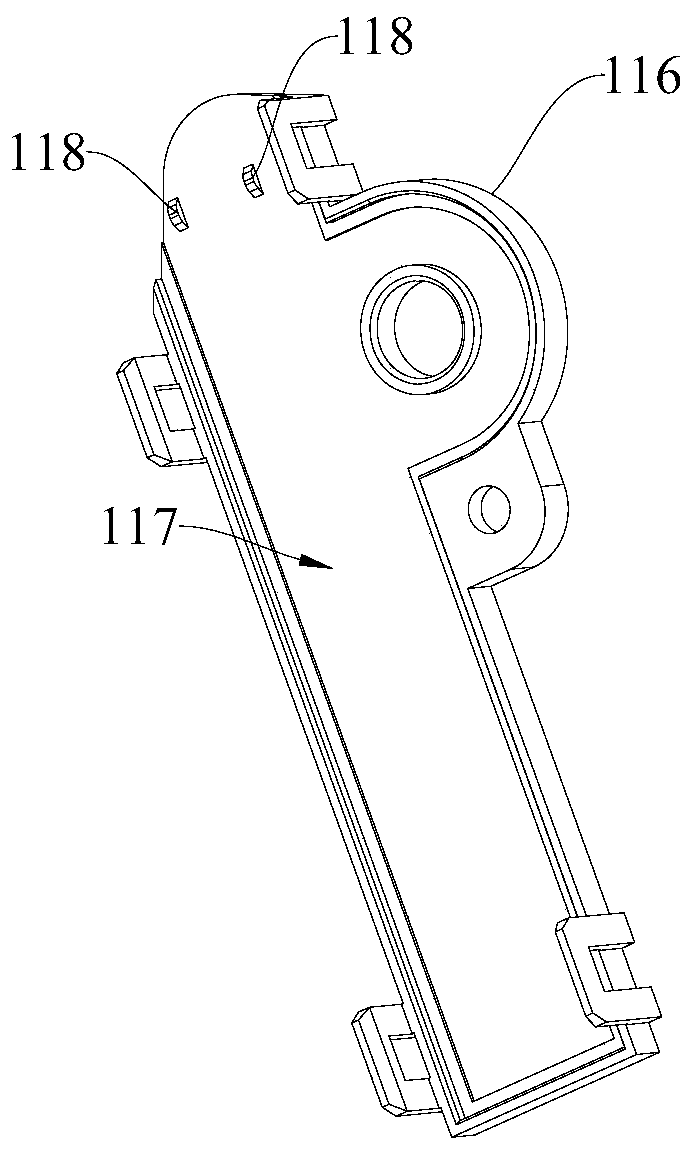

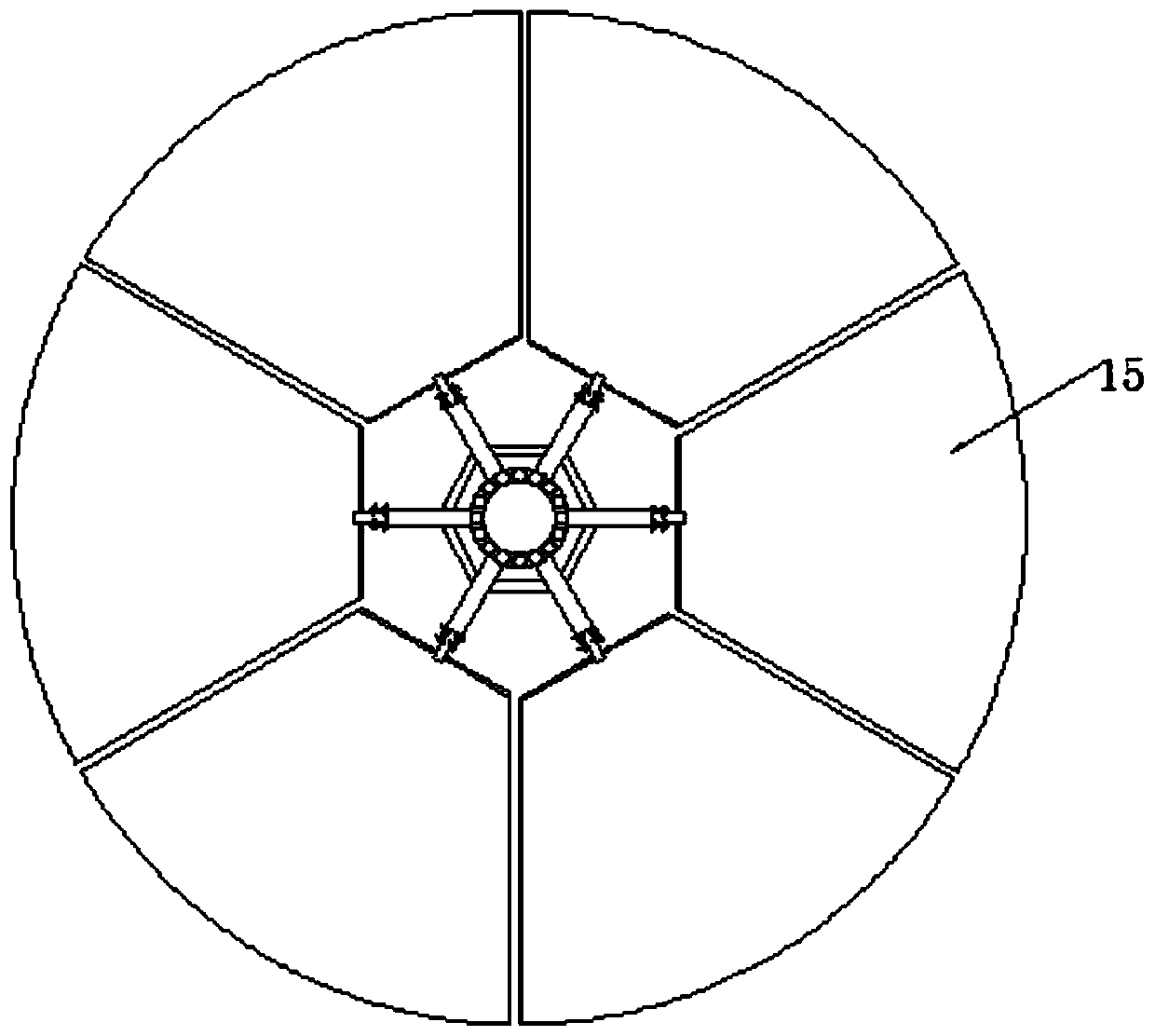

Flexible multi-joint surgical instrument for robot assisted minimally invasive surgery

ActiveCN107468339ARealize opening and closing movementAchieve bending motionSurgical manipulatorsSurgical robotsSurgical operationForceps

The invention discloses a flexible multi-joint surgical instrument for robot assisted minimally invasive surgery, and relates to the technical field of enterocoelia minimally invasive surgery department medical facilities. The instrument can achieve spatial displacement and positioning of tail end operating forceps by itself inside a patient, the tail end gesture adjusting capability of the surgical instrument is enhanced, the good flexibility is achieved, and the tissue surgical operation is completed inside the small space; by means of a self-rotation joint designed between the wrist of the surgical instrument and the tail end operating forceps, and the problem that joint restoration is needed during autorotation is avoided; the instrument comprises the tail end operating forceps mechanism, the autorotation joint, the wrist flexible joint and a power driving box; the power driving box comprises a wiring pipe, a shell, an upper base plate, a lower base plate, five sets of motor rope sheave devices, a rope guiding wheel set and a rope guiding column set; one end of the wiring pipe is connected with the tail end ball hinge structure of the wrist flexible joint, and the other end of the wiring pipe is fixed to the lower base plate. The instrument is used for the robot assisted minimally invasive surgery.

Owner:JILIN UNIV

Propeller casting molding method

ActiveCN105598385ARealize opening and closing movementReduce thicknessFoundry mouldsFoundry coresPropellerGrowth point

The present invention discloses a propeller casting molding method comprising the following steps: making a propeller steel mold; making a sand core; assembling for forming a propeller sand core; making a pouring gate steel mold; making a mud core; and making a sand box; and the manufacturing process comprises casting; picking up; sawing a riser, and grinding for molding. The propeller casting molding method is strong in operability and good in technology, and can improve propeller quality, increase production efficiency and reduce production costs, product quality meets customer demand for products, and a new profit growth point is created for enterprises.

Owner:WUHU FUJIHENG MACHINERY

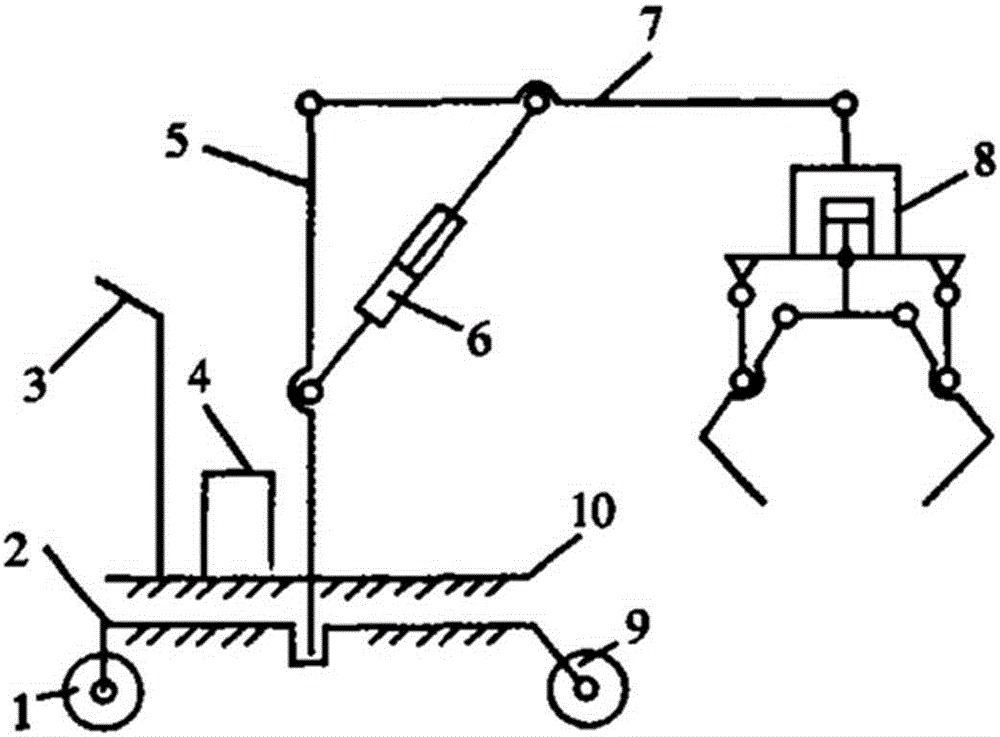

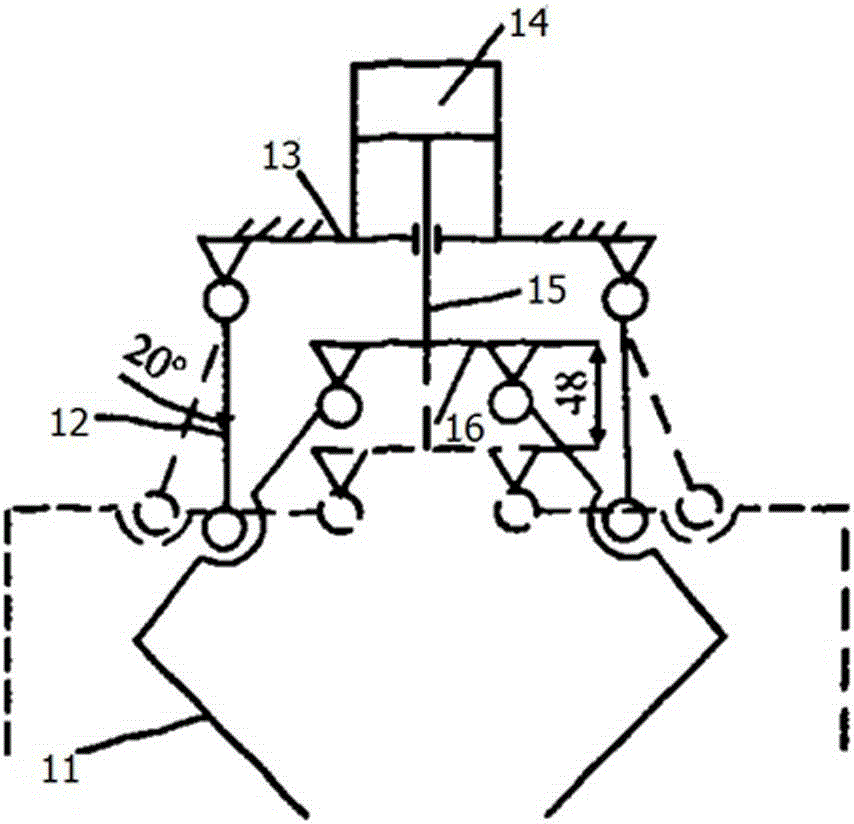

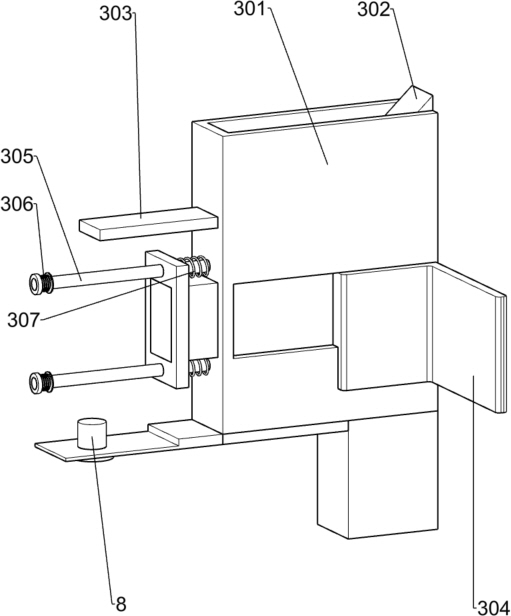

Garbage removal mechanical arm

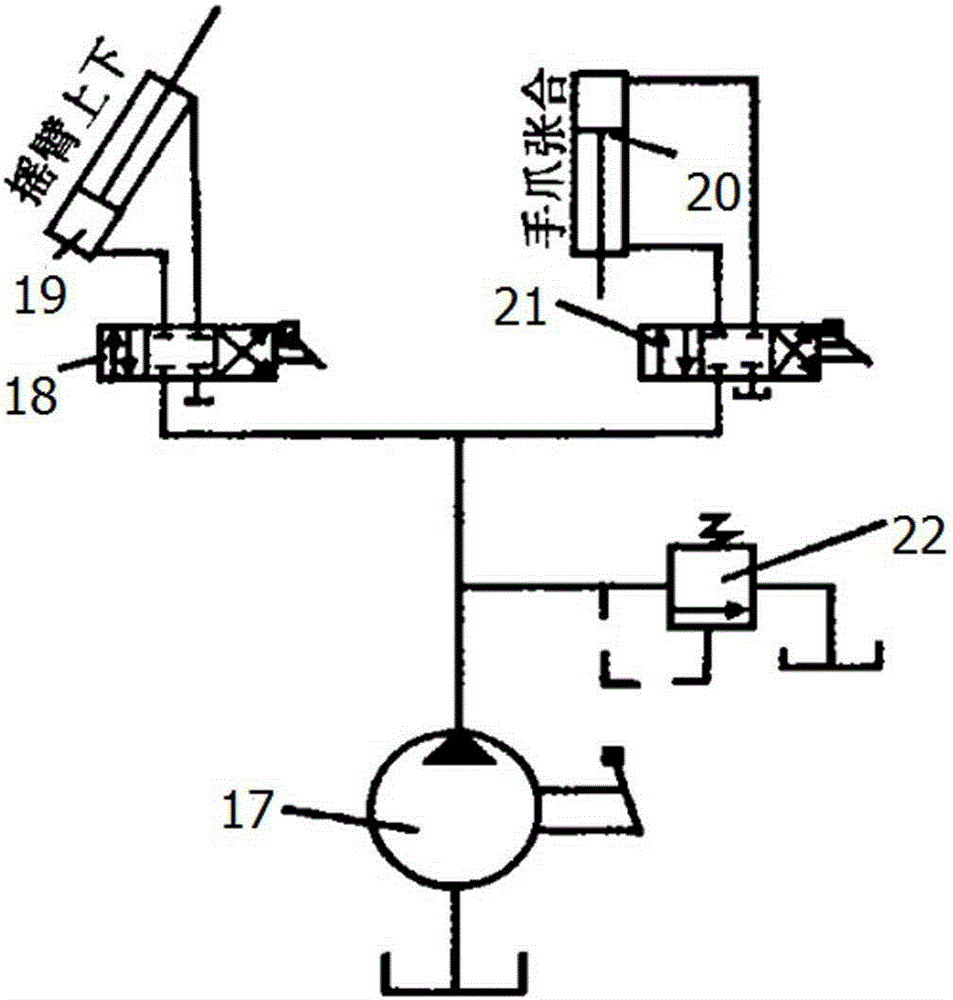

InactiveCN106607863ASimple structureEasy to operateProgramme-controlled manipulatorHydraulic cylinderHand parts

A garbage removal mechanical arm is mainly composed of a hand part, a rocker, a stand column, a manual hydraulic pump assembly, a lifting hydraulic cylinder, a rotary disc, a base and the like. The body movement includes up-down swinging of the rocker, clockwise and anticlockwise rotation of the rotary disc and movement of wheels in any direction in the horizontal plane. The mechanical arm is used for grabbing, conveying and unloading garbage, and mechanical garbage removal is achieved. According to the mechanical arm, the labor load of operators can be relieved, the production efficiency is improved as well, and high application and popularization value is achieved.

