Full-automatic plastic sucking and punching former

A fully automatic, forming machine technology, applied in the field of forming equipment, can solve the problems of difficult to realize automatic production of thermoforming machines, increase the difficulty of folding, and reduce production efficiency, so as to increase the shearing rate and improve the quality of folding , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

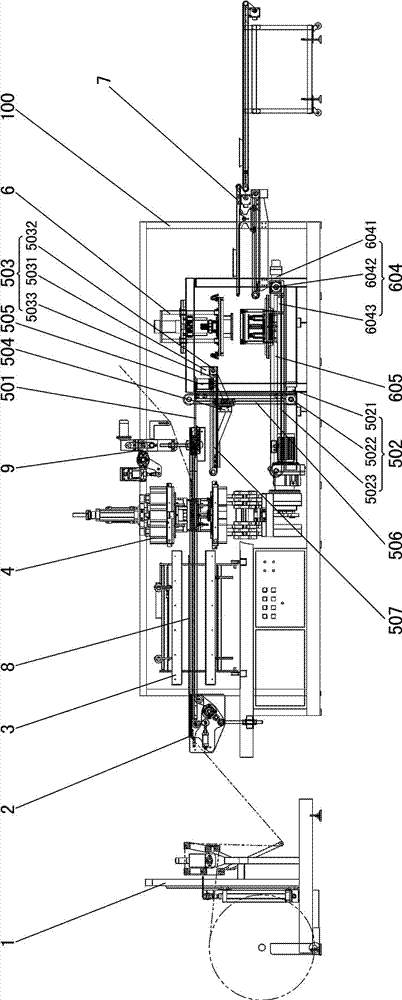

[0022] Such as figure 1 As shown, this fully automatic blister punching forming machine includes an unwinding device 1, a sheet feeding device 2, a heating device 3, a forming device 4, a cup transfer device 5, and a cup hemming device arranged sequentially on a frame 100. The device 6 and the finished product exit device 7, as well as the chain rail device 8 and the chain rail adjustment device 9 arranged on the heating device 3 and the forming device 4 and connected with the film feeding device 2.

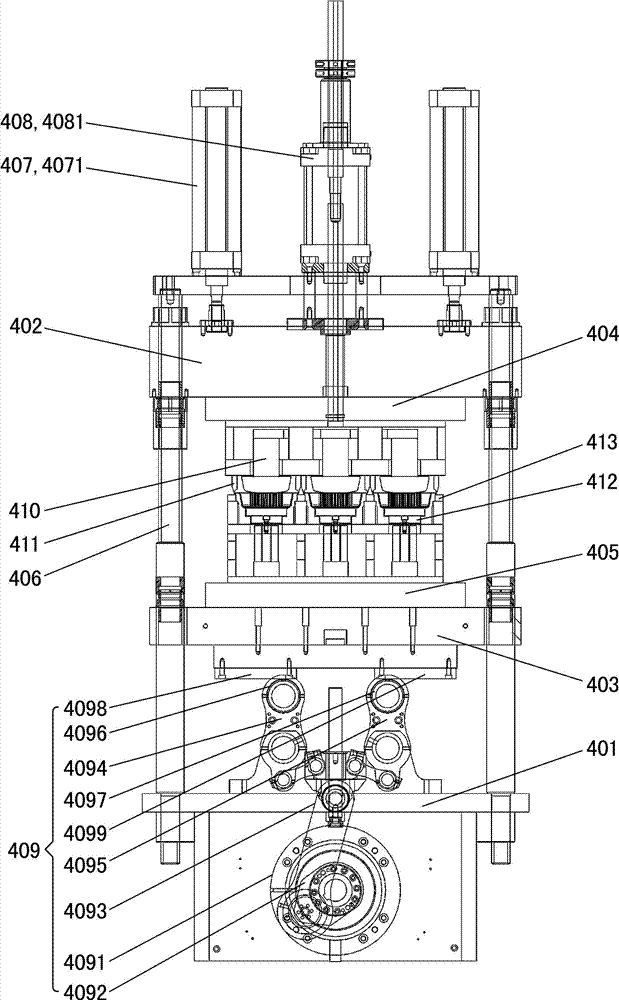

[0023] Such as figure 2As shown, the molding device 4 includes a mold table support 401, an upper mold table 402, a lower mold table 403, an upper template 404, a lower template 405, a guide post 406, an upper mold table adjustment mechanism 407, an upper template lifting mechanism 408 and a lower template lifting mechanism. Mechani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com