Patents

Literature

43 results about "Fiber crossing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of three-dimensional fiber-based aerogel material and product thereof

ActiveCN103285789AImprove pore structureWide pore structure adjustable rangeColloidal chemistry detailsSolubilityFiber

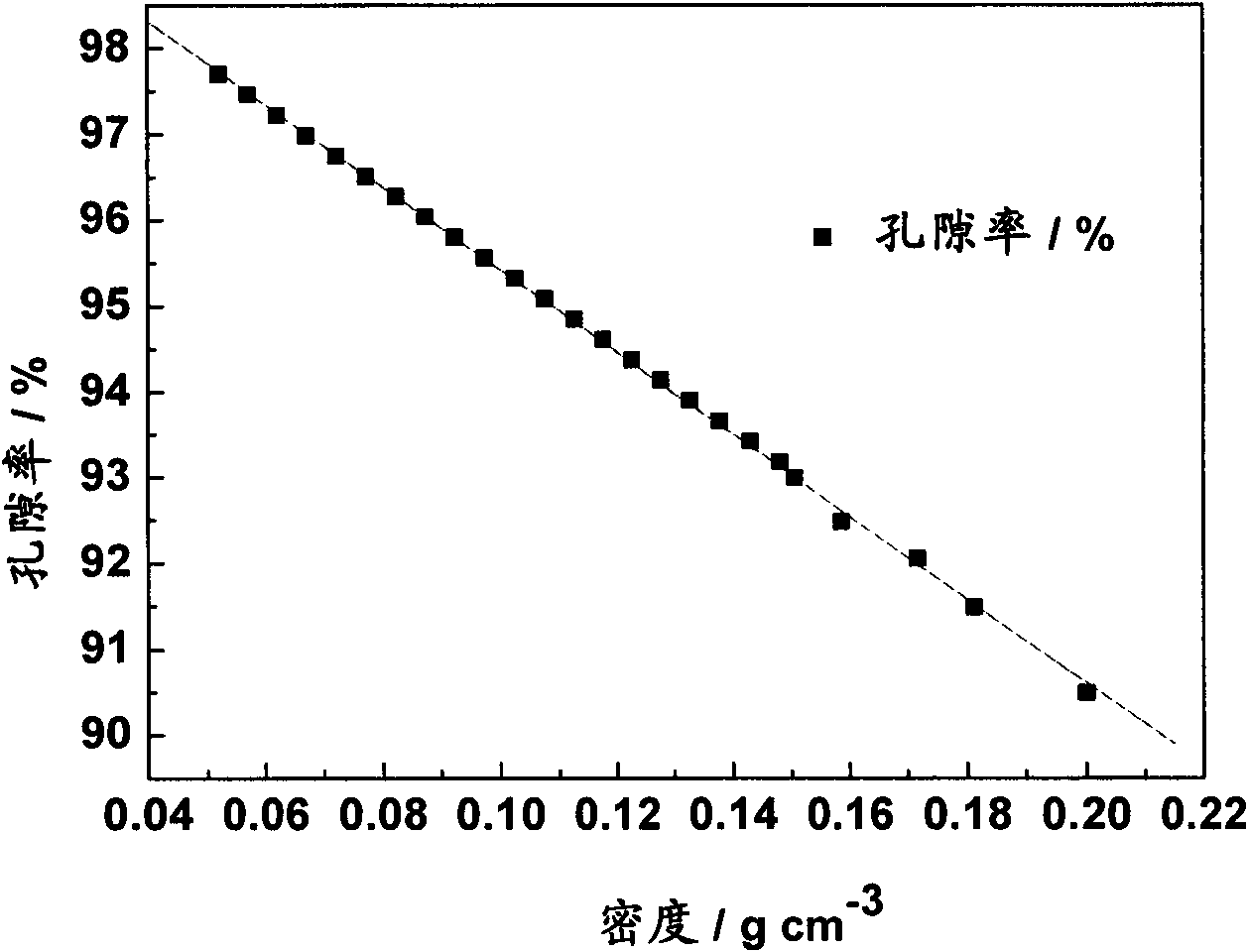

The invention relates to a preparation method of a three-dimensional fiber-based aerogel material and a product thereof. The preparation method comprises the following steps of: firstly dispersing fibers in solvents which do not have fiber solubility to form turbid liquid; secondly curing the turbid liquid to form cured pieces; thirdly removing cured solvents in the cured pieces to form non-crosslinked fiber-based aerogel; and finally carrying out crosslinking stabilization treatment on the non-crosslinked fiber-based aerogel to obtain the fiber crossing point bonded and fixed three-dimensional fiber-based aerogel material. The product is a three-dimensional network-shaped material formed through mutual penetration and stagger of fibers. The fiber crossing points are effectively interconnected through non-hydrogen-bond bonding. The three-dimensional fiber-based aerogel material has volume density of 0.1-500mg / cm<3>, average pore size of 0.01-2000mu m and specific surface area of 0.2-2000m<2> / g. The preparation method and the product have the advantages that the preparation process is simple; the raw material limitations are less; and the aerogel product has good flexibility and connectivity and has broad application prospects in numerous fields.

Owner:DONGHUA UNIV

Three-dimensional fiber-based aerogel tissue engineering scaffold and preparation method thereof

The invention relates to a preparation method of a three-dimensional fiber-based aerogel tissue engineering scaffold and a product thereof. The preparation method comprises the following steps of: firstly dispersing fibers in solvents to form turbid liquid; secondly curing the turbid liquid to form cured pieces; thirdly removing cured solvents to form non-crosslinked fiber-based aerogel; finally carrying out crosslinking stabilization treatment and then carrying out sterilization treatment, thus obtaining the three-dimensional fiber-based aerogel tissue engineering scaffold. The product is a three-dimensional network-shaped material formed through mutual penetration and stagger of fibers. The fiber crossing points are effectively interconnected through non-hydrogen-bond bonding. The three-dimensional fiber-based aerogel tissue engineering scaffold has volume density of 0.1-500mg / cm<3>, average pore size of 0.01-2000mu m and specific surface area of 0.2-2000m<2> / g. The preparation method and the product have the advantages that the preparation process is simple; the raw material limitations are less; the aerogel tissue engineering scaffold product has good flexibility, connectivity and tissue growing environment and has broad application prospects in the tissue engineering field.

Owner:DONGHUA UNIV

Three-dimensional fiber-based aerogel catalyst carrier and preparation method thereof

ActiveCN103285920AGood flexibilitySufficient reactive sitesCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsFiberPliability

The invention relates to a preparation method of a three-dimensional fiber-based aerogel catalyst carrier and a product thereof. The preparation method comprises the following steps of: firstly dispersing fibers in solvents to form turbid liquid; secondly curing the turbid liquid to form cured pieces; thirdly removing cured solvents to form non-crosslinked fiber-based aerogel; finally carrying out crosslinking stabilization treatment and then carrying out activation treatment, thus obtaining the three-dimensional fiber-based aerogel catalyst carrier. The product is a three-dimensional network-shaped material formed through mutual penetration and stagger of fibers. The fiber crossing points are effectively interconnected through non-hydrogen-bond bonding. The three-dimensional fiber-based aerogel catalyst carrier has volume density of 0.1-500mg / cm<3>, average pore size of 0.01-2000mu m and specific surface area of 0.2-2000m<2> / g. The preparation method and the product have the advantages that the preparation process is simple; the raw material limitations are less; and the aerogel catalyst carrier product has good flexibility, connectivity and catalyst supporting capacity and has broad application prospects in the catalytic application field.

Owner:DONGHUA UNIV

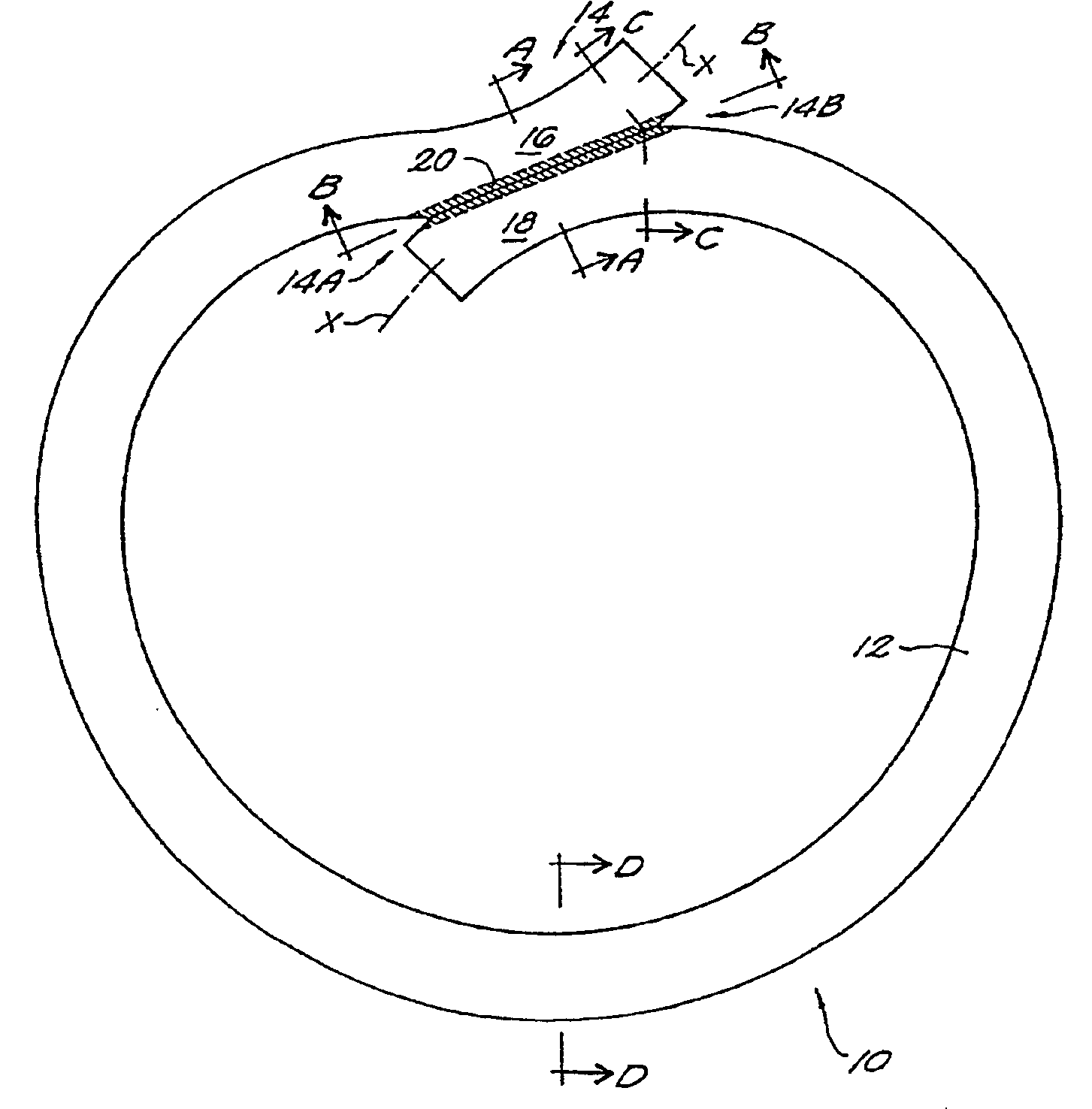

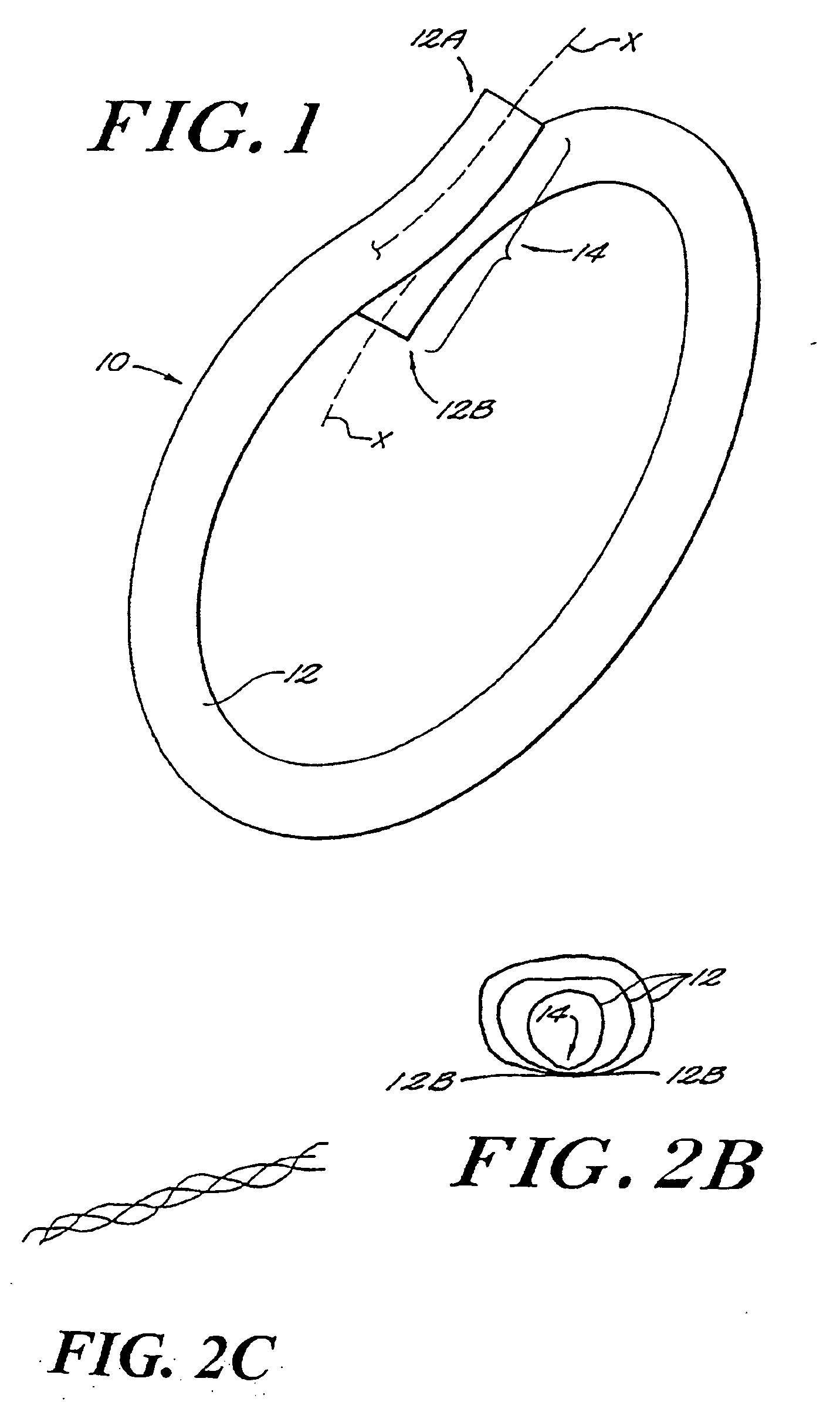

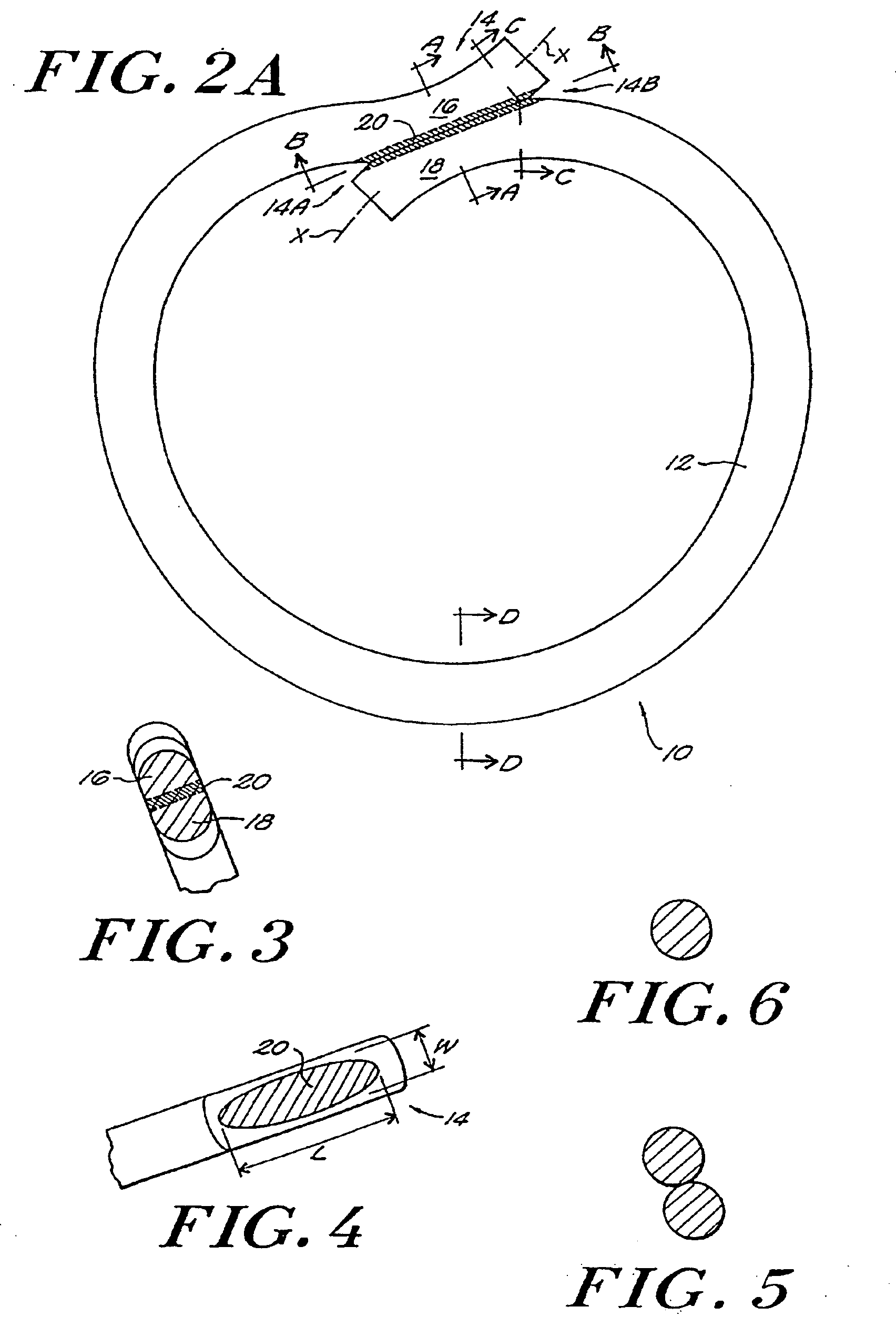

Fused loop of filamentous material and apparatus for making same

InactiveUS20050216058A1Maximize joint strengthSuture equipmentsSurgical needlesElastic fibresPolymer science

A method of forming an elastic cloth structure comprising fibers of synthetic, organic, relatively elastomeric polymer and fibers of a synthetic, organic, elongatable, but relatively nonelastic polymer. The relatively elastomeric fibers and the elongatable but relatively nonelastic fibers are forwarded for well dispersed random lay down of an unbonded web with random fiber crossings on a porous forming surface. Some of the fiber crossings are then bonded to provide a coherent bonded cloth web and the web is stretched to elongate some of the fibers in at least one direction. The web is then released so that retraction by the relatively elastomeric fibers provides looping and bunching of the elongated relatively nonelastic fibers to thereby provide a low modulus of elasticity in the direction in which the web was worked.