Owner:张桂春

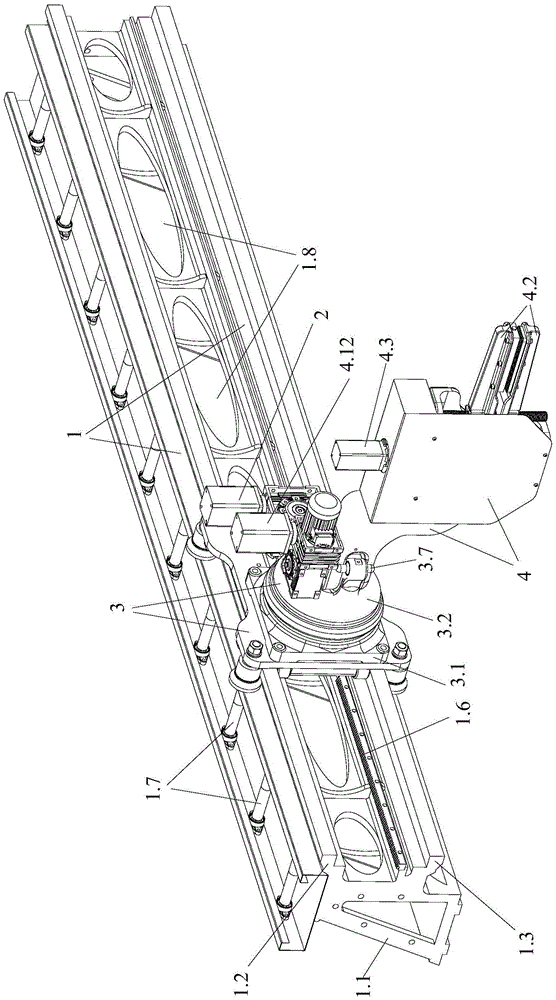

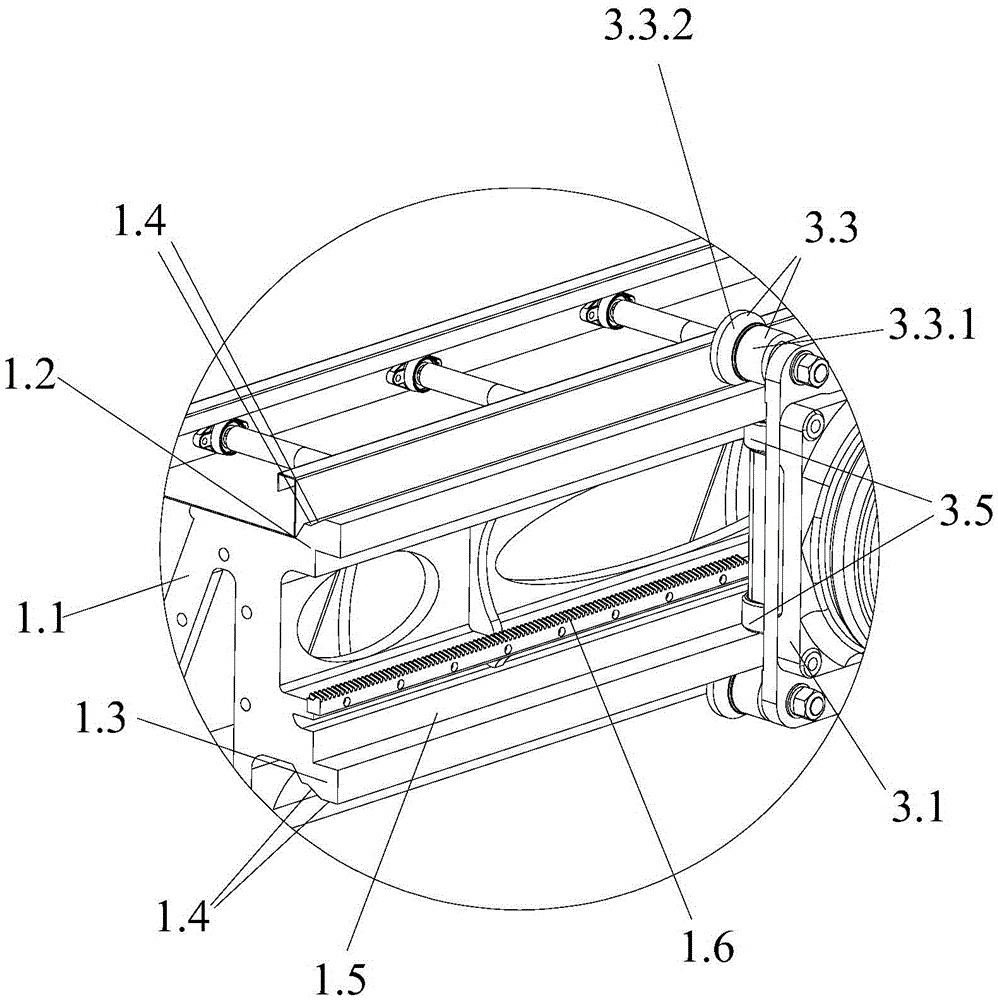

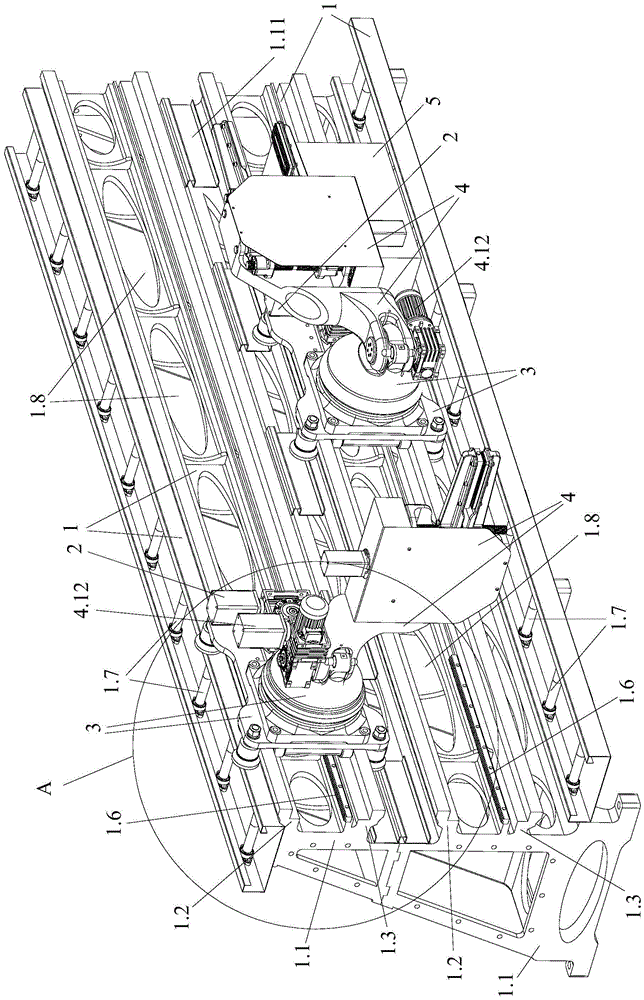

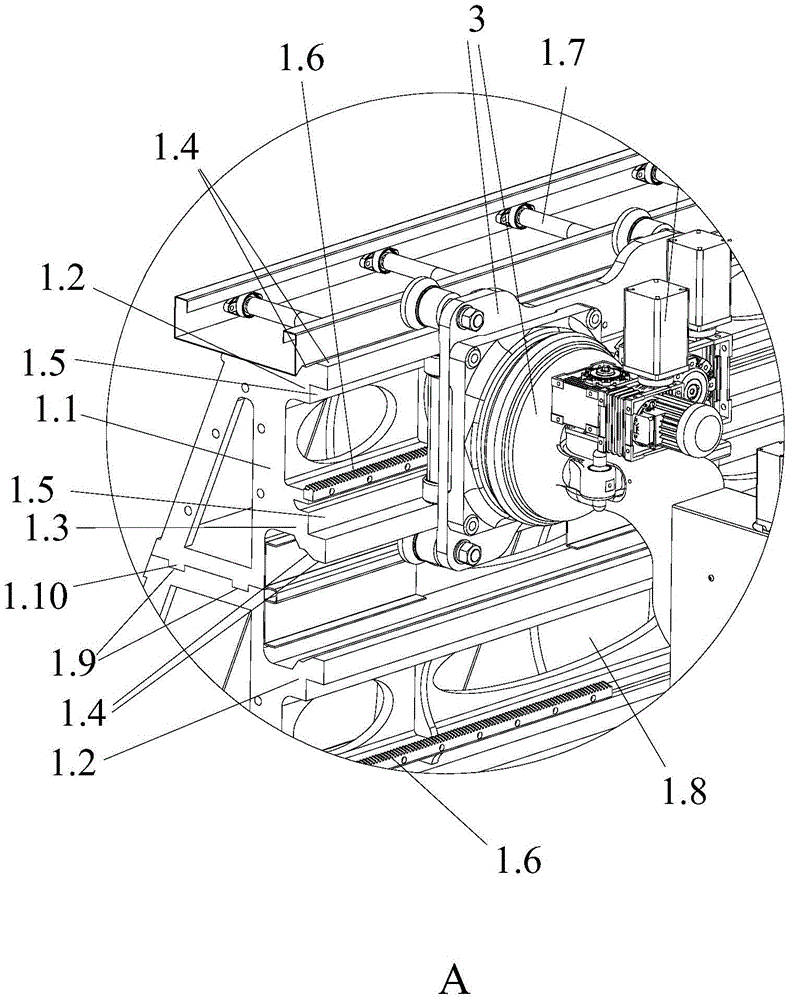

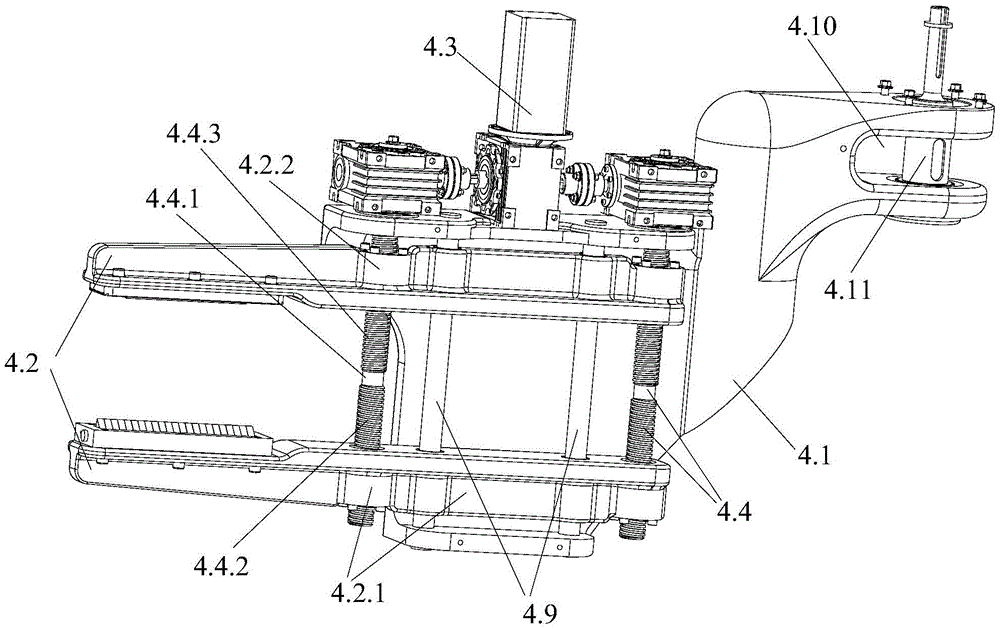

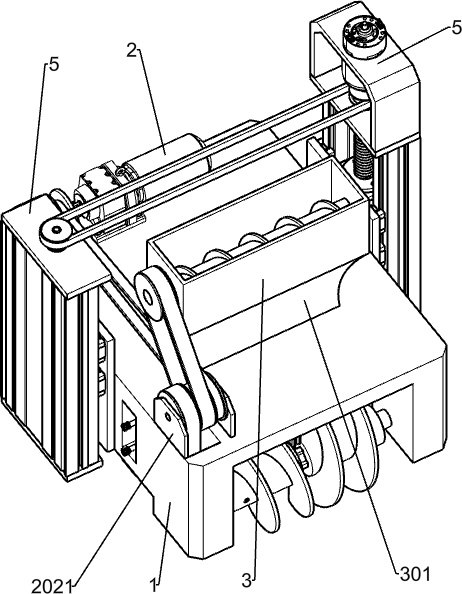

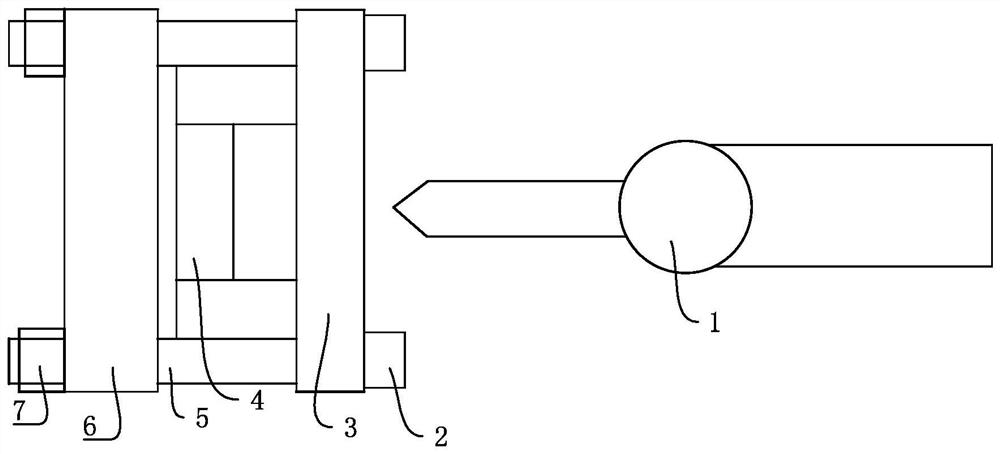

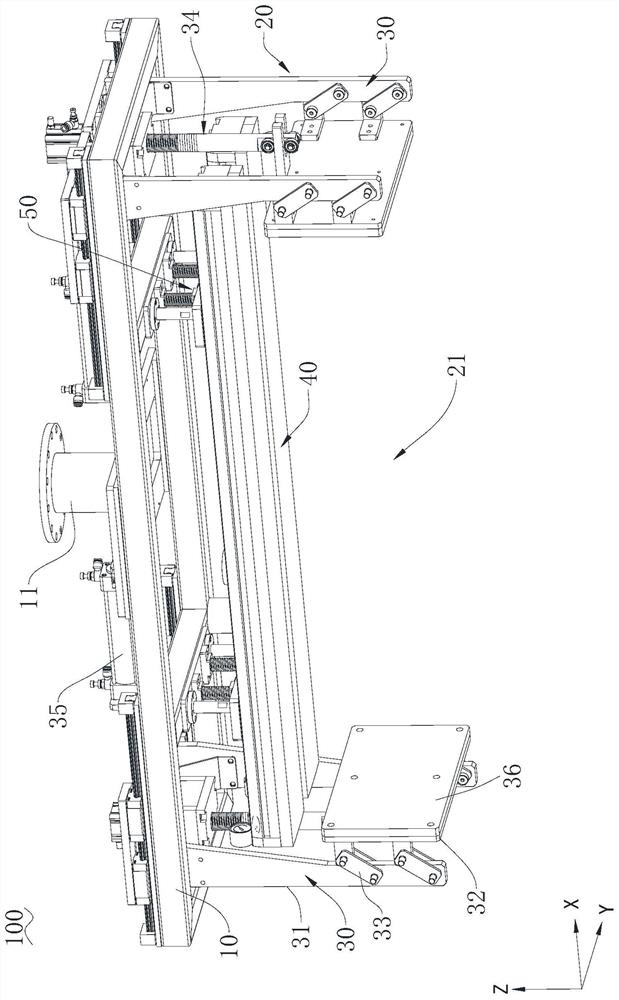

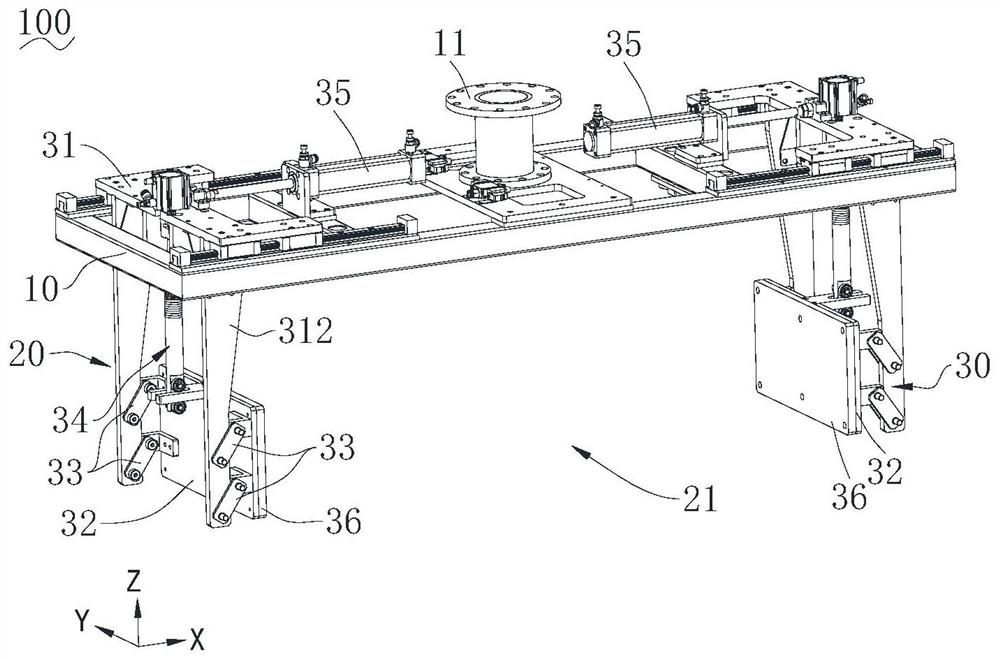

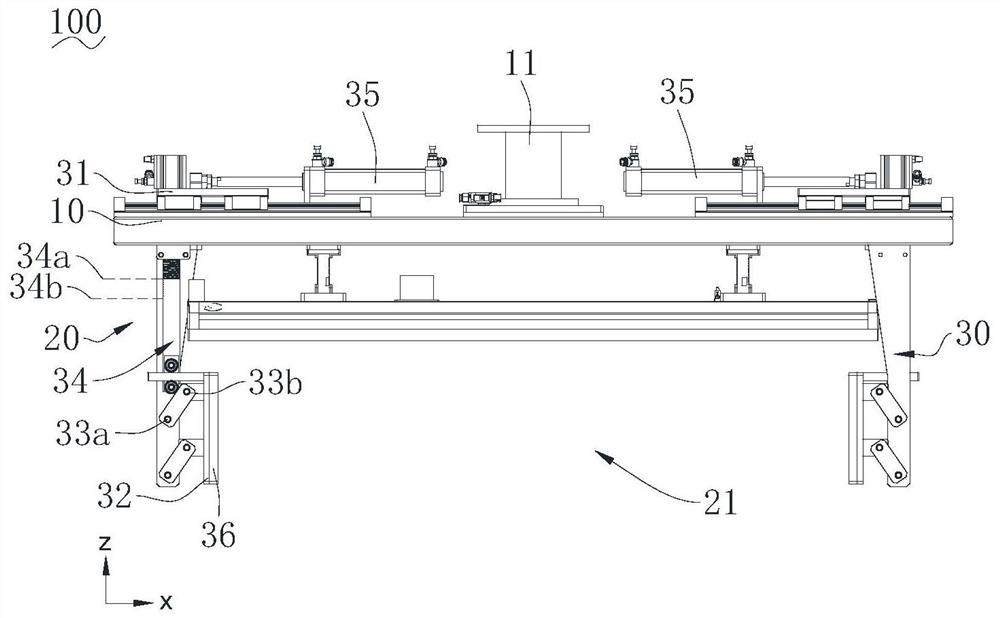

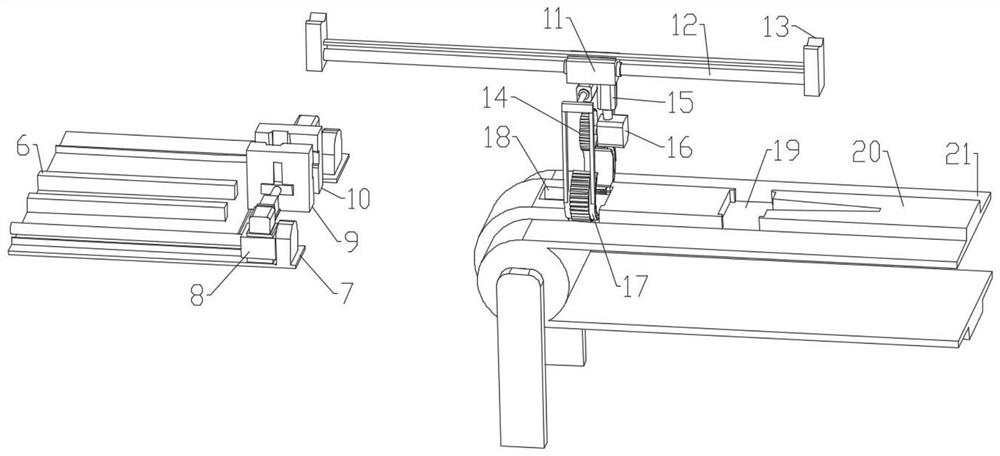

Vertical profile single-rail traction robot

The invention provides a vertical profile single-rail traction robot. The vertical profile single-rail traction robot comprises a vertical walking rail, a mechanical arm for clamping and towing a profile, a transmission mechanism, a driving mechanism for connecting with the transmission mechanism, and a control mechanism; the mechanical arm is buckled on the side surface of the vertical walking rail, and is slidingly connected with the side surface of the vertical walking rail to realize walking movement by hanging on the side surface of the vertical walking rail; the transmission mechanism consists of a transmission device 1 arranged on the mechanical arm and a transmission device 2 arranged on the vertical walking rail; and the control mechanism is respectively in signal connection with the driving mechanism and the mechanical arm. The vertical profile single-rail traction robot adopts the mechanical arm as an actuation mechanism for towing the profile, and is flexible in operation and convenient for control. Meanwhile, the vertical profile single-rail traction robot can shrink the floor area to reduce the production cost, and is not influenced by the ground condition to effectively solve the problem of incapability of guaranteeing the profile towing straightness caused by uneven ground so as to improve the profile towing processing quality.

Owner:广东泰格威机器人科技有限公司

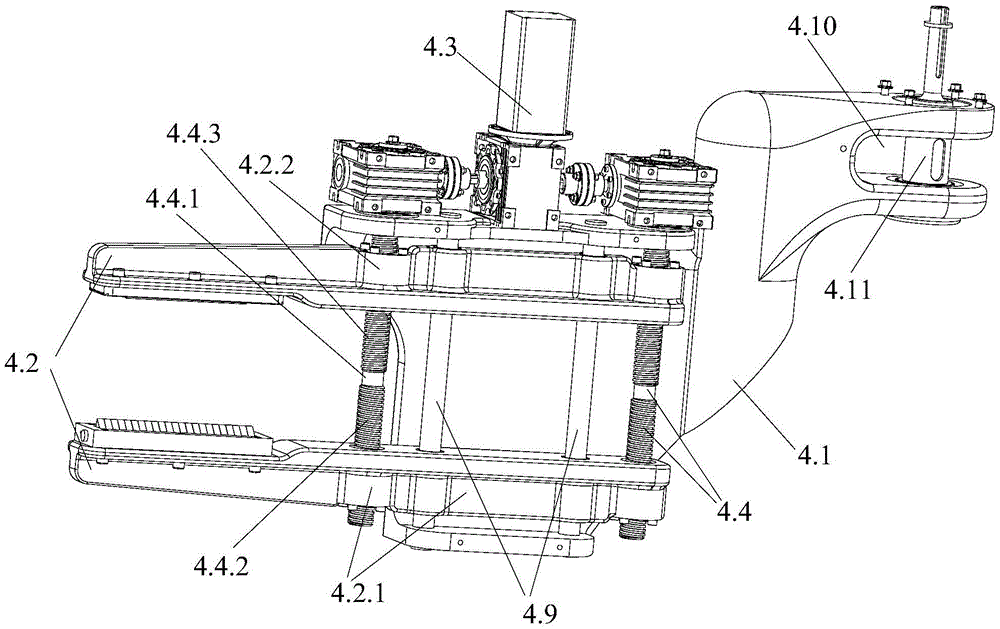

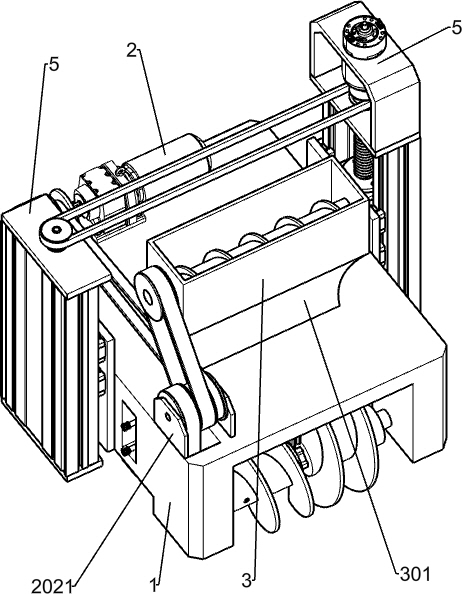

Vertical multi-track pulling robot for section bars

ActiveCN105598942AImprove the efficiency of automatic tractionExpand traction workspaceManipulatorEngineeringElectrical and Electronics engineering

The invention provides a vertical multi-track pulling robot for section bars. The vertical multi-track pulling robot comprises M pulling units and a control mechanism. Each pulling unit comprises a vertical travel track, a mechanical arm, a transmission mechanism and a driving mechanism, the mechanical arms are used for clamping and pulling the section bars, the driving mechanisms are used for being connected with the transmission mechanisms, and the mechanical arms are clipped on the side surfaces of the vertical travel tracks and are slidably connected with the side surfaces of the vertical travel tracks, so that the mechanical arms can be suspended on the side surfaces of the vertical travel tracks and can travel and move; the transmission mechanisms comprise first transmission gears and second transmission gears, the first transmission gears are arranged on the mechanical arms, and the second transmission gears are arranged on the vertical travel tracks; the M pulling units are spliced with one another in an overlapped manner by the aid of the vertical travel tracks, and the mechanical arms of each two adjacent pulling units are suspended on the corresponding vertical travel tracks and can cooperatively alternately travel and move, so that the section bars can be pulled in a cooperative alternative manner. The vertical multi-track pulling robot has the advantages that the section bars can be fully automatically pulled in a multi-track mode according to production requirements, and accordingly the section bar pulling efficiency can be improved.

