Efficient assembling equipment for sprayer assembly of flusher

A nozzle component and assembly equipment technology, applied in the direction of assembly machines, metal processing equipment, metal processing, etc., can solve the problems of easy contamination, easy misuse, and heavy labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is further illustrated by the following examples.

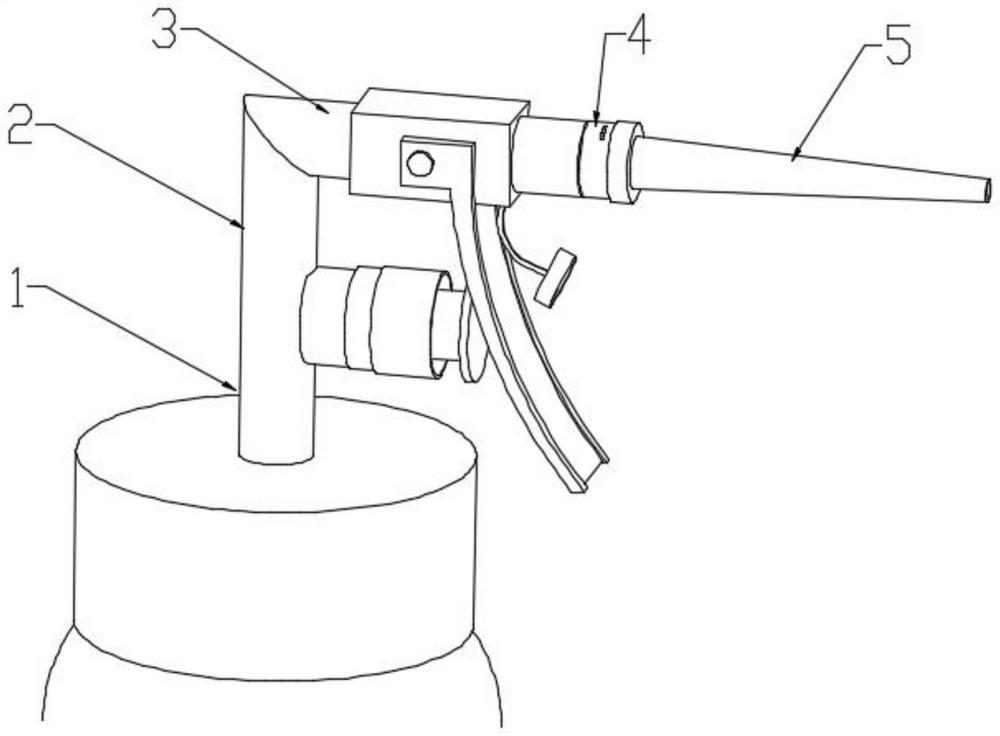

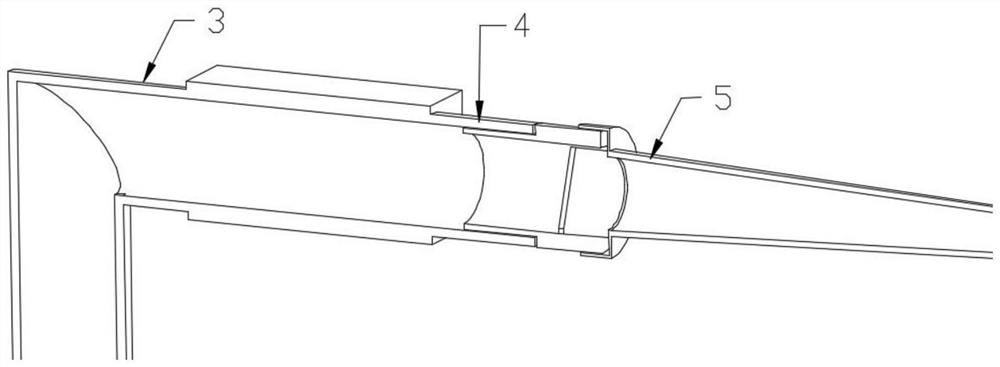

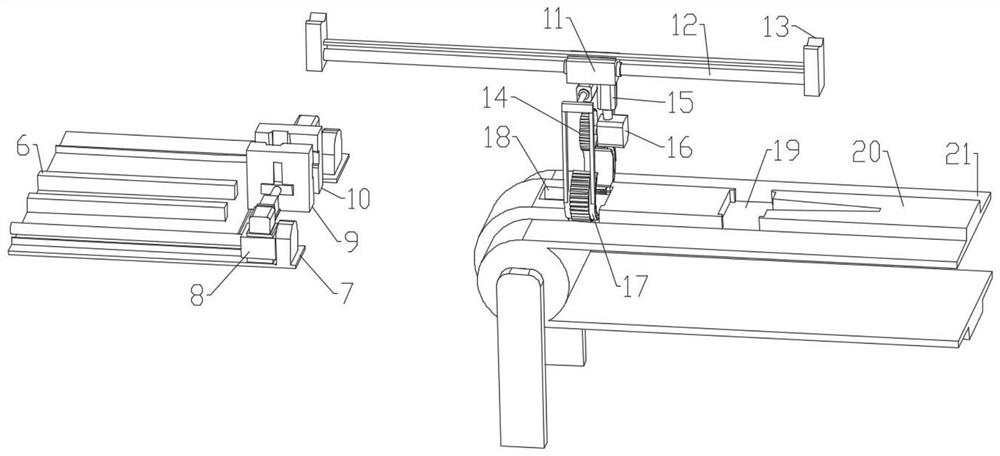

[0046] A high-efficiency assembly equipment for the spray head assembly of the washer, including a clamping and transferring part of the press seat and a transfer assembly part of the spray head assembly, the clamping and transferring part of the press seat includes a support platform 7, and a first tubular linear motor is arranged on the support platform 7 Drive the press seat fixture for transfer, and the nozzle assembly transfer assembly part includes a conveyor belt 21, the tail end of the conveyor belt 21 is set opposite to the tail end of the support table 7, and a second tubular linear motor is arranged above the tail of the conveyor belt 21 to drive the nozzle assembly fixture For transshipment, the second tubular linear motor is connected to the support on the top of the workshop through the mounting plate 13. It is characterized in that the press seat fixture includes a mold clamping fixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com