Semiaxis gear dismounting force and press mounting force testing device

A technology of half-shaft gears and testing devices, which is applied to measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of huge equipment, complicated operation and calculation, and complicated manual disassembly and assembly, so as to improve rigidity and strength, The effect of expanding the specification range and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

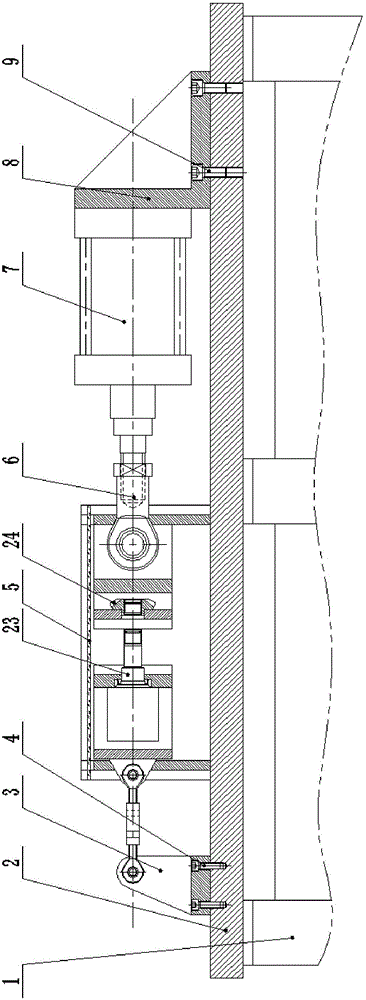

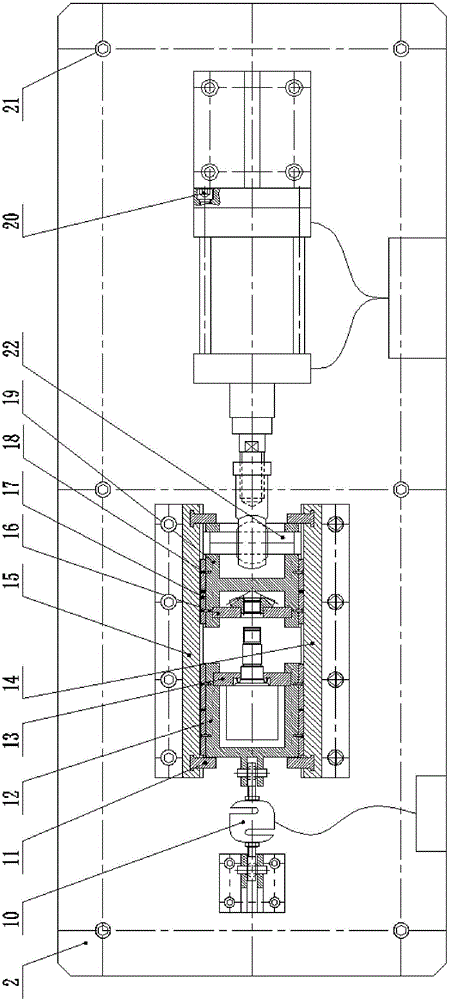

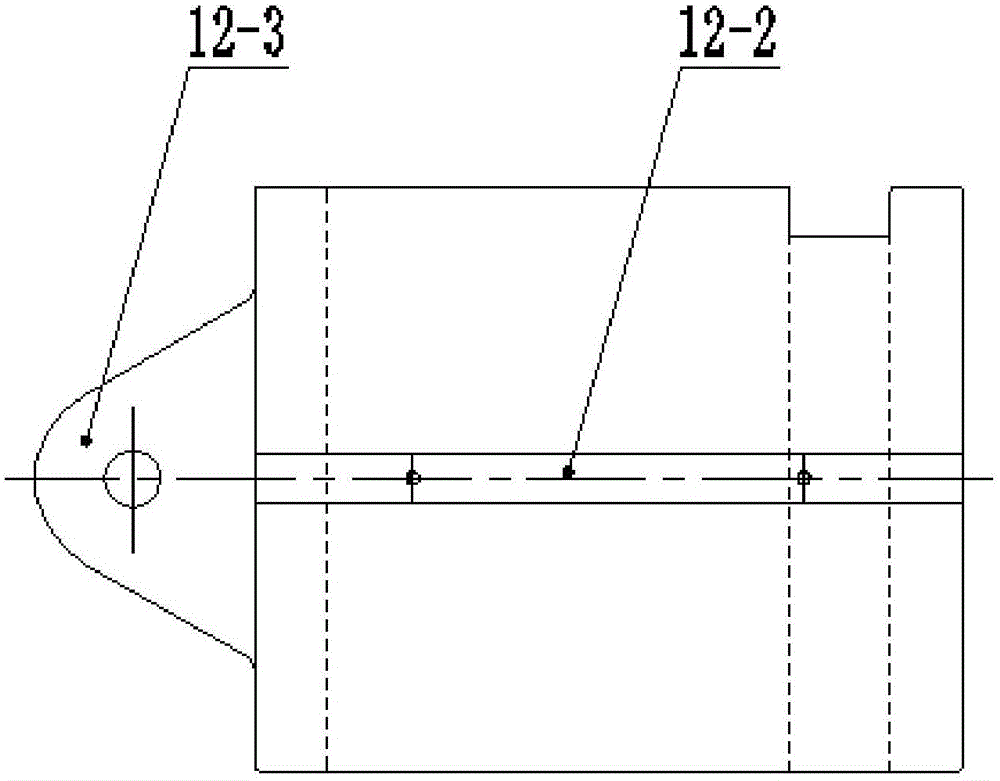

[0029] The invention discloses a device for testing the dismounting force and press-fitting force of a half-shaft gear, such as figure 1 , 2 As shown, it includes a platen 2 and a half shaft seat, a gear seat, a tension pressure sensor 10 and a cylinder 7 installed on the platen, and the half shaft seat is used for installing the half shaft 23 to be tested and for the half shaft Axial limit, the gear seat is used to install the gear to be tested 24 and axially limit the gear, the half shaft seat and the gear seat are arranged on the left and the right, and each adopts a linear sliding fit connection Installation, for example, can be directly slidably connected with the table by setting guide rails and sliders, and can be slidably connected with other parts fixed on the table by means of a similar connection structure. In a word, the half shaft seat and the gear seat are It can linearly reciprocate left and right relative to the table, so it can carry the half shaft and the ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com