Owner:广东省智行机器人科技有限公司

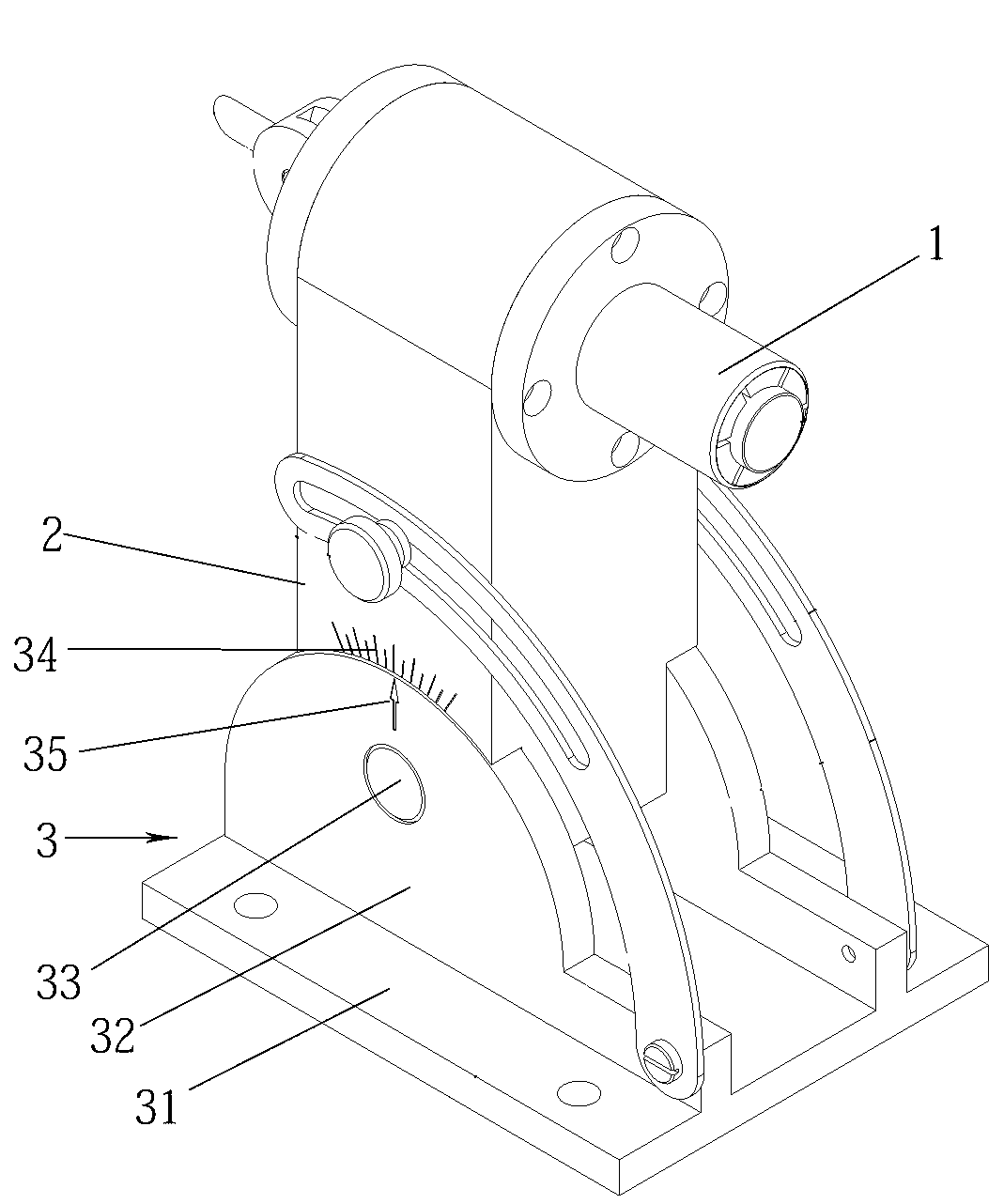

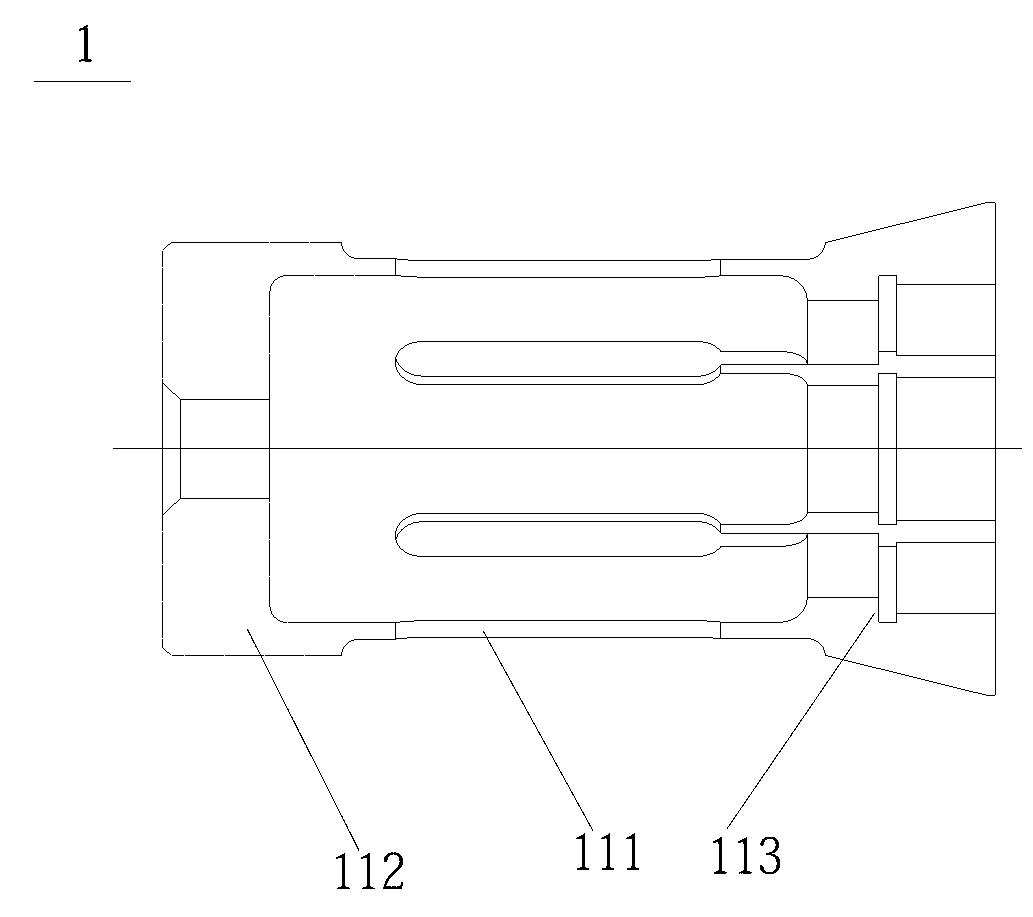

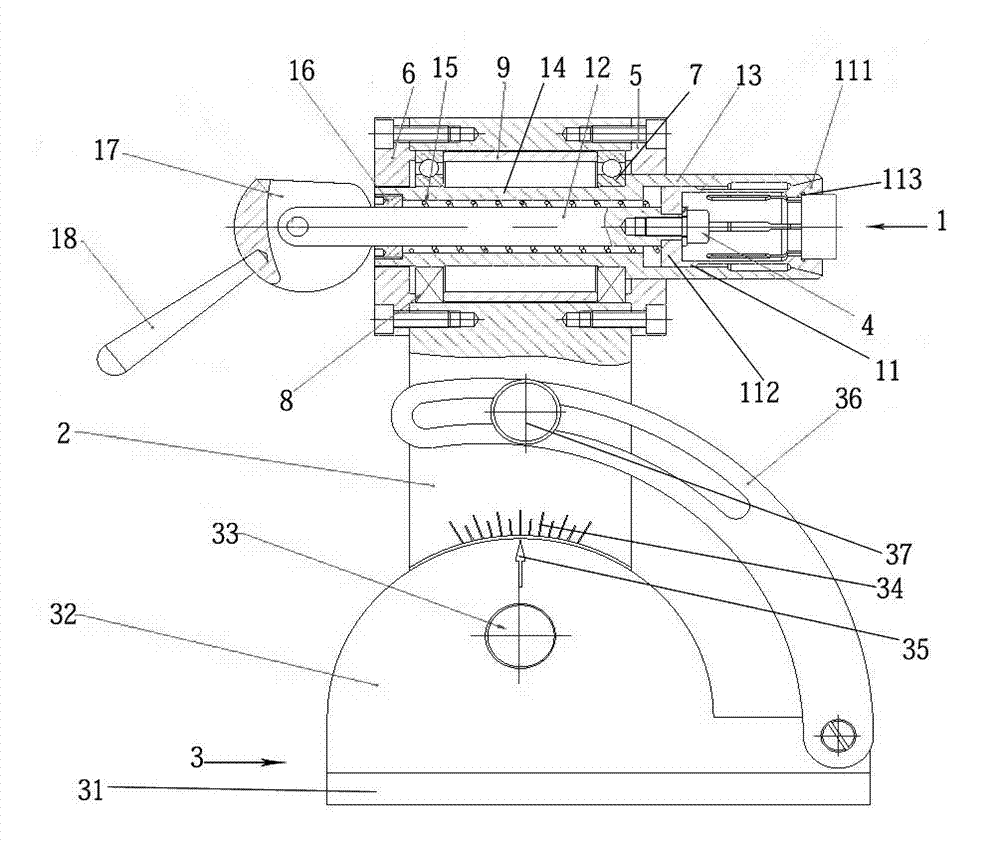

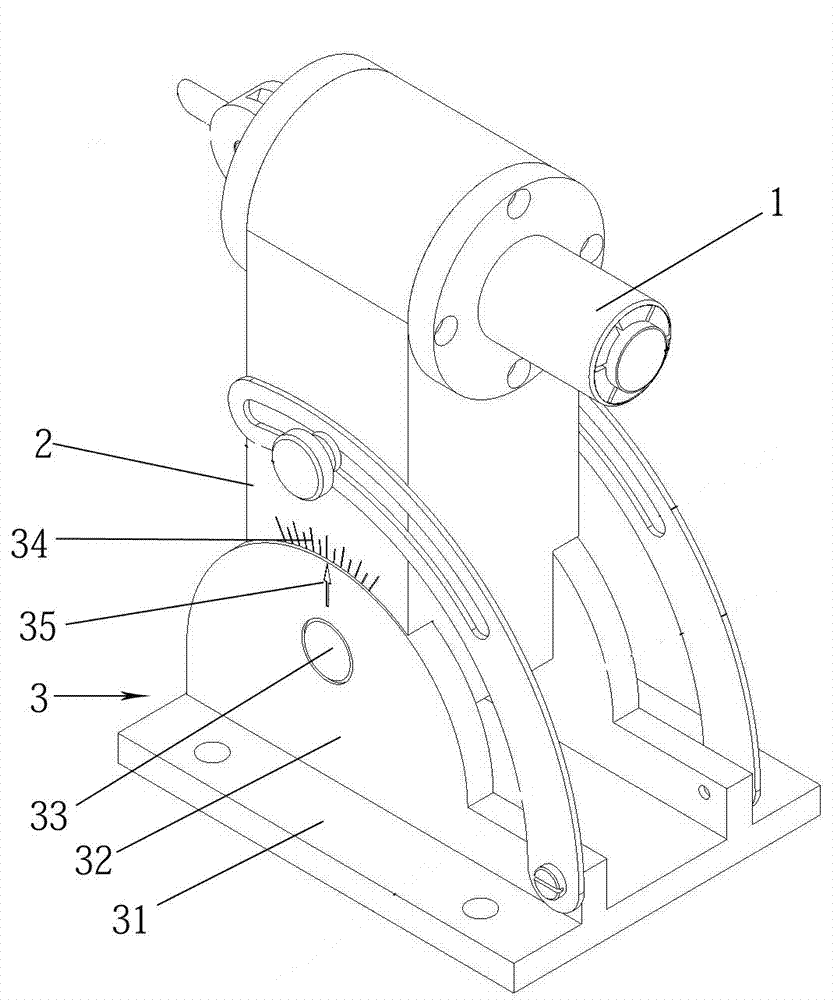

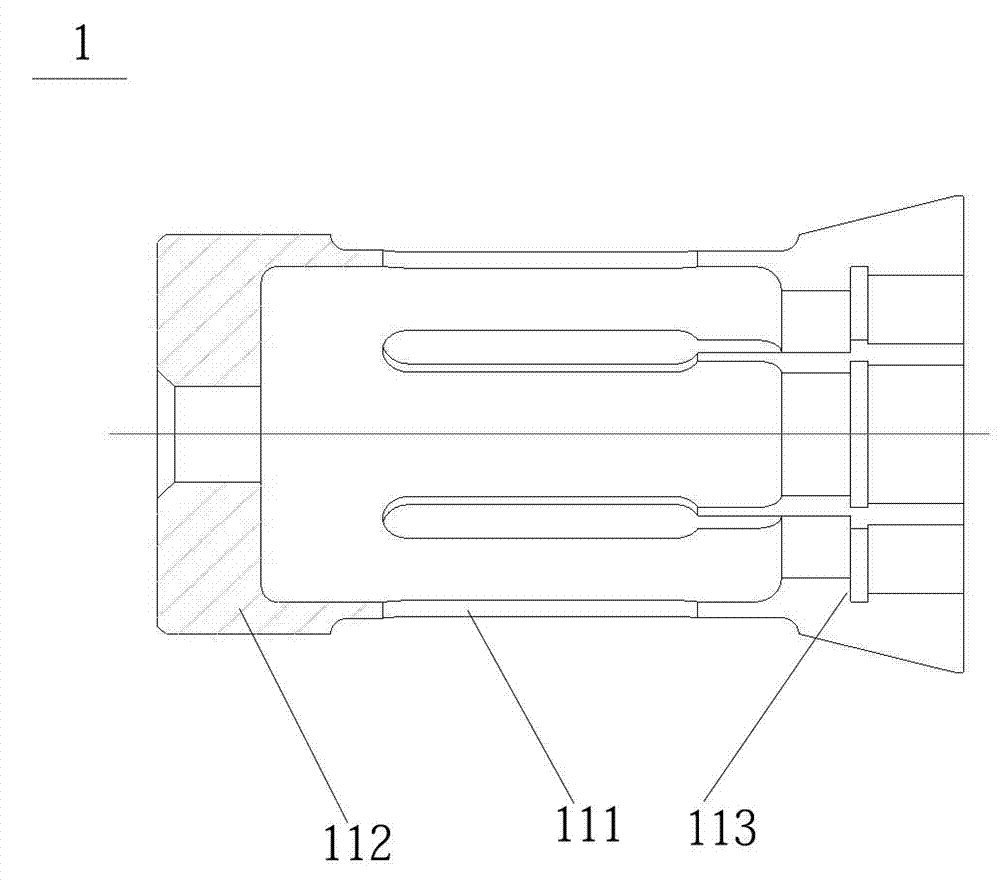

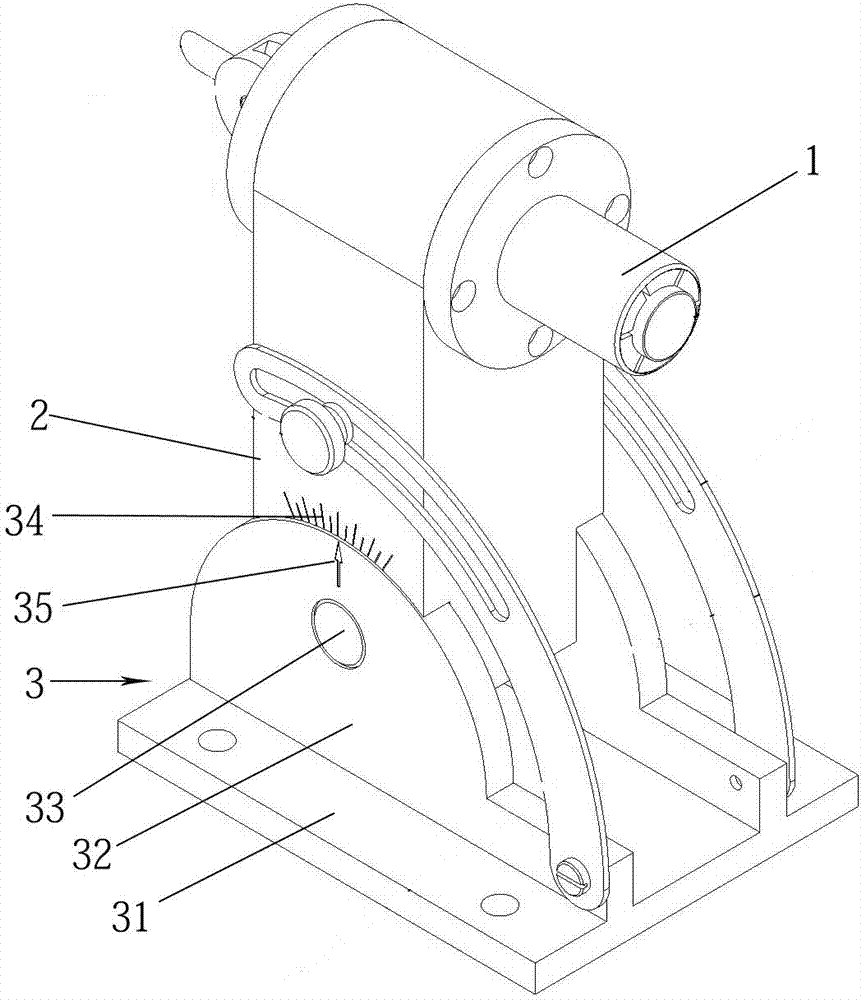

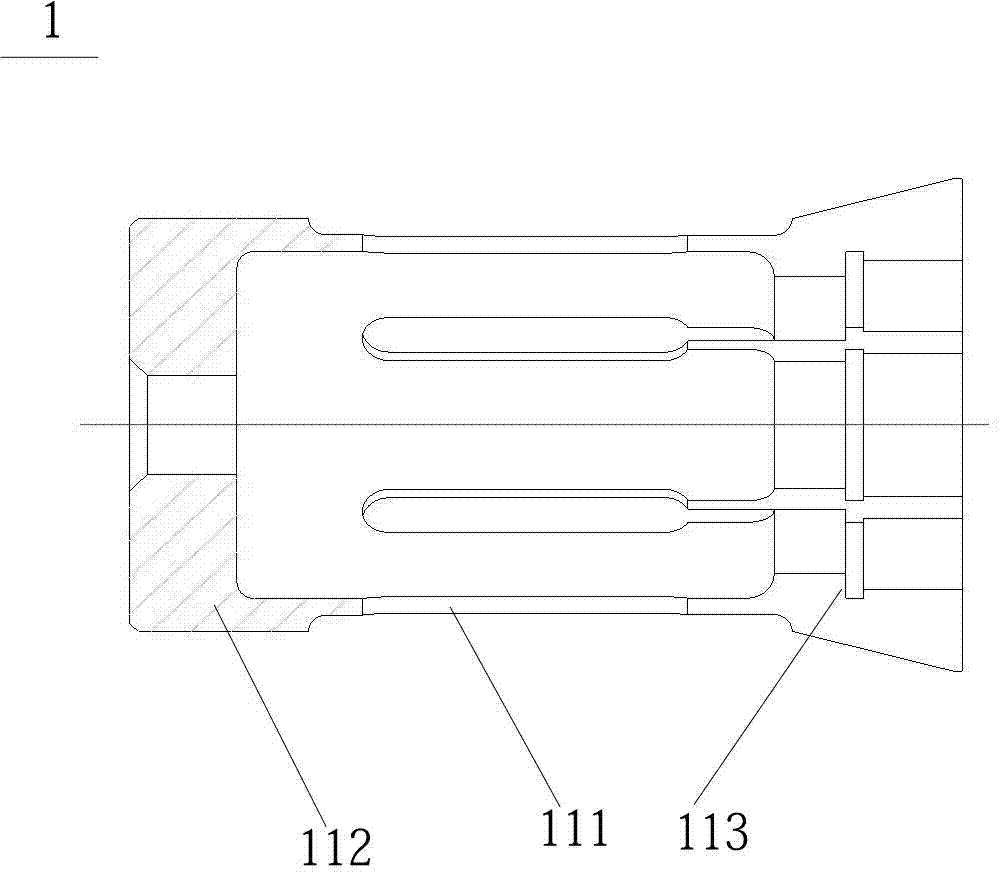

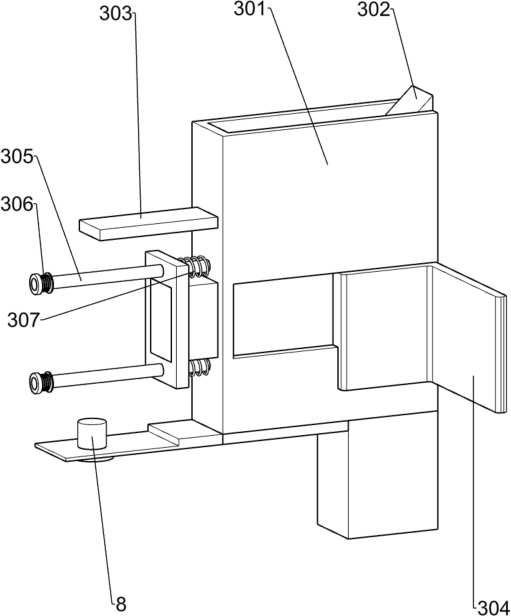

Cutter grinding fixture

ActiveCN102990483ARealize opening and closing movementFast clamping speedOther manufacturing equipments/toolsStructural engineeringIndustrial engineering

The invention discloses a cutter grinding fixture. The periphery of each elastic piece in a fixture body is provided with a mounting sleeve, the front ends of the elastic pieces are provided with clamping ends, and the clamping ends open outwards to be at an open state when the elastic pieces reveals from the from ends of the mounting sleeves and closes inwards to be at a closed state when the elastic pieces are withdrawn into the mounting sleeves. Hole walls or front end ports of the mounting sleeves are provided with close-up edges, and the close-up edges are matched with elastic claws along the anterior-posterior direction in stopping mode when the clamping ends are at the open state and stops the clamping ends on the peripheries of the elastic claws when the clamping ends are at the closed state. In use, opening and closing movements of the elastic claws can be achieved through matching between the close-up edges and the clamping ends, accordingly column-shaped solid cutters to be grinded can be tightly clamped, and further clamping speed of the column-shaped solid cutters is improved. Automatic centering can be achieved through wedge surface matching, and accuracy of column-shaped solid cutter clamping and cutter grinding processing can be improved.

Owner:FUNIK ULTRAHARD MATERIAL

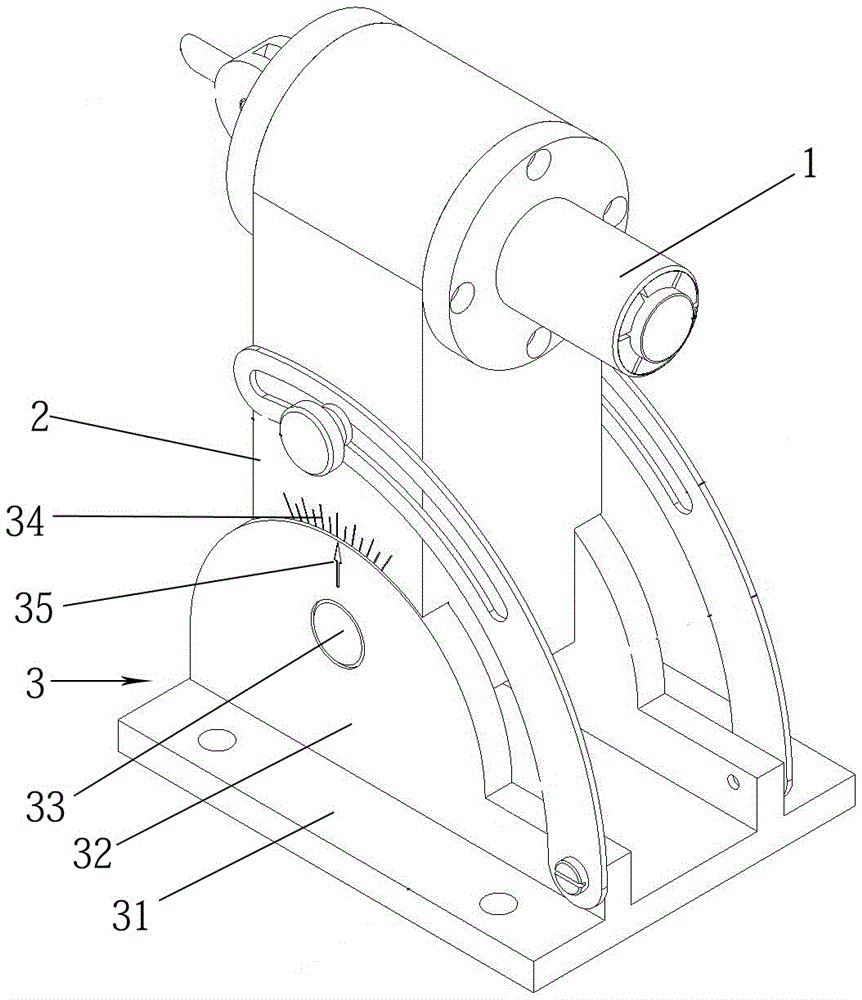

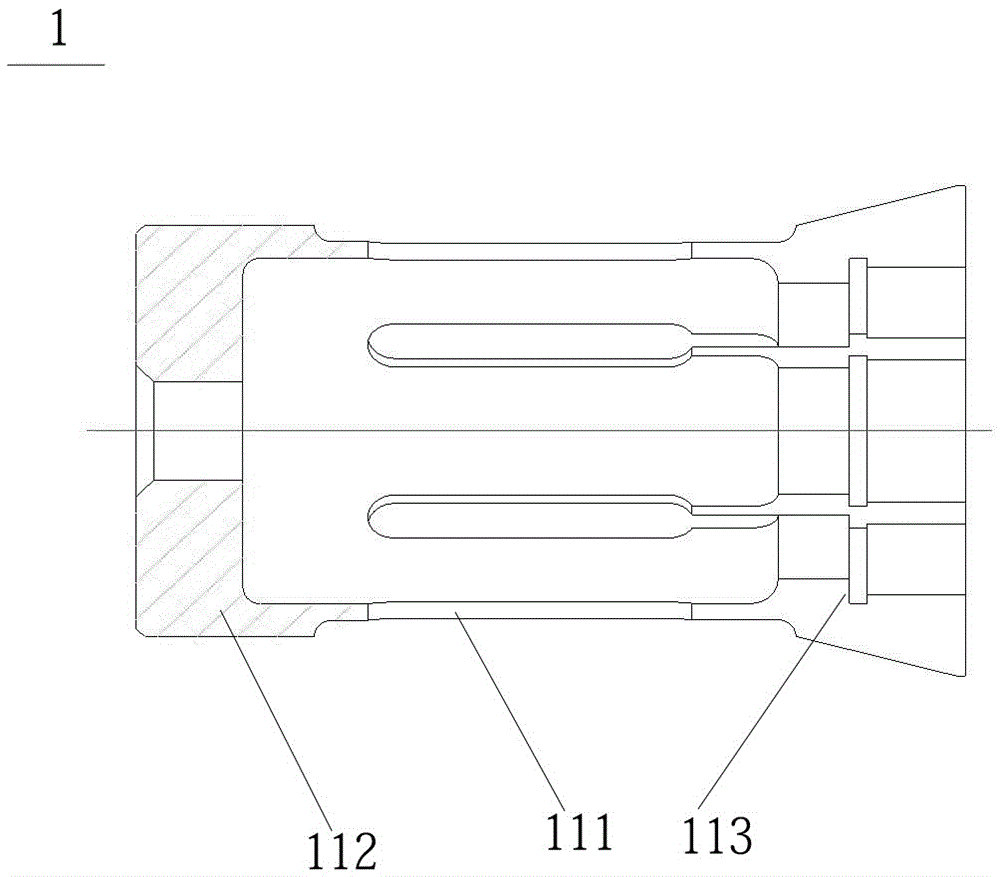

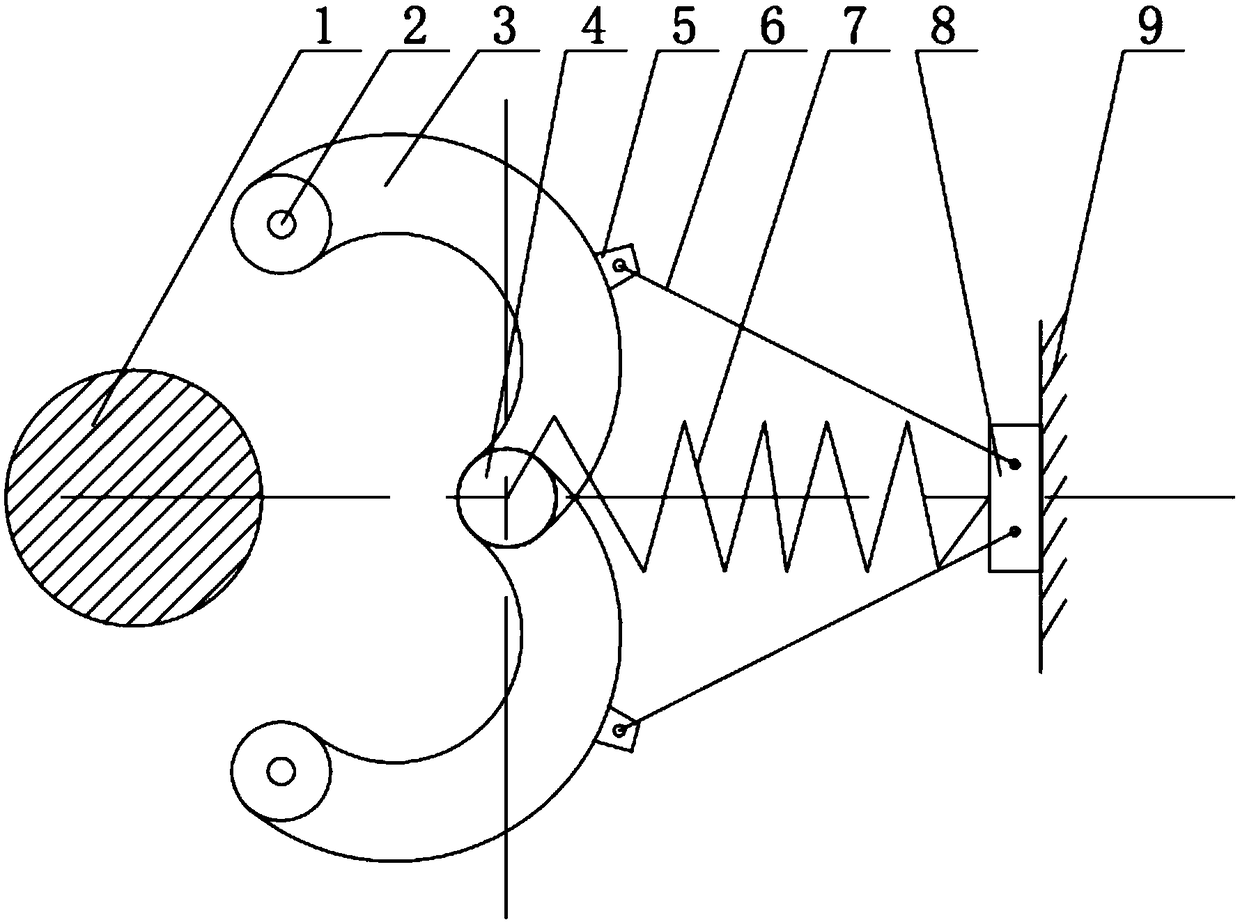

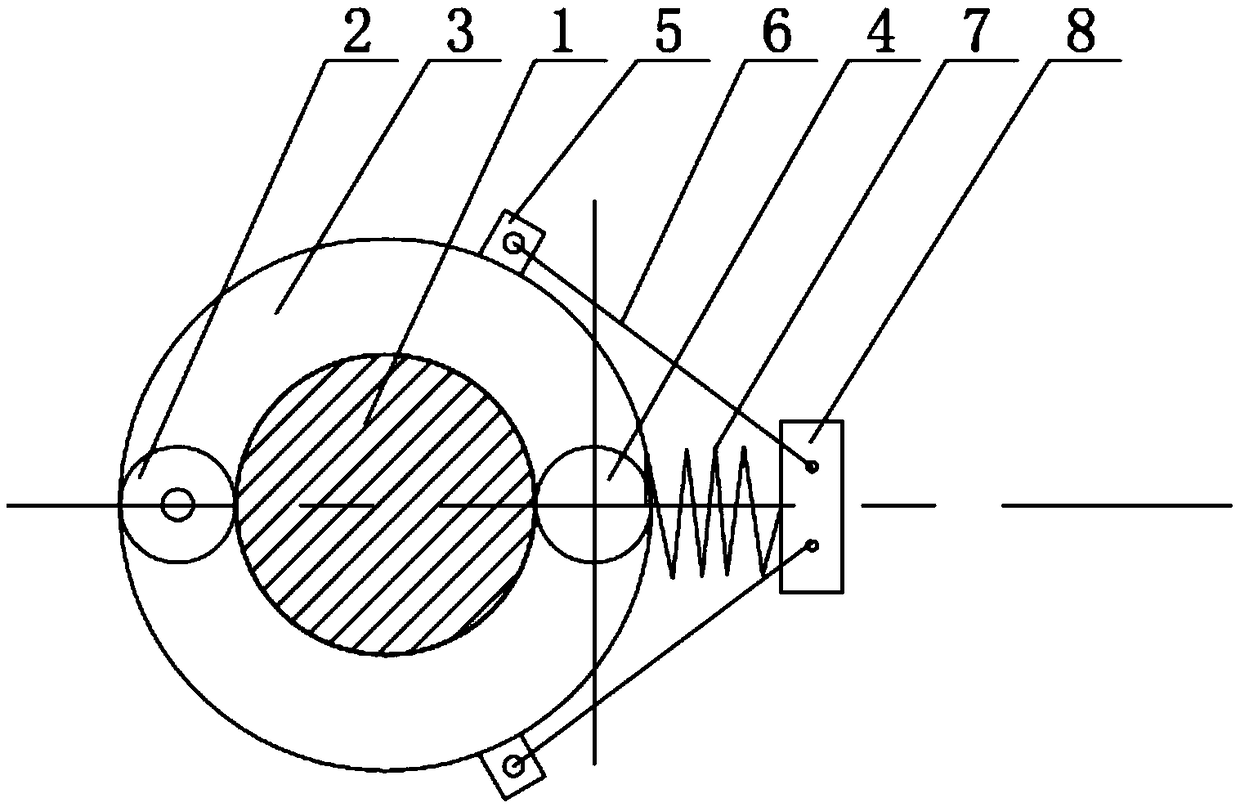

Mechanical arm mechanism for industrial robot

InactiveCN107214718ASimple structureSimple transmission structureGripping headsFinger structureSlide plate

The invention discloses a mechanical arm mechanism for an industrial robot, and relates to the technical field of industrial robots. The mechanical arm mechanism for the industrial robot comprises a sliding plate, a motor, an output shaft, a crank, a first connecting rod, a sliding block, a rail, a second connecting rod, a rocker, fingers and a spring. The motor is arranged below the sliding plate. The motor is connected with the output shaft. The output shaft is connected with the crank. The crank is connected with the first connecting rod. The first connecting rod is connected with the sliding block. The rail is arranged on the sliding plate. The sliding block is slidably connected with the rail. The sliding block is connected with the second connecting rod. The second connecting rod is hinged to the rocker. The rocker is hinged to the two fingers. The spring is connected between the two fingers. According to the mechanical arm mechanism for the industrial robot, a finger structure and a transmission structure are simple, the mechanical arm mechanism for the industrial robot is not prone breaking down and convenient to maintain, normal carrying is ensured, and the mechanical arm mechanism for the industrial robot has the advantages of being simple in structure, reasonable in arrangement, low in manufacture cost and the like.

