Tool Grinding Fixtures

A tool grinding and fixture technology, applied in the field of tool grinding fixtures, can solve the problems of low machining accuracy and low machining efficiency of cylindrical solid tools, and achieve the effect of improving accuracy and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

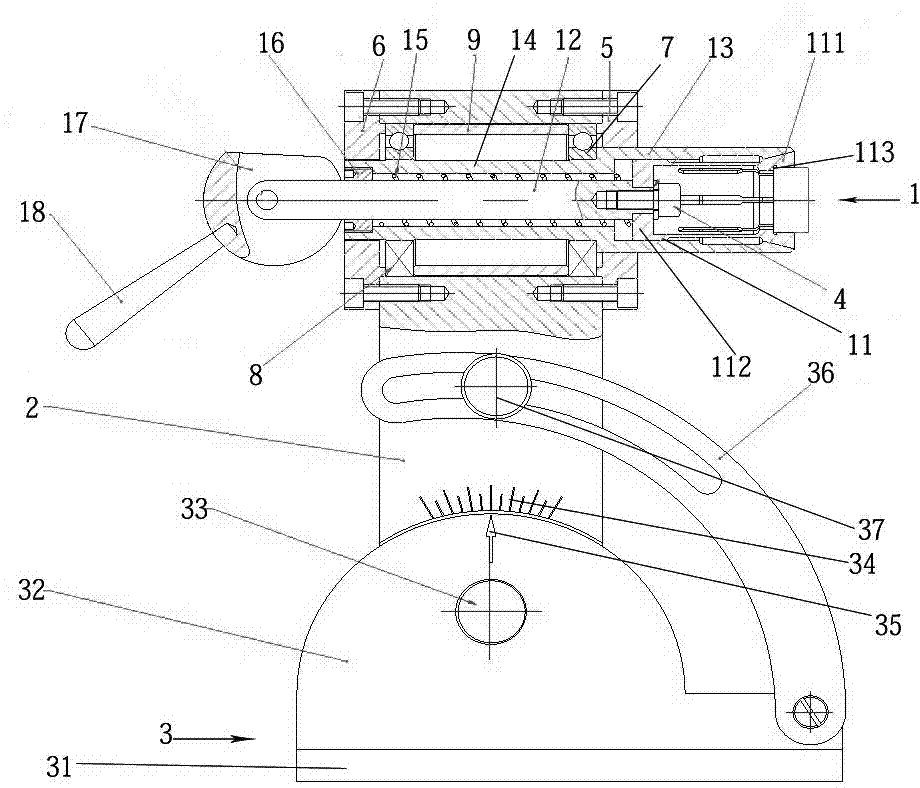

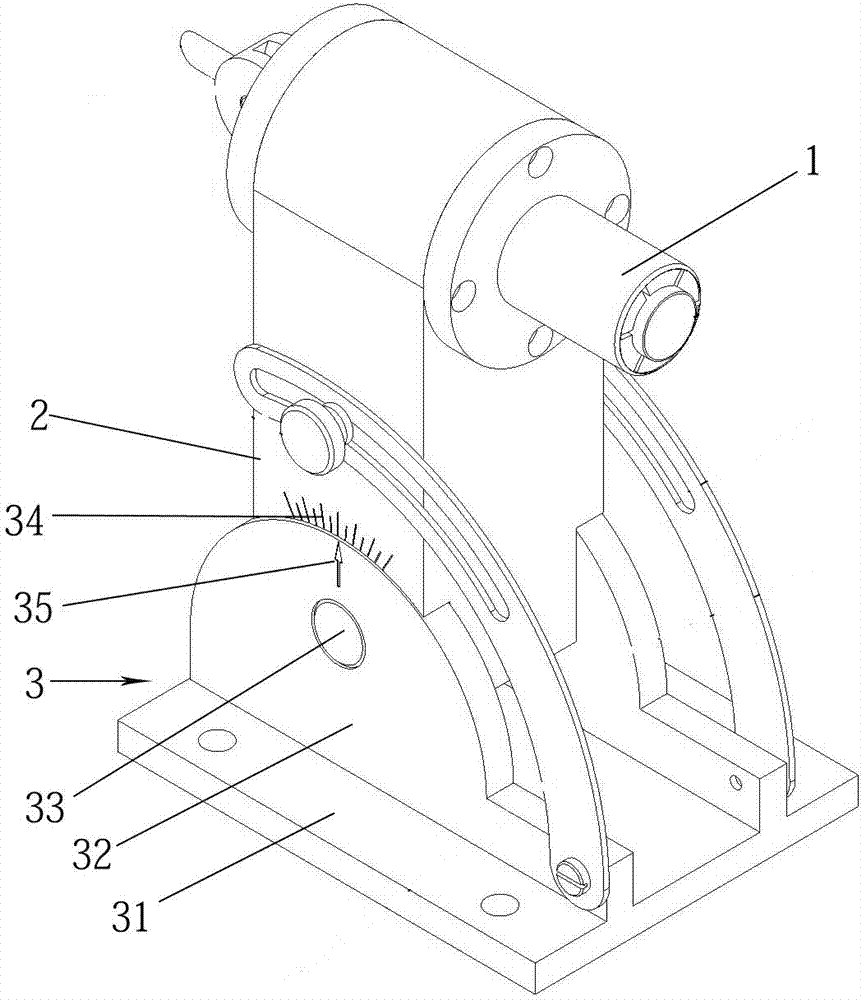

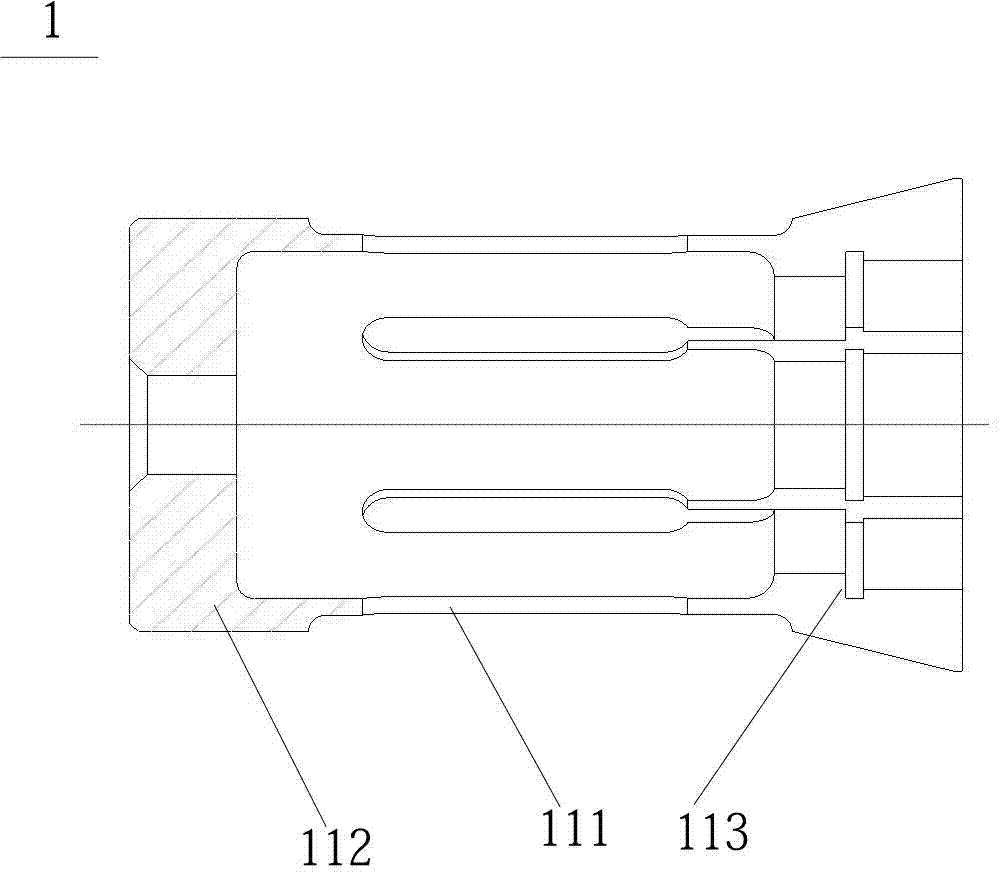

[0021] Embodiments of the tool grinding fixture of the present invention: as Figure 1 to Figure 4 As shown, the clamp includes a clamp body 1, a clamp seat 2 and a base 3 arranged sequentially from top to bottom, wherein the clamp body 1 includes an expansion body 11, a tail handle rod 12, a mounting sleeve 13, a positioning sleeve 14, and a return spring 15 , Plug 16, eccentric wheel 17 and handle 18. The expansion body 11 is composed of an annular guide plate 111 fixed on the front end of the tail handle rod 12 through the connecting screw 4, and four annular claws 112 that can be radially opened and closed at intervals on the outer edge of the guide plate 111. The rear end of the claw 112 is annularly distributed on the front end surface of the handle 18 rod. The front end is in an open state when it is exposed from the front end of the installation sleeve 13, and is inwardly folded when it is received in the installation sleeve 13. At the clamping end in the folded state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com