Owner:HOWMEDICA OSTEONICS CORP

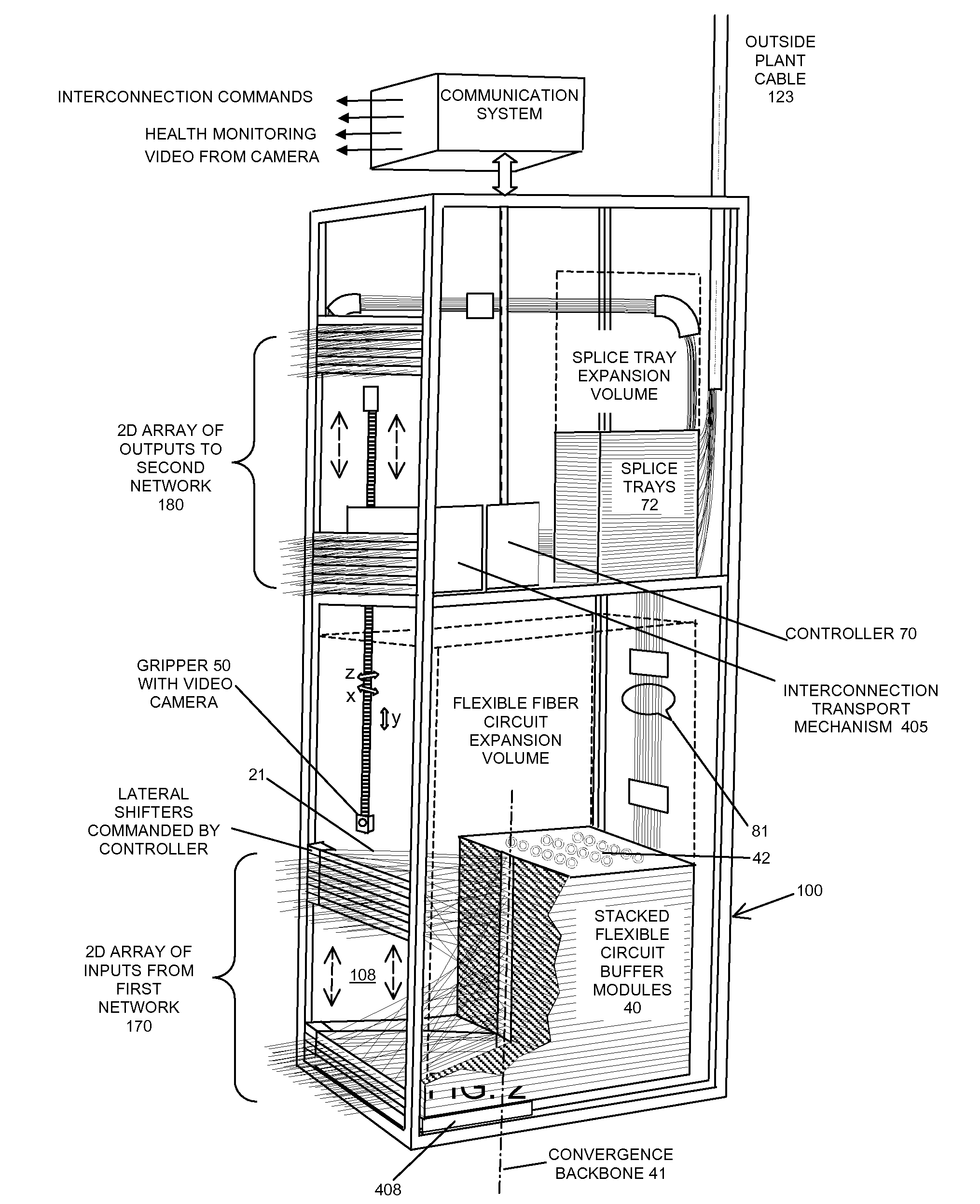

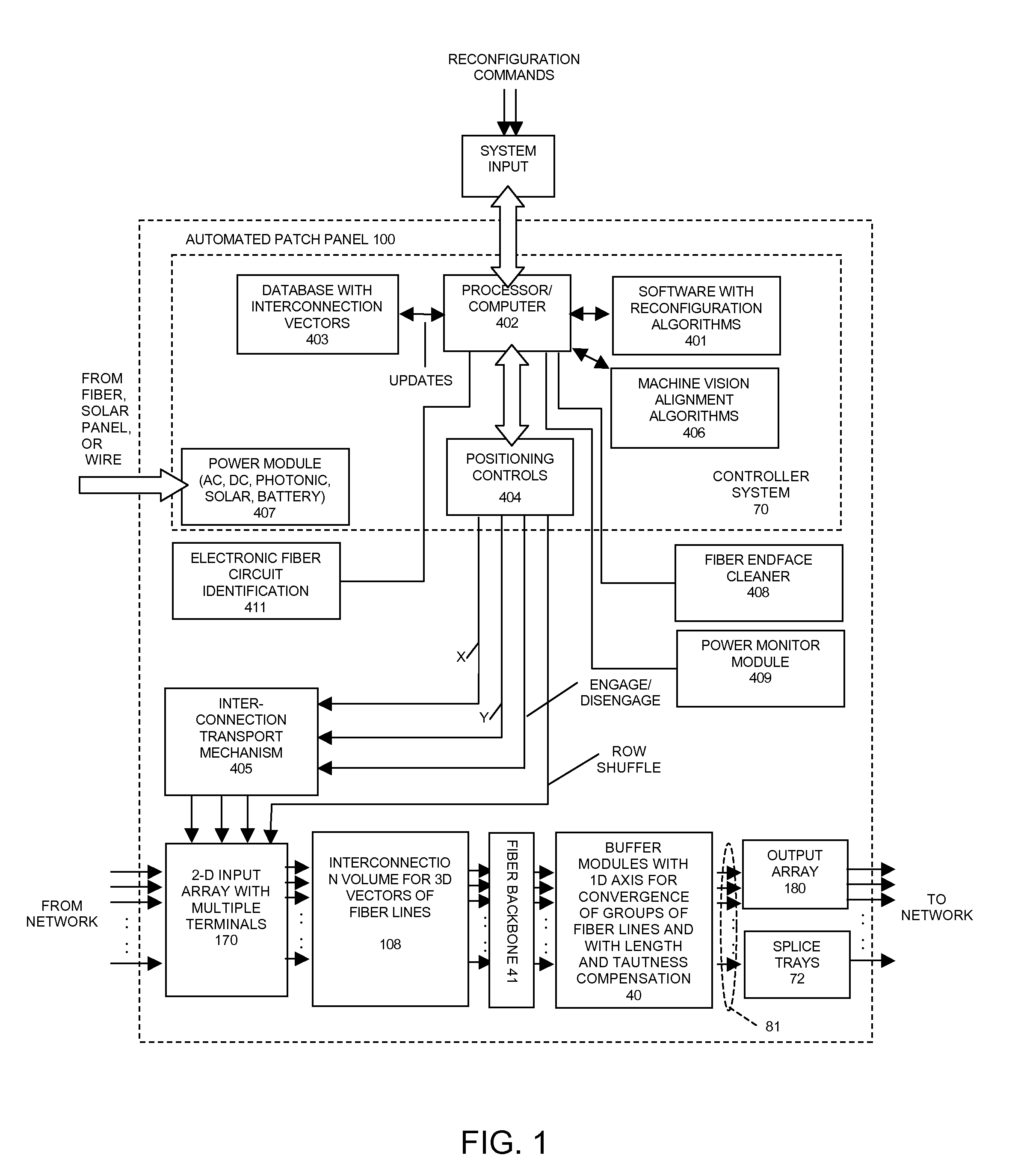

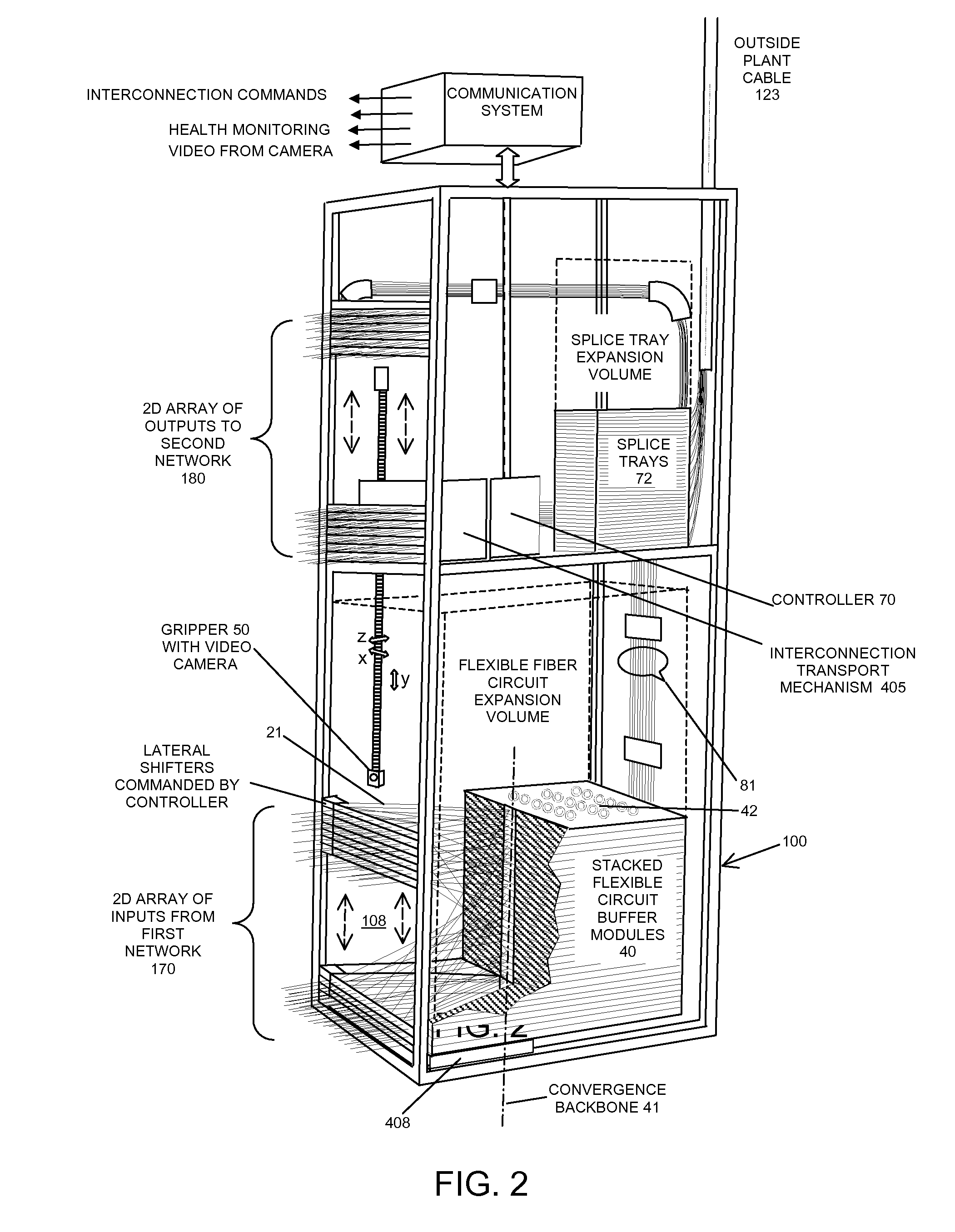

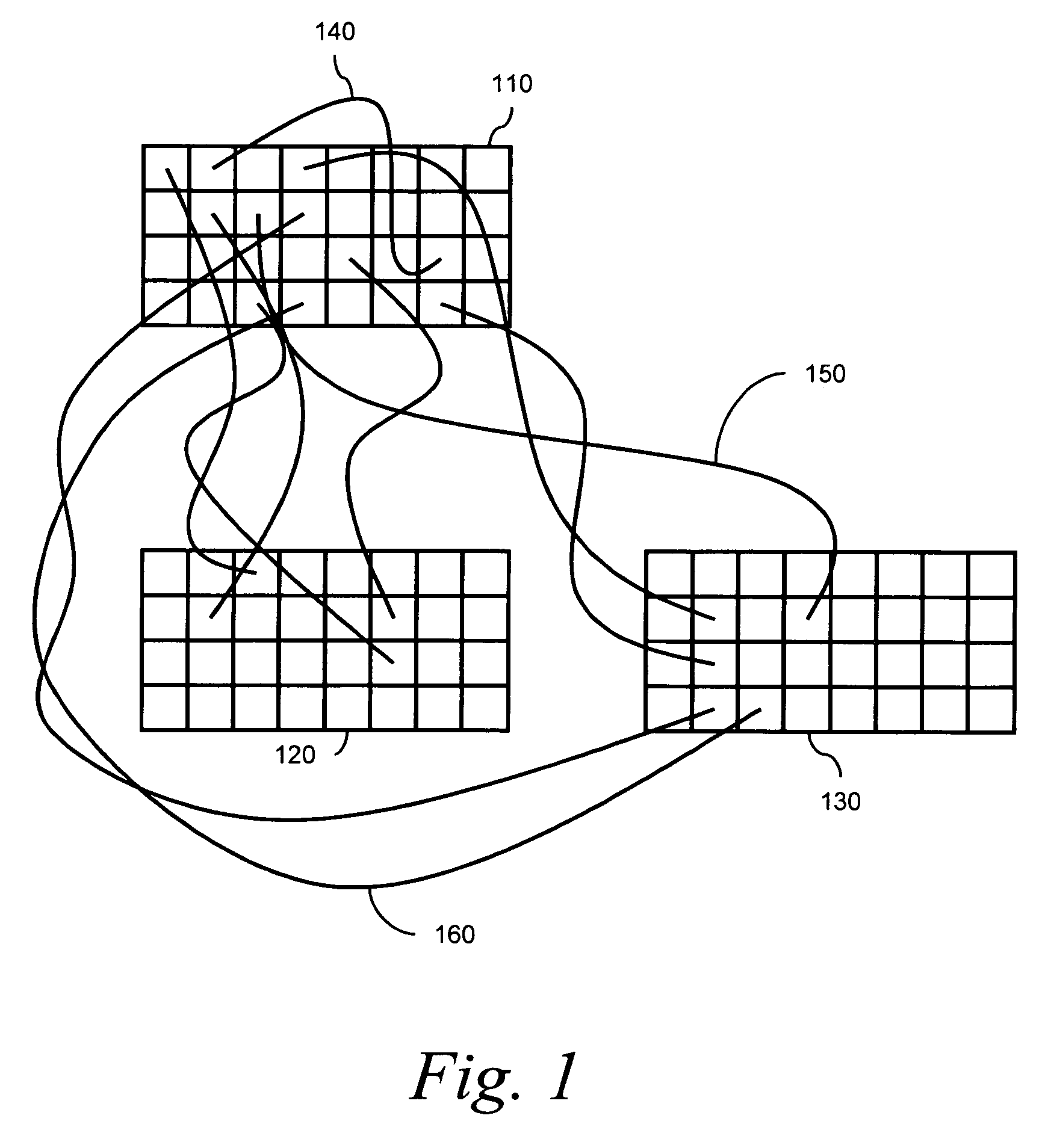

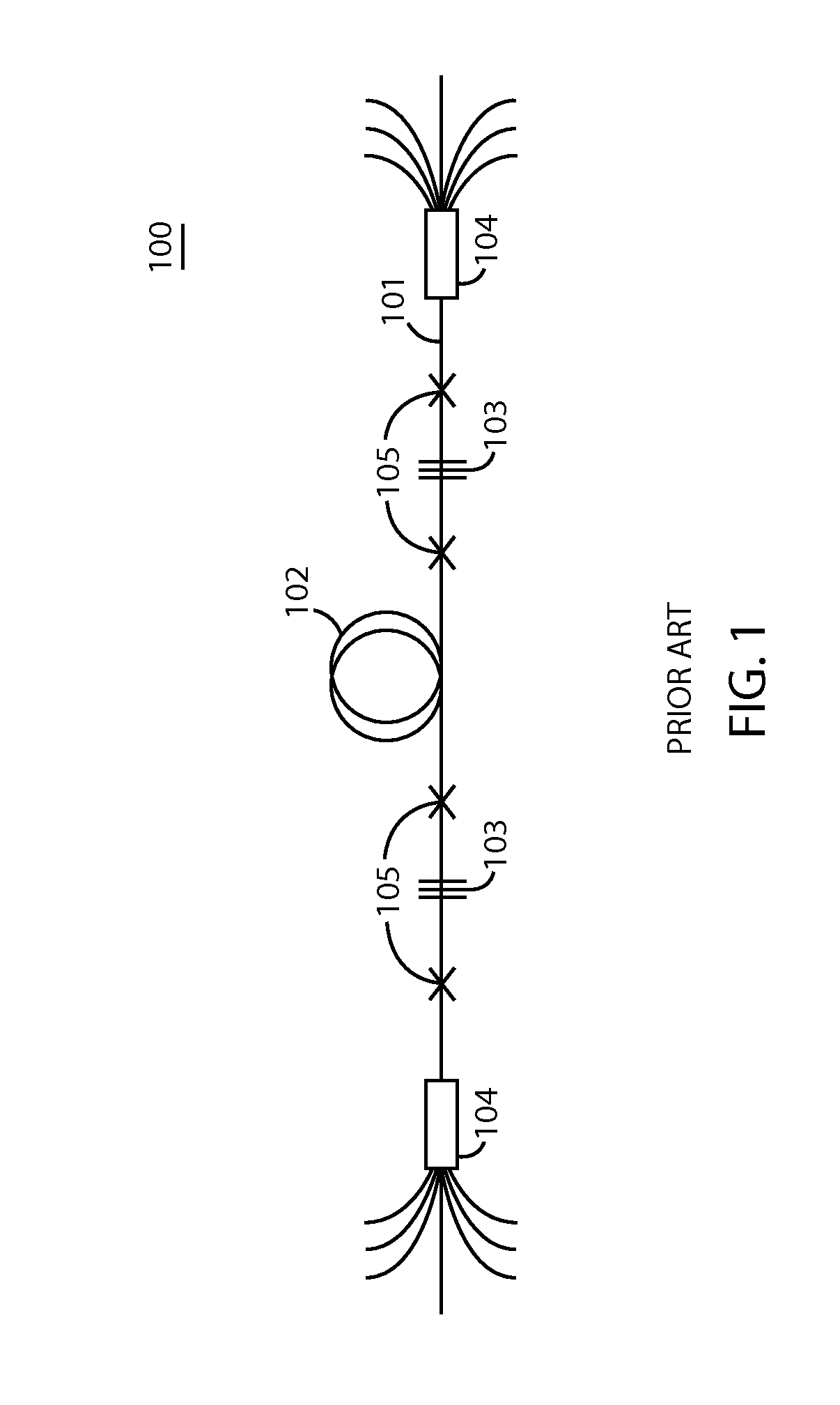

Methods to reconfigure all-fiber optical cross-connects

ActiveUS20090097797A1Speed up the processGuaranteed uptimeMultiplex system selection arrangementsCoupling light guidesFiberModularity

This invention discloses methods to reconfigure highly scalable and modular automated optical cross connect switch devices comprised of large numbers of densely packed fiber strands suspended within a common volume. In particular, methods enabling programmable interconnection of large numbers of optical fibers (100's-1000's) are provided, whereby a two-dimensional input array of fiber optic connections is mapped in an ordered and rule-based fashion into a one-dimensional array. A particular algorithmic implementation for a system reconfigured by a three-axis robotic gripper as well as lateral translation of each row in the input port array is disclosed.

Owner:TELESCENT

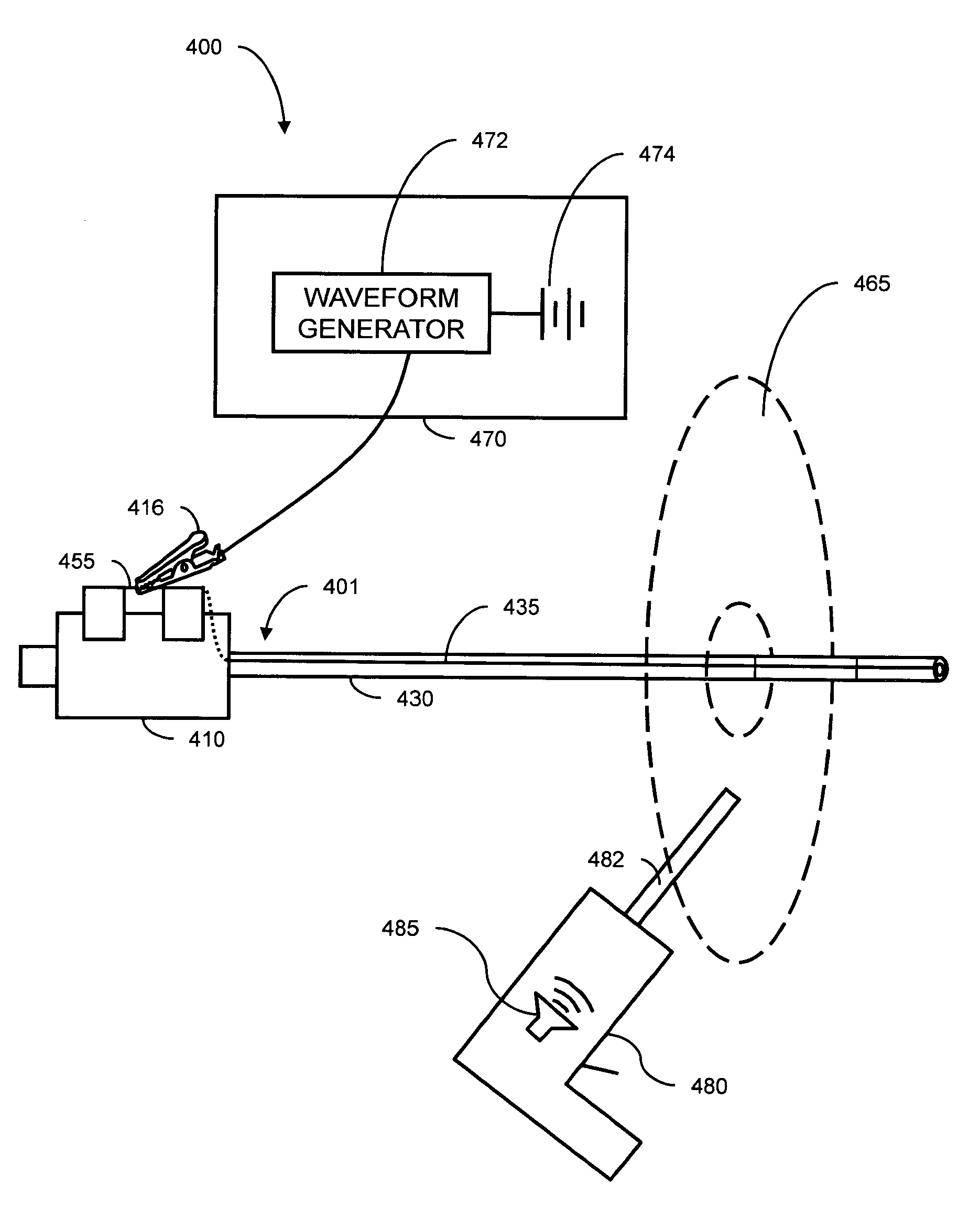

Traceable fiber optic jumpers

ActiveUS20100148747A1Need be addressCurrent/voltage measurementFibre mechanical structuresFiberElectrical conductor

An optical fiber jumper cable includes a single tracing conductor for tracing the jumper cable through a fiber cross-connect facility such as a central office. An electrical locating tone is impressed on the conductor so that the conductor radiates an electromagnetic field along the length of the fiber jumper cable. A locating tone detector is used to trace the fiber jumper cable along its length by monitoring a presence-indicating signal emitted by the locating tone detector.