Owner:FOSHAN JIANJINJIAN ELECTRONICS TECH CO LTD

Enveloping under-actuated robot gripper

The invention discloses an enveloping under-actuated robot gripper. The enveloping under-actuated robot gripper can solve the problems that an existing mechanical robot gripper has large movement stroke, a complex mechanism, and large number of parts. The enveloping under-actuated robot gripper comprises a driving motor, a base, a driving seat, a driving pad, a connecting key for a motor and a movable base, four claw plates, four connecting rod kinematic chains for connecting the claw plates and the driving seat, a driving seat connecting rod, a bearing connecting rod, and a clamping jaw connecting rod, wherein the driving seat and the driving pad are fixedly connected to the driving motor to form a first-level fixing mechanism; and the moving base and the four claw plates are connected toform a second-level moving mechanism. When the gripper works, the rotation movement of the driving motor is transferred to the second-level moving mechanism through the connecting key to realize theenveloping and unfolding of the moving gripper. The connecting rod kinematic chains use the direction change of the rotation axis to ensure that the distance between two levels of platforms remains unchanged, and can convert 6 degrees of freedom into 1 degree of freedom. The enveloping under-actuated robot gripper has a simple and reliable structure, clever configuration, and few driving sources,and is suitable for application scenarios such as grabbing and picking of fruits and vegetables.

Owner:SHANGHAI UNIV

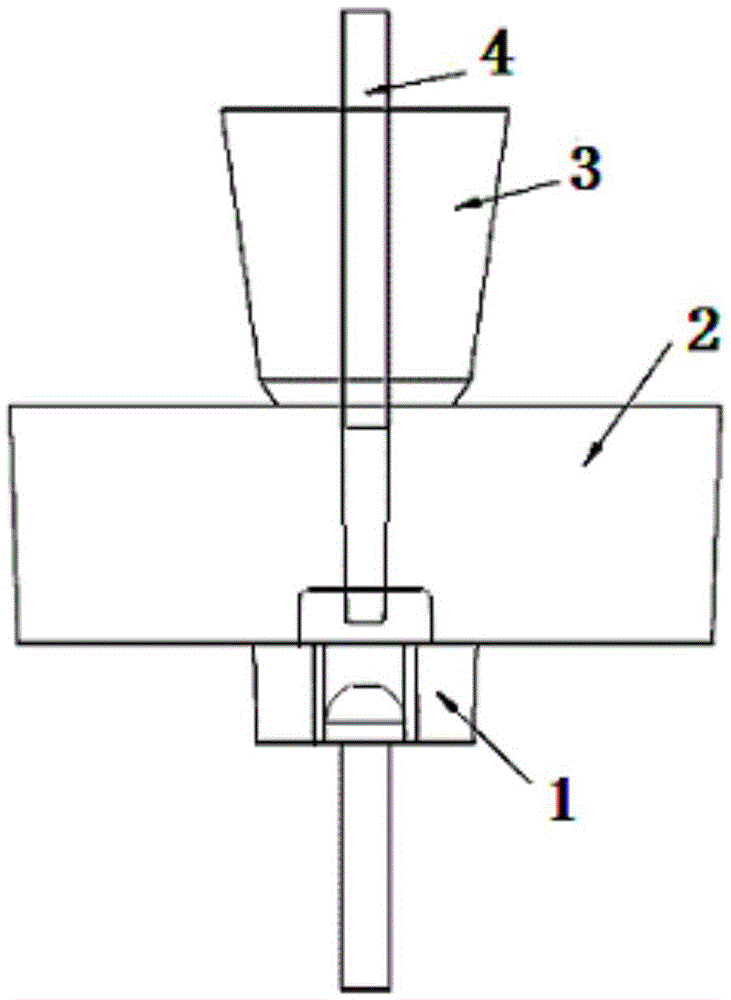

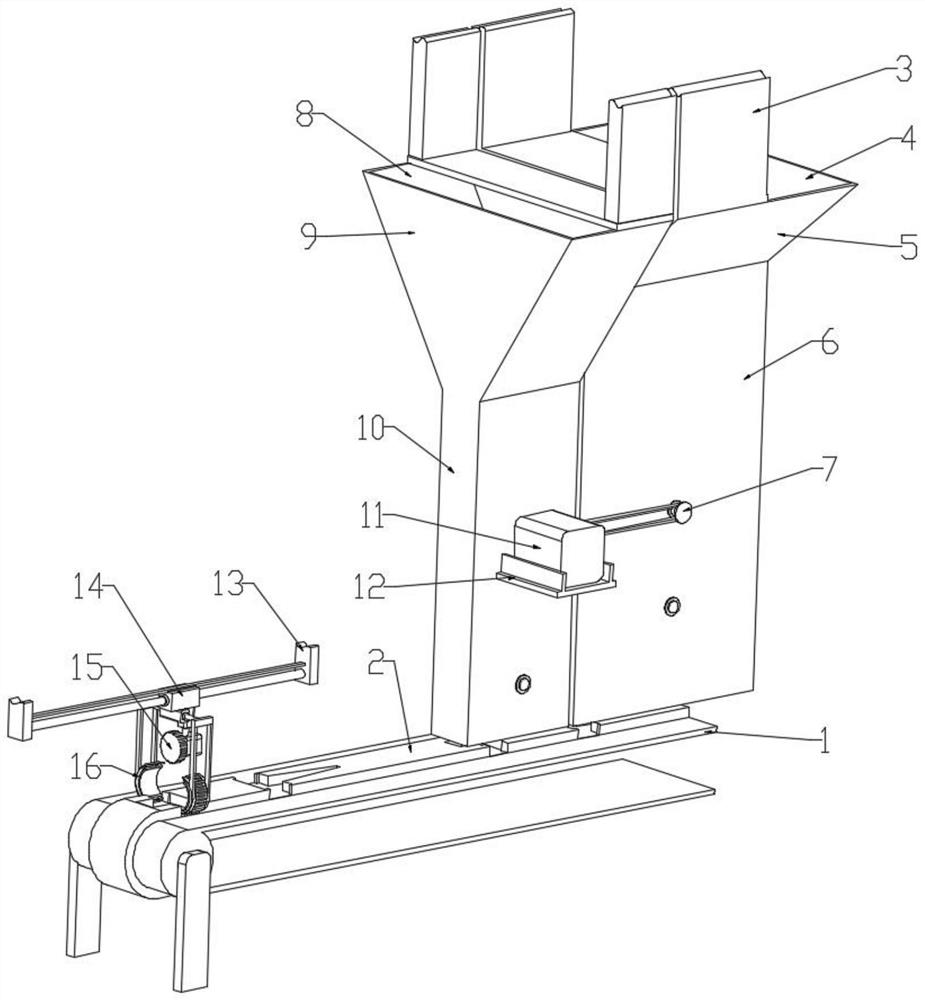

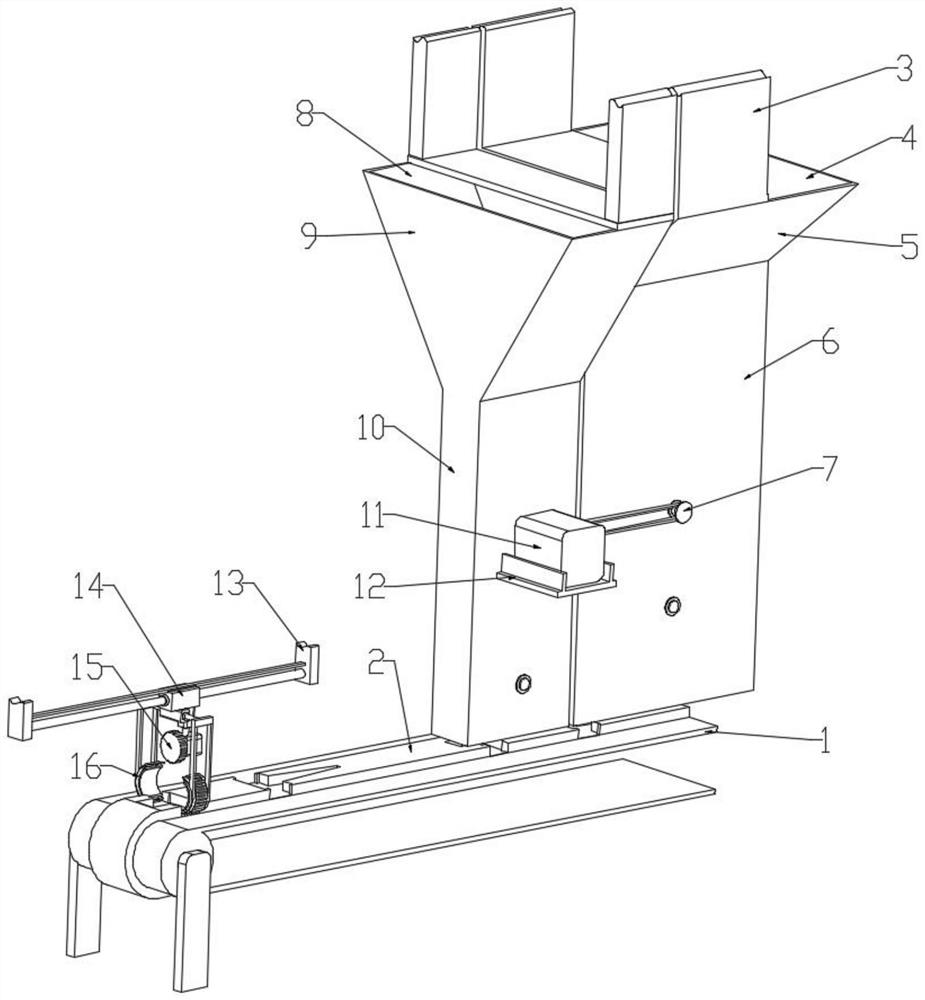

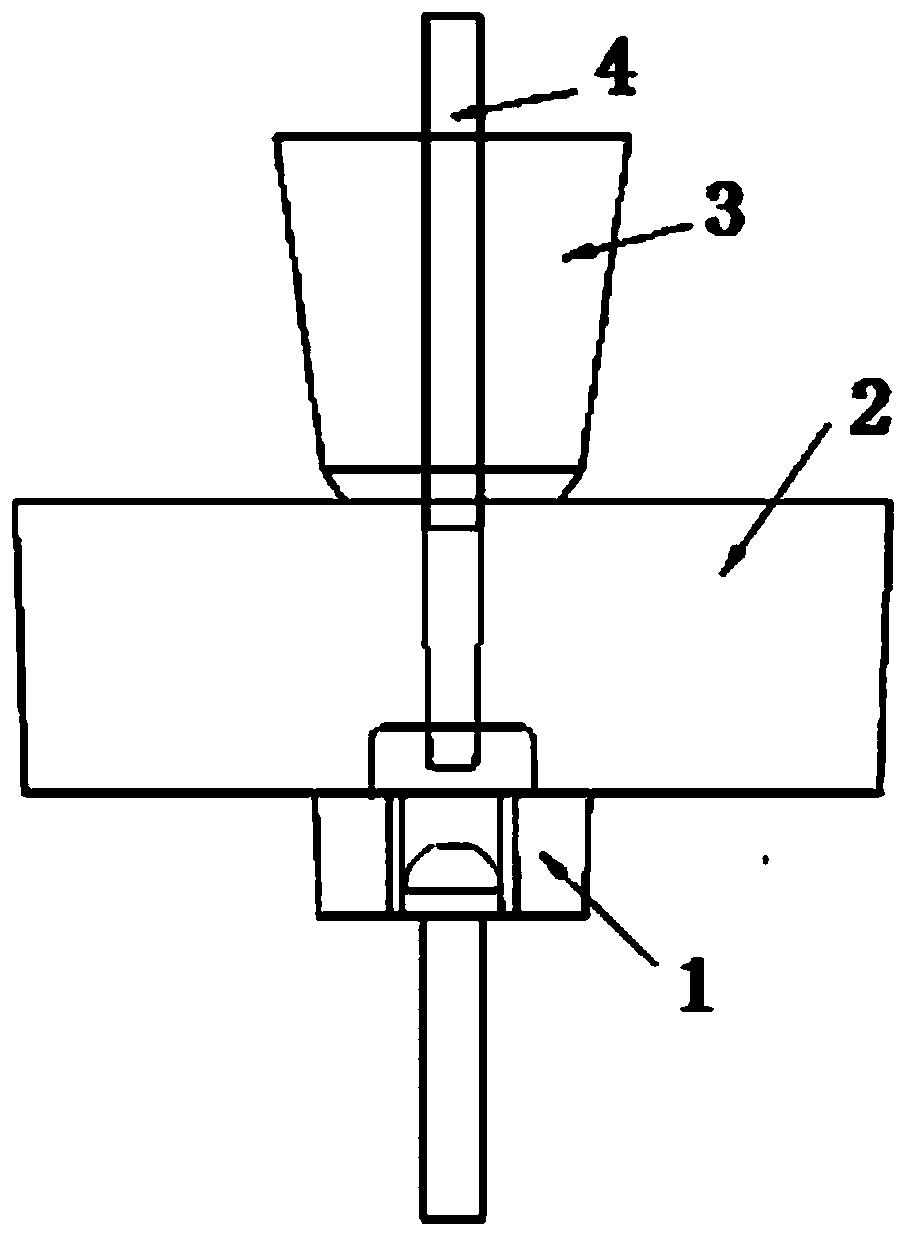

Uniform and quantitative fertilizing device for agricultural planting

ActiveCN112400391ARealize opening and closing movementAvoid cloggingSpadesFertiliser distributersAgricultural engineeringAgricultural science

The invention relates to a fertilizing device, in particular to a uniform and quantitative fertilizing device for agricultural planting. The technical problem to be solved is to provide the uniform and quantitative fertilizing device for agricultural planting, and the uniform and quantitative fertilizing device can be used for final landfill, can achieve quantitative fertilization and is anti-clogging. According to the technical scheme, the uniform and quantitative fertilizing device for agricultural planting comprises a frame and the like; a power mechanism is fixedly installed at one side ofthe frame, a discharging mechanism is fixedly installed at the other side of the frame, the discharging mechanism is connected with the power mechanism, a soil turning mechanism is installed at the side, away from the discharging mechanism, of the frame, the soil turning mechanism is in sliding connection with the discharging mechanism, and the soil turning mechanism is connected with the power mechanism; and in a discharging device, a second screw rod is adopted to drive a sliding plate to continuously slide in a fixed frame, so that the opening and closing movement of a discharging openingof an organic fertilizer is realized, and the blockage of the organic fertilizer at the discharging opening is prevented.

