Door engagement device for elevator

A door card and elevator technology, which is applied to elevators, transportation and packaging in buildings, etc., can solve the problem of inconsistent movement between the drive belt and the first and second sleds, and difficulty in opening and closing the first and second sleds. Speed adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

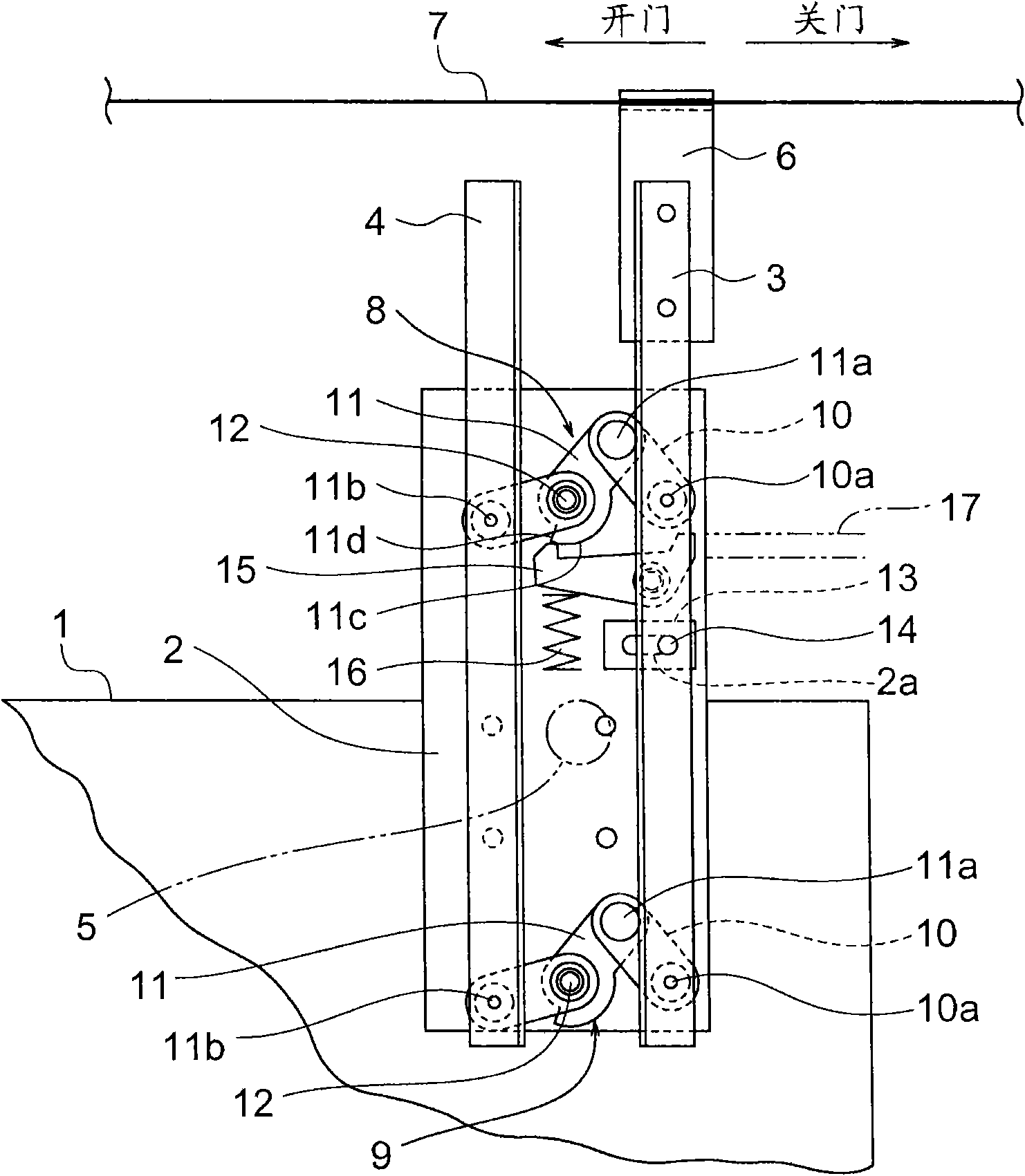

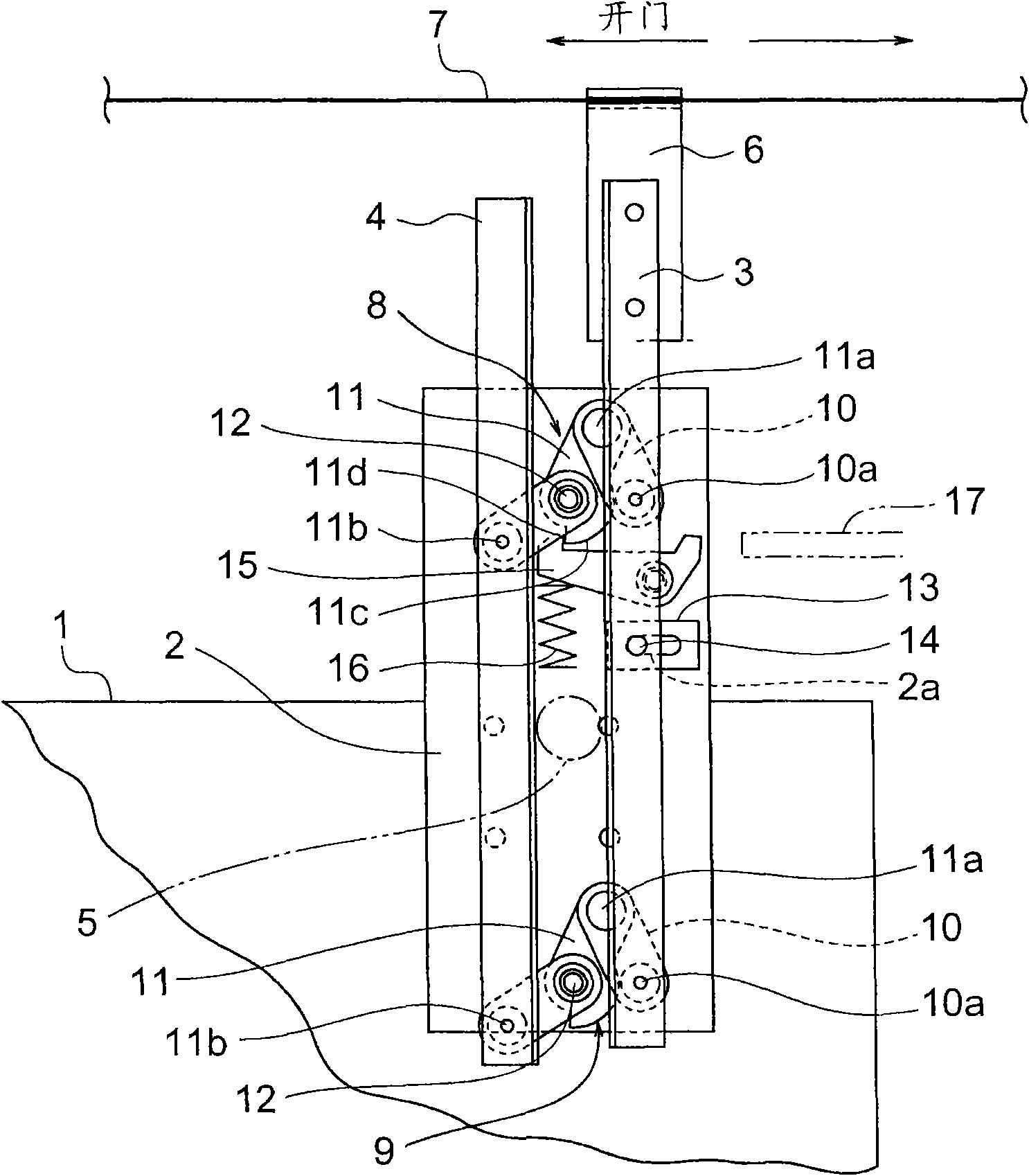

[0016] figure 1 It is a front view of the elevator door engaging device according to Embodiment 1 of the present invention viewed from the hall side. In the drawing, a base plate 2 is fixed to an upper portion of a car door 1 . A first engaging member (driving-side engaging fin) 3 and a second engaging member (driven-side engaging fin) 4 are provided on the base plate 2 . The longitudinal directions of the first and second engaging members 3 and 4 are parallel to the vertical direction.

[0017] In addition, the first and second engaging members 3 and 4 are in the opening and closing direction of the car door 1 ( figure 1 in the left-right direction) and are spaced apart from each other. The spacing between the first and second engaging parts 3, 4 can vary. When the car moves into the door area, the engaging roller 5 provided on the landing door (not shown) as the engaging portion on the landing door side is located between the first and second engaging members 3 , 4 . In...