Owner:AT&T INTPROP I L P

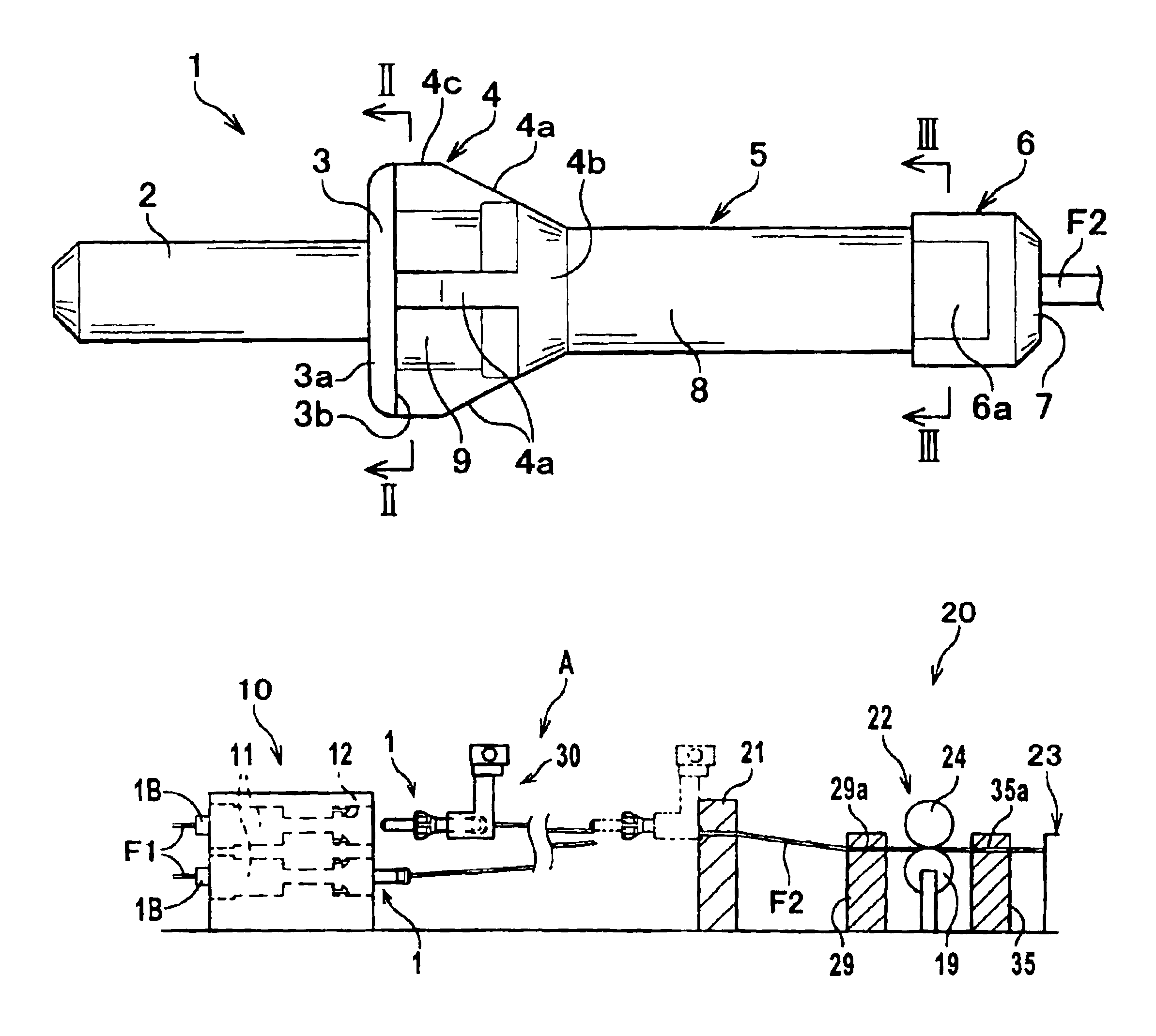

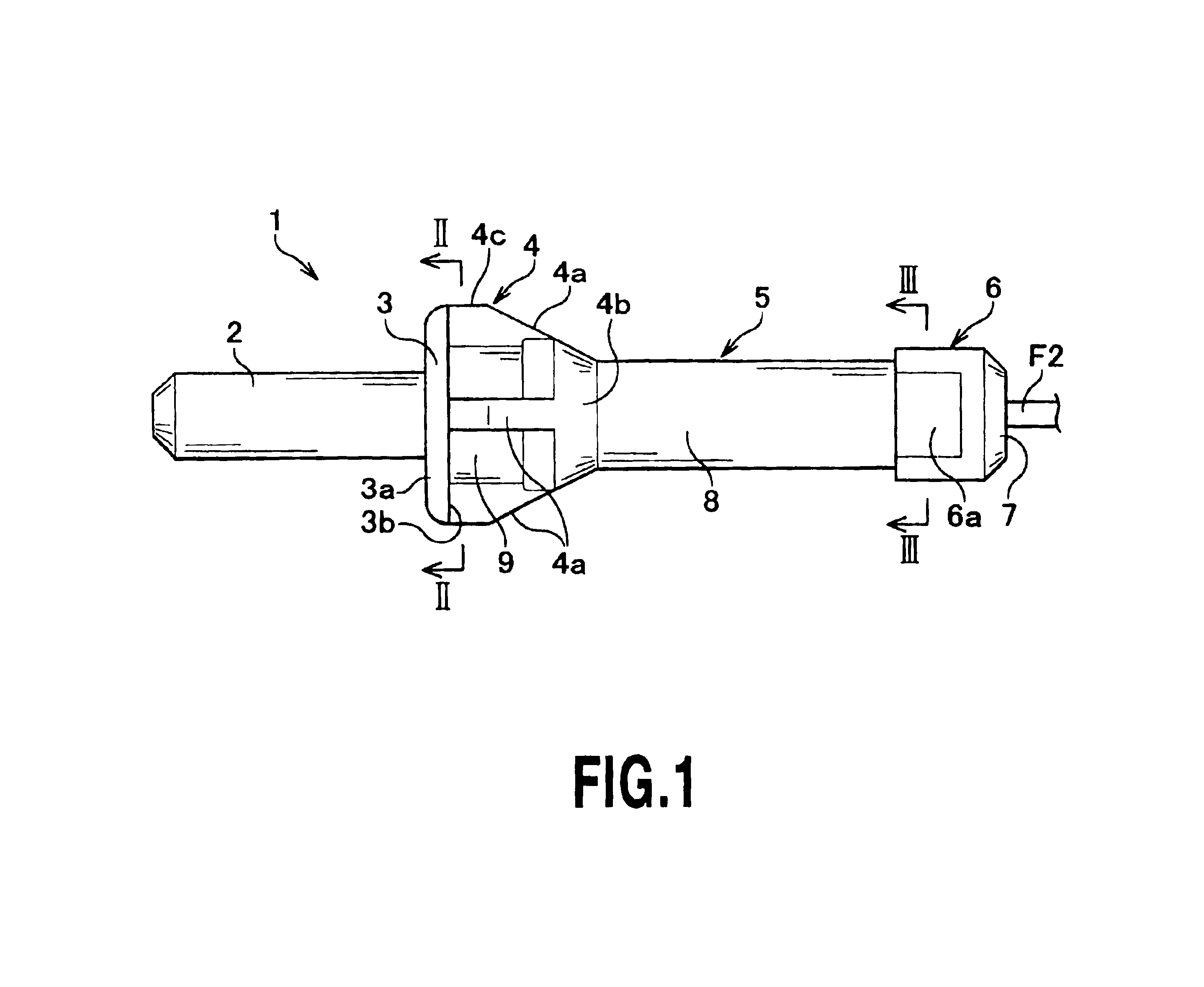

Optical fiber cross-connect with a connection block, an alignment block and a handling device

InactiveUS6877906B2Secure high reliabilityEliminate entanglementCoupling light guidesEngineeringFront end of line

An optical connector plug according to the present invention which is joined to a front end of an optical fiber cord covering an optical fiber and which is removably inserted to one end of an optical adapter having a locking member for locking the optical connector plug in an engaged state, includes an inserted portion removably inserted to one end of the optical adapter, a plug body joined to a front end of the optical fiber cord, a locking portion formed between the plug body and the inserted portion and locked by the locking member of the optical adapter, and a rotational phase reference surface formed on the plug body away from the locking portion. The optical connector plug according to the present invention can be applied to APC optical connector plug, secure high reliability for optical cross-connecting, and also reduce cost.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

Process for preparing flame-retarding washable filtering material

The invention provides a process for preparing a flame-retarding washable filtering material. The flame-retarding washable filtering material is prepared by the following steps of: needling various terylene or polypropylene staple fiber and three-dimensional crimp polyester staple fiber by a certain proportion to prepare a basic material; subsequently soaking the basic material in a flame-retarding adhesive solution prepared by mixing an acrylate polymer and a cyclic phosphate flame retardant with a certain proportion; subsequently rolling by dual rollers, drying and spraying the flame-retarding adhesive; and subsequently drying and ironing out the solution, thus forming the filtering material with the fiber crossing fixed by adhesive point and fiber surface covered by a smooth adhesive layer. The process is flame-retarding and washable.

Owner:HENAN ANKELIN FILTER IND

Preparation method of anti-flaming washable filter material

The invention discloses a preparation method of a flame-retardant and washable filter material. The flame-retardant and washable filter material is the filter material which is prepared by the following steps: a basic material is acupunctured and compounded by a polyester or a polypropylene fiber fine filter layer with a polyester or a polypropylene rough fine filter layer, then is emerged into a flame-retardant solution which is prepared by waterborne polyurethane, an acyclic phosphate flame retardant and sodium dihydrogen phosphate according to a certain proportion and then compacted by a twin-roll and dried and ironed out after being sprayed with the flame-retardant solution; and the formed fiber crossing points are fixed by gel points with the filter material with the fiber surface being covered by a smooth glue layer. The filter material is flame-retardant and washable.