Owner:宋建国

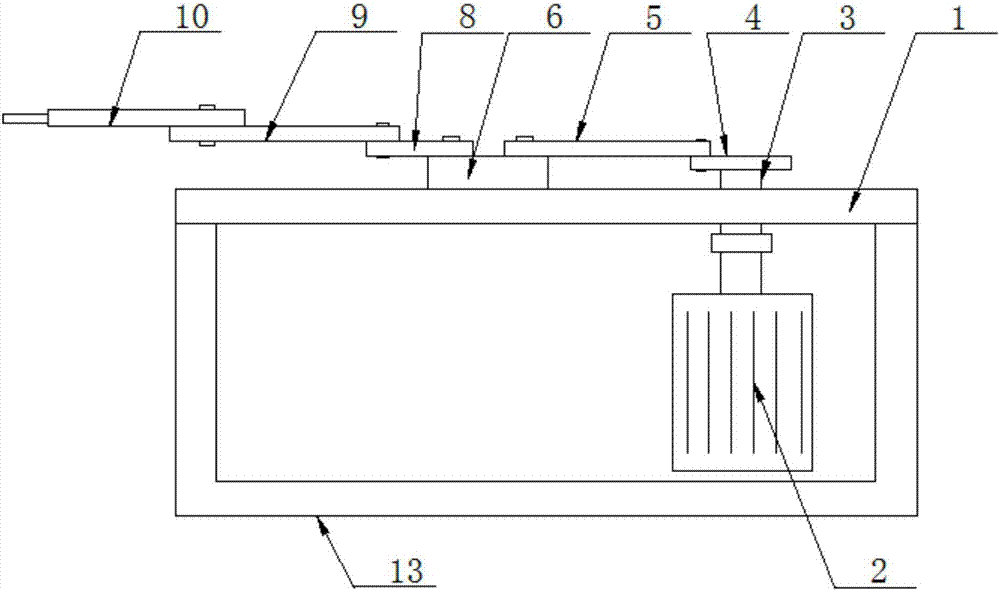

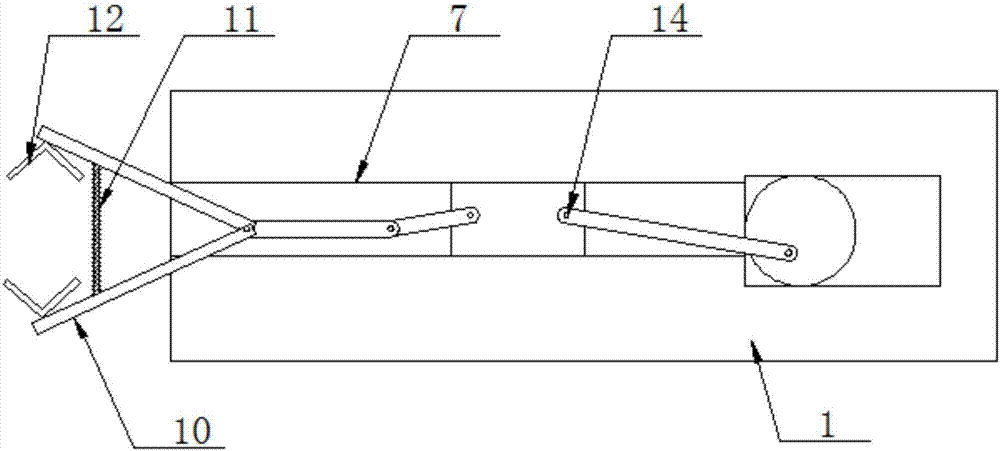

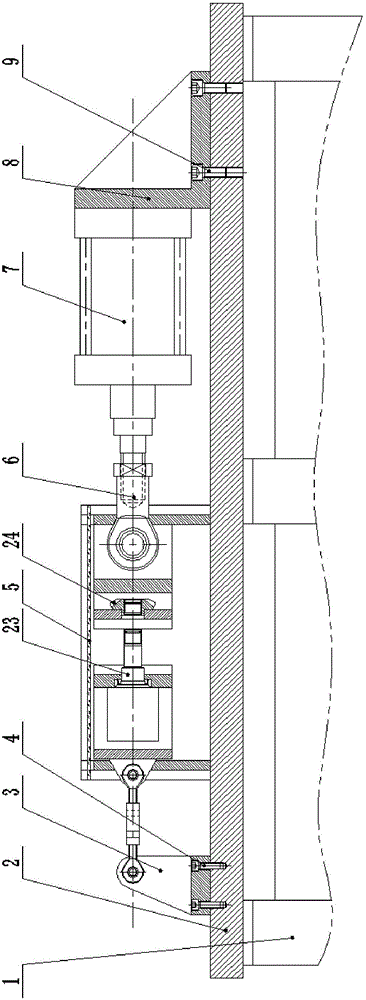

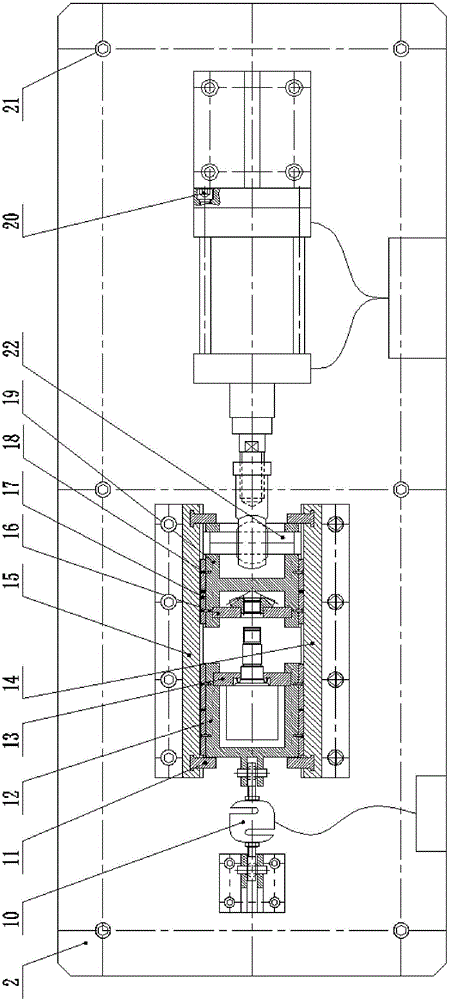

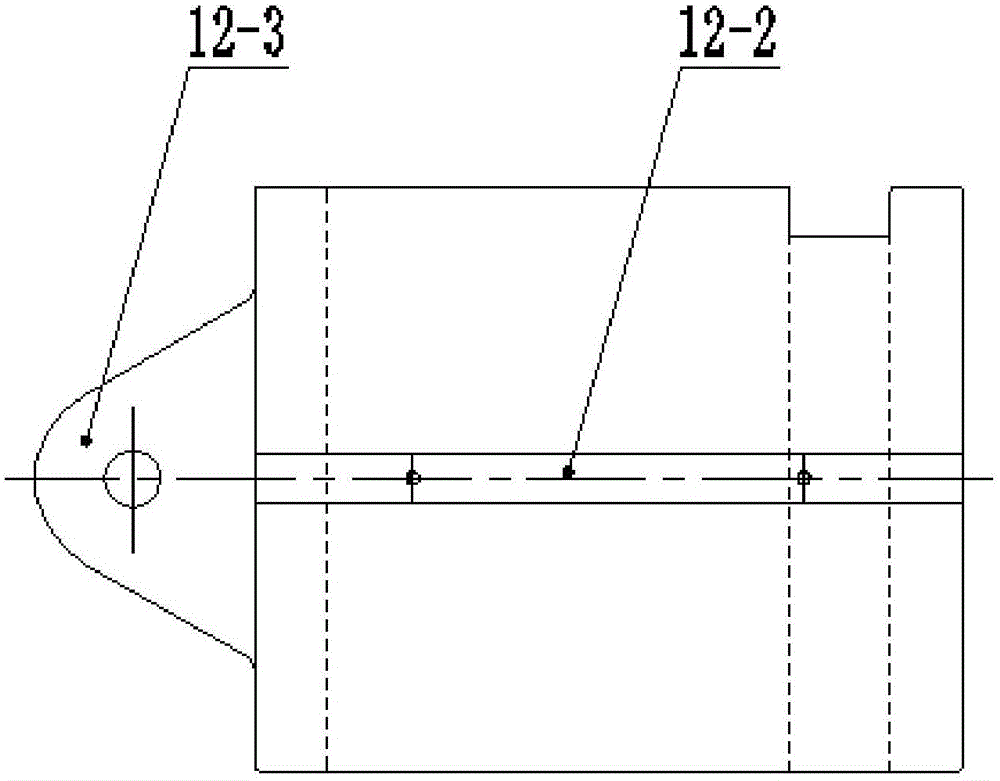

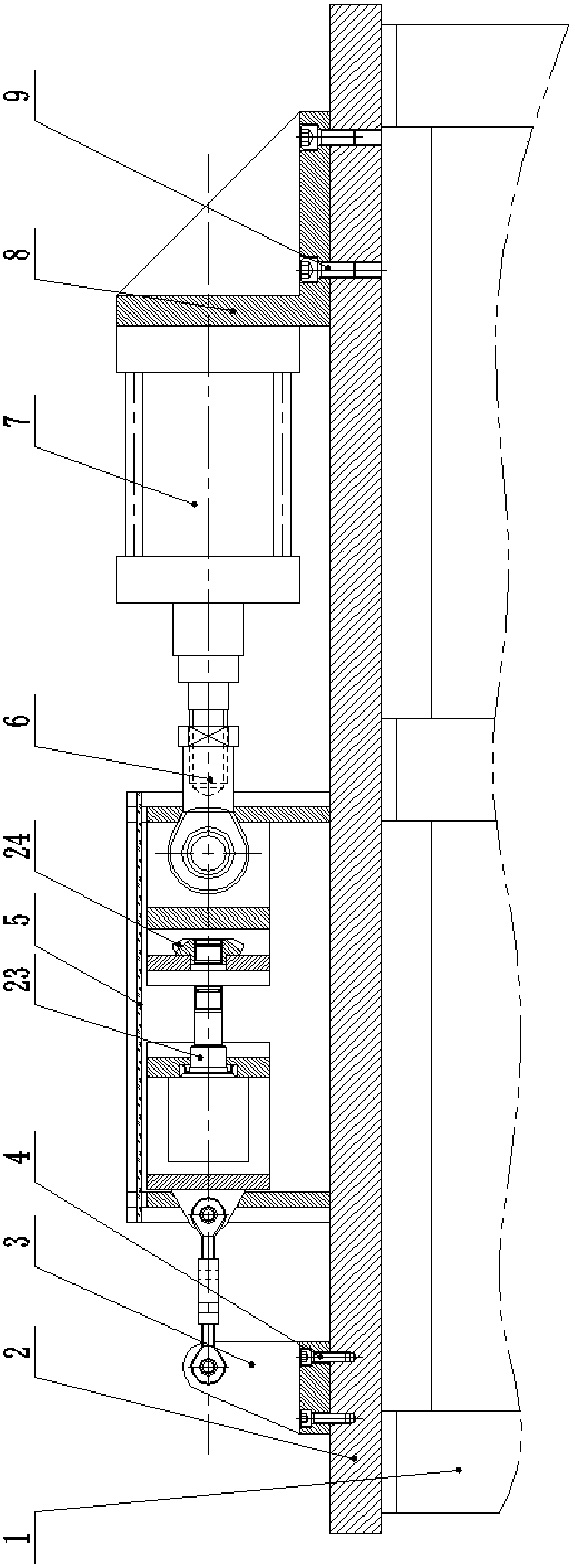

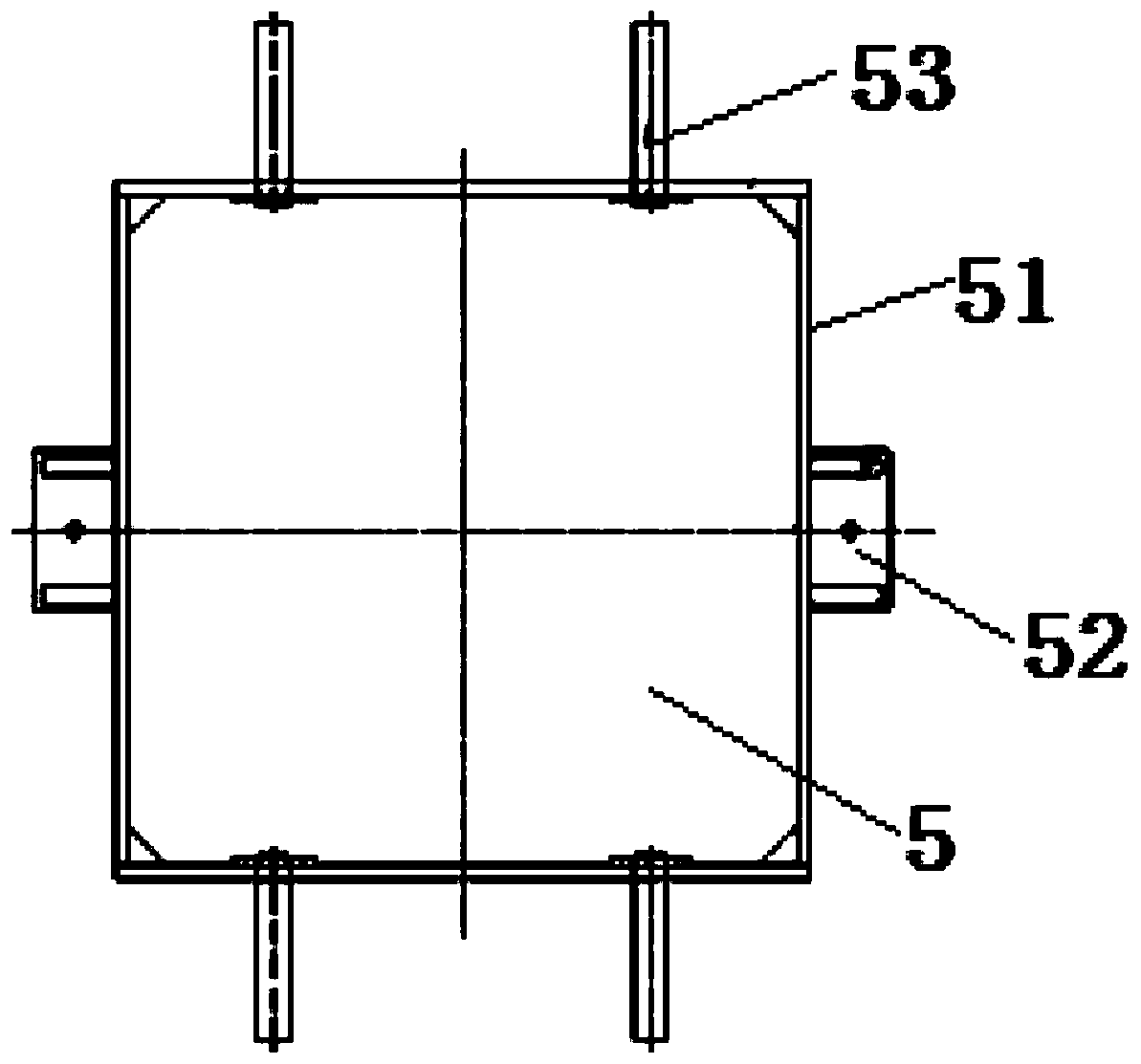

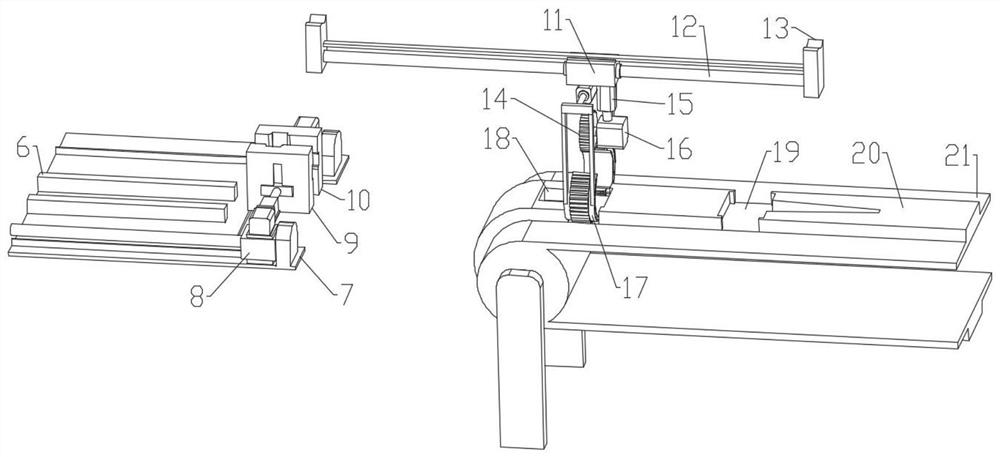

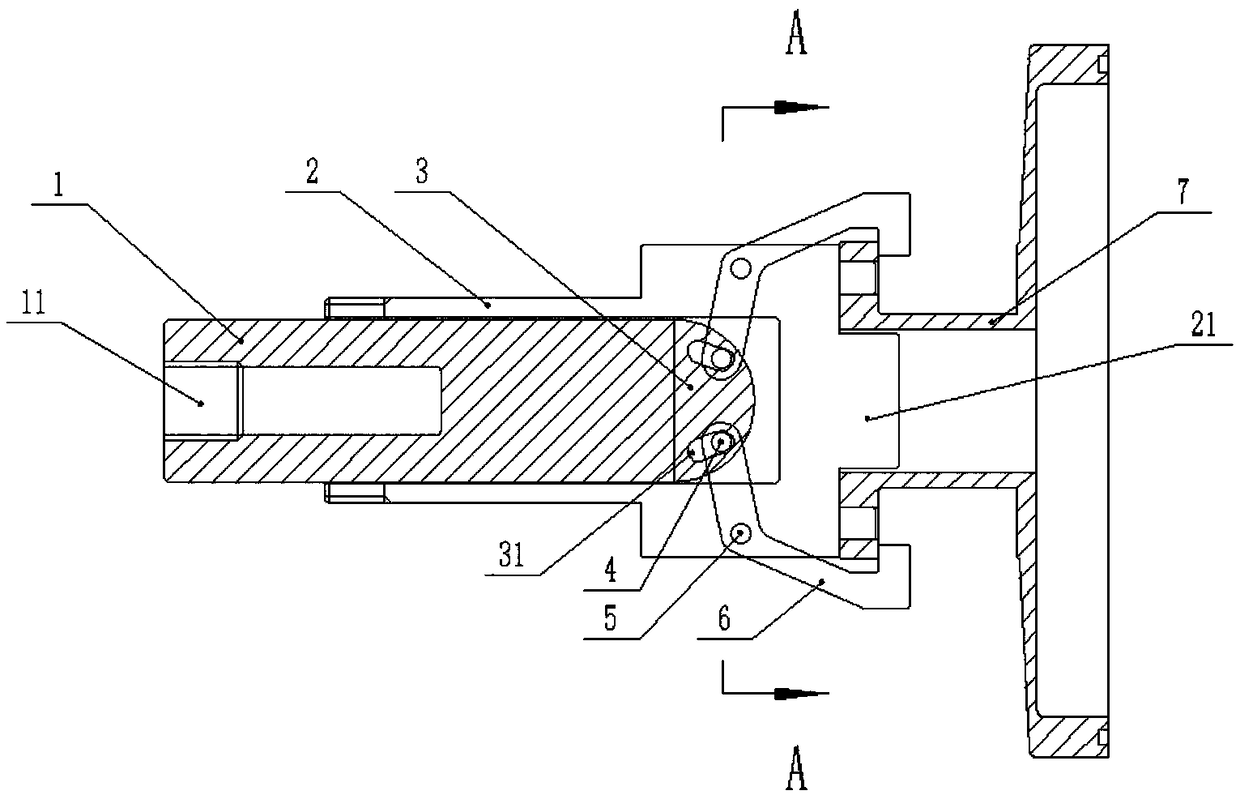

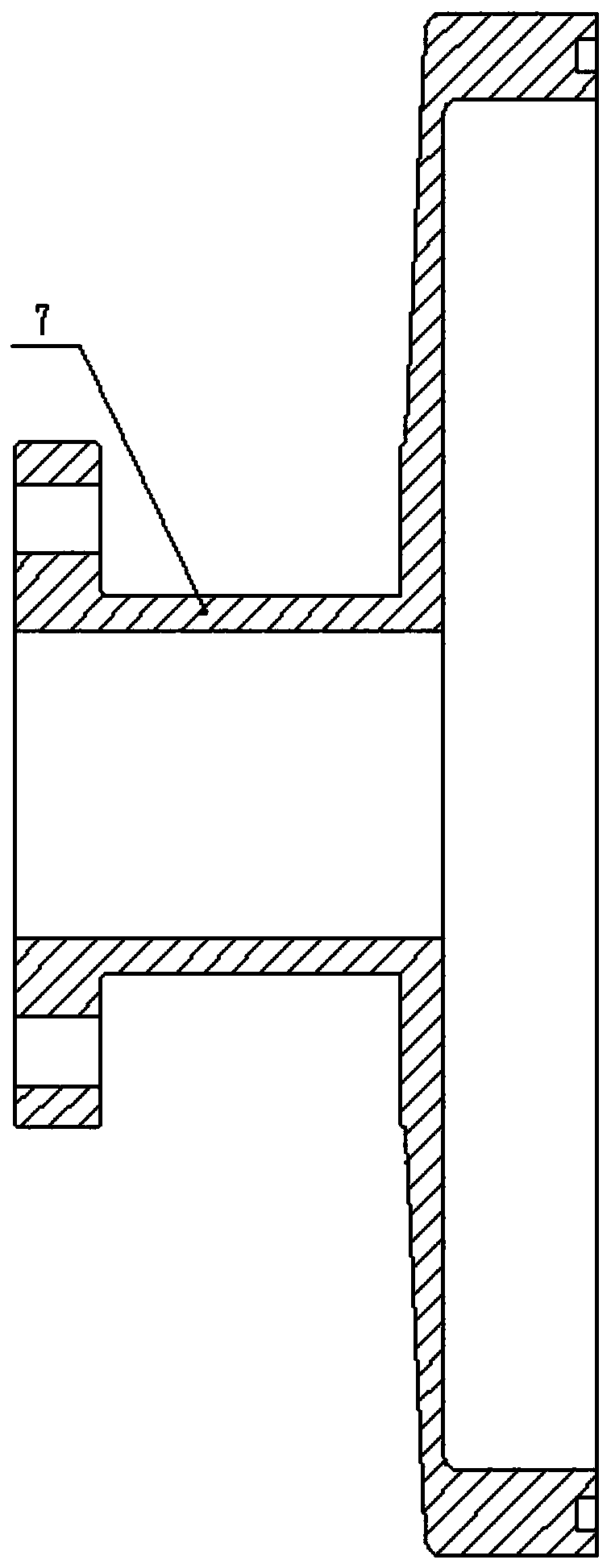

Semiaxis gear dismounting force and press mounting force testing device

ActiveCN106092408AVerify rationalityRealize slidingApparatus for force/torque/work measurementEngineeringPiston

The invention relates to a semiaxis gear dismounting force and press mounting force testing device, comprising a platen and a semiaxis seat, a gear seat, a pull pressure sensor and a cylinder which are all arranged on the platen. The semiaxis seat and the gear seat are arranged on left and right sides, and are both installed in a liner sliding cooperative connection mode; the pull pressure sensor is located on the left side of the semiaxis seat, and has the left end fixed, and the right end connected to the semiaxis seat; the cylinder is located on the right side of the gear seat, the cylinder body located on the right end is fixed, and a piston extending terminal located on the left end is connected to the gear seat; the semiaxis seat is provided with a semiaxis seat hole used for insertion of a semiaxis and restricting the semiaxis from separating from the semiaxis seat towards the right; the gear seat is provided with a gear seat hole used for insertion of a gear and restricting the gear from separating the gear hole of the gear seat towards the left; the axes of the pull pressure sensor, the semiaxis seat, the gear seat hole and the cylinder are parallel and coaxial. The semiaxis gear dismounting force and press mounting force testing device can realize semiaxis gear dismounting force and press mounting force test so as to verify the reasonability of improved designs.

Owner:ZHEJIANG SIEKON PRECISION MACHINERY CO LTD

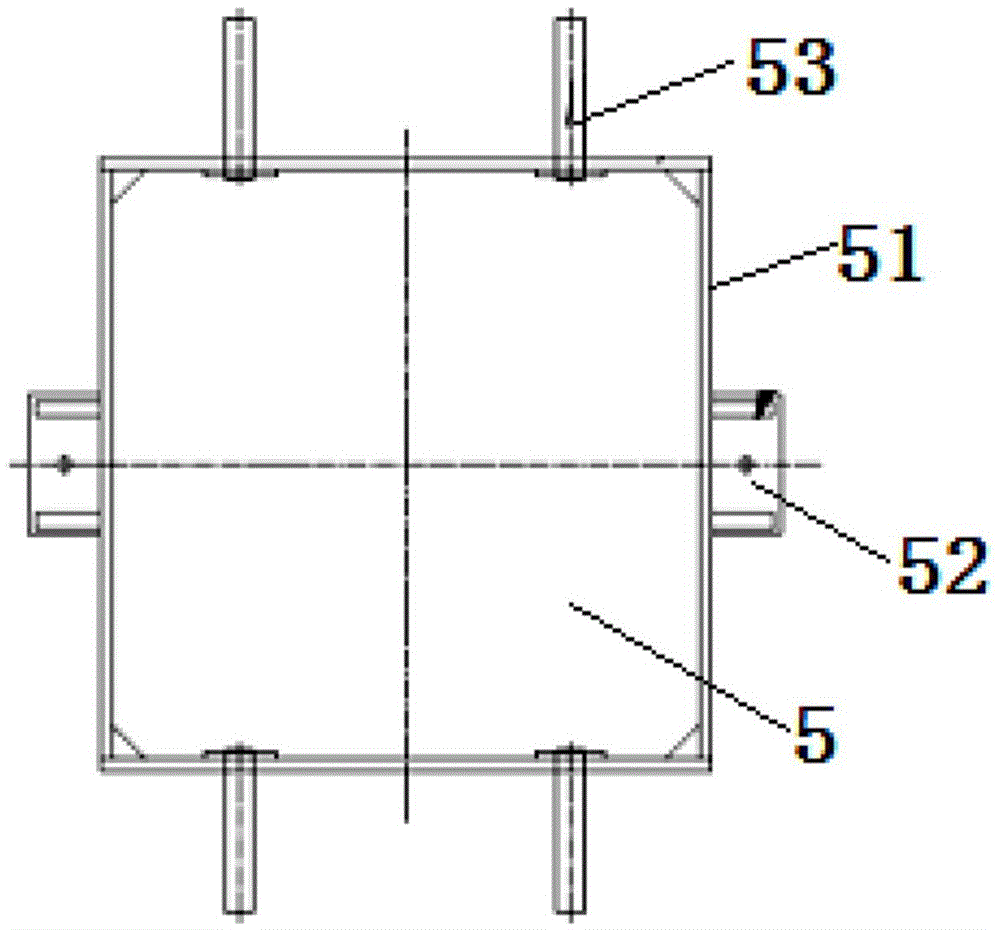

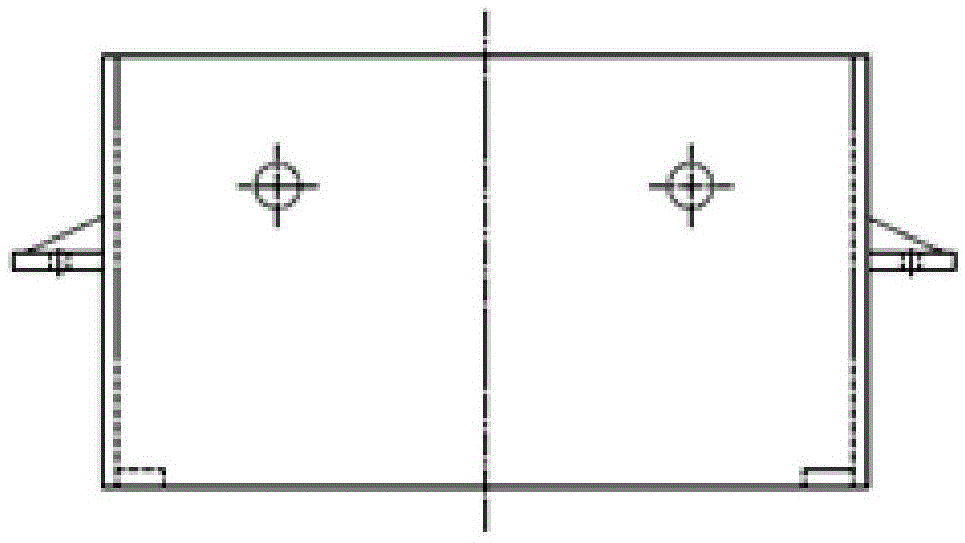

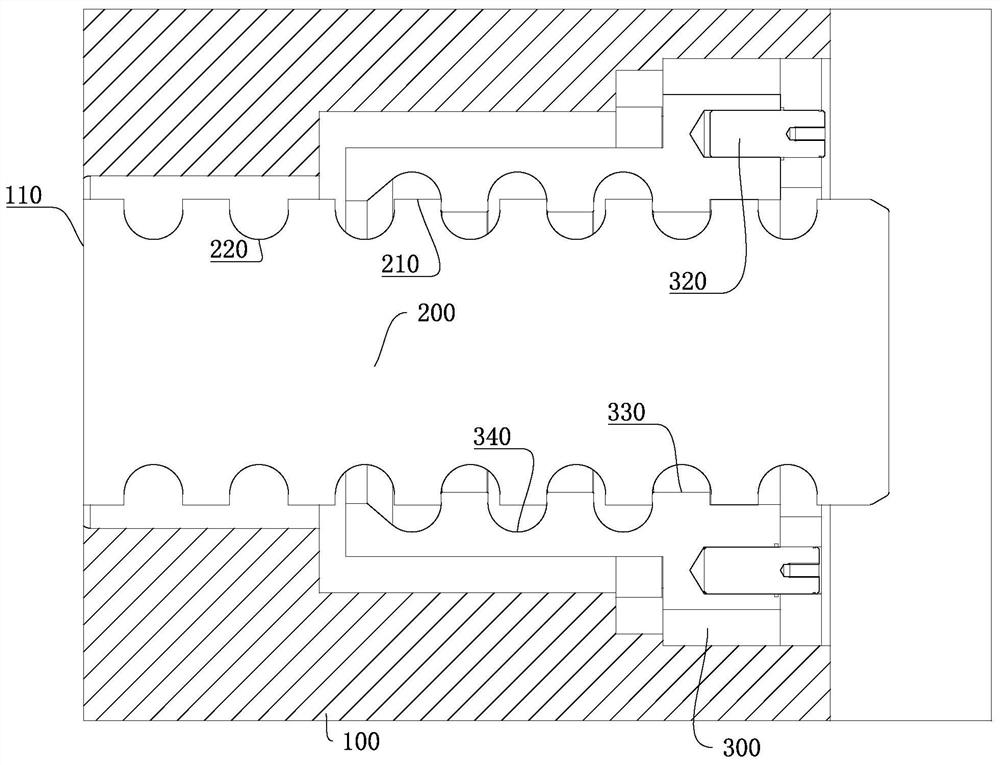

Novel direct opening type injection molding machine synchronous hooping device

PendingCN111993650ARealize opening and closing movementConsistent movementStructural engineeringMachine

The invention discloses a novel direct opening type injection molding machine synchronous hooping device. The problems that in the prior art, a hooping device in an injection molding machine cannot besynchronous, consequently, a die is damaged and noise is generated are solved. The novel direct opening type injection molding machine synchronous hooping device comprises a movable die plate, a pullrod, a hooping device and a synchronous device. Due to the fact that sliding grooves are formed in the inner side of a pull rod hole, two semi-hooping nuts can only move in the opening direction of the sliding grooves due to sliding blocks, meanwhile, a synchronous rotary disc is arranged so that the two semi-hooping nuts can be driven to move synchronously, various kinds of damage and noise generated when synchronization is not conducted are prevented, the two semi-hooping nuts are arranged in the pull rod hole, the length of a pull rod can be shortened, and therefore the length of the wholemachine is shortened; and when the two semi-hooping nuts are used for hooping the pull rod, the two semi-hooping nuts are fixed to the pull rod under the cooperation of protrusions and grooves, and the hooping effect of the two semi-hooping nuts is better.

Owner:HAITIAN PLASTICS MACHINERY GRP

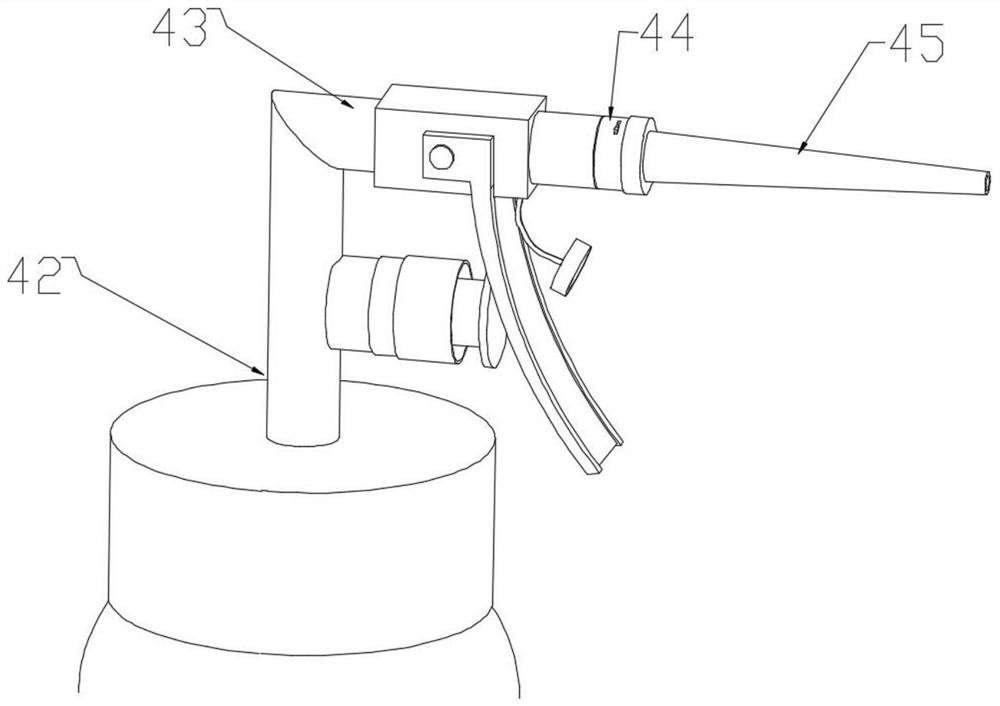

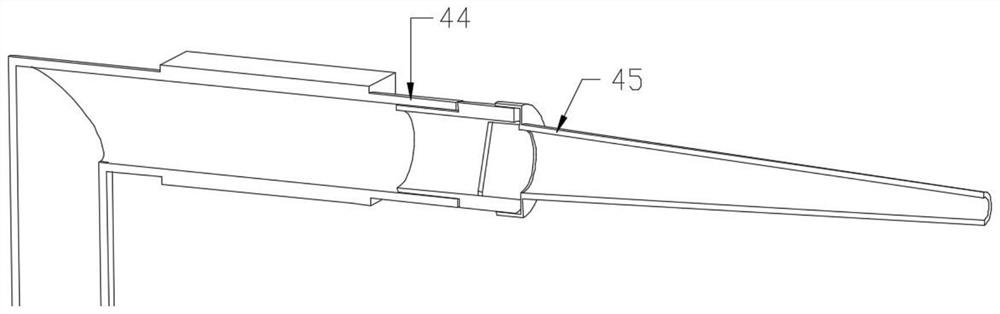

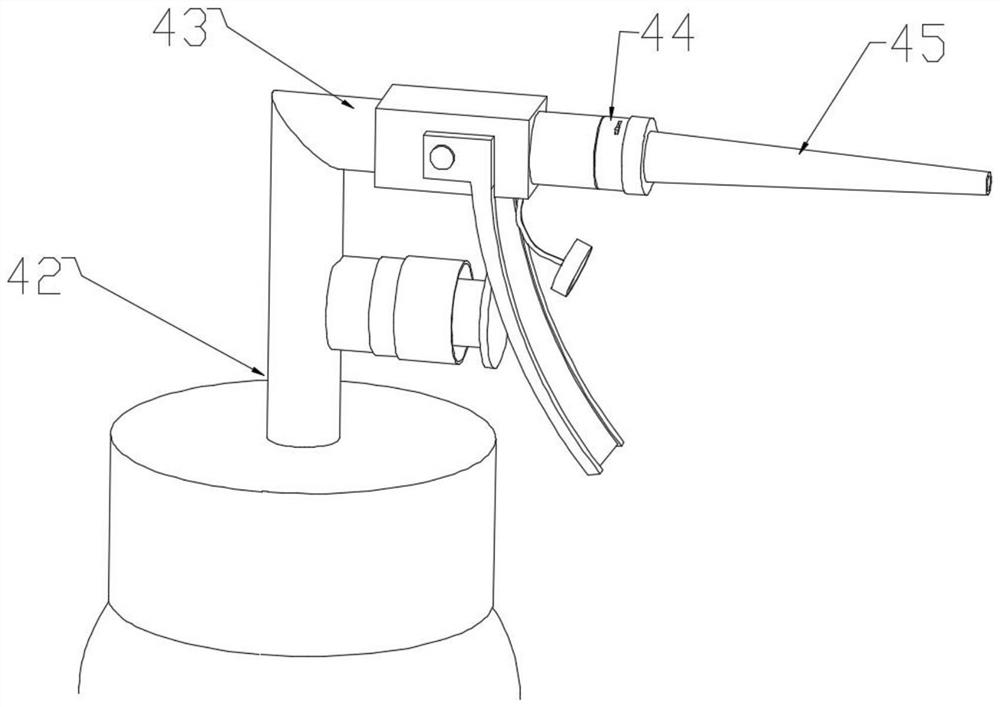

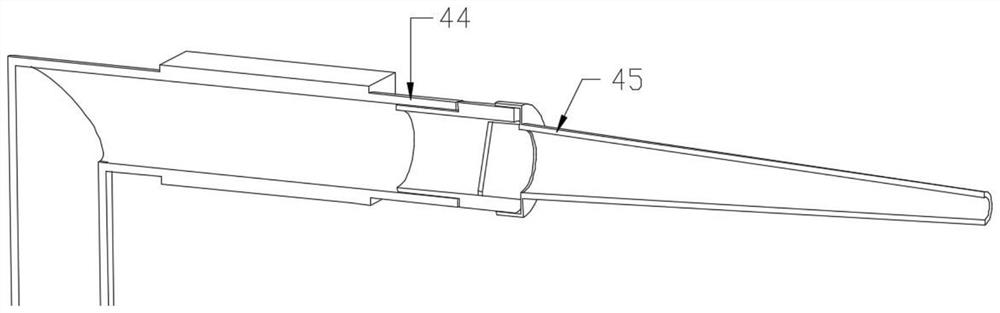

Sprayer assembly taking and clamping device for irrigator production

InactiveCN113233179AAchieve transshipmentRealize opening and closing movementConveyorsConveyor partsTubular linear motorSprayer

The invention discloses a sprayer assembly taking and clamping device for irrigator production, and belongs to the technical field of irrigator machining. The sprayer assembly taking and clamping device comprises a conveying belt, and a nozzle discharging device, a connecting base discharging device and a tubular linear motor are sequentially arranged above the conveying belt. A clamping device is connected to a rotor of the tubular linear motor. A protruding limiting belt is arranged on the surface of the conveying belt, and paired nozzle limiting grooves and connecting base limiting grooves are formed in the surface of the limiting belt in an array mode. The nozzle discharging device comprises a nozzle storage box, a nozzle feeding port is formed in the top of the nozzle storage box, a nozzle discharging channel with an opening in the bottom end is formed in the lower portion of the nozzle storage box, and a first discharging conveying belt is arranged in the nozzle discharging channel. The connecting base discharging device comprises a connecting base storage box, a connecting base feeding port is formed in the top of the connecting base storage box, a connecting base discharging channel with an opening in the bottom end is formed in the lower portion of the connecting base storage box, and a second discharging conveying belt is arranged in the connecting base discharging channel. The clamping device comprises a driving gear, and a rotatable clamp is arranged below the driving gear.

