Frock clamp for hub cap end face turning

A technology of face turning and tooling and fixtures, which is applied in the field of tooling and fixtures, can solve the problems of cost, cumbersome replacement, and inability to control the parallelism of two planes, and achieve the effect of stable and reliable fixation and increased clamping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

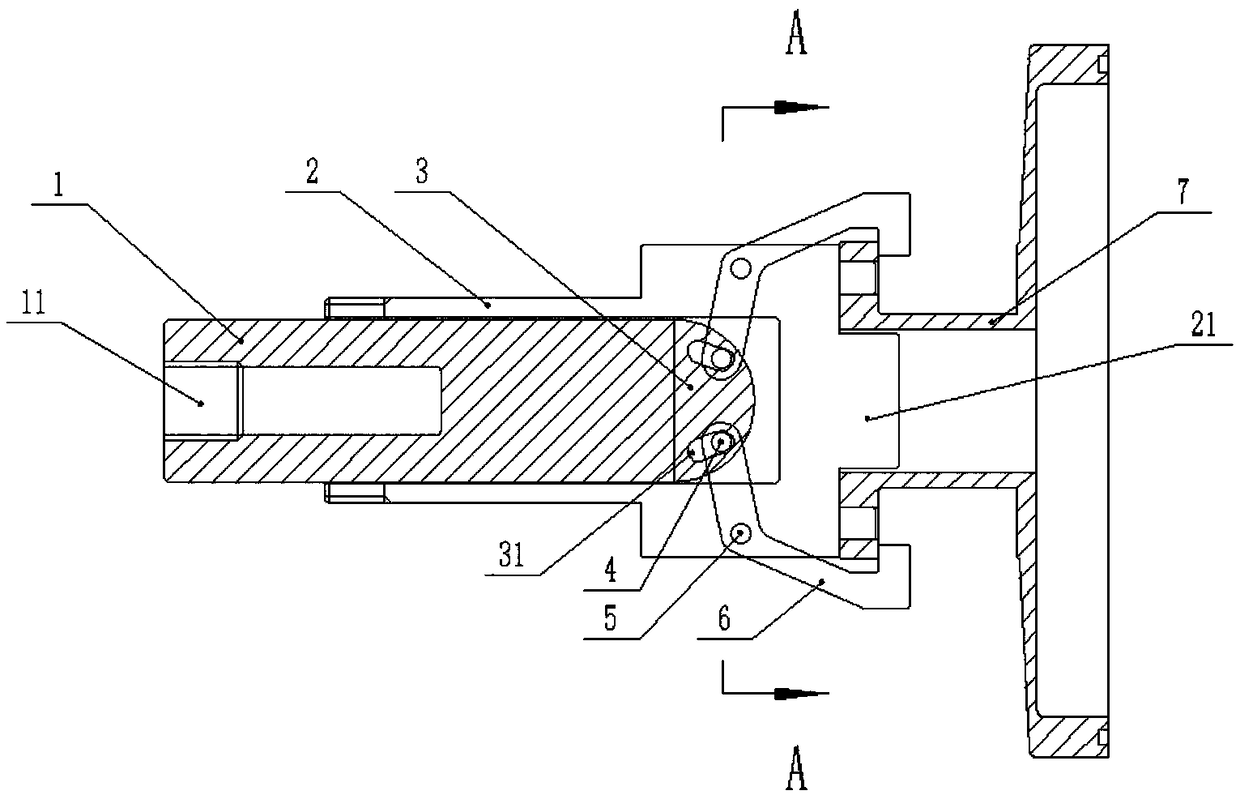

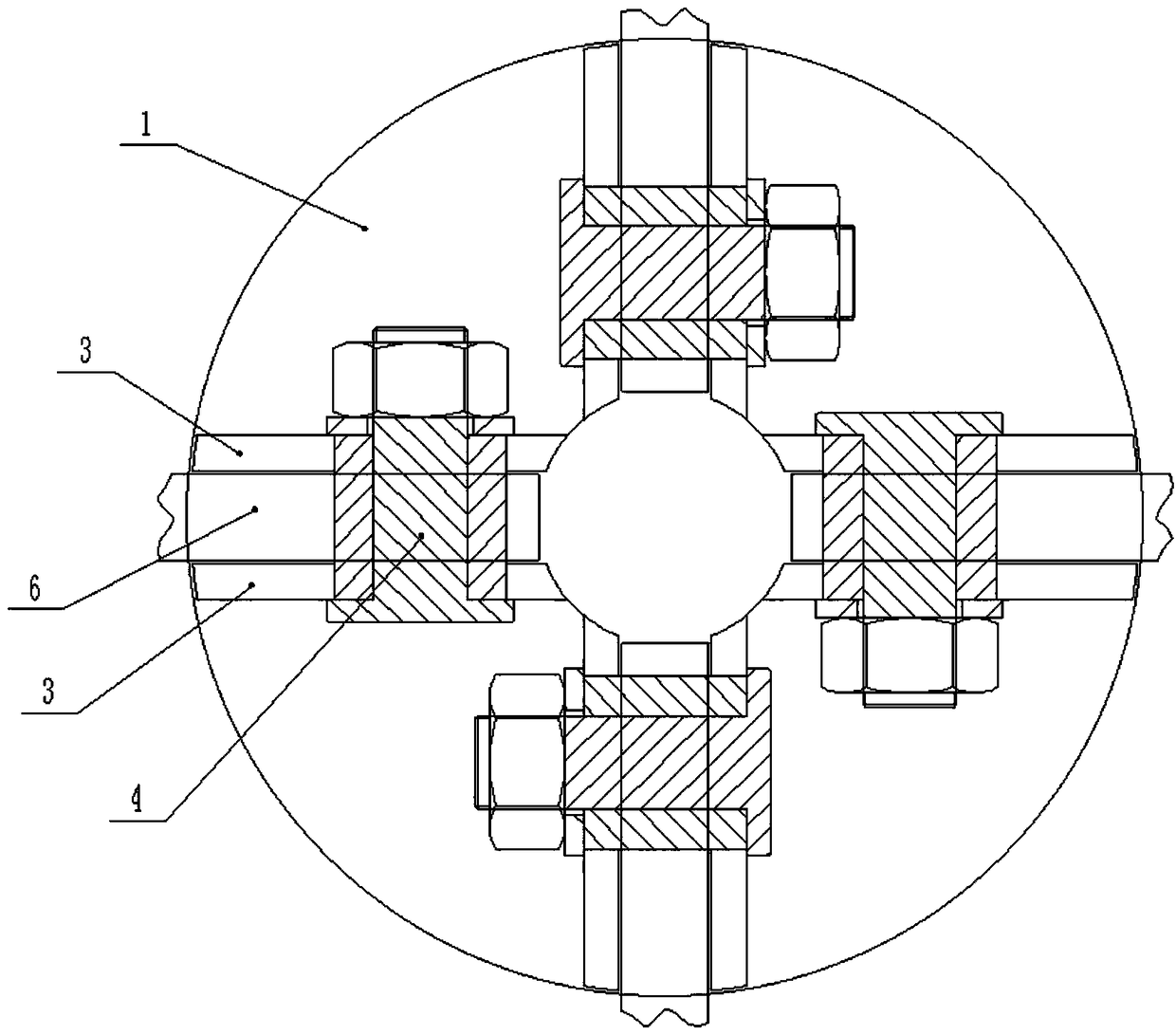

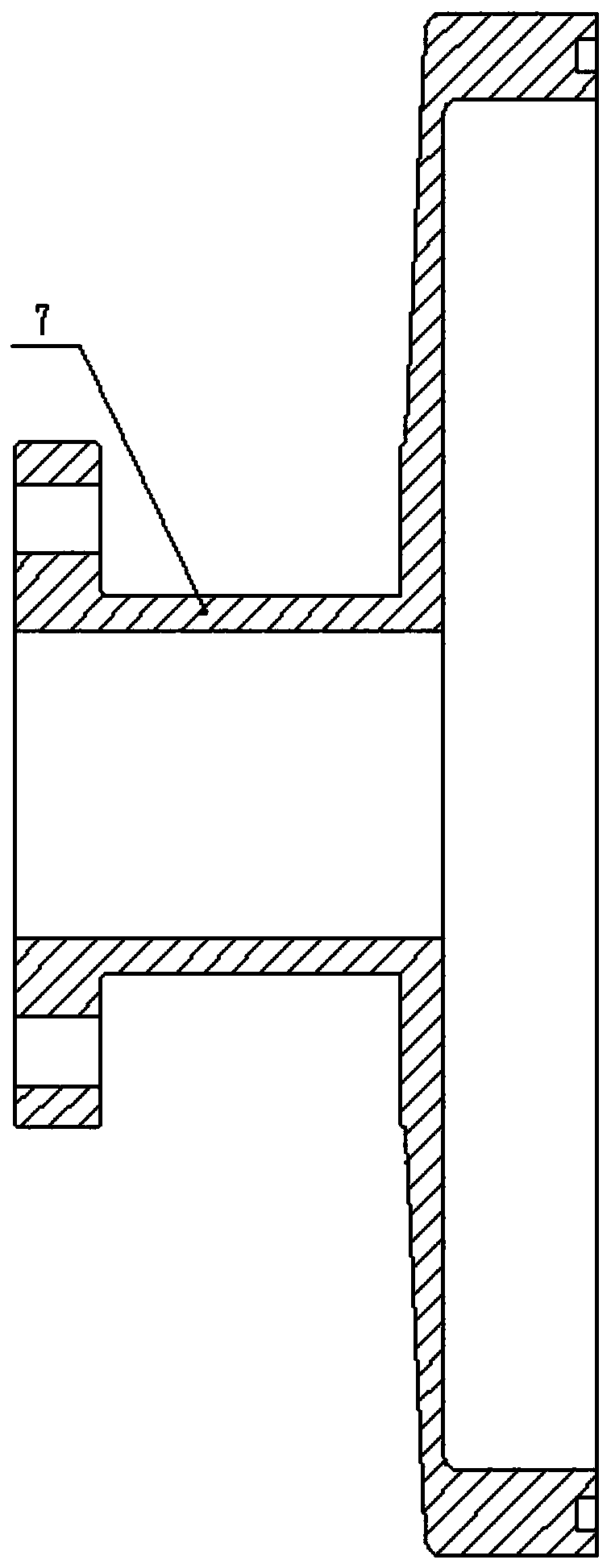

[0016] Such as figure 1 , figure 2 As shown, a tooling fixture for hub cap end face turning according to an embodiment of the present invention includes an outer shaft sleeve 2 fixed on the machine head through threads, placed in the outer shaft sleeve 2 and can be used as a shaft along the outer shaft sleeve 2 The movable shaft 1, the swing arm 6, and the right end surface of the outer shaft sleeve 2 protrude to form a positioning part 21. The size of the positioning part 21 matches the inner diameter of the hub cover 7. The left side of the movable shaft 1 is processed with a threaded hole 11. Hydraulic pressure The ejector rod is screwed into the threaded hole 11 and drives the movable shaft 1 to move. The right end of the movable shaft 1 is fixed with a connecting plate 3 that is a cross. The single connecting plate 3 is semicircular in shape. The connecting plate 3 is processed with an arc-shaped groove 31. The middle part of the swing arm 6 is connected to the outer b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com