Owner:HENAN ANKELIN FILTER IND

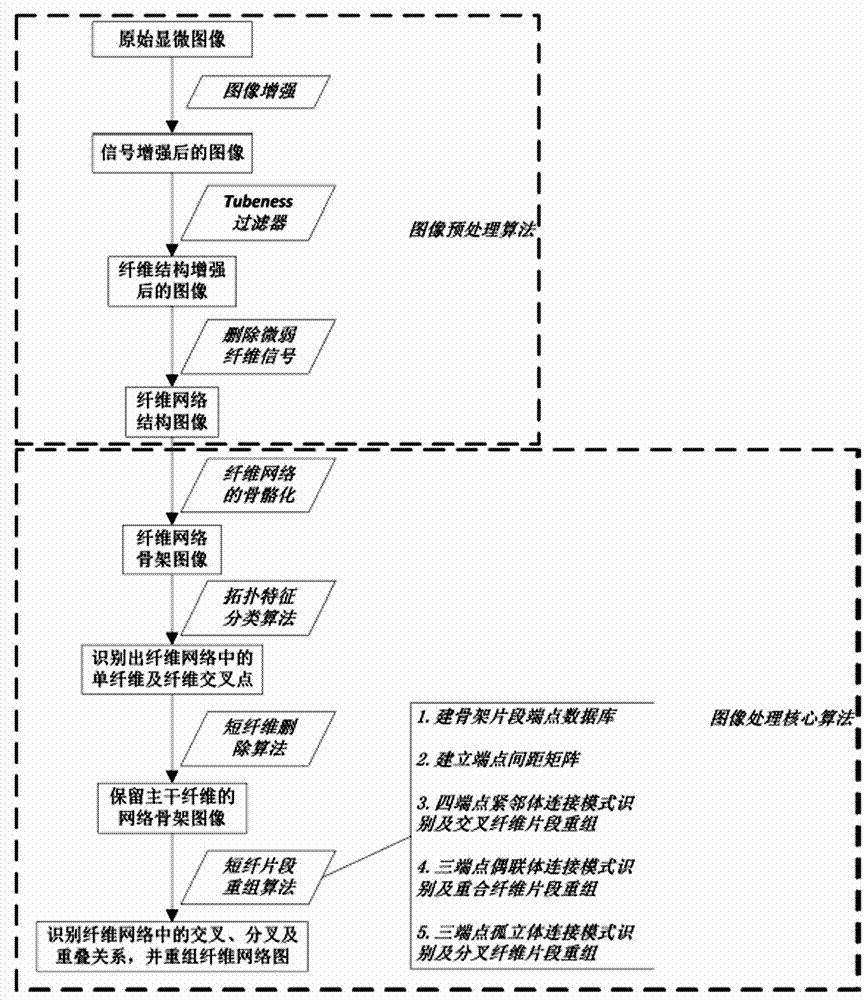

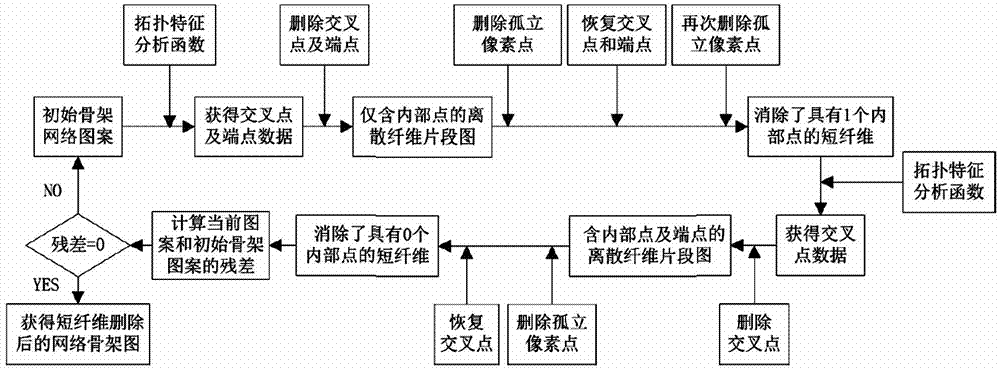

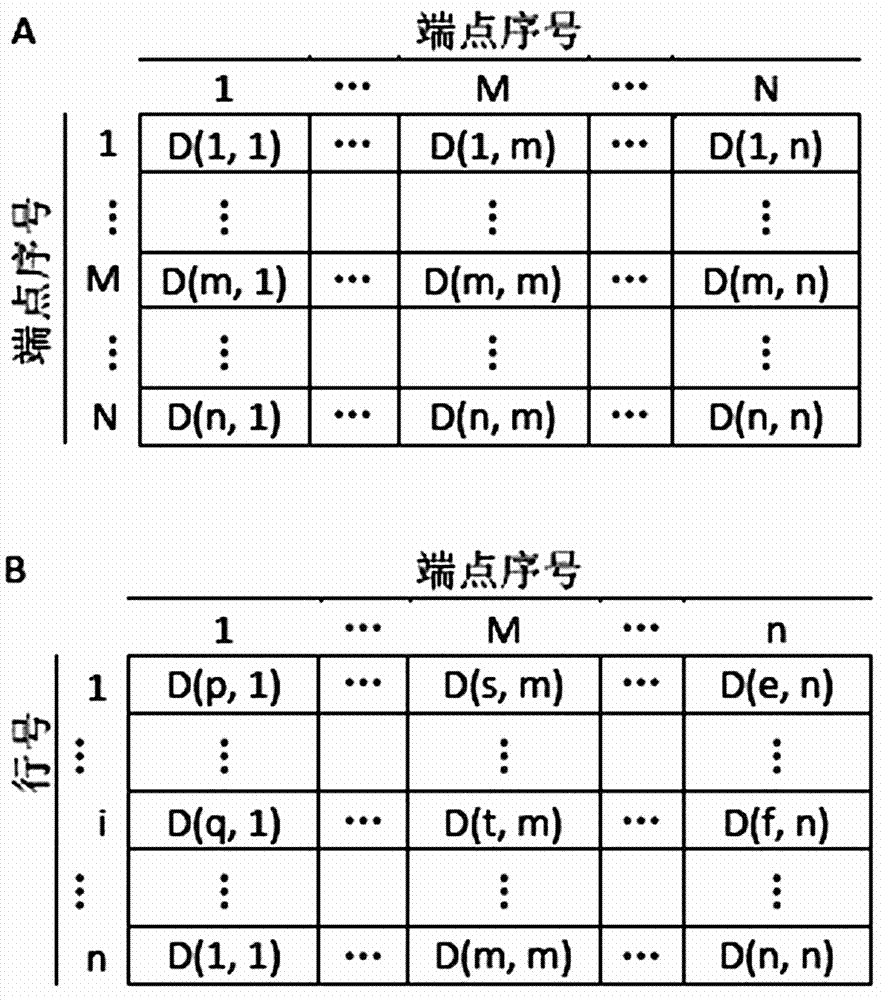

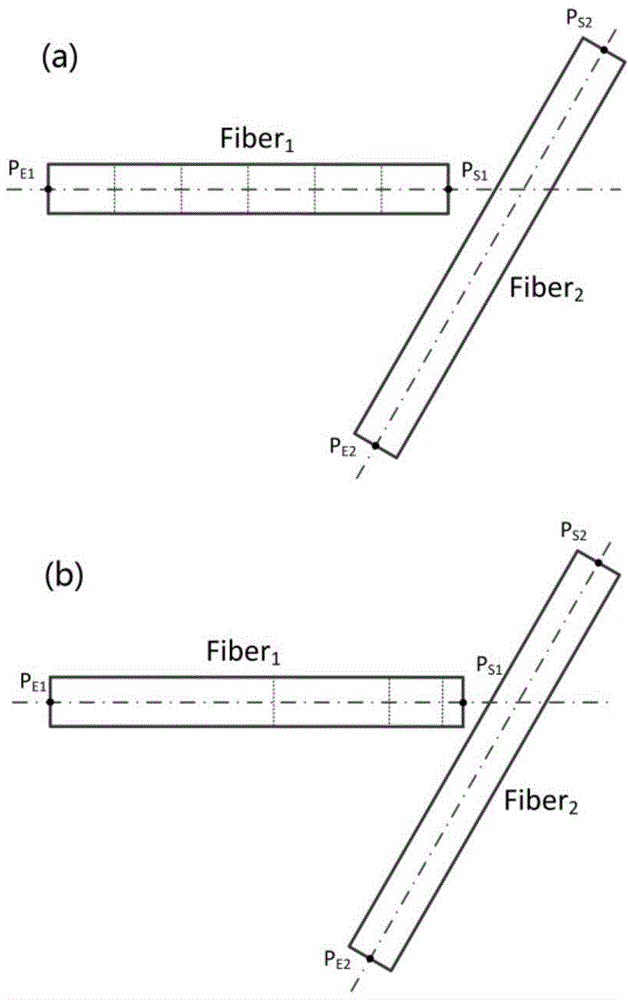

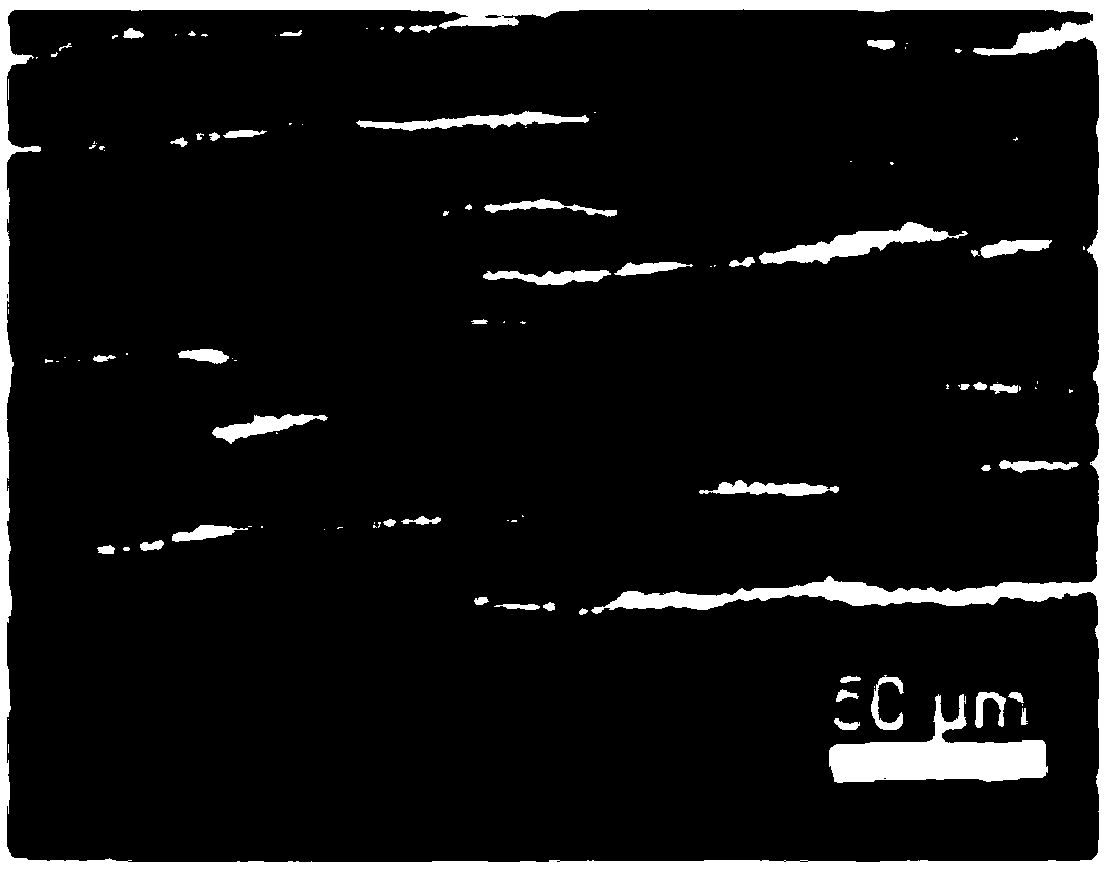

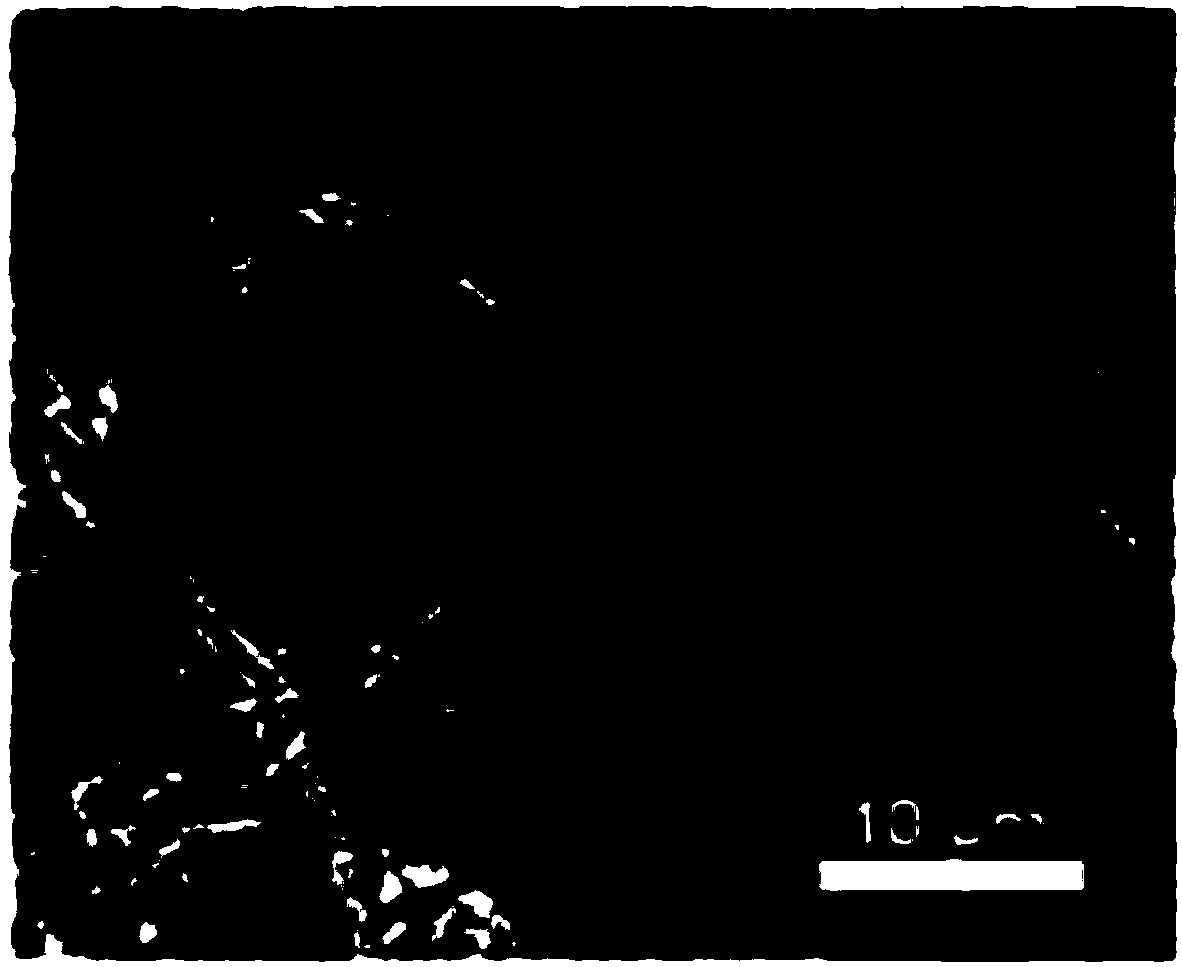

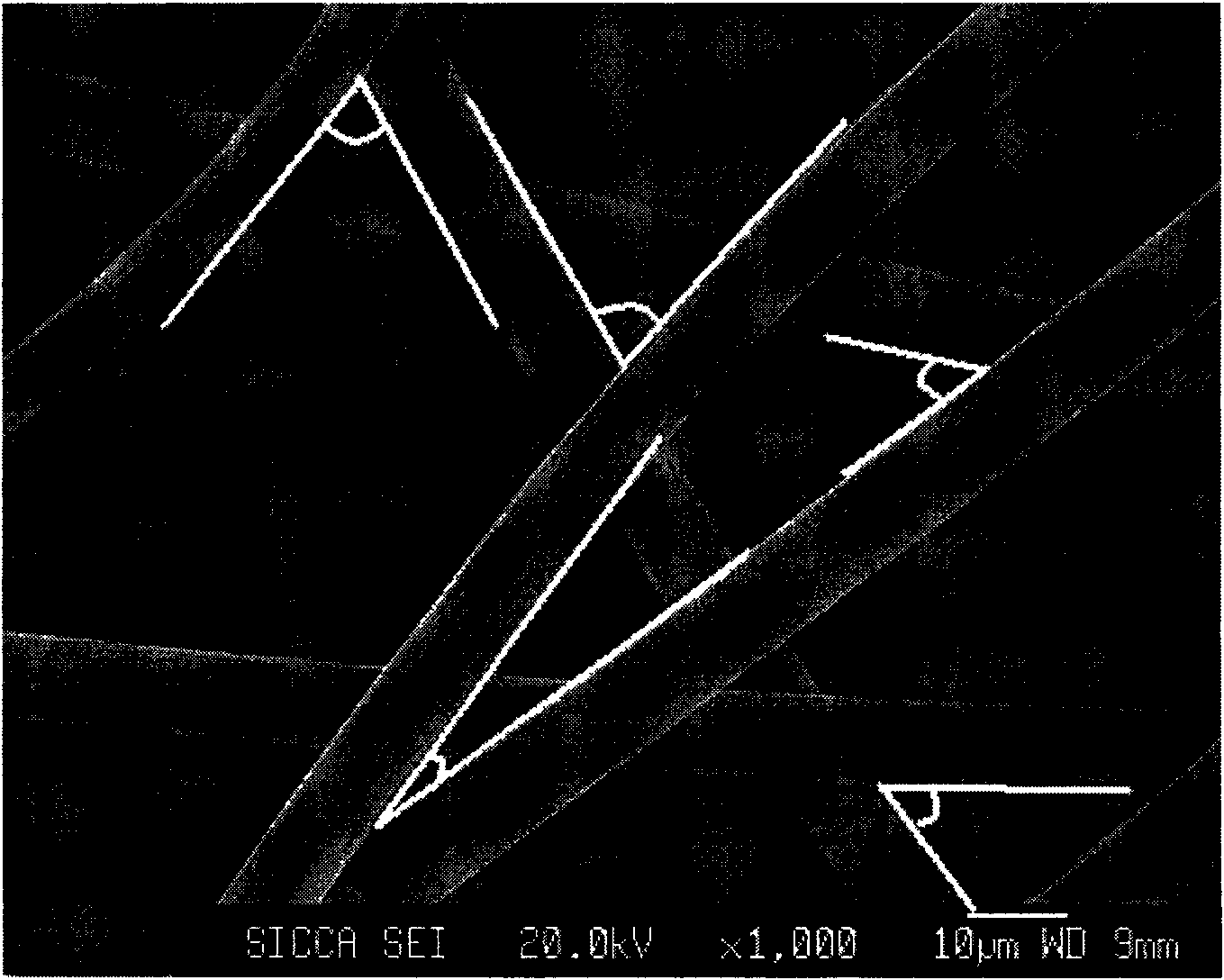

Curve fiber network structural morphology feature measurement method based on digital image processing

ActiveCN103673923AImprove noise immunityUsing optical meansDigital signal processingMicroscopic image

A curve fiber network structural morphology feature measurement method based on digital image processing includes the steps: firstly, skeletonize fiber networks to obtain fiber network skeleton patterns; secondly, classifying topological features of the fiber network skeleton patterns and identifying single fibers and fiber crossing points in the fiber networks; thirdly, deleting short fibers and reserving network skeleton patterns of trunk fibers; fourthly, recombining fiber fragments, identifying crossing, branching and overlapping relationships in the fiber networks and recombining fiber network graphs. Curve fiber network structural morphology features of sub-cellular scales are obtained by the aid of the steps. The measurement method can be used for quantitatively analyzing curve fiber network structures of the sub-cellular scales, and can analyze quantitative topologies of the curve network structures in microscopic images without relying on human intervention and judgment after fiber structures in the curve networks are identified and segmented.