Owner:岳阳职业技术学院

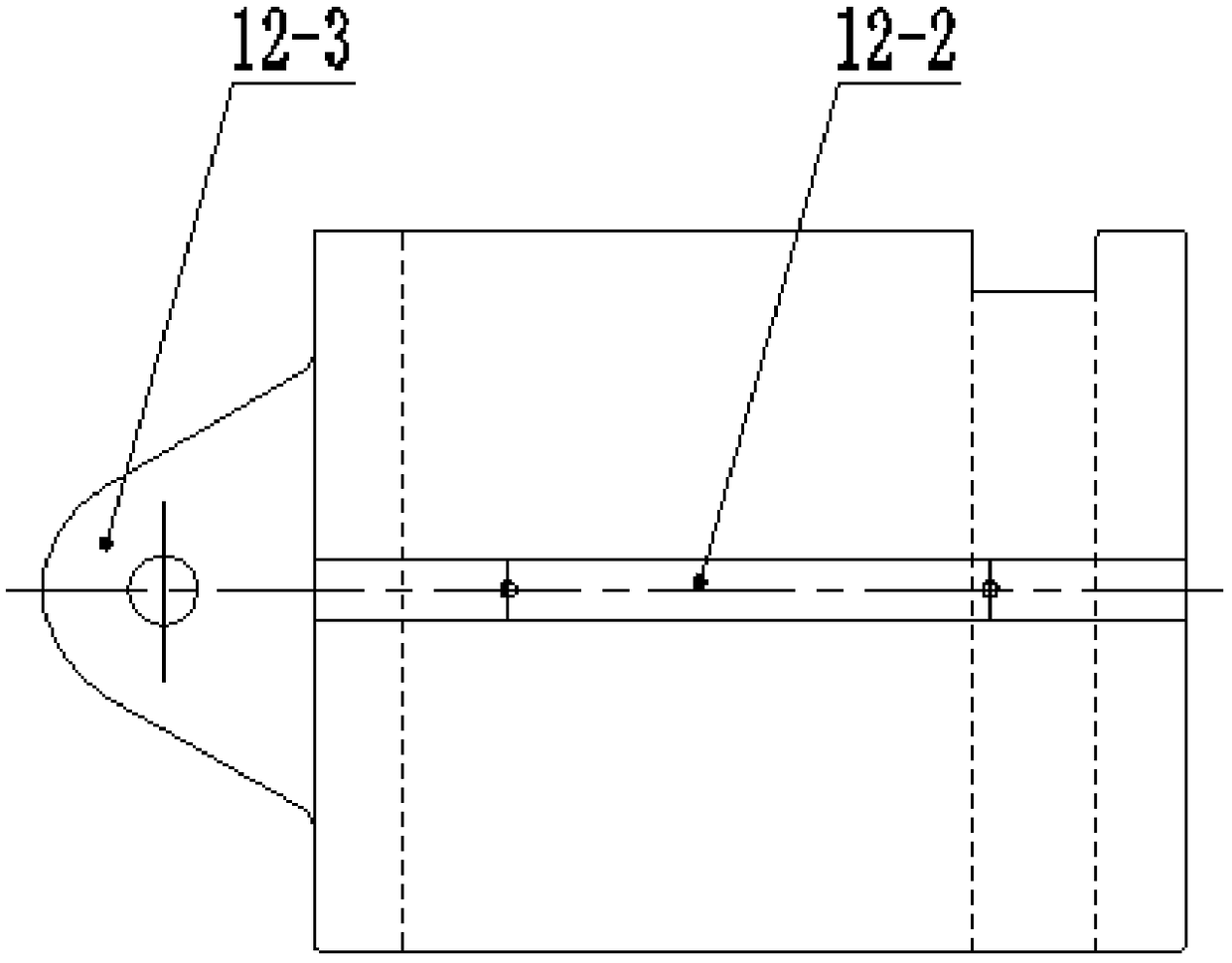

a clamp body

ActiveCN103029011BRealize opening and closing movementFast clamping speedOther manufacturing equipments/toolsEngineeringClosed state

The invention discloses a clamp body. An installation sleeve is arranged outside each elastic sheet in the clamp body, wherein the front end of the elastic sheet is provided with a clamping end which is an open state while being exposed out of the front end of the installation sleeve to outwards open, and is in an closed state while being folded to the installation sleeve to close inwards; the hole wall or the front end port of the installation sleeve is provided with a close-up edge which is blocked and matched with an elastic claw along the front and rear direction when the clamping end is in the open state, and is blocked outside the elastic claw when the clamping end is in the closed state. During a using process, the close-up edge is matched with the clamping end to realize the opening-closing motion of the elastic claw, thereby realizing clamping a cylindrical solid tool to be grinded and improving the clamping speed of the cylindrical solid tool. Moreover, self-centering is realized through the matching of wedge surfaces, and the precision of clamping the cylindrical solid tool and grinding and machining the tool is improved.

Owner:FUNIK ULTRAHARD MATERIAL

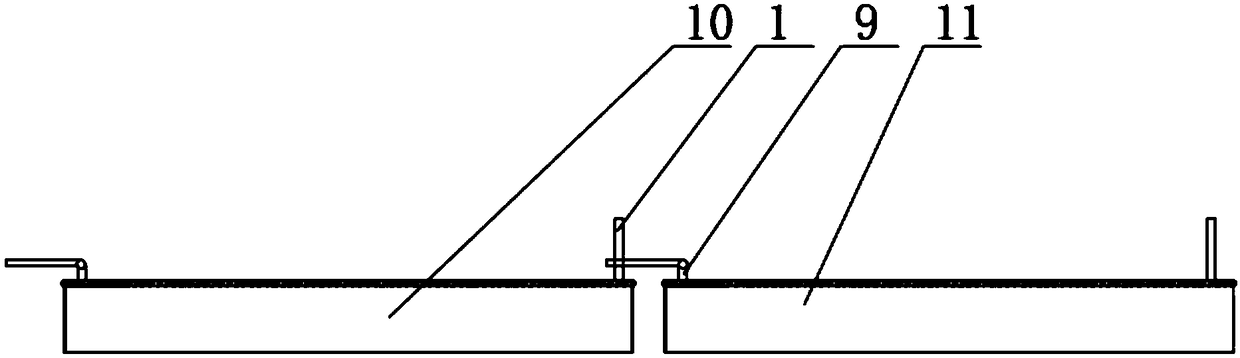

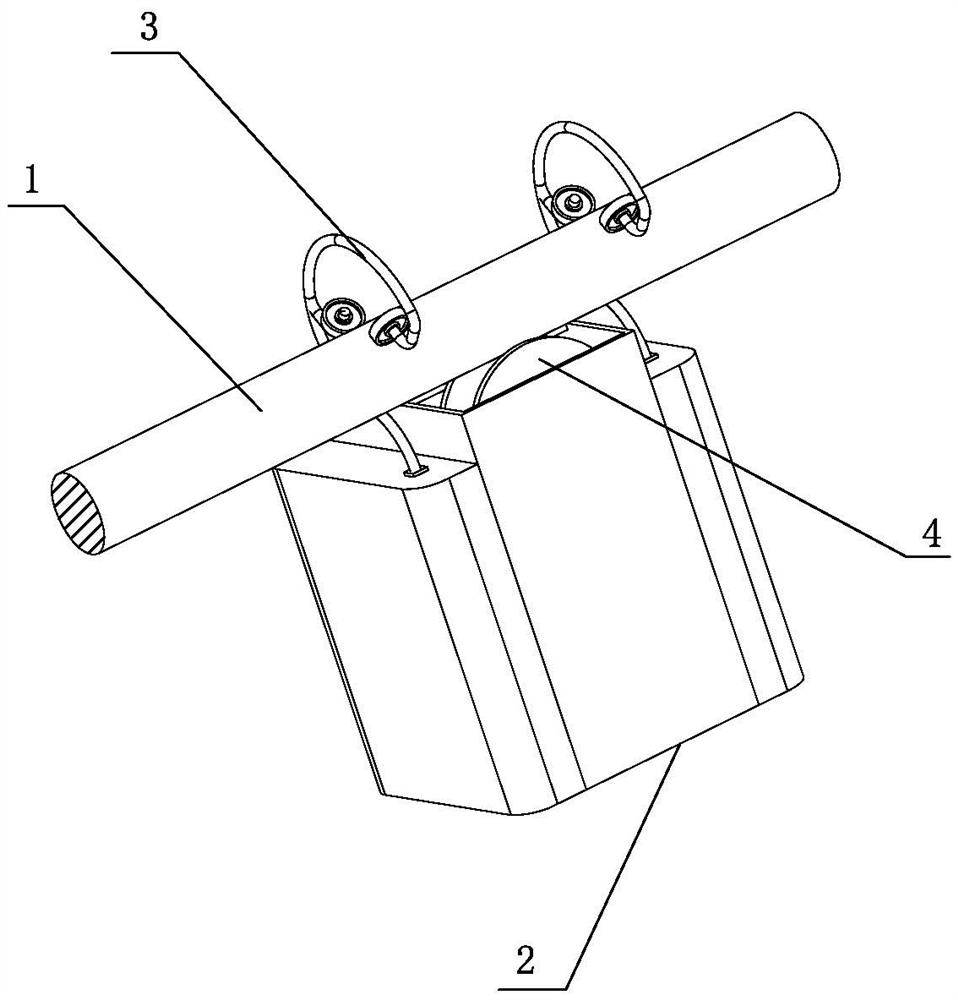

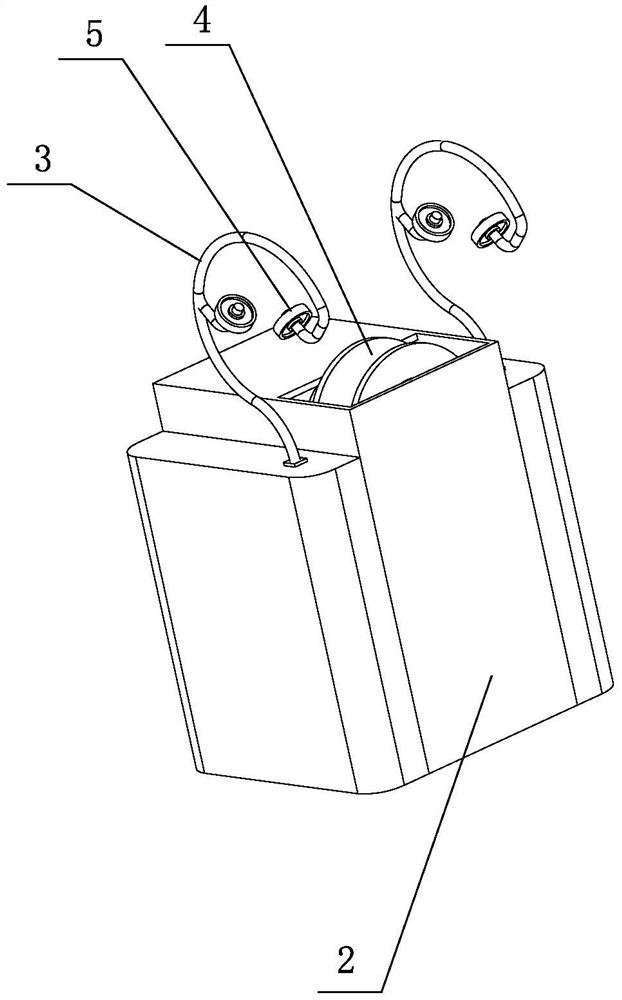

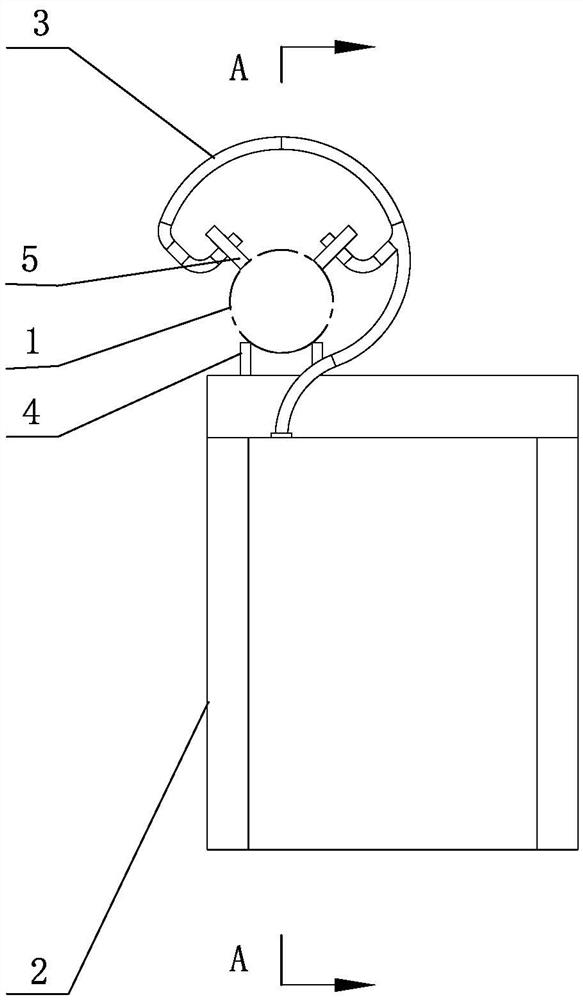

Holding column type connecting device used between two carriers

The invention relates to a holding column type connecting device used between two carriers. The holding column type connecting device used between the two carriers comprises a fixed block; one end ofthe fixed block is connected with a movable rotating shaft through a long-stroke spring; a pair of symmetric flap bodies is mounted on the movable rotating shaft; pin holes are formed in the head parts of both the two flap bodies; the two flap bodies surround an upright after being closed; fixing brackets are arranged on the external sides of the two flap bodies; the fixing brackets are connectedwith the fixed block through telescopic connecting rods; the two telescopic connecting rods are symmetrically placed on the two sides of the long-stroke spring. According to the holding column type connecting device used between the two carriers, the structure is compact and reasonable; the operation is convenient; through adoption of the holding column type connecting device, the opening and closing motions of the connection between the two carriers can be conveniently realized to satisfy a self-locking function; and meanwhile, automatic opening and closing in any horizontal direction can berealized; and additional load of a connecting body is supported.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Stacking device and stacking system for stacking packaging box bodies

PendingCN113371471ARealize the clamping effectAchieve releaseConveyorsStacking articlesClassical mechanicsEngineering

The invention relates to the technical field of air conditioner outdoor unit stacking, and provides a stacking device and a stacking system for stacking packaging box bodies. The stacking device comprises a mounting frame and a clamping device. The clamping device comprises two clamping mechanisms capable of relatively moving in the length direction of the mounting frame. A clamping space for clamping a packaging box body is formed between the two clamping mechanisms. Each clamping mechanism comprises a movable seat, a clamping plate, a connecting rod and a maintaining assembly. The movable seats can be movably arranged on the mounting frame in the length direction of the mounting frame. The clamping plates are used for abutting against the packaging box bodies. The first end of each connecting rod is hinged to the corresponding movable seat, and the second end of each connecting rod is hinged to the corresponding clamping plate. The maintaining assembly is used for driving the clamping plates to rotate towards the clamping space around the first ends. Therefore, when in emergency of power failure and / or gas failure, the clamping plates are driven by the maintaining assembly to clamp one packaging box body, and it is avoided that the packaging box body falls off accidentally.

Owner:SHENZHEN JASIC ROBOT TECH CO LTD

Portable curtain opening and closing mechanism

InactiveCN112471874AOpening and closingRealize opening and closing movementCurtain accessoriesEngineeringStructural engineering

The invention relates to a portable curtain opening and closing mechanism. The mechanism comprises a box body, wherein a driving part and a driving power source are arranged in the box body, a horizontal output shaft is arranged at the output end of the driving part, a roller is connected to the output shaft, and an opening allowing the rim to protrude to the outer side of the top of the box bodyconveniently is formed in the top, corresponding to the upper rim of the roller, of the box body; a concave arc-shaped rim which is in rolling fit with a curtain rod conveniently is arranged on the peripheral rim of the roller, the upward rim of the roller is in rolling contact with the rod wall of the lower side of the curtain rod in the length direction, elastic hooks which are elastically clamped with the curtain rod conveniently are arranged on the two sides of an opening of the box body respectively, and after the elastic hooks are elastically clamped with the curtain rod, the curtain rodcan be hung; and the upward rim of the roller is in rolling contact with the lower side rod wall of the curtain rod in the length direction. According to the portable curtain opening and closing mechanism, after the elastic hook is hooked on the curtain rod, the roller abuts against and makes contact with the curtain rod, and after the roller rolls along the curtain rod, the box body can be driven to push curtain cloth to be opened and closed.

Owner:张翔

Clamp body

ActiveCN103029011ARealize opening and closing movementFast clamping speedOther manufacturing equipments/toolsEngineeringClosed state

The invention discloses a clamp body. An installation sleeve is arranged outside each elastic sheet in the clamp body, wherein the front end of the elastic sheet is provided with a clamping end which is an open state while being exposed out of the front end of the installation sleeve to outwards open, and is in an closed state while being folded to the installation sleeve to close inwards; the hole wall or the front end port of the installation sleeve is provided with a close-up edge which is blocked and matched with an elastic claw along the front and rear direction when the clamping end is in the open state, and is blocked outside the elastic claw when the clamping end is in the closed state. During a using process, the close-up edge is matched with the clamping end to realize the opening-closing motion of the elastic claw, thereby realizing clamping a cylindrical solid tool to be grinded and improving the clamping speed of the cylindrical solid tool. Moreover, self-centering is realized through the matching of wedge surfaces, and the precision of clamping the cylindrical solid tool and grinding and machining the tool is improved.

Owner:FUNIK ULTRAHARD MATERIAL

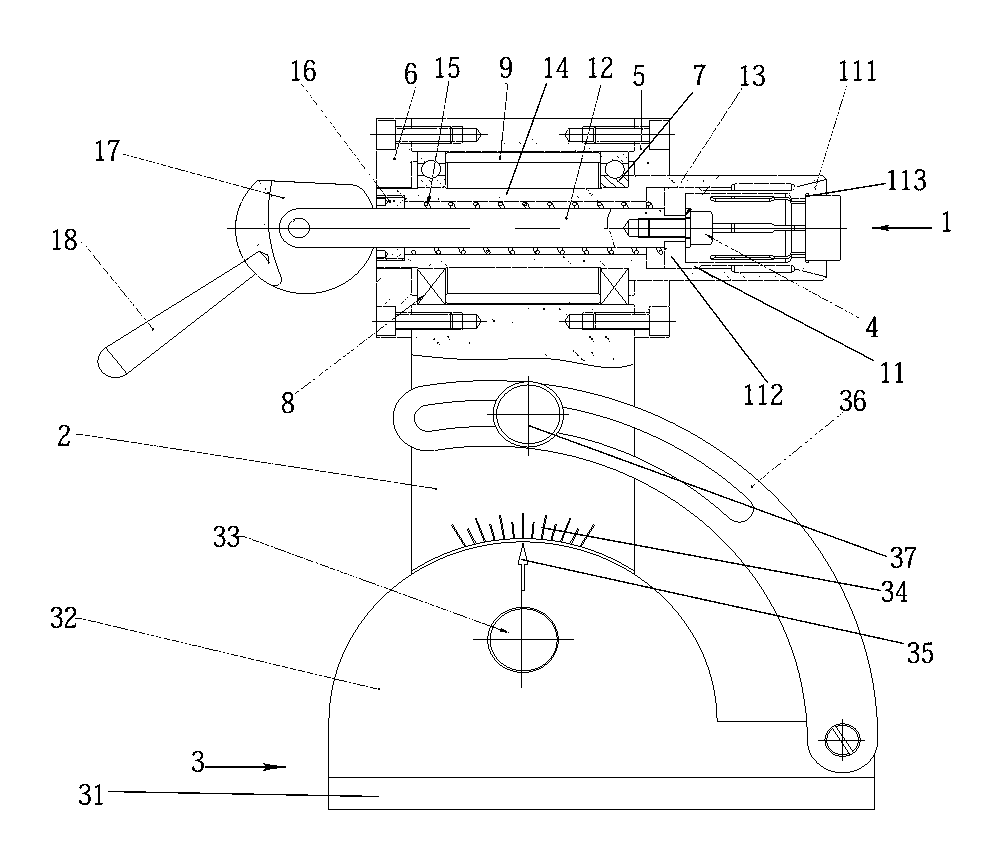

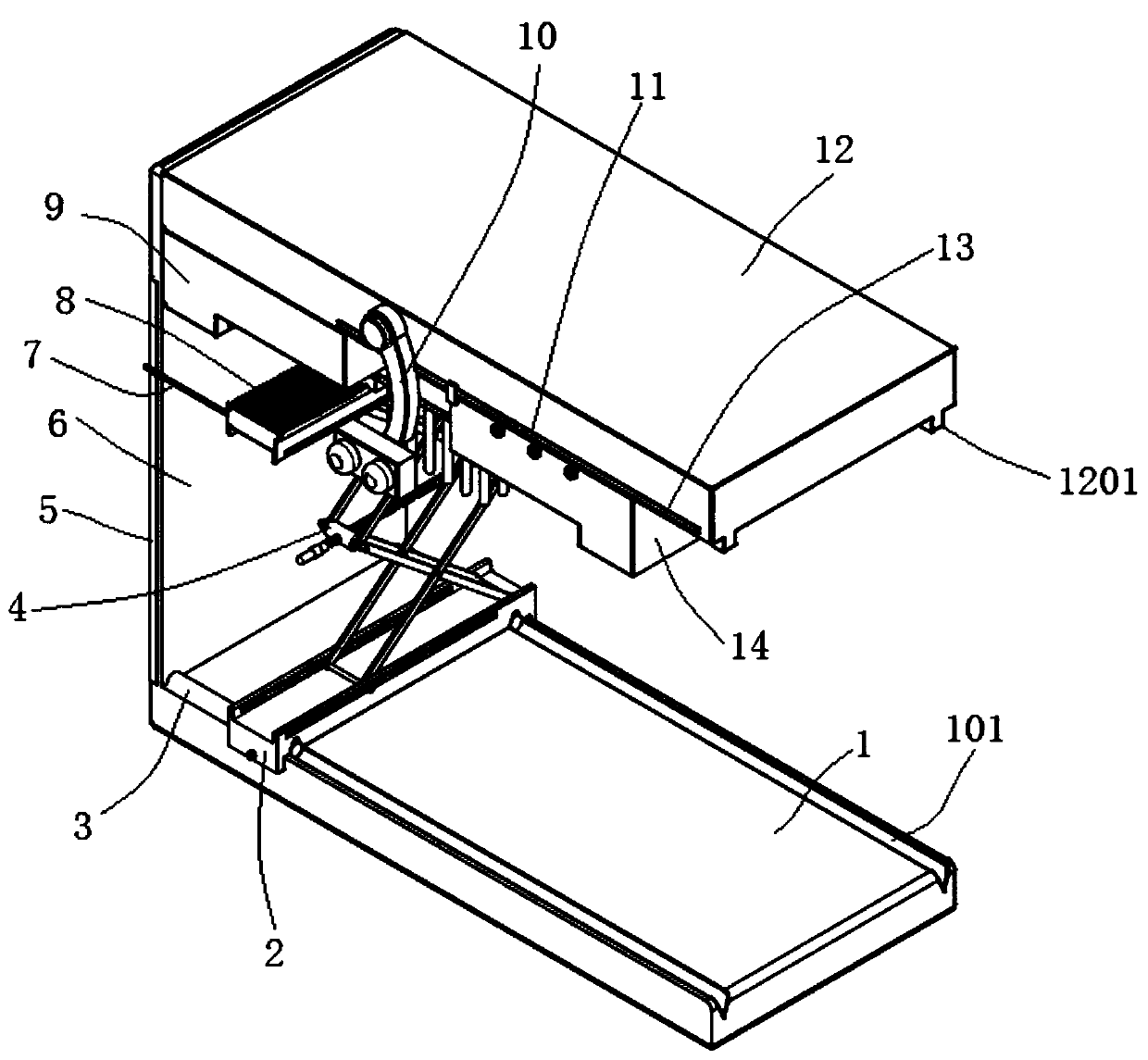

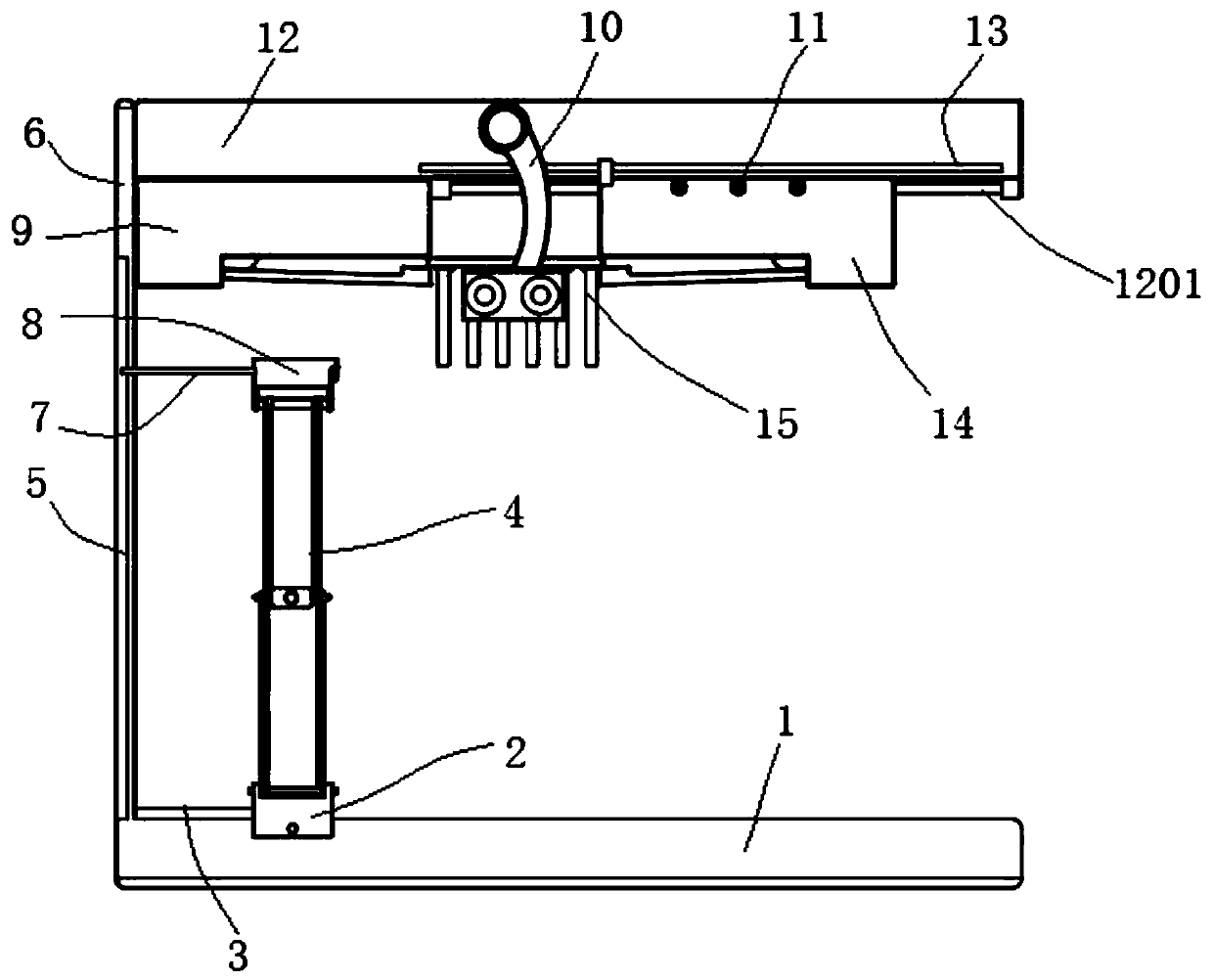

Probe card probe-grinding machine

PendingCN110253436AEasy to control the lengthEasy to useEdge grinding machinesGrinding carriagesProbe cardPulp and paper industry

The invention discloses a probe card probe-grinding machine, and relates to the technical field of probe card manufacturing. The probe-grinding machine comprises a probe-grinding mechanism, a clamping mechanism, a horizontal ruler and a vertical ruler, wherein the probe-grinding mechanism comprises a lower sliding seat and an upper supporting seat, a lifting mechanism is arranged between the lower sliding seat and the upper supporting seat, the clamping mechanism comprises a fixed clamping body and a movable clamping body, and an amplifying device is rotationally arranged on one side of an upper base. According to the probe card probe-grinding machine, the height of the upper supporting seat is adjusted by rotating a screw, so that the grinding device on the upper supporting seat is in contact with clamping pins on the probe card, the distance between the grinding device and the probe card can be intuitively obtained through the vertical ruler and a side indicating rod, and the length of the pin tip in the grinding process can be conveniently controlled; the clamping mechanism is used for clamping the probe card, a telescopic rod is adjusted to drive a gear and a rack to move, so that opening and closing movement of a pressing plate is realized, and the probe card is clamped or taken down; and the distance between the fixed clamping body and the movable clamping body can be adjusted by referring to the horizontal ruler, and the machine is suitable for being used for the probe cards with different sizes.

