Pneumatic type chuck

A pneumatic chuck technology, applied in chucks, auxiliary devices, applications, etc., can solve problems such as reduced work efficiency, slow clamping speed, and insufficient clamping force, so as to improve work efficiency, reduce production costs, The effect of high clamping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

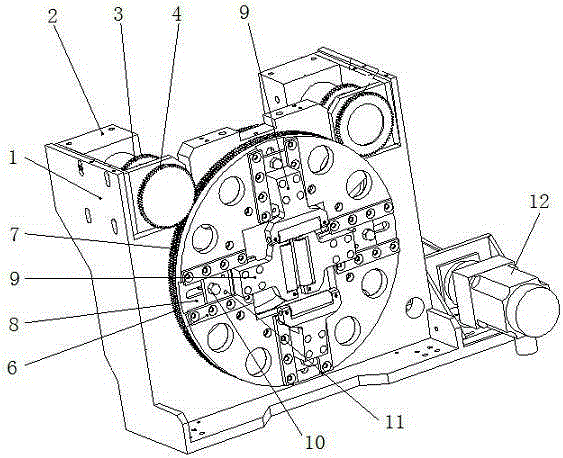

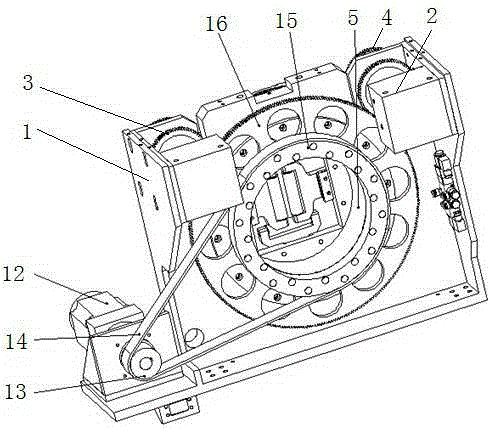

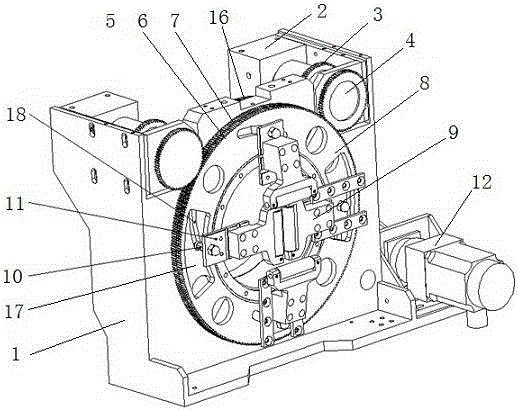

[0014] Accompanying drawing is the specific embodiment of the present invention. Such as Figure 1 to Figure 3 As shown, this kind of pneumatic chuck includes a machine base 1, which is a vertical plate shape, and two air motors 2 arranged left and right are symmetrically arranged on the machine base 1, and each air motor 2 is fixed with a The motor brake disc 3 and the motor locking disc 4, wherein the motor locking disc 4 is located on the front of the base 1, the two motor locking discs 4 are not in the same plane, they are set one after the other, the air motor 2 and the motor brake The moving plate 3 is located on the back of the machine base 1. A round hole is opened in the center of the machine base 1 and a rotating sleeve 5 is installed. The rotating sleeve 5 protrudes from both sides of the machine base 1. 5 is fixed with a brake disc 16 and a driven pulley 15, the brake disc 16 and the driven pulley 15 are driven to rotate by the driving pulley 13 and the synchronou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com