Owner:裘钧

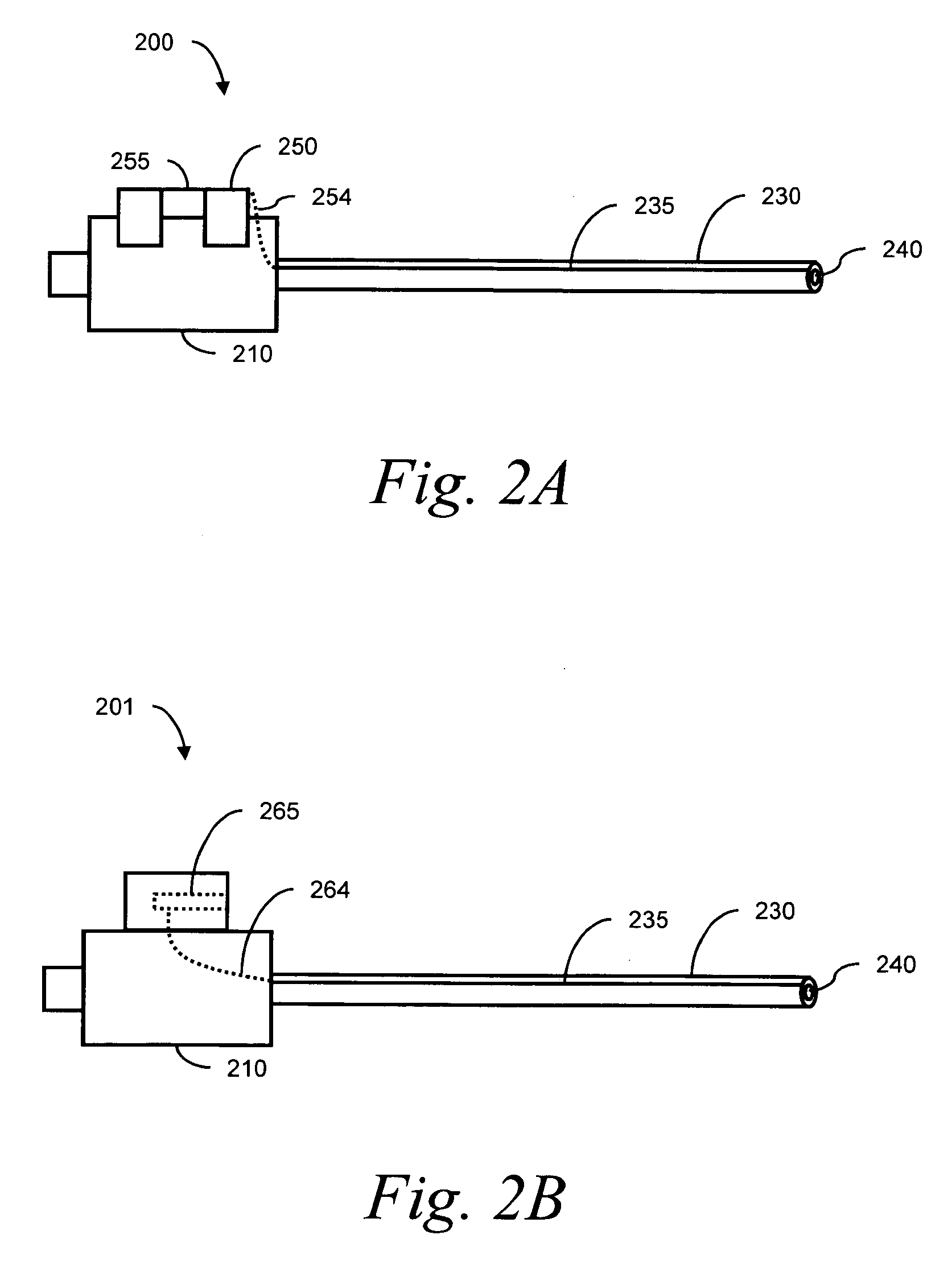

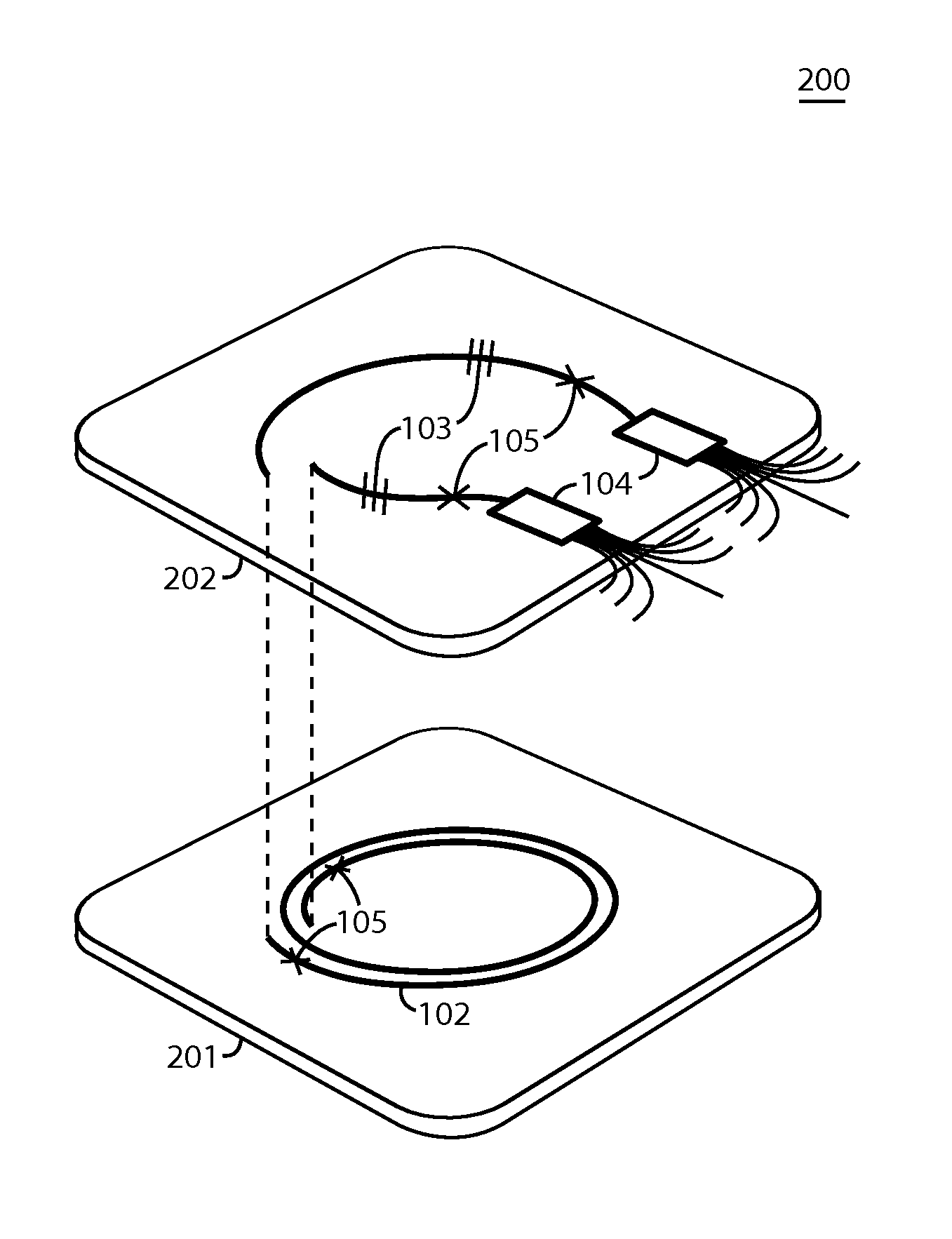

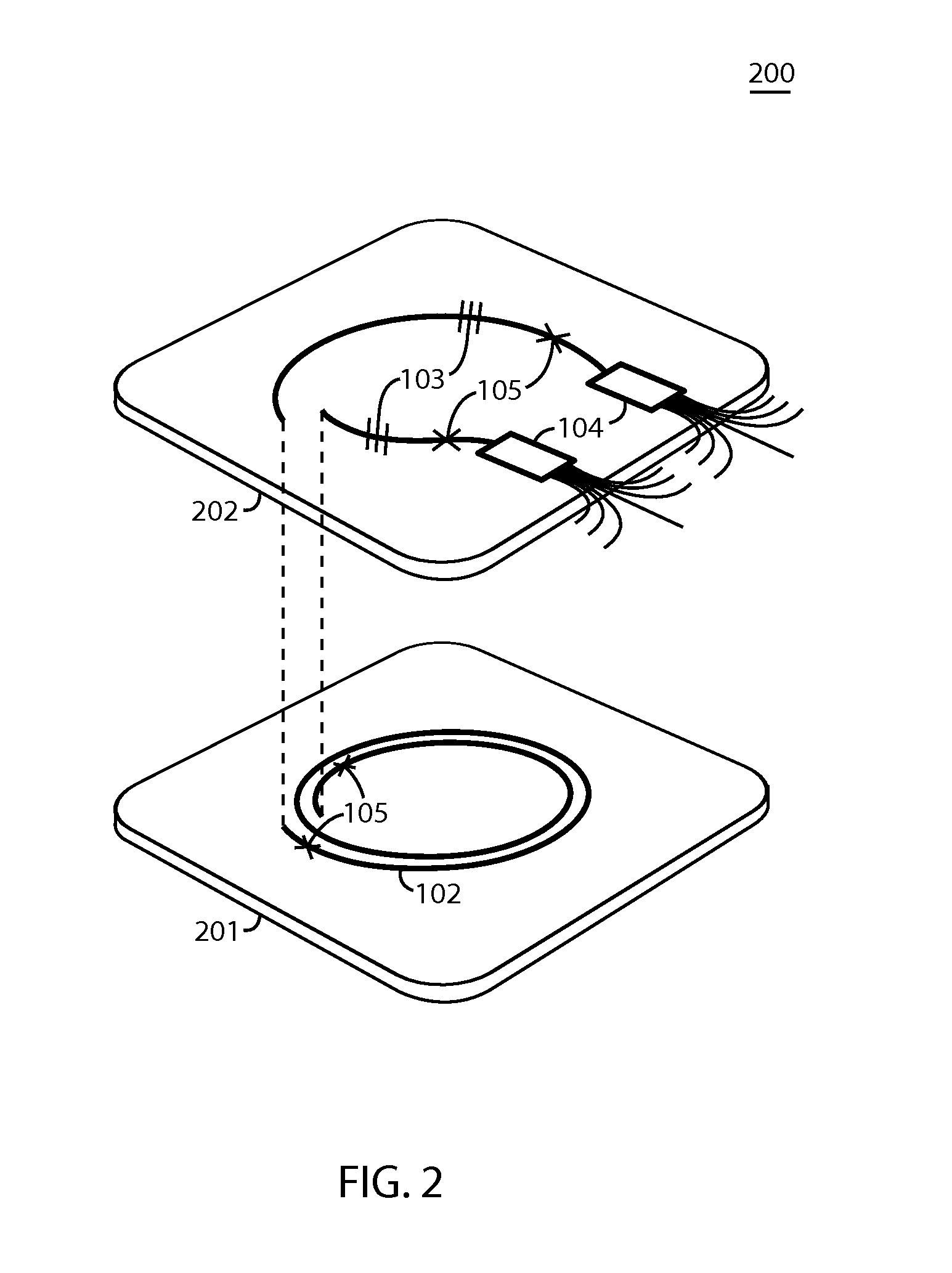

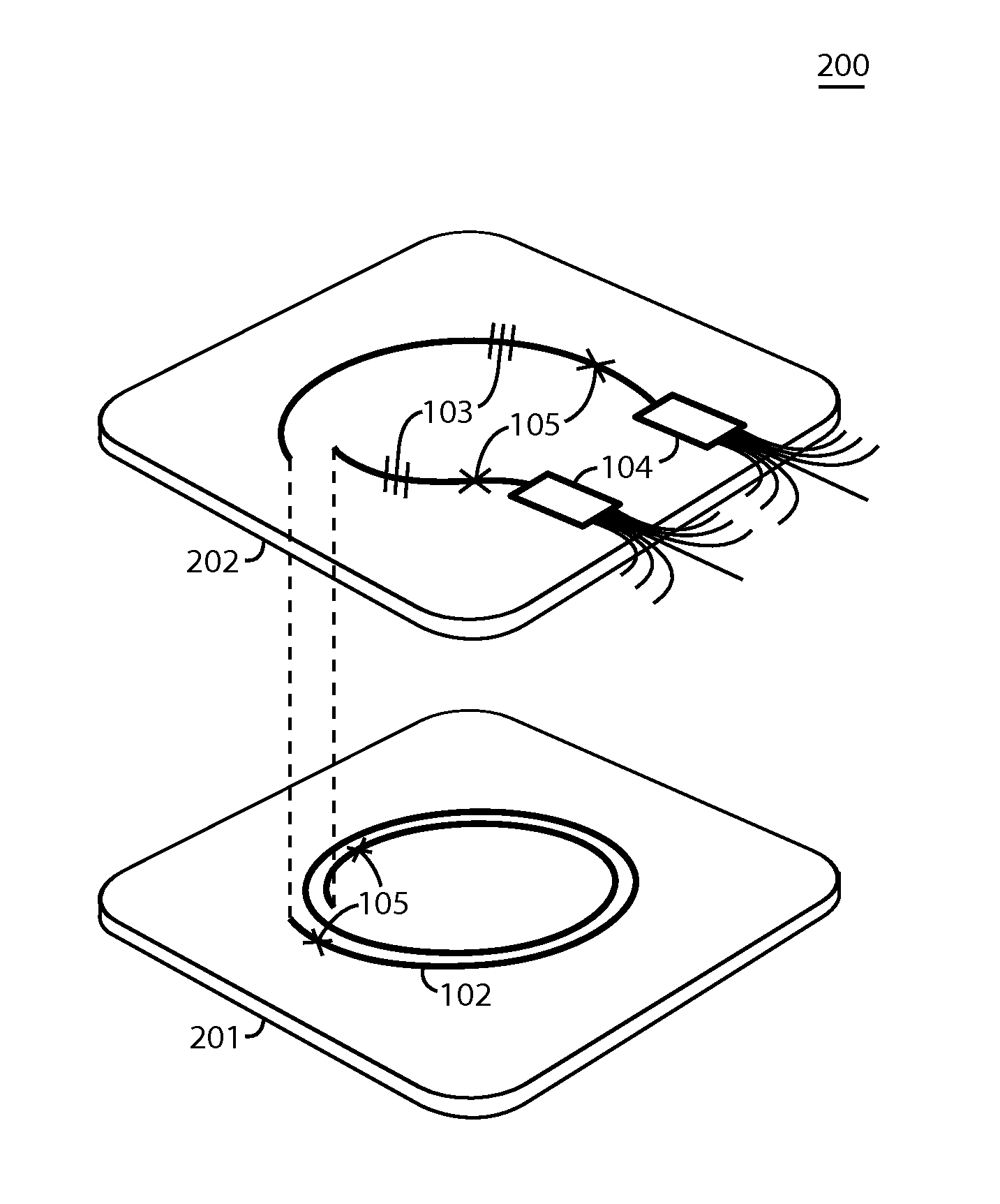

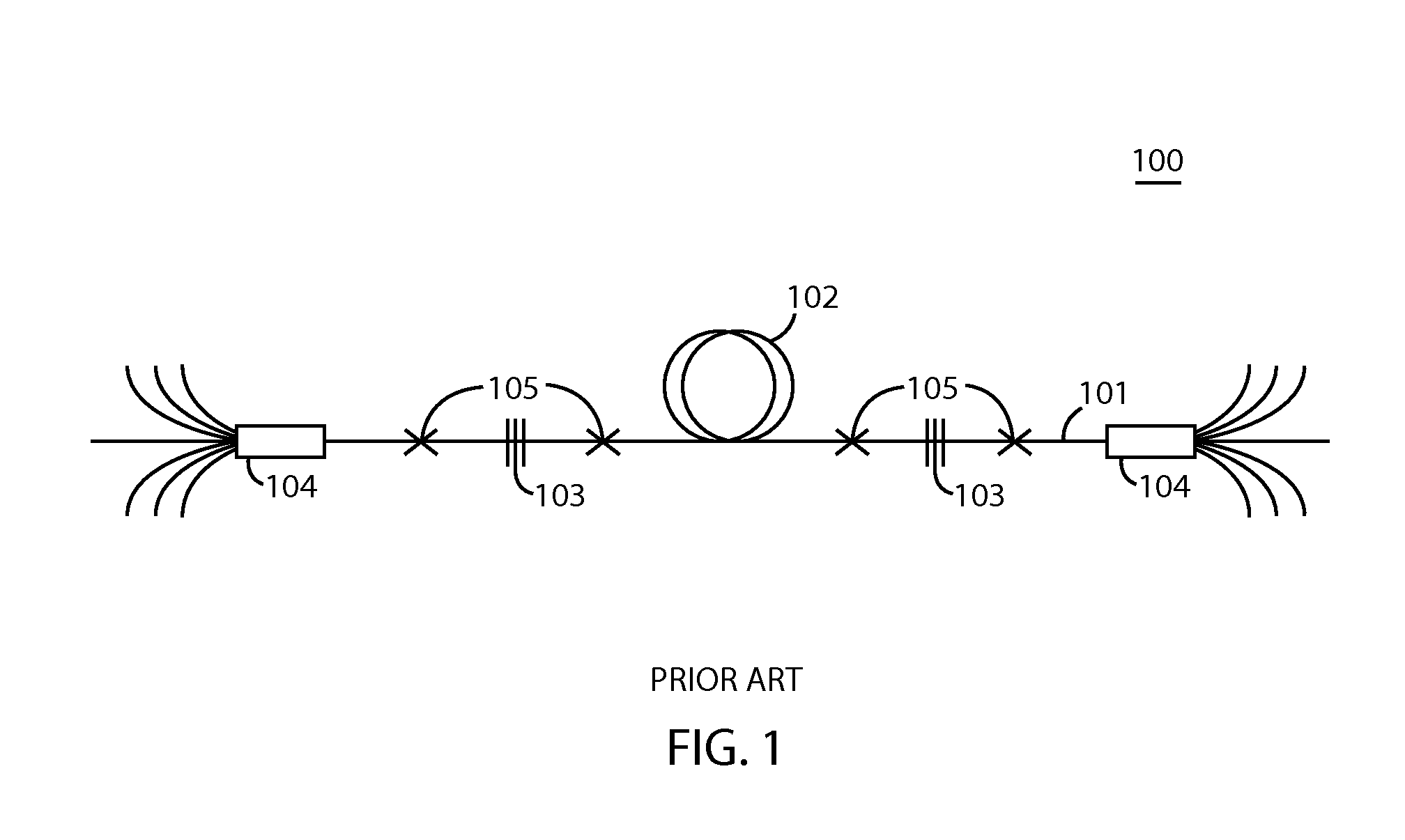

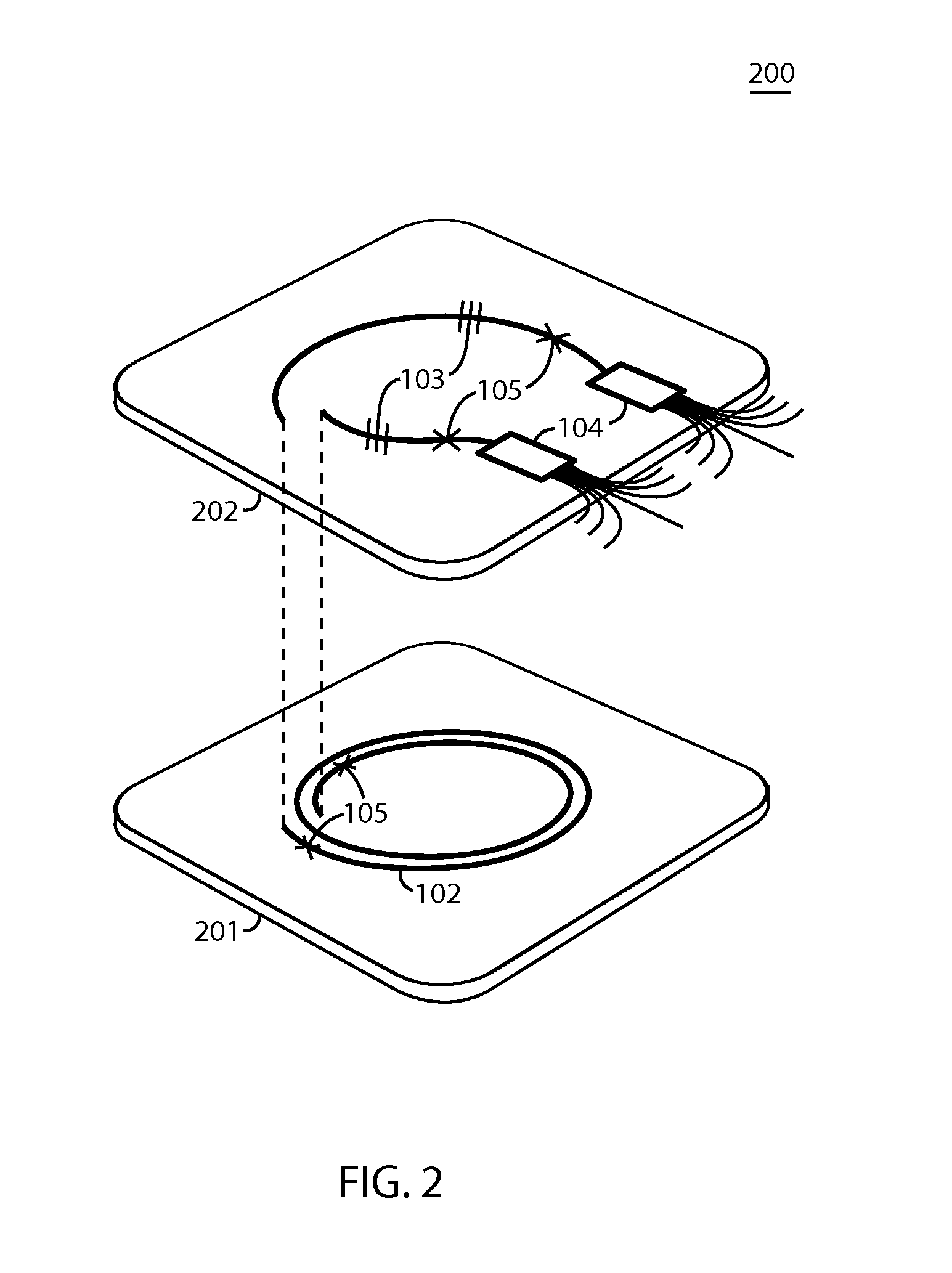

Fiber laser cavity optical engine package and method of making the same

ActiveUS20130230061A1Improved fiberImprove methodLaser using scattering effectsOptical articlesHeat conductingOptoelectronics

Embodiments of the invention include a fiber laser cavity package having improved fiber management and thermal management capability and methods of making such fiber laser cavity package. Each element of the fiber laser cavity is grouped into plurality of sections and each section is placed onto a heat conducting surface within the fiber laser cavity package to dissipate unwanted heat from the elements. When the fiber laser cavity is stored in the package, the fiber laser cavity is arranged such that fiber crossings are substantially reduced or eliminated within the package.

Owner:OFS FITEL LLC

Anti-flaming washable filter material and preparation technique thereof

The invention discloses a flame-retardant and washable filter material and a preparation technology thereof. The flame-retardant and washable filter material is the filter material which is prepared by the following steps: a basic material is acupunctured and compounded by a polypropylene staple fiber and a fiber mesh base cloth, then emerged into a flame-retardant solution which is prepared by melamine resin, an acyclic phosphate flame retardant and poly butylene terephthalate diester according to a certain proportion and then compacted by a twin-roll and dried and ironed out after the surface is sprayed with the flame-retardant solution; and the formed fiber crossing points are fixed by gel points with the filter material with the fiber surface being covered by a smooth glue layer. The filter material is flame-retardant and washable.

Owner:HENAN ANKELIN FILTER IND

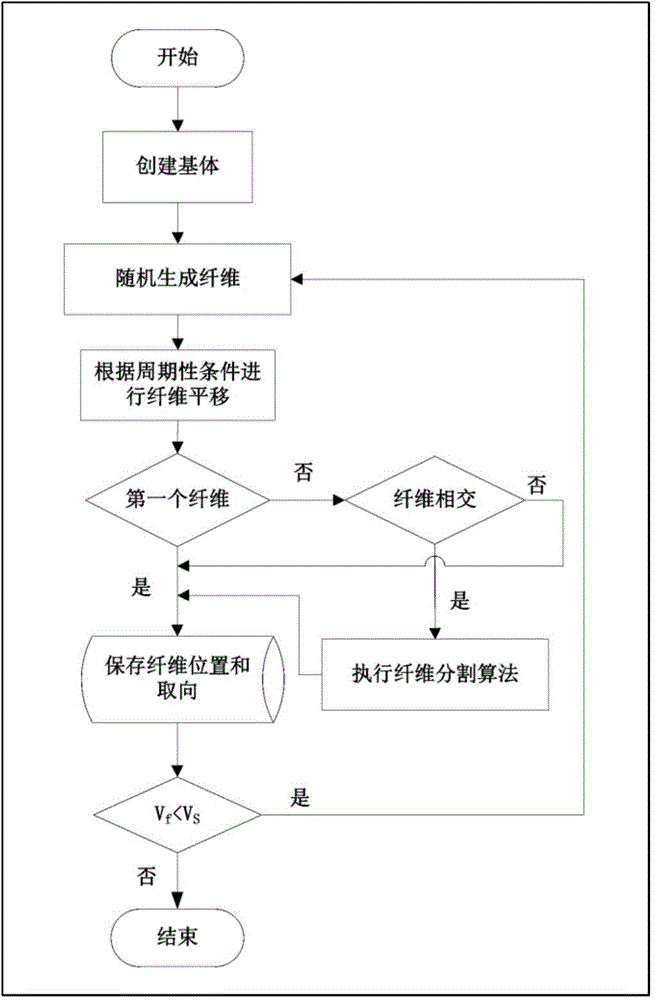

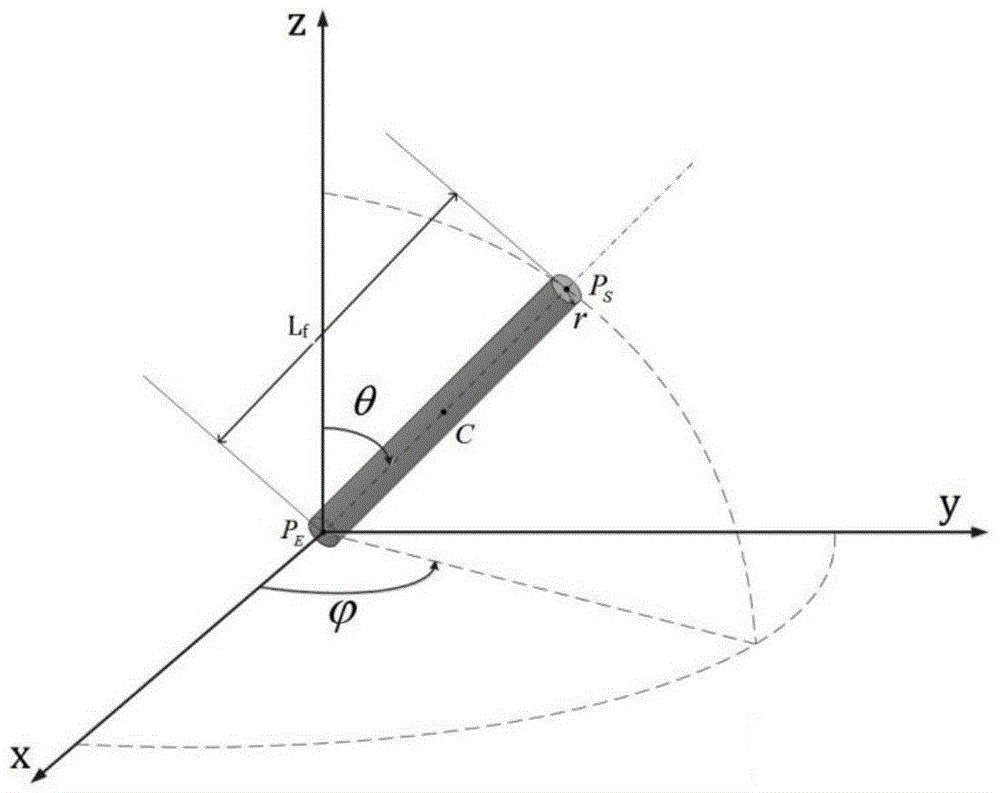

Method for creating three-dimensional microscopic cell model of composite material based on random-sequence growth method

ActiveCN104835194AEasy to createCreate efficiently3D modellingFiber-reinforced compositeComputer science

The invention relates to a method for creating a three-dimensional microscopic cell model of a composite material based on a random-sequence growth method. According to the method, a fiber is randomly added into a substrate area, and the length of the fiber increases from zero until the fiber is crossed with an existing fiber or the length of the fiber reaches a maximal preset length. Compared with a traditional random sequence adsorption method, the method of the invention is advantageous in that only several times of judging for fiber crossing are required in successively adding one fiber, and therefore the method of the invention can simply and efficiently create the three-dimensional microscopic cell model of the composite material, wherein randomly distributed short fibers with a relatively high fiber volume fraction exist in the three-dimensional microscopic cell model of the composite material. The method of the invention can be applied for creating the three-dimensional microscopic cell model which represents the microscopic structure of the composite material. The method settles the problems of low fiber volume friction and low execution efficiency in creating a microscopic periodical cell model according to an existing method and furthermore can save relatively more computing resource.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