Owner:苏州光和精密测试有限公司

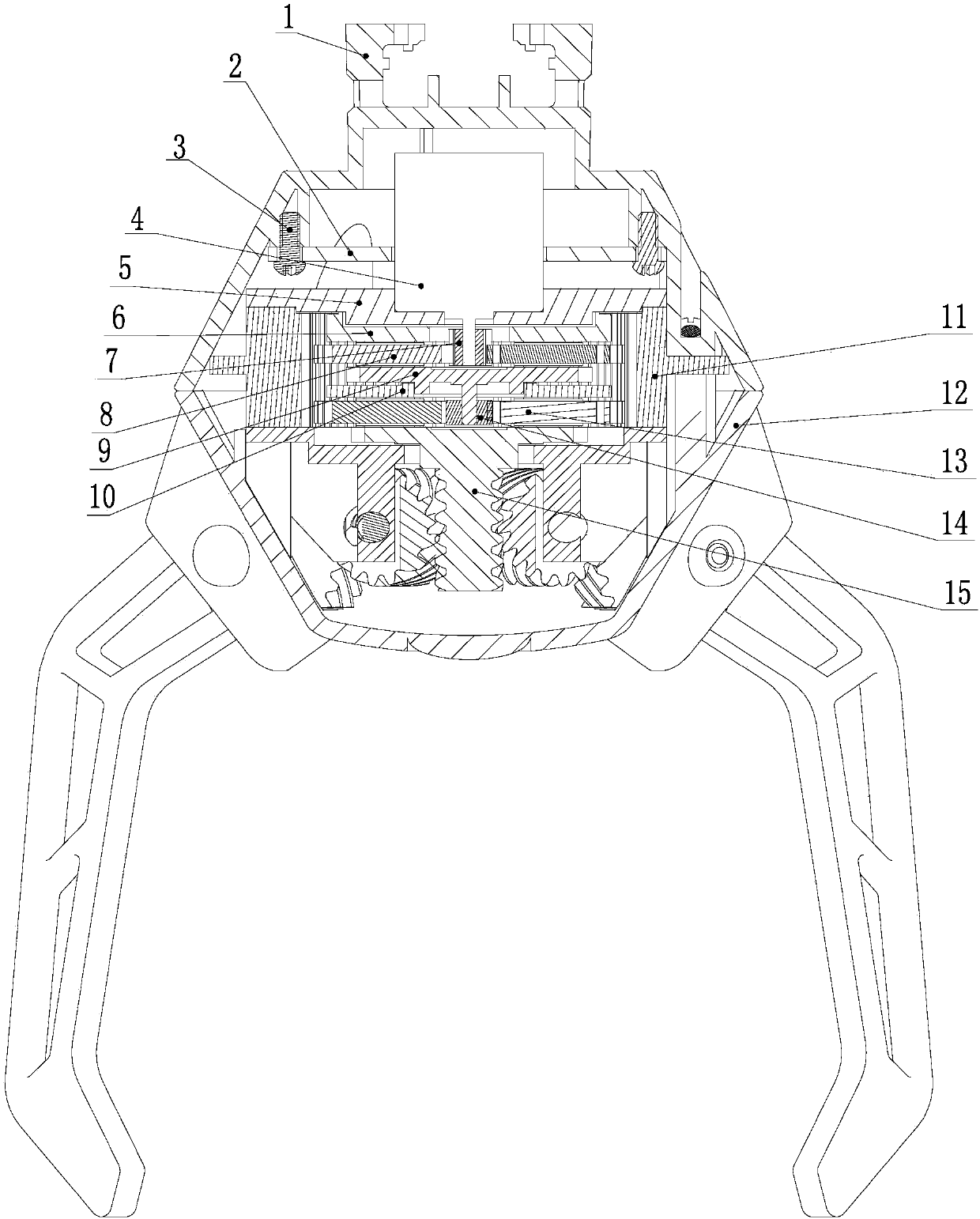

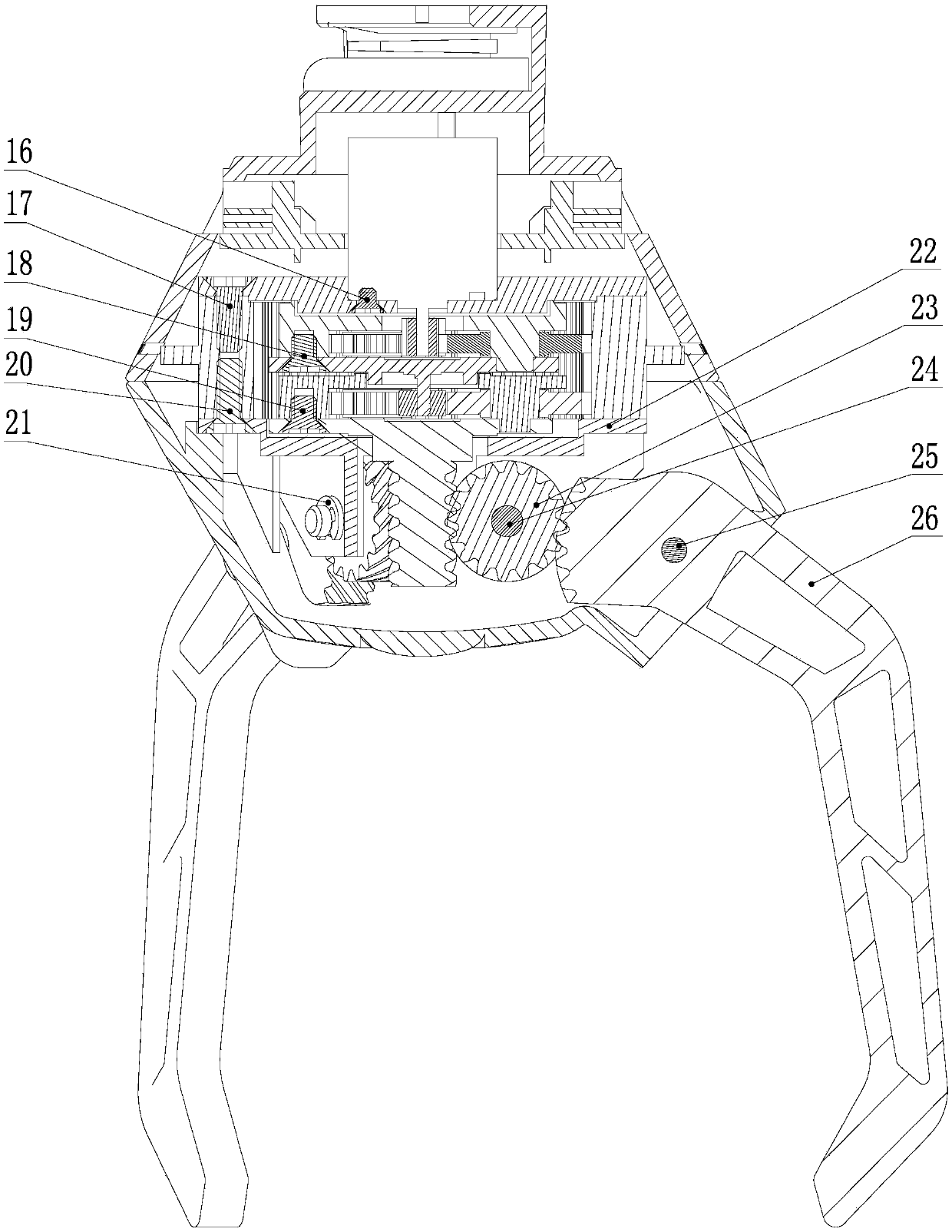

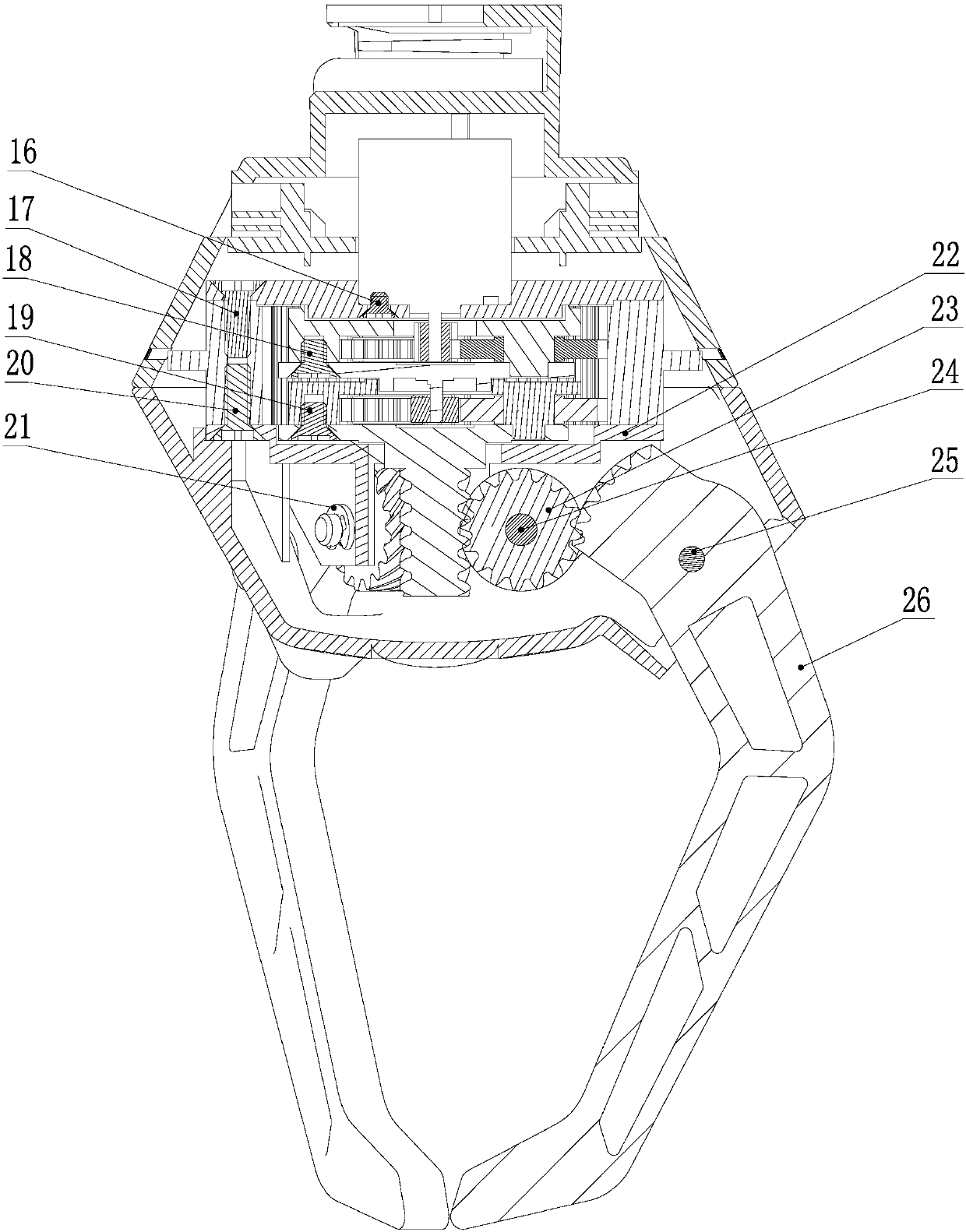

Robot arm

PendingCN107598961ARealize opening and closing functionRealize opening and closing movementGripping headsCamControl theory

The invention is applicable to the technical field of robots, and provides a robot arm. The robot arm comprises a steering engine shell, a PCB, a motor, a planetary gear transmission system, and a plurality of claw hooks, wherein the PCB, the motor and the planetary gear transmission system are sequentially installed in the steering engine shell from top to bottom, and the claw hooks are rotationally connected to the steering engine shell; the motor is electrically connected with the PCB; the input end of the planetary gear transmission system is connected with an output shaft of the motor, the output end of the planetary gear transmission system is provided with a helical gear shaft and a plurality of transmission helical gears meshed with the helical gear shaft and the claw hooks, and the transmission helical gears are in one-to-one correspondence with the claw hooks; and one ends of the claw hooks are rotationally connected to the steering engine shell and are used for carrying outopening and closing motions under the driving of the transmission helical gears. The robot arm is used for intelligence products like building blocks; and according to the robot arm, an opening and closing function of a three-jaw mechanism is realized in a manner of combining planetary gear transmission and cam transmission, so that structure is compact, and function requirements are achieved.

Owner:UBTECH ROBOTICS CORP LTD

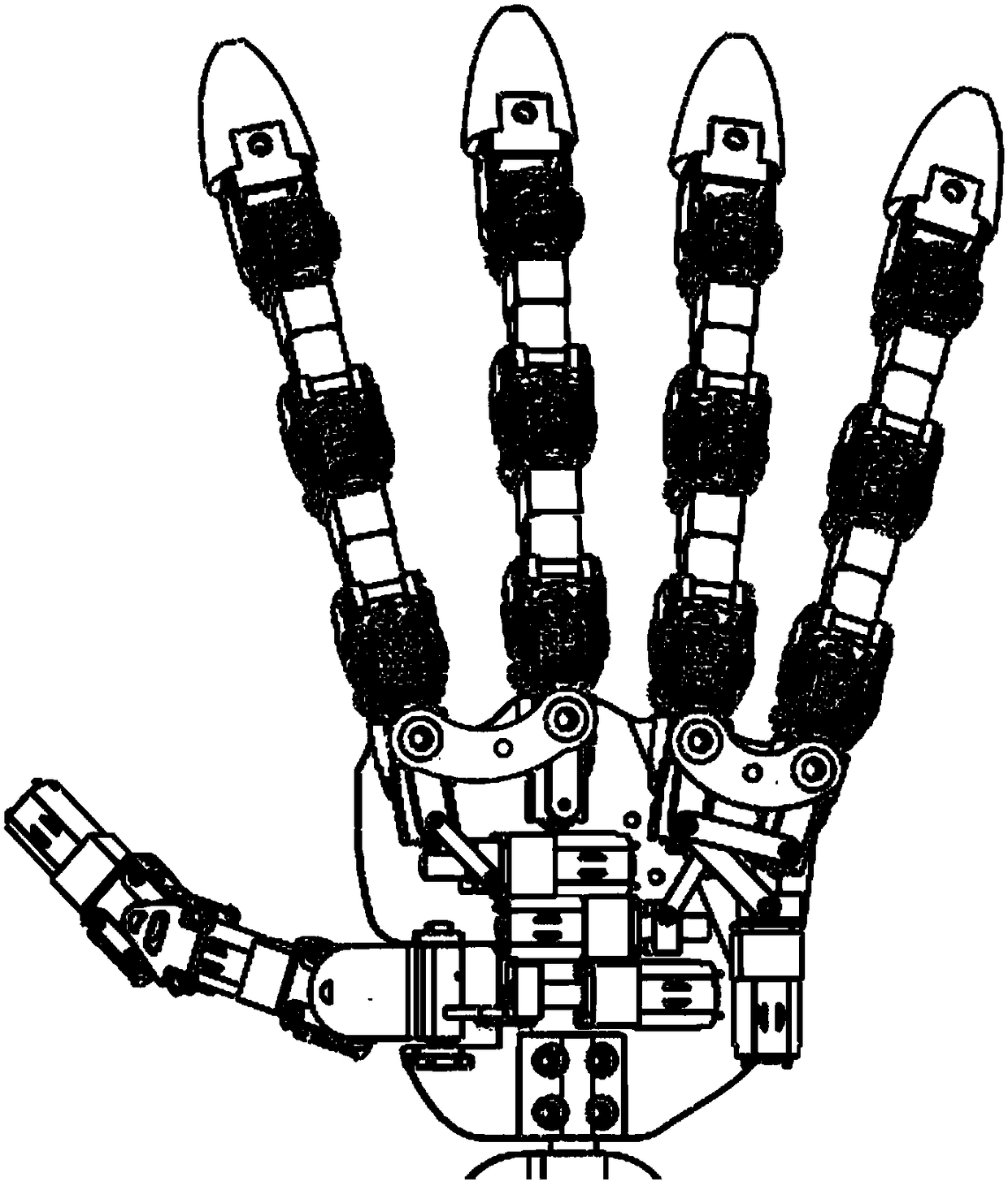

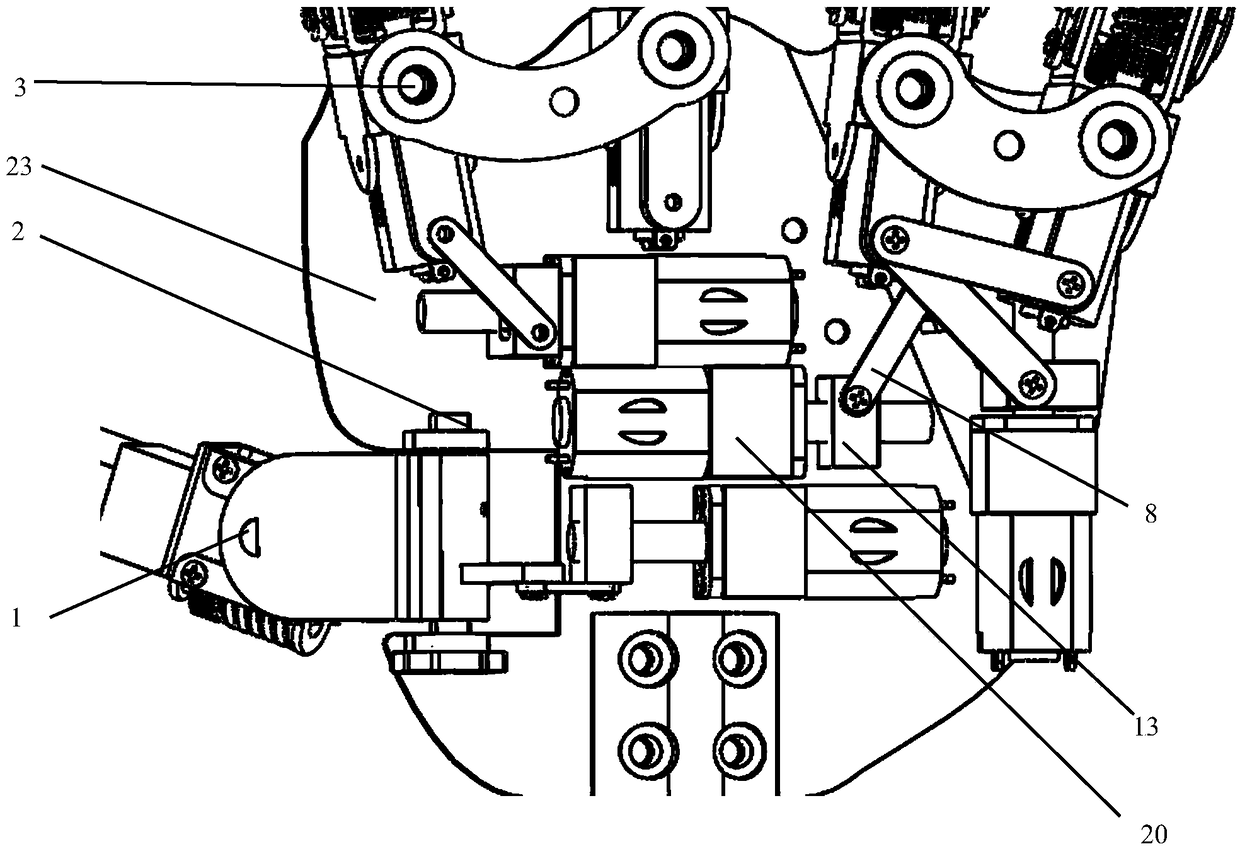

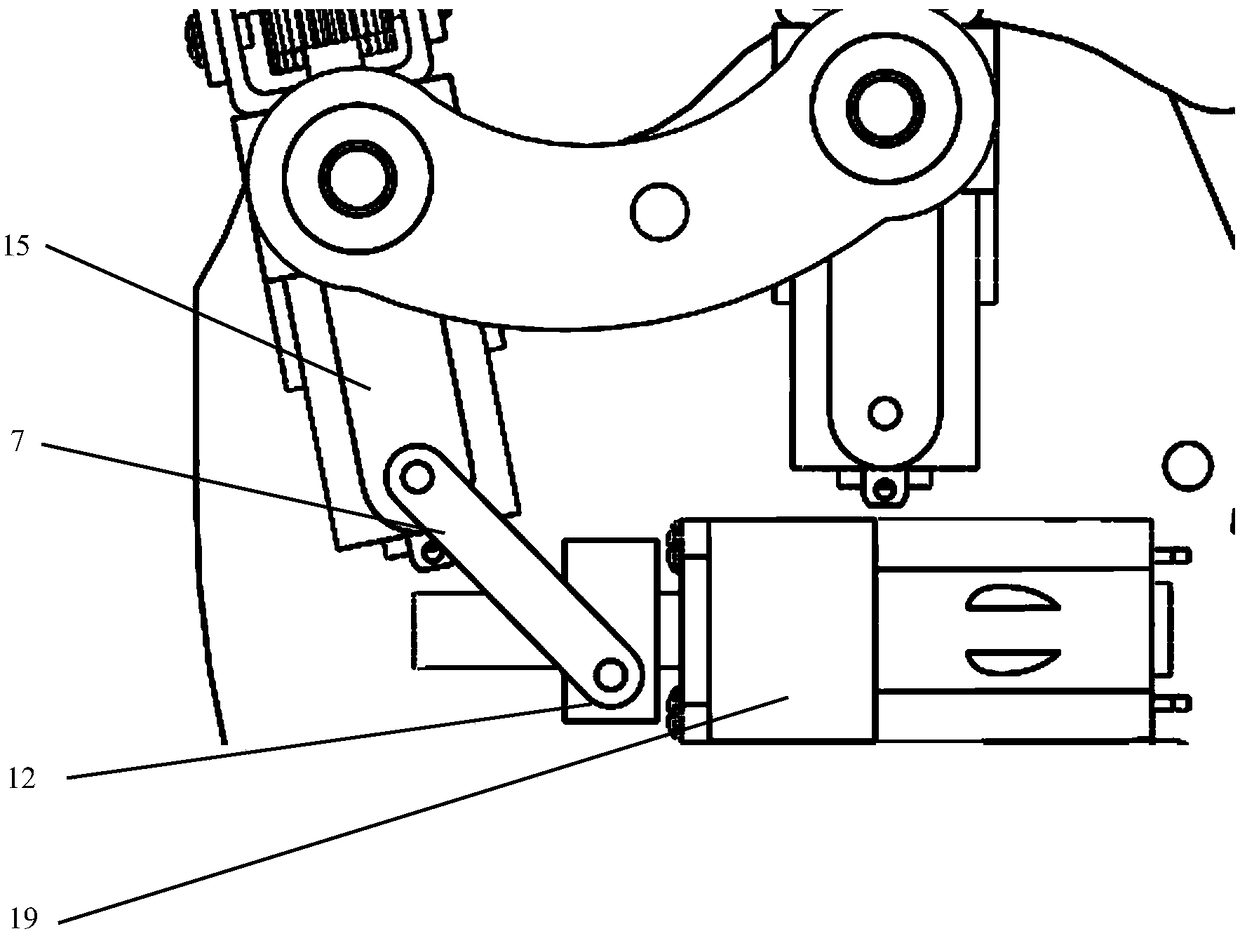

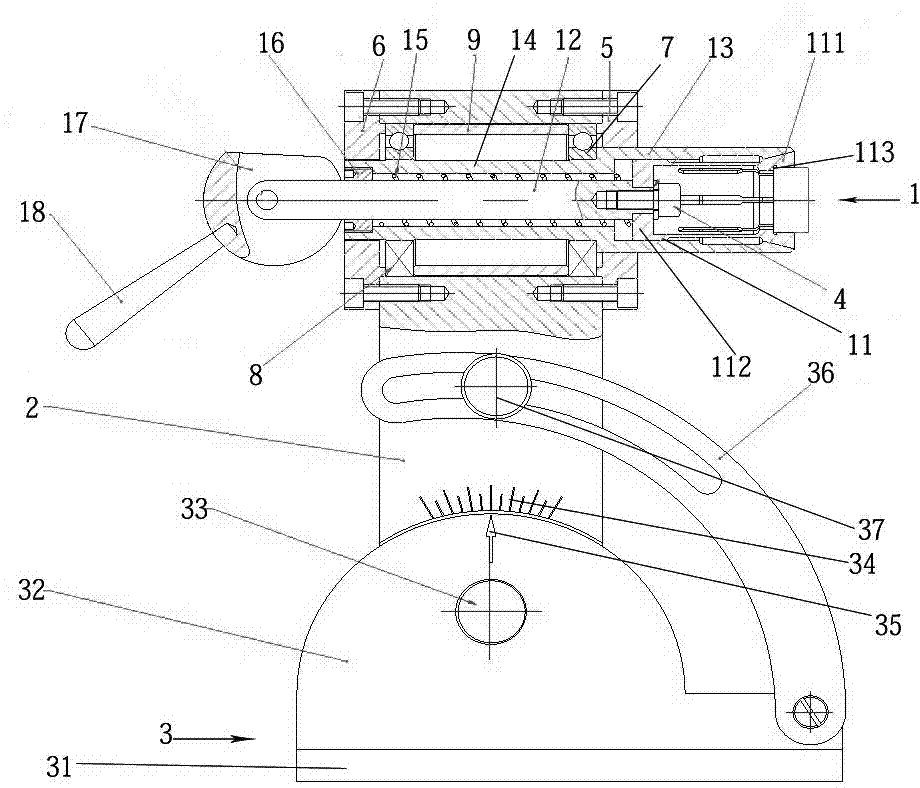

A five-finger dexterous hand finger side swing and palm-to-palm mechanism based on screw linkage mechanism

InactiveCN105881566BIncrease flexibilityRealize opening and closing movementGripping headsFixed frameCore component

The invention designs a finger side swinging and opposing mechanism of a five-finger dextrous hand based on a screw linkage mechanism. Dextrous movement of all fingers are satisfied, and additionally, the finger side swinging and opposing mechanism has the poweroff self-locking pose keeping ability, so that the grasping function of the five-finger dextrous hand is obviously increased, and different requirements of the five-finger dextrous hand for reliably grasping different articles are satisfied. The side swinging and opposing mechanism which is designed by using the screw linkage mechanism as a core component is mainly composed of an N20 screw gear motor as a power component, sliding blocks, a linkage pair, a palm mainboard, a thumb D shaft fixed frame, hinges and accessories, wherein the thumb D shaft fixed frame is used for fixing a D shaft of a thumb root joint; the palm mainboard is a base on which the screw gear motor, fingers, an opposing small plate and the hinges are connected; linkages are movement transmission components for connecting the sliding blocks with finger roots and the palm mainboard with the opposing small plate and the palm mainboard with the thumb D shaft fixed frame; the hinges are used for connecting the opposing small plate with a rack, and a bearing and a shaft are mainly used in the side swinging driving aspect of the fingers, so that the rotating efficiency and the movement flexibility can be increased.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Tool Grinding Fixtures

ActiveCN102990483BRealize opening and closing movementFast clamping speedOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention discloses a cutter grinding fixture. The periphery of each elastic piece in a fixture body is provided with a mounting sleeve, the front ends of the elastic pieces are provided with clamping ends, and the clamping ends open outwards to be at an open state when the elastic pieces reveals from the from ends of the mounting sleeves and closes inwards to be at a closed state when the elastic pieces are withdrawn into the mounting sleeves. Hole walls or front end ports of the mounting sleeves are provided with close-up edges, and the close-up edges are matched with elastic claws along the anterior-posterior direction in stopping mode when the clamping ends are at the open state and stops the clamping ends on the peripheries of the elastic claws when the clamping ends are at the closed state. In use, opening and closing movements of the elastic claws can be achieved through matching between the close-up edges and the clamping ends, accordingly column-shaped solid cutters to be grinded can be tightly clamped, and further clamping speed of the column-shaped solid cutters is improved. Automatic centering can be achieved through wedge surface matching, and accuracy of column-shaped solid cutter clamping and cutter grinding processing can be improved.

