Intersecting line welding seam welding equipment and method

A welding equipment and intersecting line technology, applied in the field of intersecting line welding seam welding equipment, can solve the problems of poor manual scribing and cutting accuracy, easy deviation of weld bead, and low flexibility in use, so as to improve convenience and reduce The effect of error and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

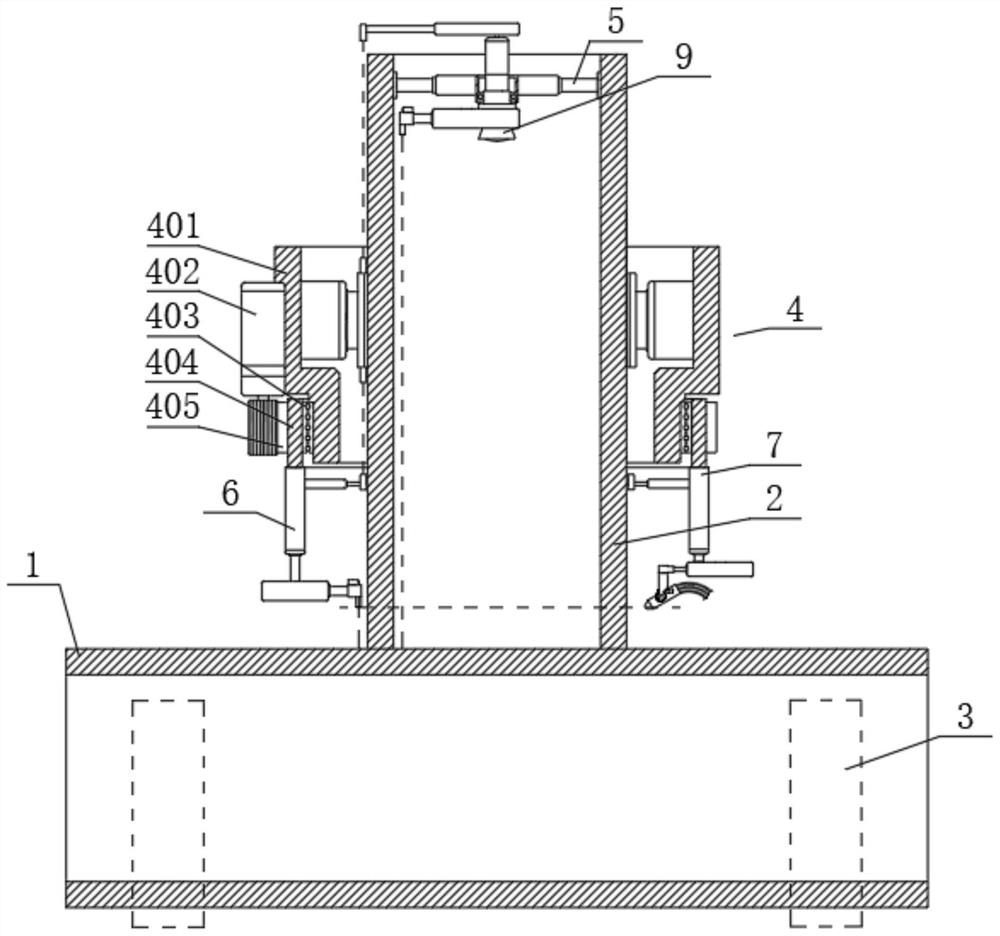

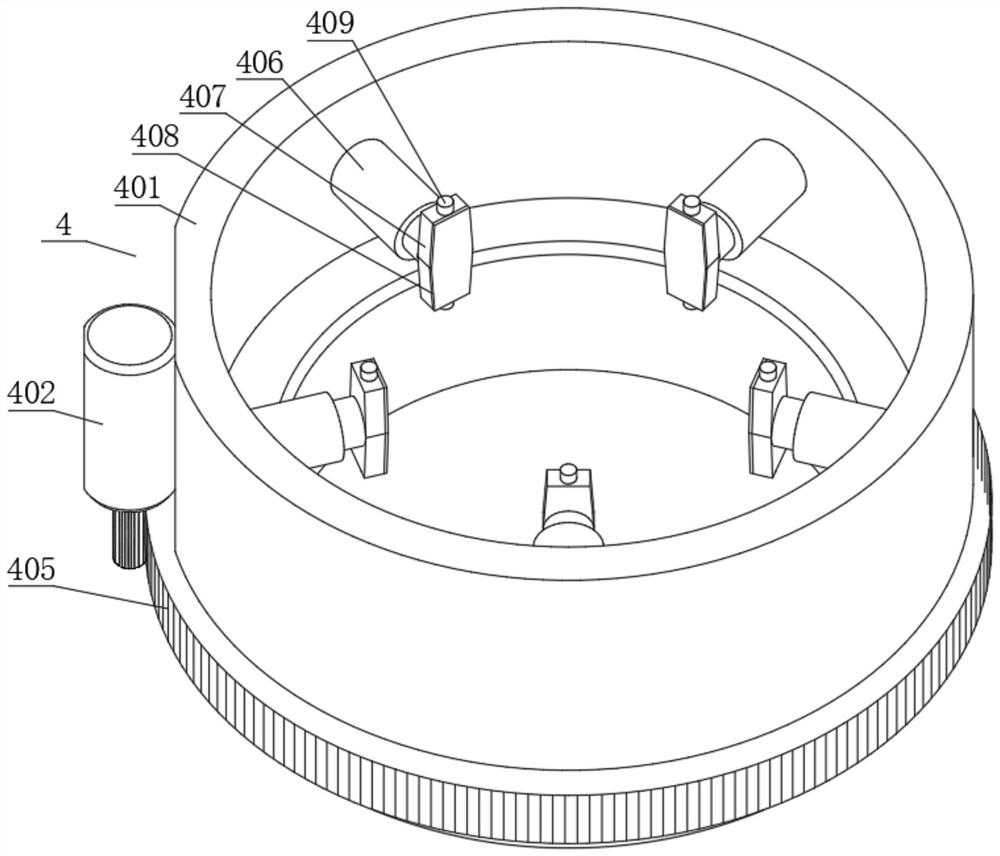

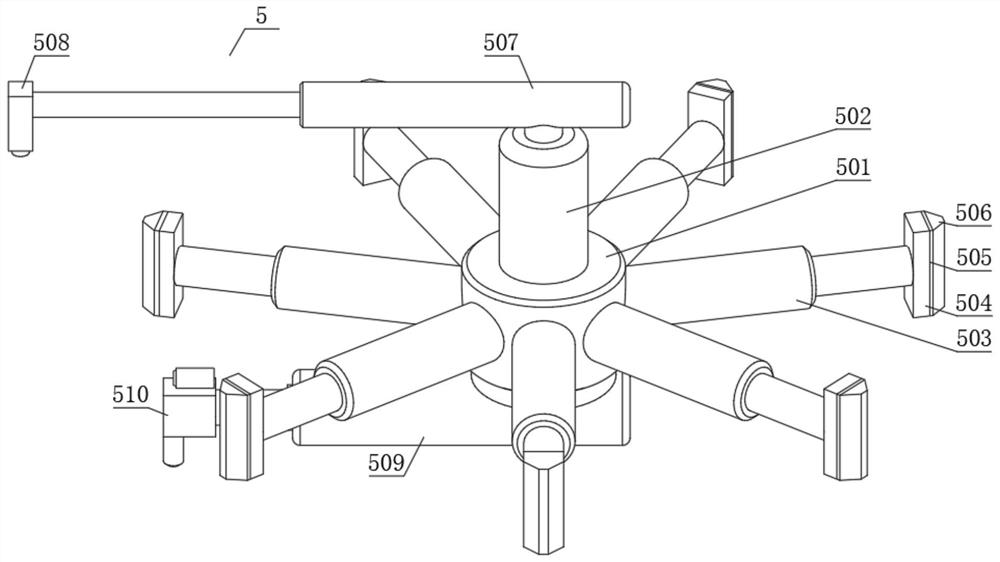

[0033] see figure 1 , a kind of intersecting line welding seam welding equipment, including a main pipe 1 and a branch pipe 2, the end of the branch pipe 2 overlaps with the side wall of the main pipe 1, and also includes a clamping table 3, and the main pipe 1 passes through the clamping table 3 Fixed, the middle part of the outer wall of the branch pipe 2 is sleeved with a fixed rotary mechanism 4, and the outer wall of the fixed rotary mechanism 4 is fixedly connected with the upper part of the clamping table 3, and the inner wall of the branch pipe 2 is fixedly connected with an inner rotary The measuring mechanism 5, the bottom of the fixed rotary mechanism 4 is fixedly connected with the first driving assembly 6, and the bottom of the first driving assembly 6 is provided with a second distance measuring assembly 605; figure 2 As shown, the fixed rotary mechanism 4 includes a fixed sleeve 401, three or more than three first electric cylinders 406, and a rotary sleeve 404...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com