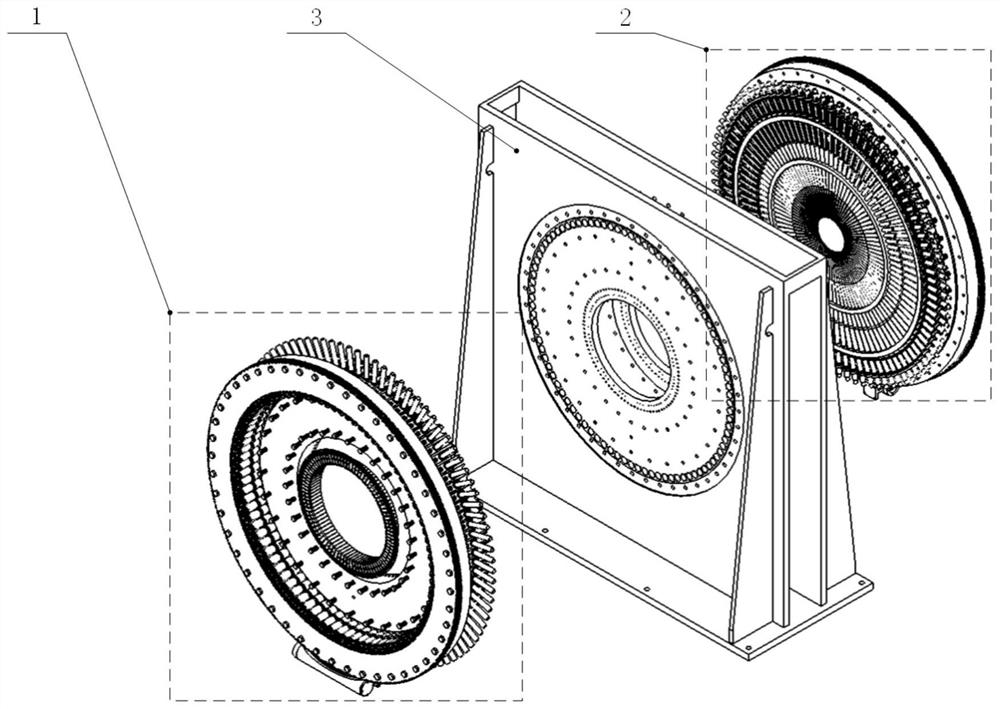

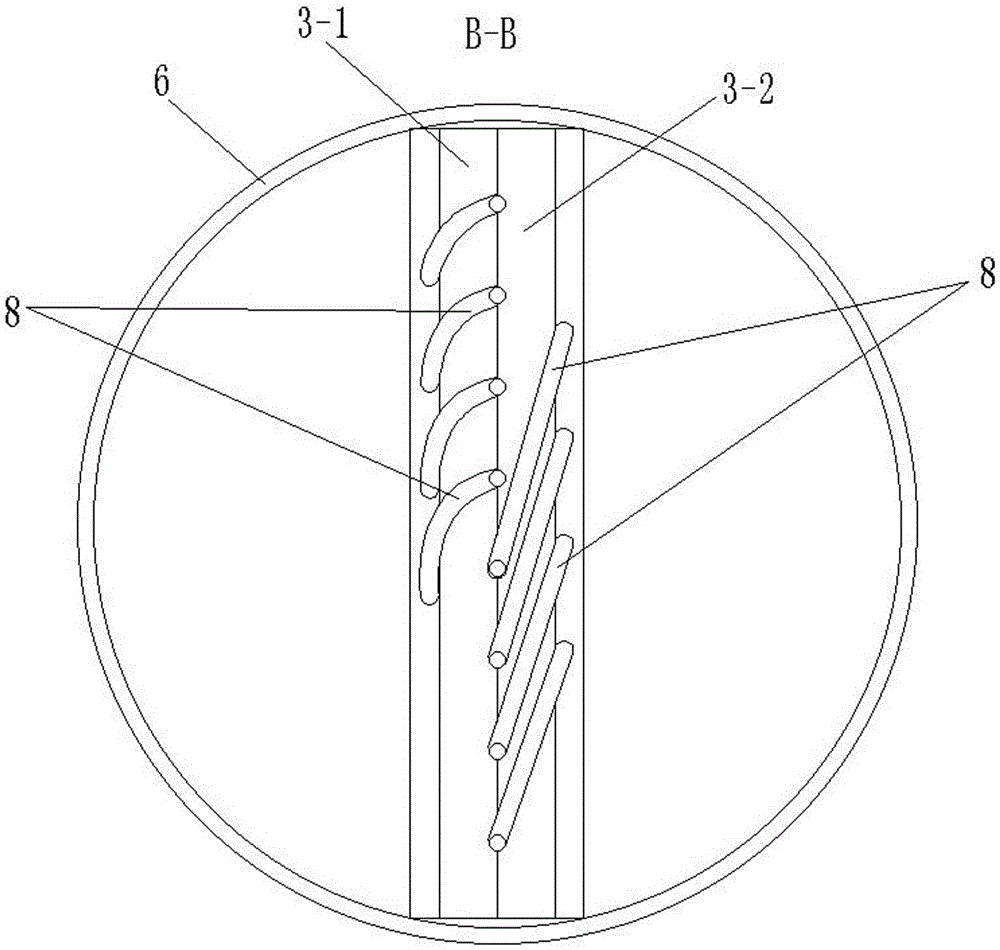

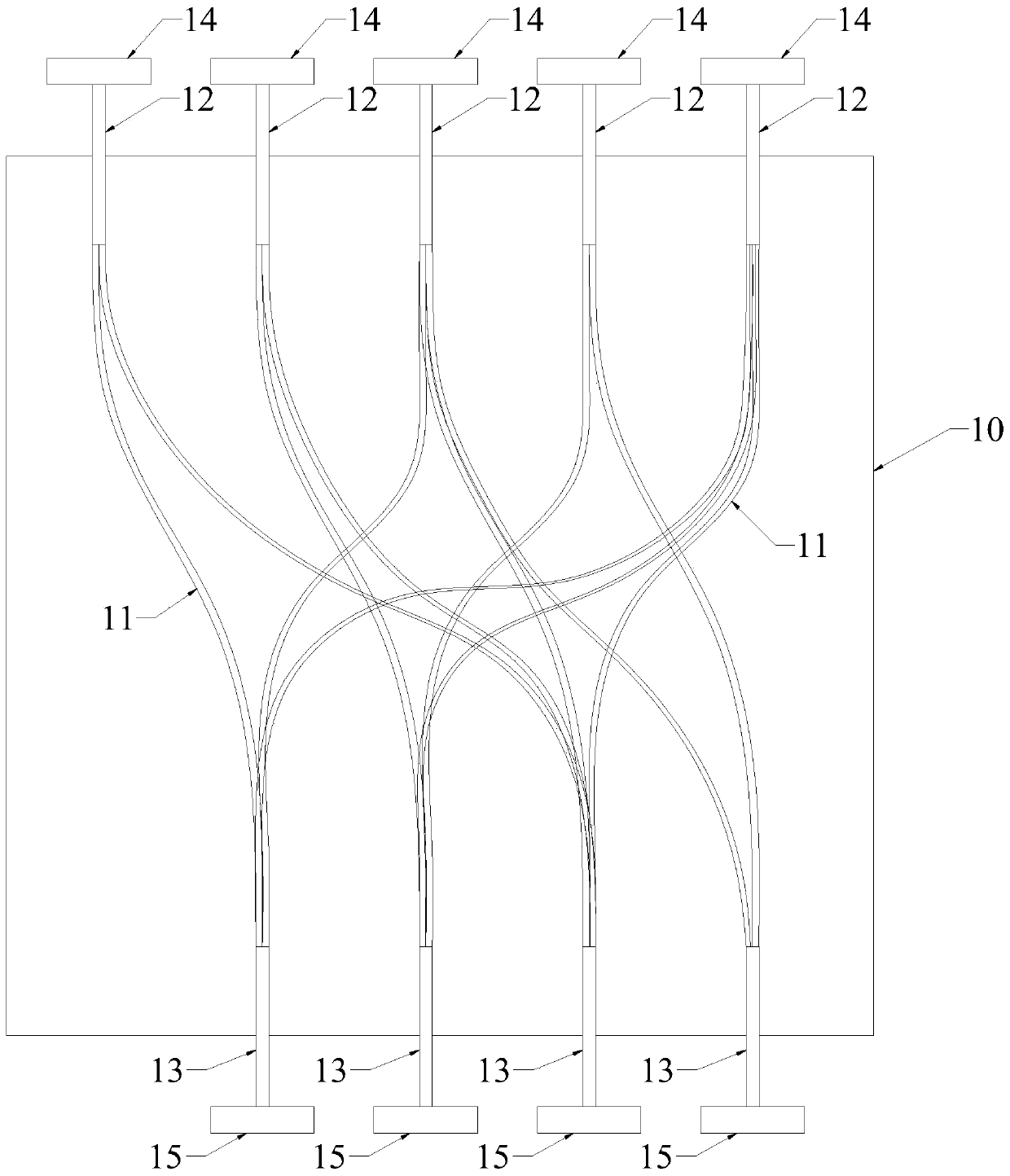

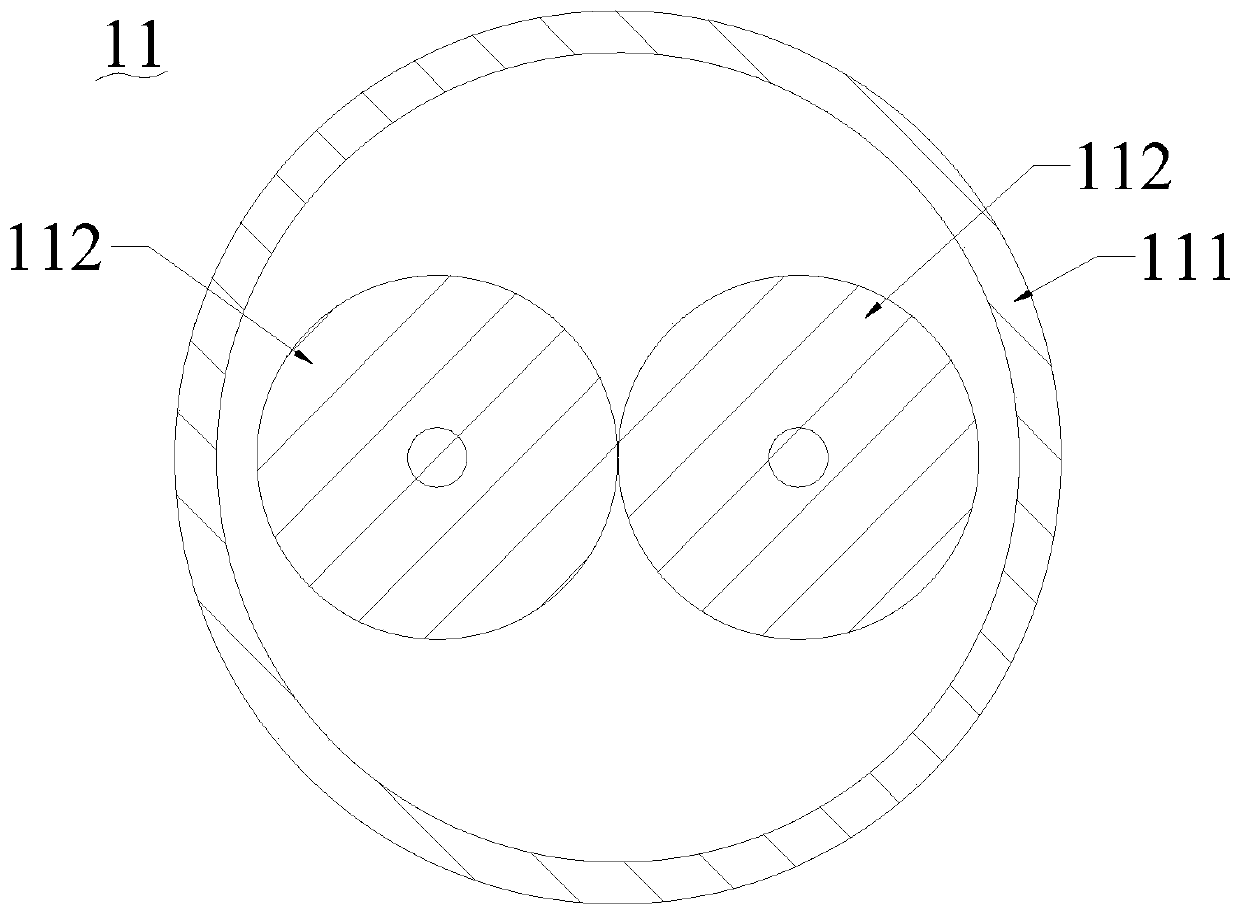

Novel multi-tow fiber synchronous spiral winding equipment

ActiveCN113211825ASimultaneously synchronized radial movementConsistent radial movementRadial motionGear wheel

The invention belongs to the technical field of fiber winding equipment, and particularly relates to novel multi-tow fiber synchronous spiral winding equipment. A rotating system is mounted on a right rack through a bolt, a radial moving system is mounted on a left rack through a bolt, and the rotating system is connected with a shifting fork of a radial moving system through a notch of a hoop. According to the novel multi-tow fiber synchronous spiral winding equipment, a first inner gear ring and a first outer gear ring drive first gears evenly distributed in the circumferential direction in an engaged manner, and therefore it is guaranteed that rotating angles transmitted to wire guide pipes are synchronous at the same time; Second gears are engaged through a second inner gear ring and a second outer gear ring, and therefore it is guaranteed that the wire guide pipes synchronously move in the radial direction; and through joint control of a rotary driving system and a radial moving system, it is guaranteed that the guide wire pipes evenly distributed in the circumferential direction move consistently. The existing single-bundle or few-bundle fiber winding process is broken through, single-layer synchronous winding is realized, and the winding efficiency is improved; and the phenomenon of fiber crossing caused by single-bundle winding is avoided, so that the phenomenon of stress concentration is greatly reduced.

Owner:TAIYUAN UNIV OF TECH

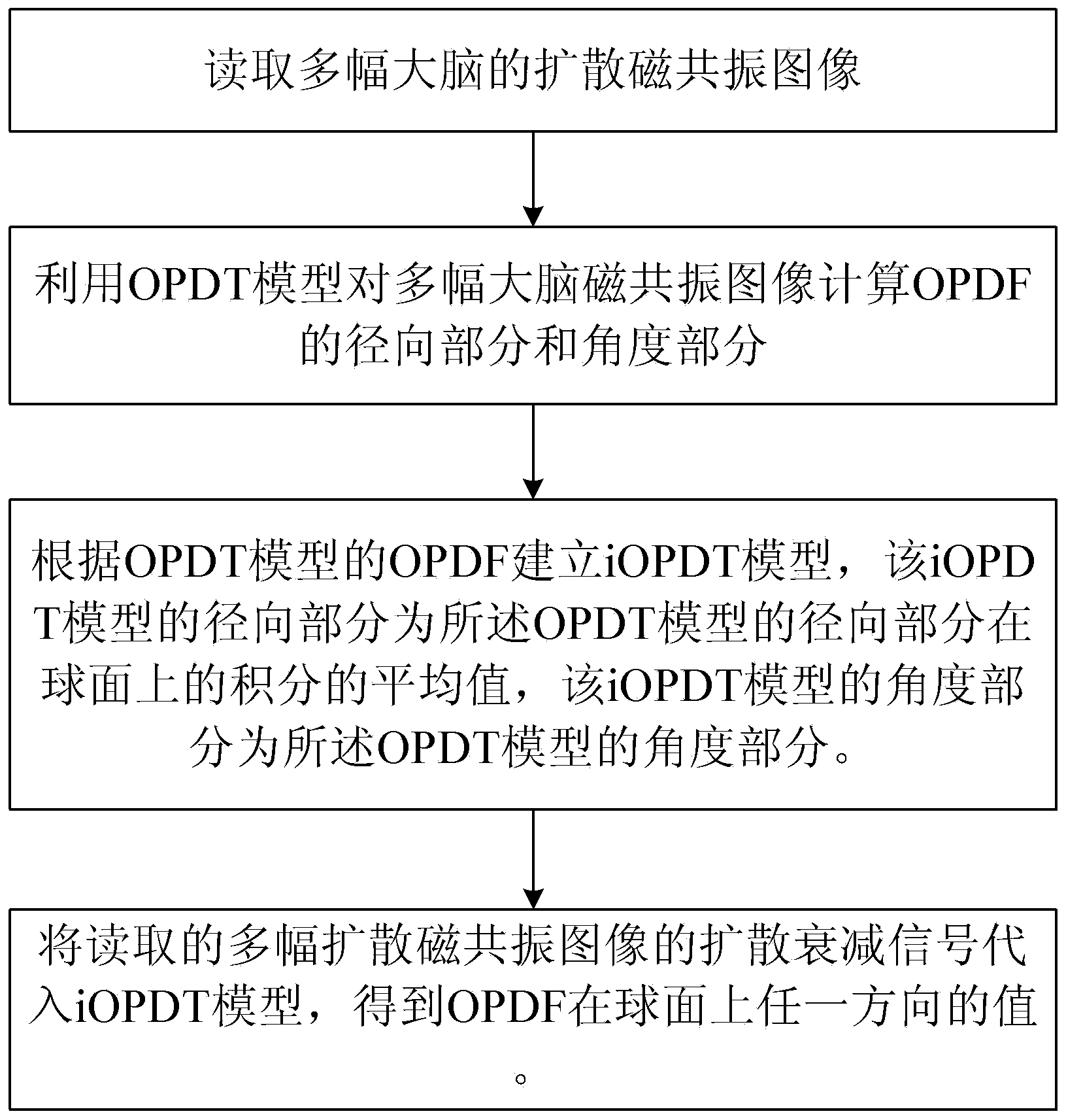

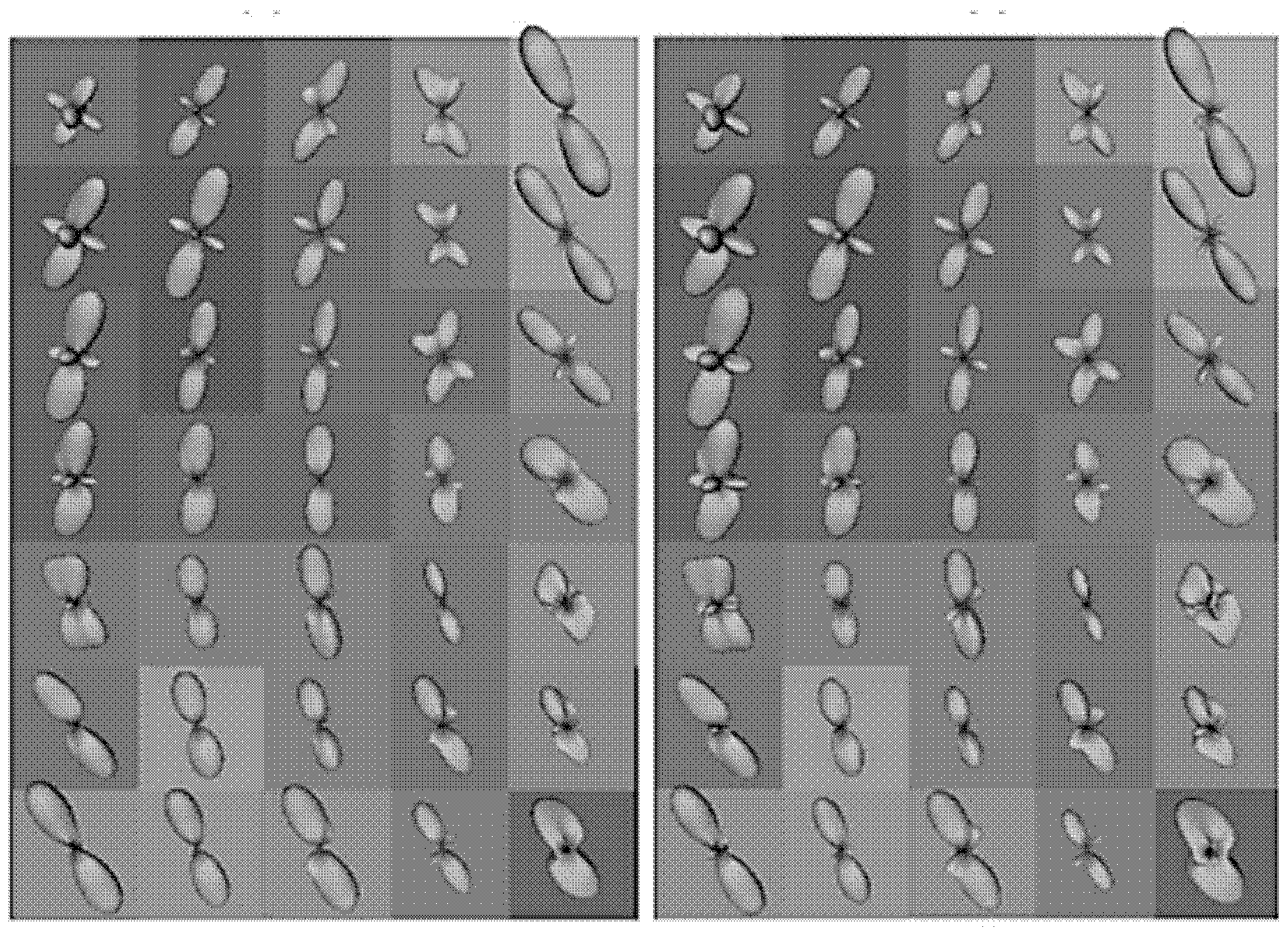

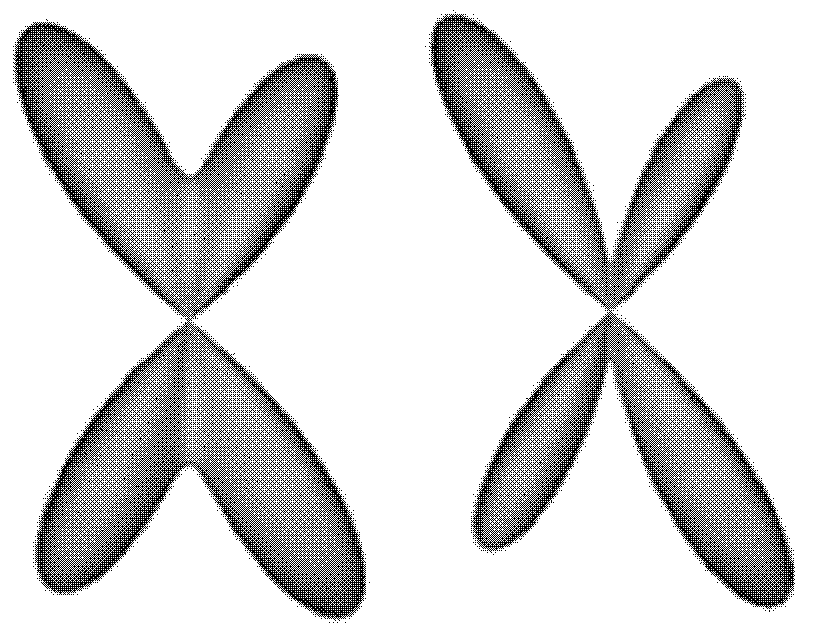

Method for estimating white matter fiber direction through diffusion magnetic resonance images

InactiveCN103413315AImprove angular resolutionImage analysisDiagnostic recording/measuringFiberDiffusion

The invention discloses a method for estimating the white matter fiber direction through diffusion magnetic resonance images. The method comprises the following steps of S1, reading a plurality of brain diffusion magnetic resonance images, S2, carrying out calculation of the radial direction part and the angle part of OPDF on the brain magnetic resonance images through an OPDT model, S3, building an iOPDT model according to the OPDF of the OPDT model, wherein the radial direction part of the iOPDT model is an average value of the integral of the radial direction part of the OPDT model on a sphere, and the angle part of the iOPDT model is the angle part of the OPDT model, and S4, substituting diffusion fading signals of the read diffusion magnetic resonance images to the iOPDT model to obtain values of the OPDF in any direction of the sphere. According to the method, through the improved OPDT model, the angular resolution of white matter fiber direction estimation is improved, and therefore the ability of distinguishing white matter fiber crossing is improved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