Embodiment approach 2

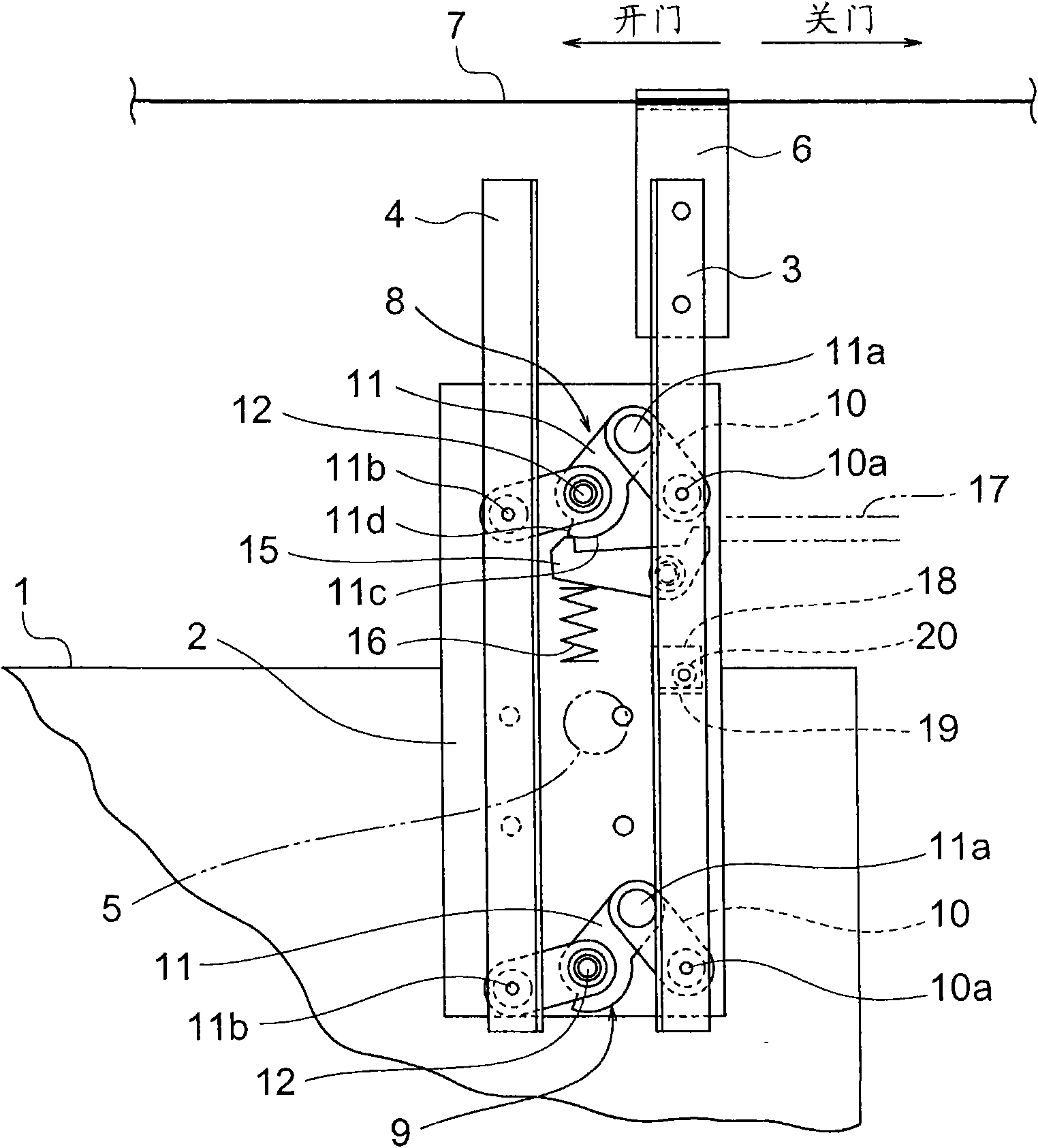

[0043] Next, image 3 It is a front view of the elevator door engaging device according to Embodiment 2 of the present invention viewed from the hall side. In the drawing, a guide mechanism 18 is provided between the base plate 2 and the first engaging member 3 , and the guide mechanism 18 limits the movement of the first engaging member 3 to the horizontal direction. The guide mechanism 18 has: a guide plate 19 provided on the base plate 2 ; and a guide roller 20 provided on the first engaging member 3 and rolling along the upper surface of the guide plate 19 . The upper surface of the guide plate 19 is provided parallel to the opening and closing direction of the car door 1 . Other structures are the same as those in Embodiment 1.

[0044] When the self-weight of the second engaging member 4 is sufficiently light relative to the rigidity of the driving belt 7, the driving belt 7 hardly bends due to the self-weight of the second engaging member 4, and the possibility of rai...

Embodiment approach 3

[0047] Next, Figure 4 It is a front view of the door engaging device of an elevator according to Embodiment 3 of the present invention viewed from the hall side. In Embodiment 3, the guide mechanism 13 in Embodiment 1 is omitted. Other structures are the same as those in Embodiment 1.

[0048] When the self-weight of the first engaging member 3 including the joint fitting 6 and the self-weight of the second engaging member 4 are sufficiently light relative to the rigidity of the driving belt 7, the possibility of the position of the first engaging member 3 changing up and down is low Next, it can also be as Figure 4 The guide mechanisms 13, 18 are omitted from the illustration. In this case, the drive belt 7 itself can be used as a guide to move the first engaging member 3 horizontally, thereby enabling simplification and cost reduction of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com