Owner:FUNIK ULTRAHARD MATERIAL

Material taking device for sprayer assembly of flusher

InactiveCN114261746AAchieve transshipmentRealize opening and closing movementConveyorsConveyor partsTubular linear motorElectric machine

The invention discloses a material taking device for a sprayer assembly of a flusher, and belongs to the technical field of flusher machining, the material taking device comprises a conveying belt, a nozzle blanking device, a connecting seat blanking device and a tubular linear motor are sequentially arranged above the conveying belt, a clamping device is connected to a rotor of the tubular linear motor, and a protruding limiting belt is arranged on the surface of the conveying belt. Paired nozzle limiting grooves and connecting seat limiting grooves are formed in the surface of the limiting belt in an array manner; the nozzle discharging device comprises a nozzle storage box, a nozzle feeding port is formed in the top of the nozzle storage box, the lower portion of the nozzle storage box is a nozzle discharging channel with an opening in the bottom end, and a first discharging conveying belt is arranged in the nozzle discharging channel. The connecting base discharging device comprises a connecting base storage box, a connecting base feeding port is formed in the top of the connecting base storage box, a connecting base discharging channel with an opening in the bottom end is formed in the lower portion of the connecting base storage box, and a second discharging conveying belt is arranged in the connecting base discharging channel. The clamping device comprises a driving gear, and a rotatable clamp is arranged below the driving gear.

Owner:岳阳职业技术学院

Half shaft gear removal force and press-fitting force test device

ActiveCN106092408BVerify rationalityRealize opening and closing movementApparatus for force/torque/work measurementGear wheelCylinder block

The invention relates to a semiaxis gear dismounting force and press mounting force testing device, comprising a platen and a semiaxis seat, a gear seat, a pull pressure sensor and a cylinder which are all arranged on the platen. The semiaxis seat and the gear seat are arranged on left and right sides, and are both installed in a liner sliding cooperative connection mode; the pull pressure sensor is located on the left side of the semiaxis seat, and has the left end fixed, and the right end connected to the semiaxis seat; the cylinder is located on the right side of the gear seat, the cylinder body located on the right end is fixed, and a piston extending terminal located on the left end is connected to the gear seat; the semiaxis seat is provided with a semiaxis seat hole used for insertion of a semiaxis and restricting the semiaxis from separating from the semiaxis seat towards the right; the gear seat is provided with a gear seat hole used for insertion of a gear and restricting the gear from separating the gear hole of the gear seat towards the left; the axes of the pull pressure sensor, the semiaxis seat, the gear seat hole and the cylinder are parallel and coaxial. The semiaxis gear dismounting force and press mounting force testing device can realize semiaxis gear dismounting force and press mounting force test so as to verify the reasonability of improved designs.

Owner:ZHEJIANG SIEKON PRECISION MACHINERY CO LTD

Efficient assembling equipment for sprayer assembly of flusher

InactiveCN114260701AAchieve transshipmentRealize opening and closing movementAssembly machinesMetal working apparatusTubular linear motorElectric machine

Owner:岳阳职业技术学院

A uniform and quantitative fertilization device for agricultural planting

ActiveCN112400391BRealize opening and closing movementAvoid cloggingSpadesFertiliser distributersAgricultural scienceAgricultural engineering

The invention relates to a fertilization device, in particular to a uniform quantitative fertilization device for agricultural planting. The technical problem is to provide a uniform quantitative fertilization device for agricultural planting that can perform final landfill, quantitative fertilization, and prevent clogging. The technical solution is as follows: a uniform quantitative fertilization device for agricultural planting, including a frame and the like; a power mechanism is fixedly installed on one side of the frame, a blanking mechanism is fixedly installed on the other side of the frame, and the blanking mechanism is connected with the power mechanism. The soil-turning mechanism is installed on the side of the frame away from the unloading mechanism, the soil-turning mechanism is slidably connected with the unloading mechanism, and the soil-turning mechanism is connected with the power mechanism. In the feeding device, the second screw is used to continuously slide the sliding plate in the fixed frame to realize the opening and closing movement of the feeding port of the organic fertilizer, so as to prevent the organic fertilizer from being blocked in the feeding port.

Owner:宋建国

A kind of propeller casting molding method

ActiveCN105598385BRealize opening and closing movementReduce thicknessFoundry mouldsFoundry coresPropellerOperability

The present invention discloses a propeller casting molding method comprising the following steps: making a propeller steel mold; making a sand core; assembling for forming a propeller sand core; making a pouring gate steel mold; making a mud core; and making a sand box; and the manufacturing process comprises casting; picking up; sawing a riser, and grinding for molding. The propeller casting molding method is strong in operability and good in technology, and can improve propeller quality, increase production efficiency and reduce production costs, product quality meets customer demand for products, and a new profit growth point is created for enterprises.

Owner:WUHU FUJIHENG MACHINERY

Sprayer assembly assembling system and method for automatic irrigator production

InactiveCN113231820AAchieve transshipmentRealize opening and closing movementAssembly machinesMetal working apparatusTubular linear motorSprayer

The invention discloses a sprayer assembly assembling system and method for automatic irrigator production, and belongs to the technical field of irrigator machining. The sprayer assembly assembling system comprises a pressing base clamping and transferring part and a sprayer assembly transferring and assembling part. The pressing base clamping and transferring part comprises a supporting table, and first tubular linear motors are arranged on the supporting table to drive a pressing base clamp to perform transferring. The sprayer assembly transferring and assembling part comprises a conveying belt, the tail end of the conveying belt is opposite to the tail end of the supporting table, and a second tubular linear motor is arranged above the tail part of the conveying belt to drive a sprayer assembly clamp to perform transferring. The pressing base clamp comprises a mold closing clamp, and the first tubular linear motors are arranged on the two sides of the mold closing clamp. A protruding limiting belt is arranged on the surface of the conveying belt, and paired nozzle limiting grooves and connecting base limiting grooves are formed in the surface of the limiting belt in an array mode. The sprayer assembly clamp comprises a driving gear, a rotatable clamp is arranged below the driving gear, and the rotatable clamp is of a symmetric structure capable of being movably opened and closed.

Owner:岳阳职业技术学院

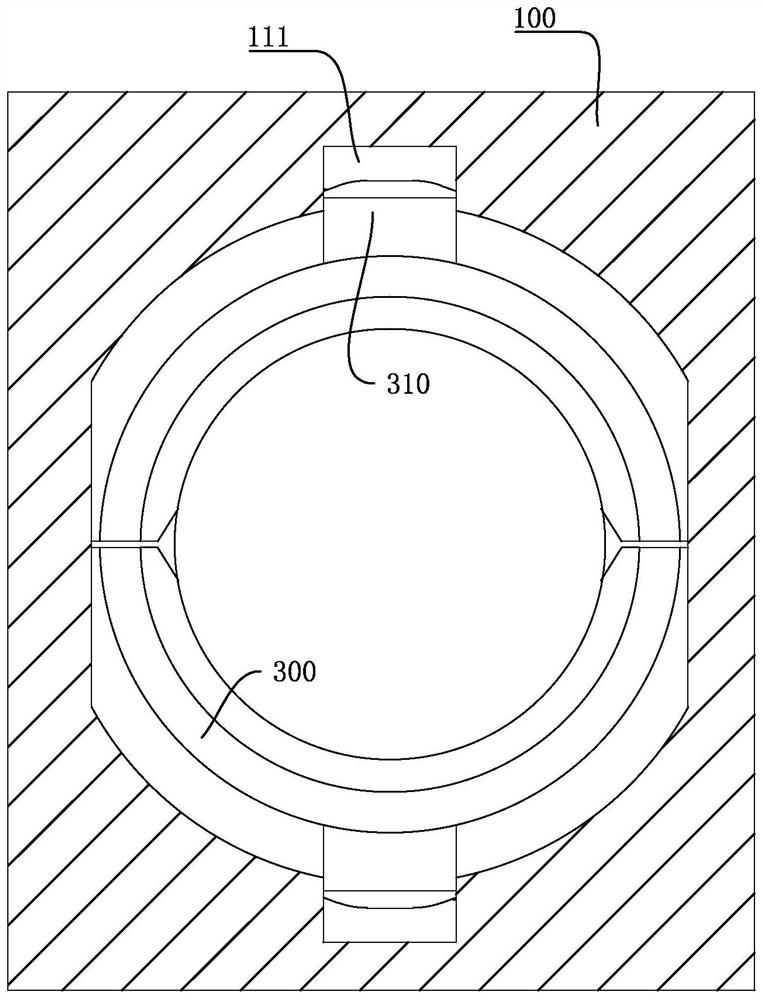

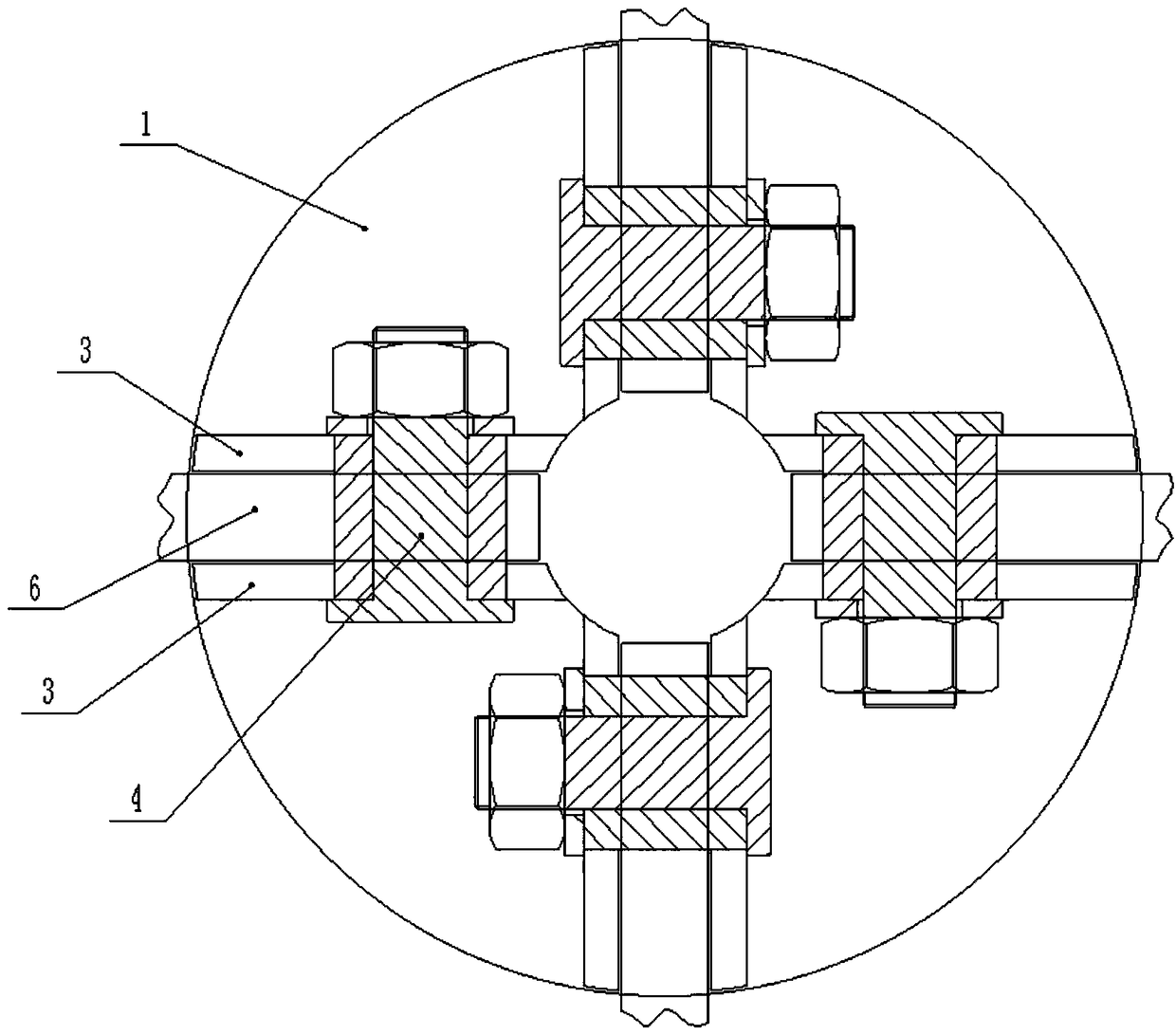

Frock clamp for hub cap end face turning

PendingCN109227175AFast clamping speedFixed and stablePositioning apparatusMetal-working holdersMechanical engineeringEngineering

The invention provides a frock clamp for hub cap end face turning. The frock clamp comprises an outer shaft sleeve, a movable shaft and swing arms, wherein the outer shaft sleeve is fixed on a machinehead through a thread, the movable shaft is arranged in the outer shaft sleeve and can conduct axial motion along the outer shaft sleeve, the right end face of the outer shaft sleeve protrudes to form a positioning part, the size of the positioning part is matched with the inner diameter of a hub cap, a threaded hole is formed in the left side of the movable shaft, a hydraulic jacking rod is screwed into the threaded hole and drives the movable shaft to move, crisscross connecting plates are fixed at the right end of the movable shaft, the single connecting plate is in a semicircular shape, arc-shaped grooves are formed in the connecting plates, the middles of the swing arms are connected to the outer shaft sleeve through hinges, the tails of the swing arms are arranged in the arc-shapedgrooves through pin shafts, the number of the swing arms is four, and the swing arms are distributed uniformly on the outer circumference of the outer shaft sleeve; through the movement of the movableshaft relative to the outer shaft sleeve, opening and closing movements of the swing arms can be achieved, the clamping speed of the hub cap is greatly improved, and through the linkage action of thehydraulic jacking rod and the four swing arms, the fixation of the hub cap is stable and firm.

Owner:宁波市慈力金属制品有限公司

Drive mechanism and air conditioner

PendingCN111351202ARealize opening and closing movementImprove transmission efficiencyLighting and heating apparatusHeating and ventilation casings/coversControl engineeringControl theory

The embodiment of the invention relates to the technical field of air conditioners, and discloses a drive mechanism and an air conditioner. In the drive mechanism provided in the embodiment, a plurality of limiting parts are adopted between a rack and a rack cavity storing the rack for limiting, during rack sliding, the rack and the inner wall of the rack cavity are kept in line contact or point contact, friction between the rack and the inner wall of the rack cavity can be effectively reduced, the problem that the rack is likely to swing can be solved, and accordingly the transmission efficiency in the whole transmission process is obviously improved. When a to-be-driven component is a panel of the air conditioner, the panel is driven to move through the movement of the rack, and then thepanel achieves the smooth opening and closing motion. Since the air conditioner provided in the embodiment adopts the drive mechanism provided in the first aspect, the transmission efficiency for driving of the panel to move is high.

Owner:NINGBO AUX ELECTRIC +1

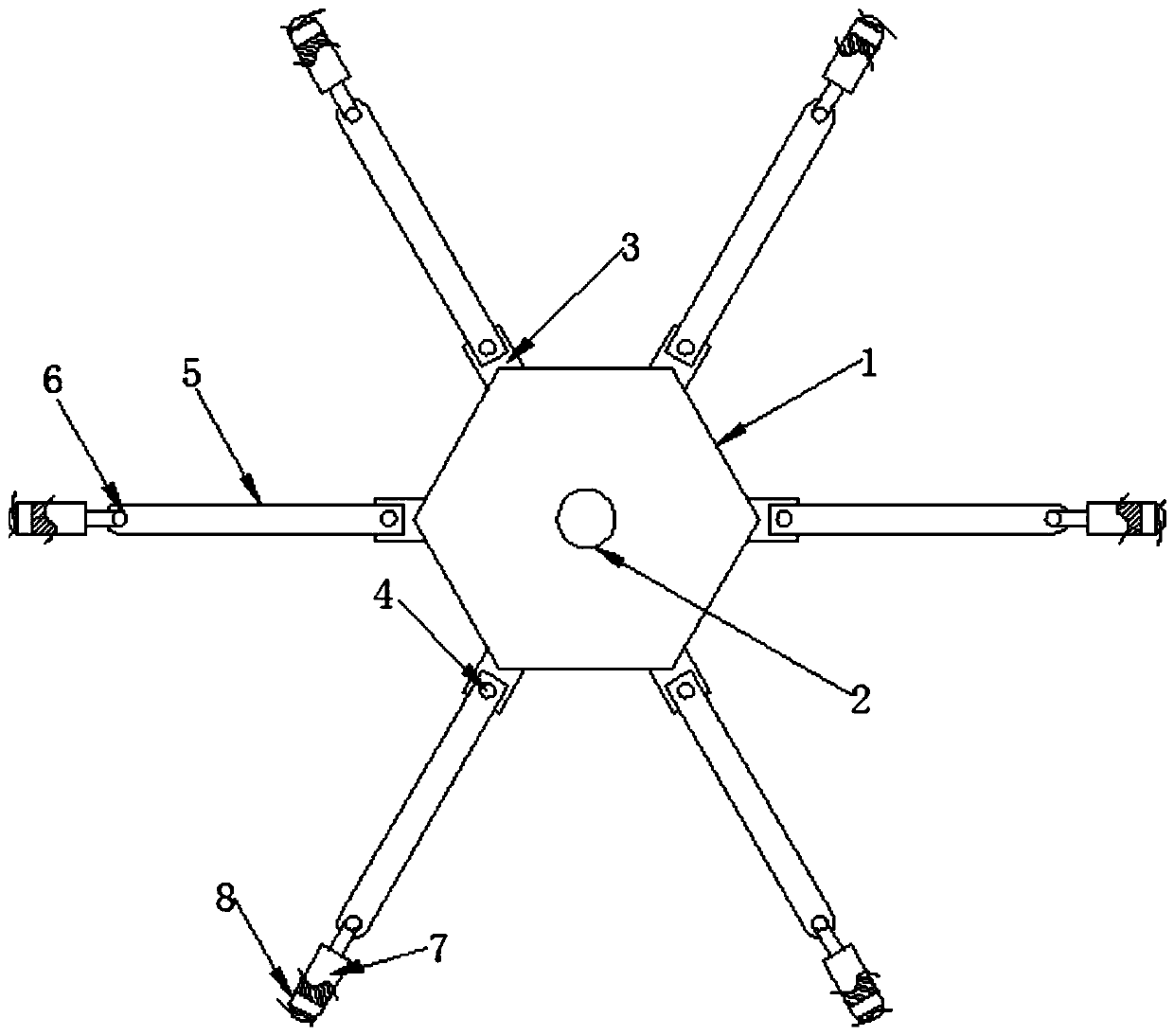

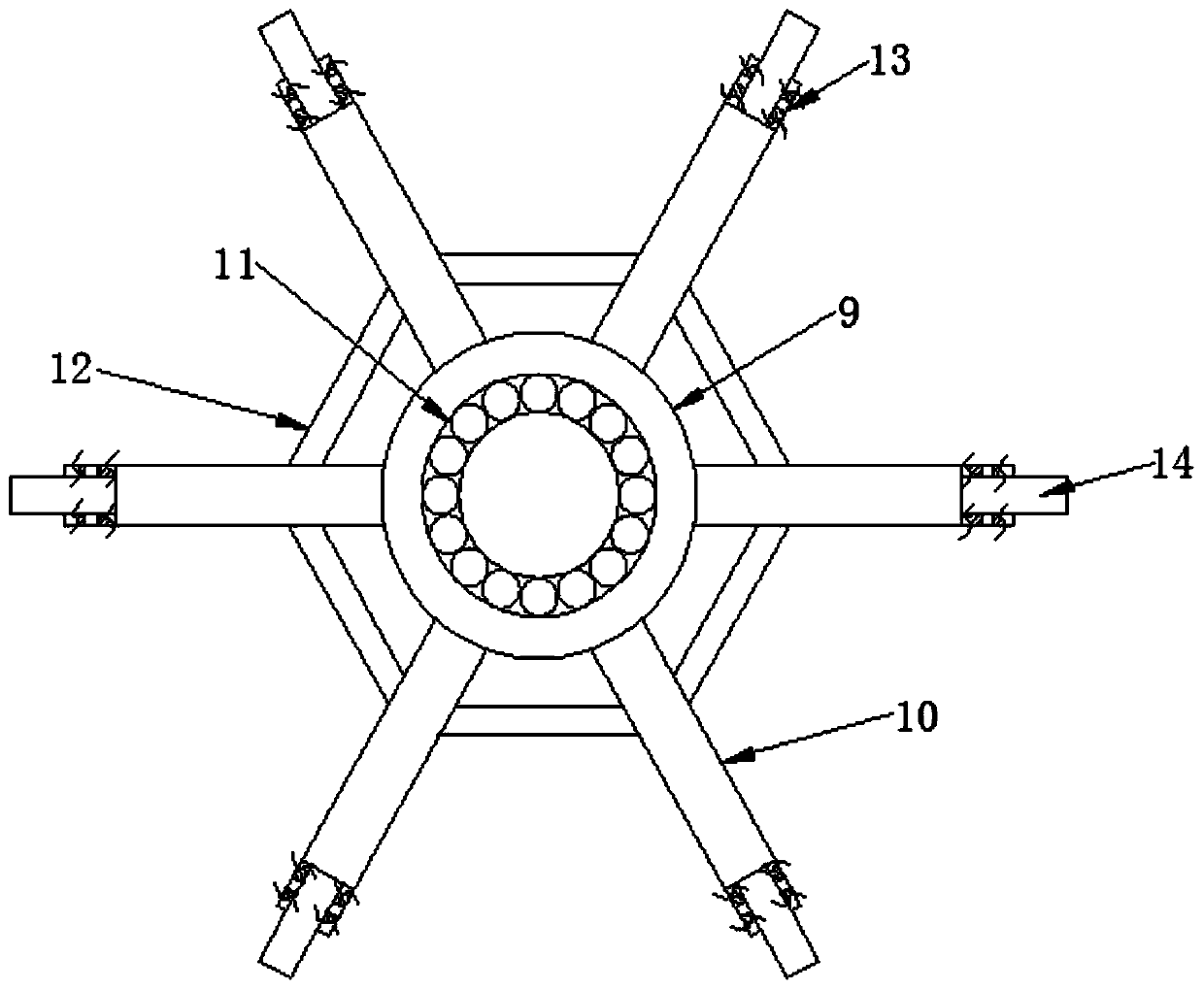

Information receiving device closed in windy days

ActiveCN110336570AWill not affect workAvoid squeezingVibration dampingWind-induced force reductionSoftware engineeringFirst insertion

The invention relates to the technical field of mobile internet, and further discloses an information receiving device closed in windy days. The information receiving device includes a hexagonal disc,a shaft hole is formed in the hexagonal disc; a rectangular sheet is fixedly connected to the outer side of the hexagonal disc; the upper surface of the rectangular piece is fixedly connected with aconnecting shaft, the outer surface of the connecting shaft is sleeved with a connecting rod; the end, away from the rectangular piece, of the connecting rod is fixedly connected with a hinge shaft, the outer surface of the hinge shaft is sleeved with a movable block, and the end, away from the connecting rod, of the movable block is provided with a first insertion hole. The curved block is L-shaped, when a lower part moves, the upper part moves in the direction opposite to that of the lower part, and the movable block converts the rotary motion of the connecting rod into the vertical motion of the curved block, so that the signal receiving plate can be opened and closed, the outer side of the signal receiving plate is bent, the contact area between airflow and the signal receiving plate can be reduced when the signal receiving plate is folded, and friction resistance is reduced.

Owner:杭州欣茂科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com