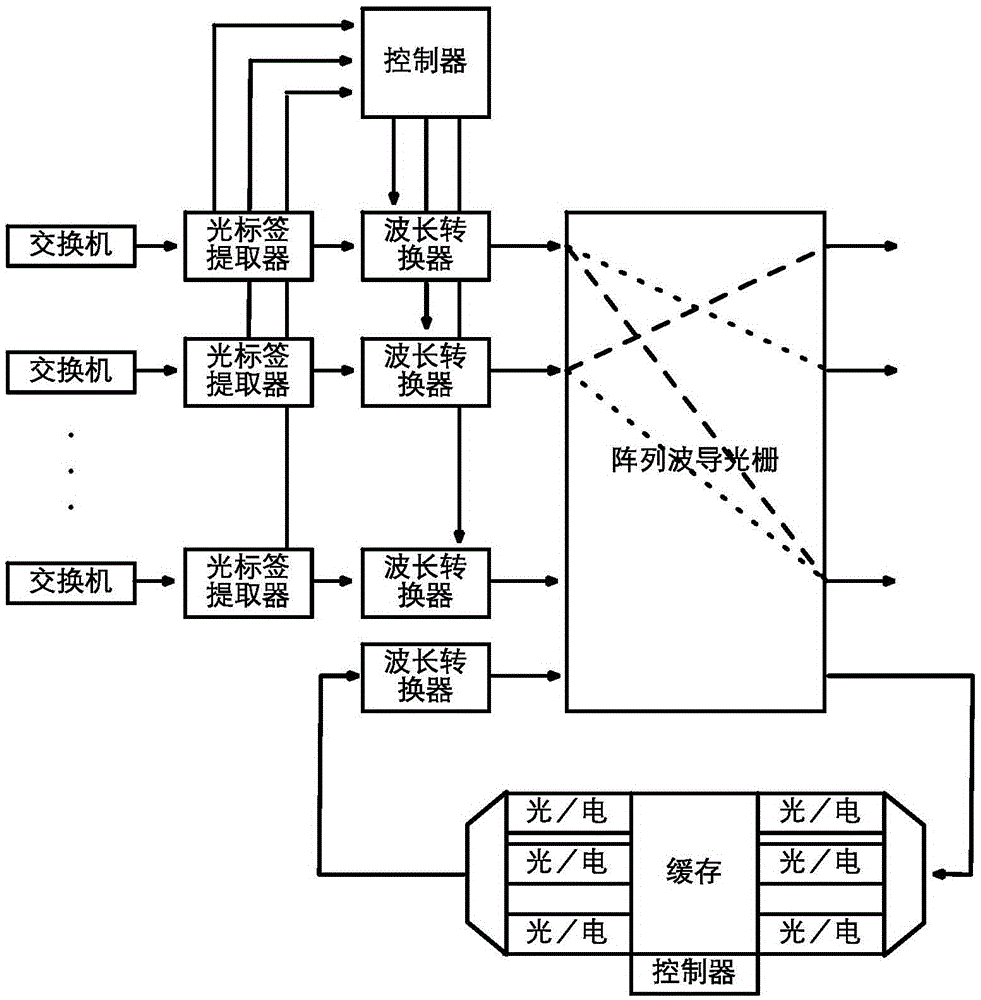

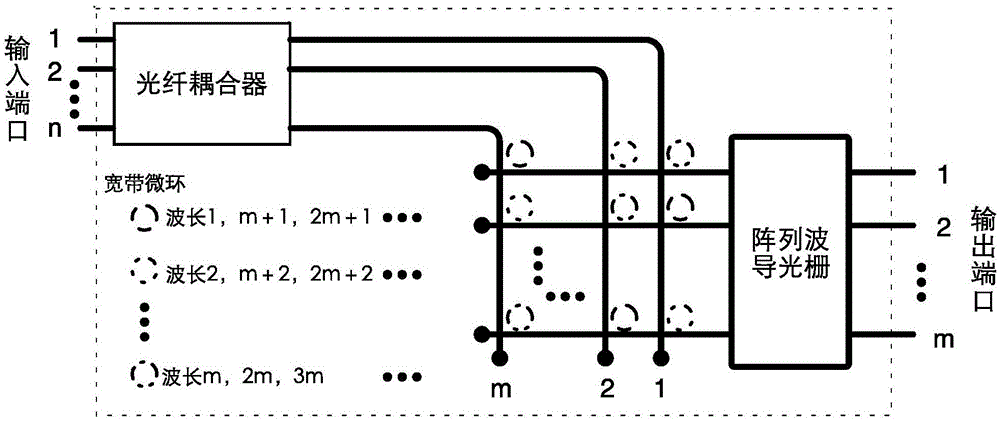

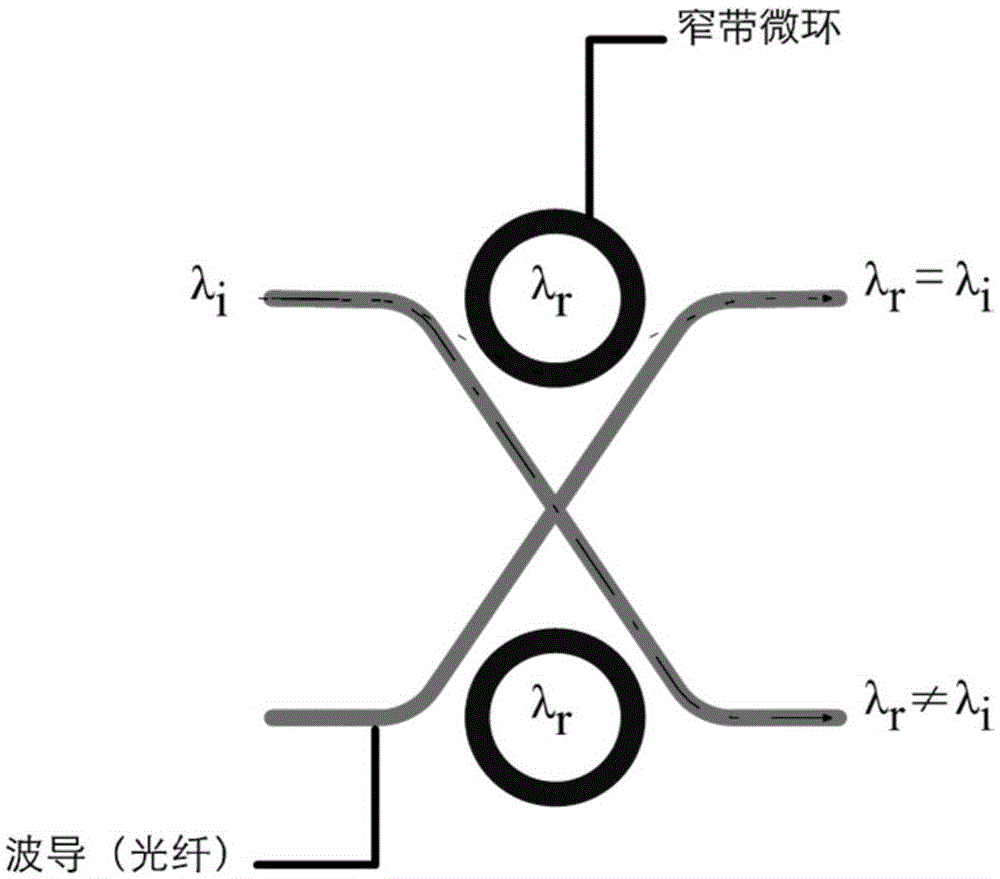

Router structure based on microring resonators and arrayed waveguide grating

ActiveCN105652370AImprove performanceAvoid complex processOptical waveguide light guideGratingTime delays

The invention relates to a router structure based on microring resonators and an arrayed waveguide grating. The router structure comprises an optical fiber coupler and an arrayed waveguide grating, wherein the input port of the optical fiber coupler is connected with n input optical fibers, and the output port of the optical fiber coupler is connected with m output optical fibers; the input port of the arrayed waveguide grating is connected with m input optical fibers; the m input optical fibers and the m output optical fibers of the optical fiber coupler are arranged in a crossed manner without contacting, microring resonators having different coupling frequencies are arranged at the crossed positions of the optical fibers, and the microring resonators are in contact with two optical fibers at the crossed position; the output port of the arrayed waveguide grating is connected with m output optical fibers; and m and n are positive integers. According to the router structure based on the microring resonators and the arrayed waveguide grating, the exchange time is reduced, the bottleneck of time delay which is the most important to optical packet switching is broken through, the performances of the whole system are improved, and communication between any one input port and any one output port is realized.

Owner:XIDIAN UNIV

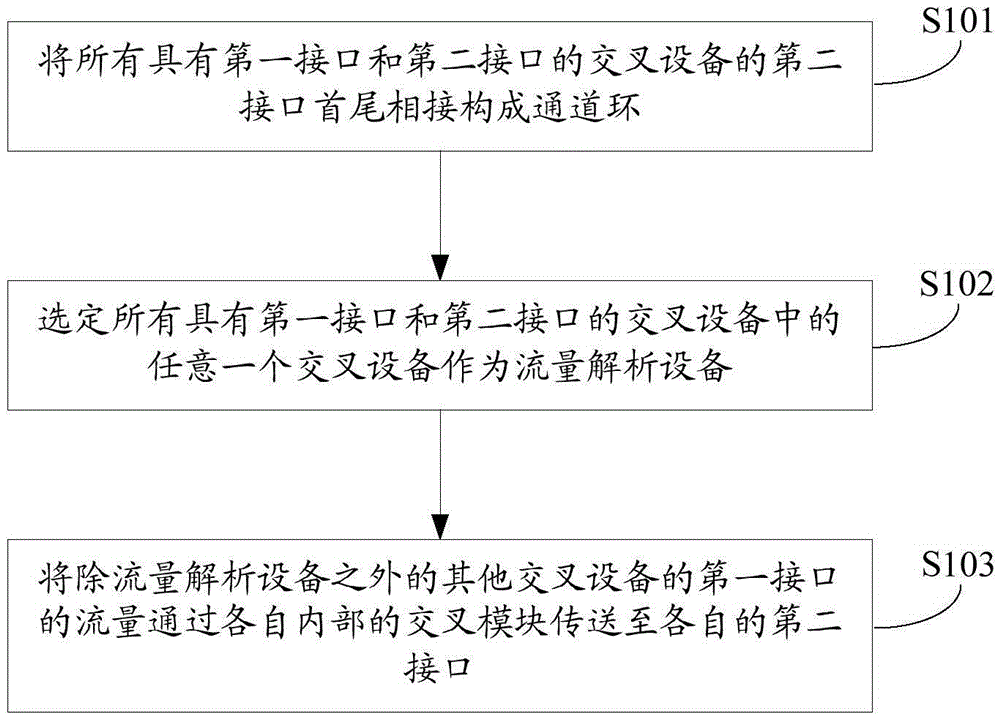

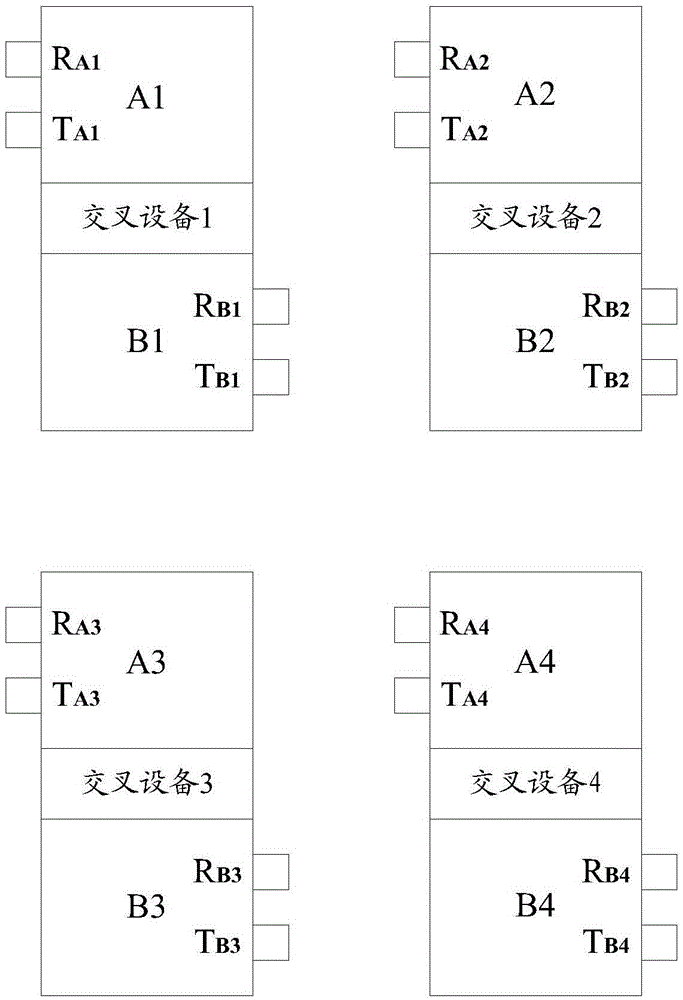

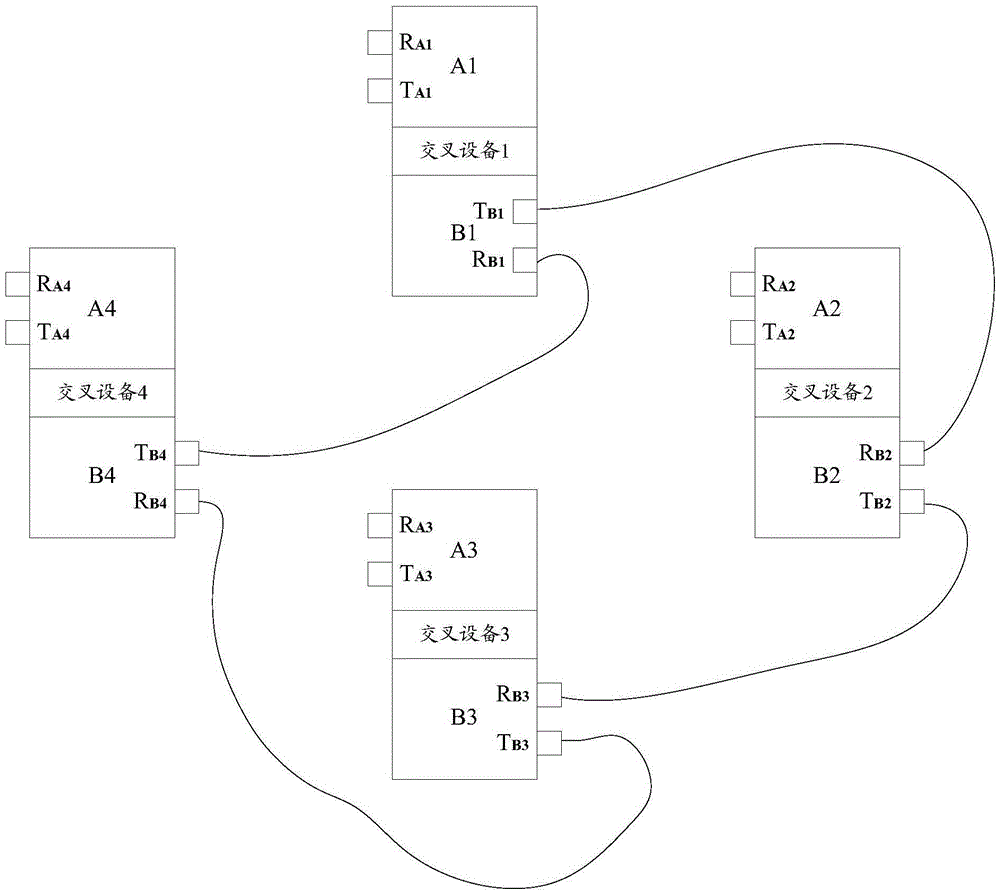

SDH multi-group multi-member fiber-crossing virtual concatenation implementation method, device and system

ActiveCN106027194ARealize gatheringImplement parsingTime-division multiplexData switching networksFiberComputer science

The invention provides an SDH multi-group multi-member fiber-crossing virtual concatenation implementation method, device and system, so as to reduce the implementation cost of SDH multi-group multi-member fiber-crossing virtual concatenation. The method comprises the steps: enabling the second interfaces of all cross connectors with first and second interfaces to be connected in an end-to-end manner to form a channel ring; selecting any one cross connector from the cross connectors with first and second interfaces as flow analysis equipment; transmitting the flow of first interfaces of other cross connectors except the flow analysis equipment to the corresponding second interfaces through internal cross modules. According to the technical scheme of the invention, the method can achieve the series connection of any cross connector, and achieves the aggregation and analysis of a lot of fiber-crossing virtual concatenation members. Moreover, the method can quickly recover the stability of a line. In addition, the method enables the fault probability of rear-end equipment of the whole system cluster to be changed into P*1 from P*N, can achieve the SDH multi-group multi-member fiber-crossing virtual concatenation under the condition that there is no MSTP equipment, and reduces the implementation cost.

Owner:深圳市恒扬数据股份有限公司

Three-dimensional bionic bone repair material and preparation method thereof

ActiveCN109966549APromote repairImprove connectivityTissue regenerationProsthesisMechanical propertyMaterials science

The invention provides a three-dimensional bionic bone repair material and a preparation method thereof. The three-dimensional bionic bone repair material forms a porous structure comprising a plurality of parallel oriented fiber layers by a bidirectional freezing method, the oriented fiber layers are composed of reticular planes formed by the mutual penetrating of bioactive glass fibers, and crossing points of the bioactive glass fibers are bonded and interconnected by dopamine. By simulating the ordered structure of bone tissues, the repair material facilitates the repair of the bone tissues. Meanwhile, the fiber crossing points realize effective bonding interconnection through dopamine crosslinking, and the preparation process is simple. According to the invention, the polylactic acid composite three-dimensional bionic bone repair material can also be prepared by coating the bioactive glass fibers with polylactic acid, so that the toughness of the bioactive glass fibers is increased, and the mechanical property of the three-dimensional bionic bone repair material is further improved.

Owner:BEIJING NATON TECH GRP CO LTD

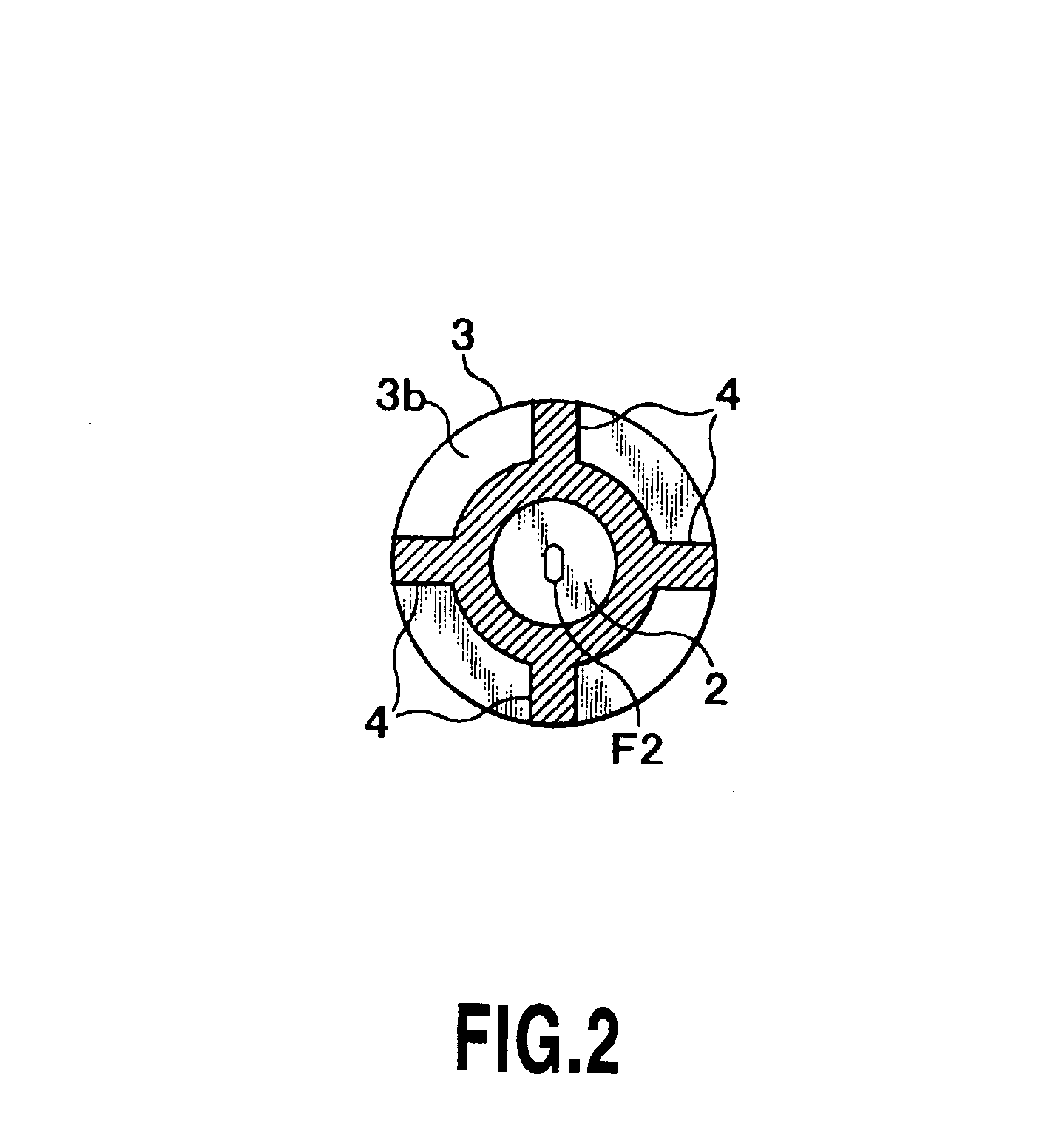

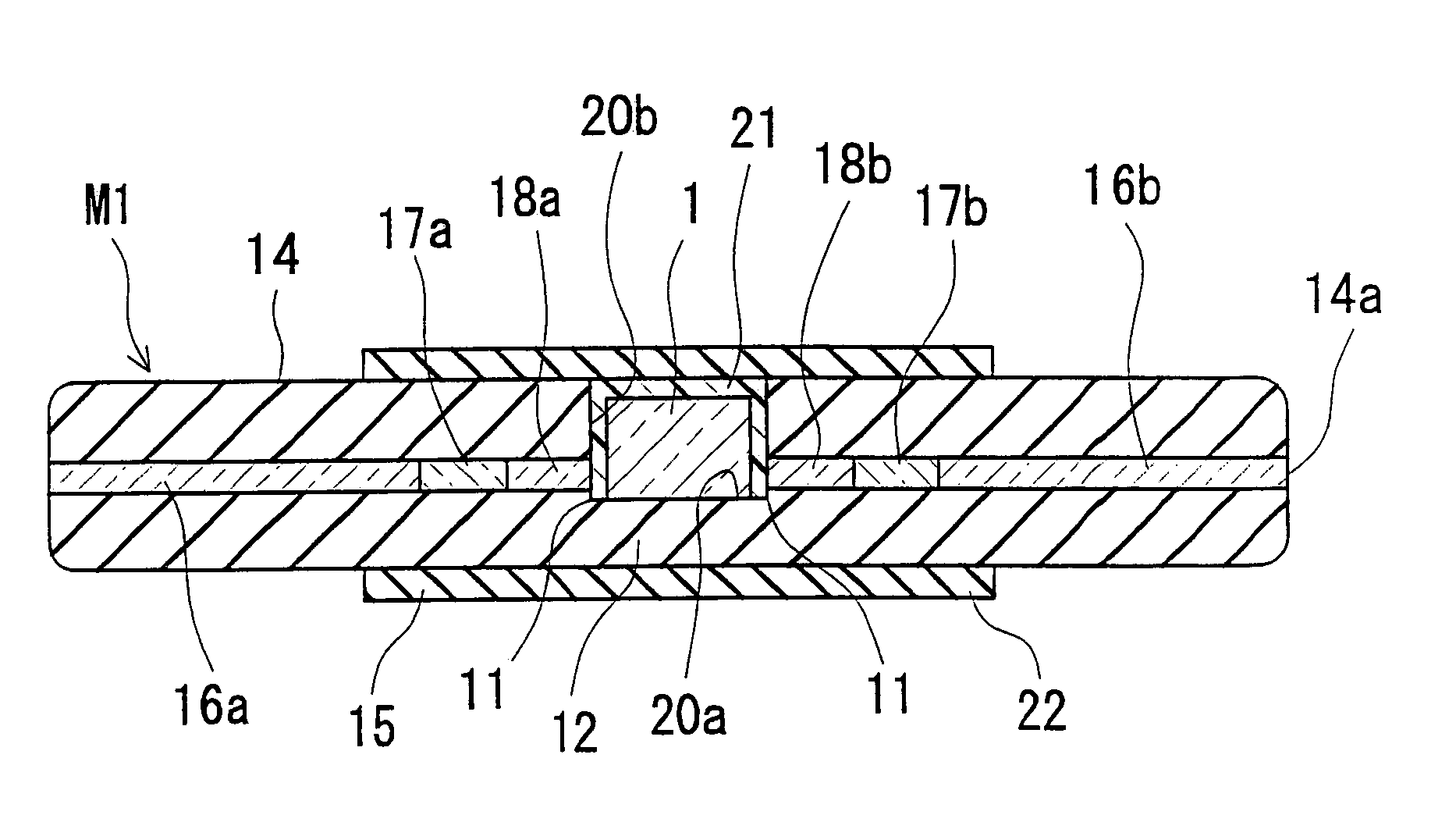

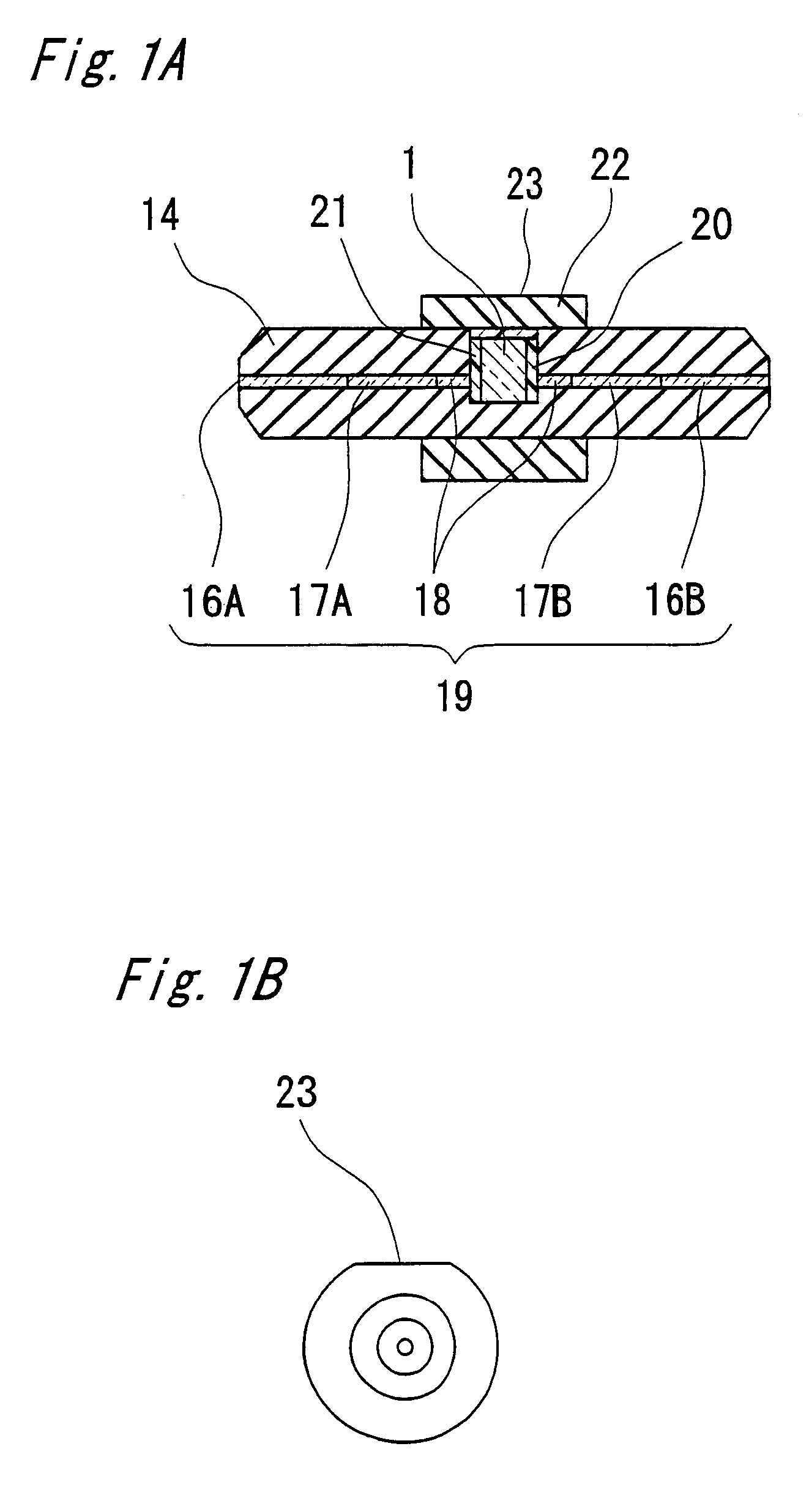

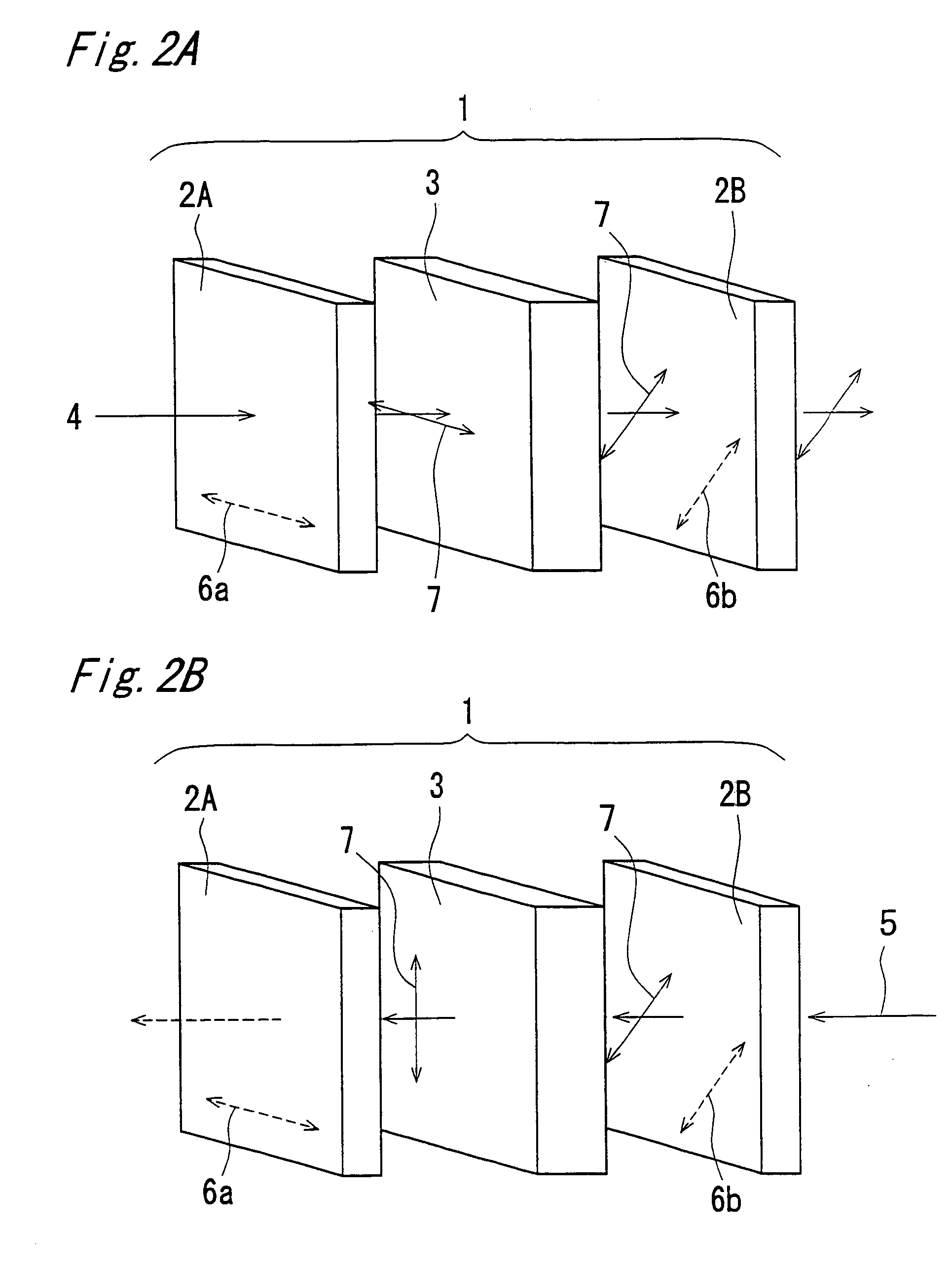

Optical device

An optical device having: an optical fiber body; a ferrule which surrounds the above described optical fiber body and to which a recess that crosses a coreless fiber within the above described optical fiber has been provided; and an optical element which is provided within the recess in said ferrule, is provided with a protective member for protecting the above described recess, and the protective member has a restriction means for physically restricting the rotation of the optical device around the optical axis.

Owner:KYOCERA CORP

A three-dimensional fiber-based airgel tissue engineering scaffold and its preparation method

The invention relates to a preparation method of a three-dimensional fiber-based aerogel tissue engineering scaffold and a product thereof. The preparation method comprises the following steps of: firstly dispersing fibers in solvents to form turbid liquid; secondly curing the turbid liquid to form cured pieces; thirdly removing cured solvents to form non-crosslinked fiber-based aerogel; finally carrying out crosslinking stabilization treatment and then carrying out sterilization treatment, thus obtaining the three-dimensional fiber-based aerogel tissue engineering scaffold. The product is a three-dimensional network-shaped material formed through mutual penetration and stagger of fibers. The fiber crossing points are effectively interconnected through non-hydrogen-bond bonding. The three-dimensional fiber-based aerogel tissue engineering scaffold has volume density of 0.1-500mg / cm<3>, average pore size of 0.01-2000mu m and specific surface area of 0.2-2000m<2> / g. The preparation method and the product have the advantages that the preparation process is simple; the raw material limitations are less; the aerogel tissue engineering scaffold product has good flexibility, connectivity and tissue growing environment and has broad application prospects in the tissue engineering field.

Owner:DONGHUA UNIV

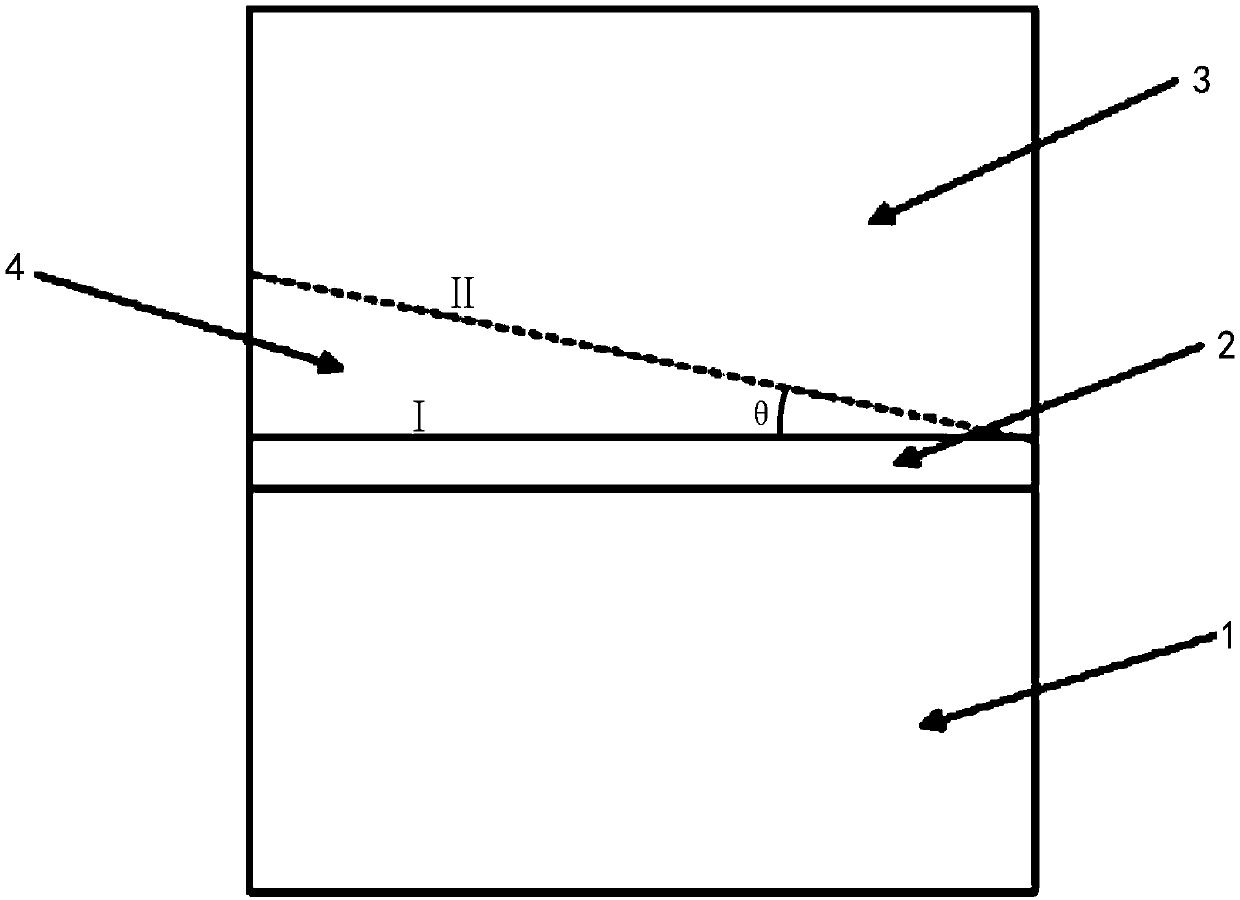

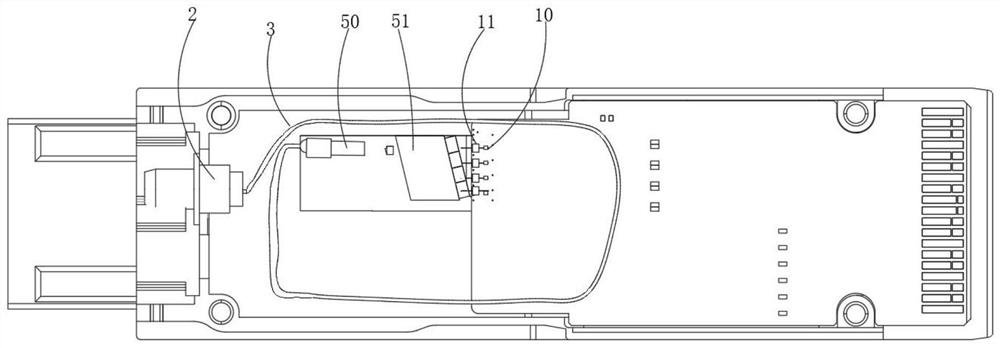

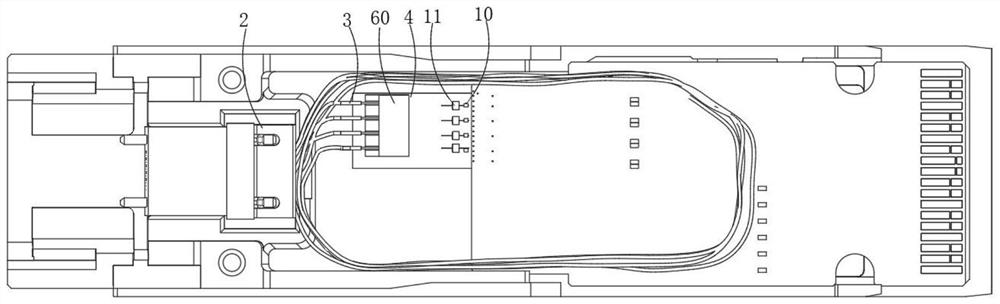

Optical module and manufacturing method thereof

InactiveCN111722331ASolve the problem of small bending radiusReduce light lossCoupling light guidesOptical ModuleEngineering

The invention relates to an optical module, which comprises a light emitting assembly, an optical port, an optical fiber and an optical fiber connecting part for guiding and sending laser. The laser emitted by the light emitting assembly sequentially passes through the optical fiber connecting part and the optical fiber and is emitted to the optical port, and the optical fiber is communicated withthe optical fiber connecting part; and a light path in the optical fiber connecting part is arranged in a downward inclined manner along the laser transmission direction. The invention discloses a manufacturing method of an optical module. The manufacturing method comprises three steps of S1-S3. According to the invention, the optical fiber connecting part is made into an inclined structure; theinclination angle of the light path in the optical fiber connecting part is controlled, so that a problem of small optical fiber bending radius is solved; further, the stress is reduced in a subsequent light path without a fiber coiling form; problems of optical fiber breakage, unattractive intersection of a plurality of internal optical fibers, possible damage to the optical fibers during assembly and the like due to fiber coiling in the module are solved, the conditions of optical loss and light instability caused by large-amplitude bending of the optical fibers are greatly reduced, the total working hours are reduced, the yield is improved, and the problem of no light after long-term use is solved.

Owner:武汉英飞光创科技有限公司

Preparation method of three-dimensional fiber-based aerogel material and product thereof

The invention relates to a preparation method of a three-dimensional fiber-based aerogel material and a product thereof. The preparation method comprises the following steps of: firstly dispersing fibers in solvents which do not have fiber solubility to form turbid liquid; secondly curing the turbid liquid to form cured pieces; thirdly removing cured solvents in the cured pieces to form non-crosslinked fiber-based aerogel; and finally carrying out crosslinking stabilization treatment on the non-crosslinked fiber-based aerogel to obtain the fiber crossing point bonded and fixed three-dimensional fiber-based aerogel material. The product is a three-dimensional network-shaped material formed through mutual penetration and stagger of fibers. The fiber crossing points are effectively interconnected through non-hydrogen-bond bonding. The three-dimensional fiber-based aerogel material has volume density of 0.1-500mg / cm<3>, average pore size of 0.01-2000mu m and specific surface area of 0.2-2000m<2> / g. The preparation method and the product have the advantages that the preparation process is simple; the raw material limitations are less; and the aerogel product has good flexibility and connectivity and has broad application prospects in numerous fields.

Owner:DONGHUA UNIV

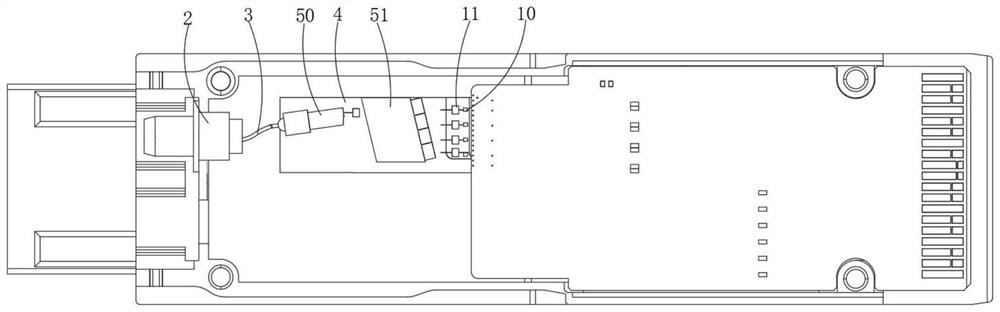

Optical signal transmission device

InactiveCN105572805AReduce the difficulty of cloth fiberPrevent looseningCoupling light guidesFiberEngineering

The invention relates to an optical signal transmission device. The device comprises a base body whose plate thickness extends along the vertical direction, the base body is provided with at least two wire-inlet optical fiber ribbons, corresponding optical fibers in the wire-inlet optical fiber ribbons are crossed and recombined to form at least two wire-outlet optical fiber ribbons, and the optical fibers in each wire-outlet optical fiber ribbon are ranked to form a linear structure outside the base body. During usage, the ranking of the optical fibers in the wire-outlet optical fiber ribbons in the linear manner is accomplished outside the base body so that the linear ranking of the optical fibers in the wire-outlet optical fiber ribbons on the base body is not needed or reduced, and the fiber-laying difficulty on the base body can be reduced.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

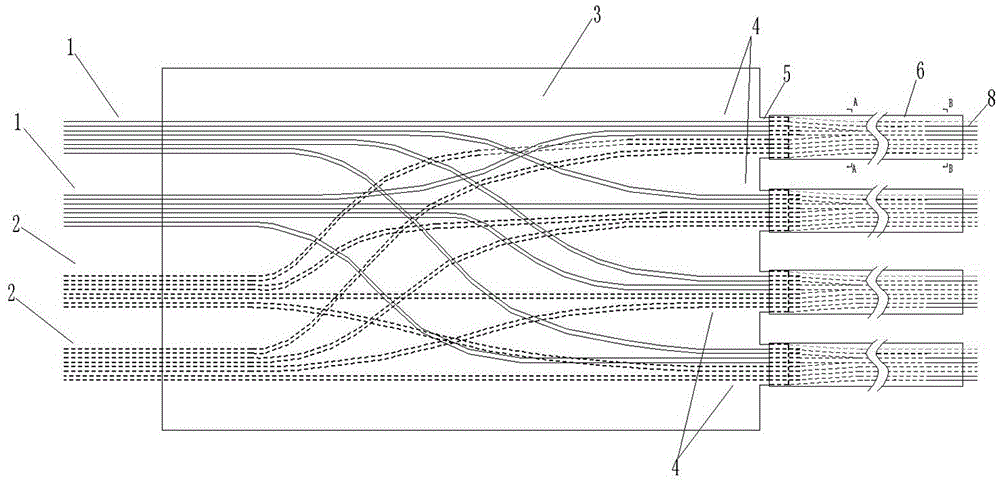

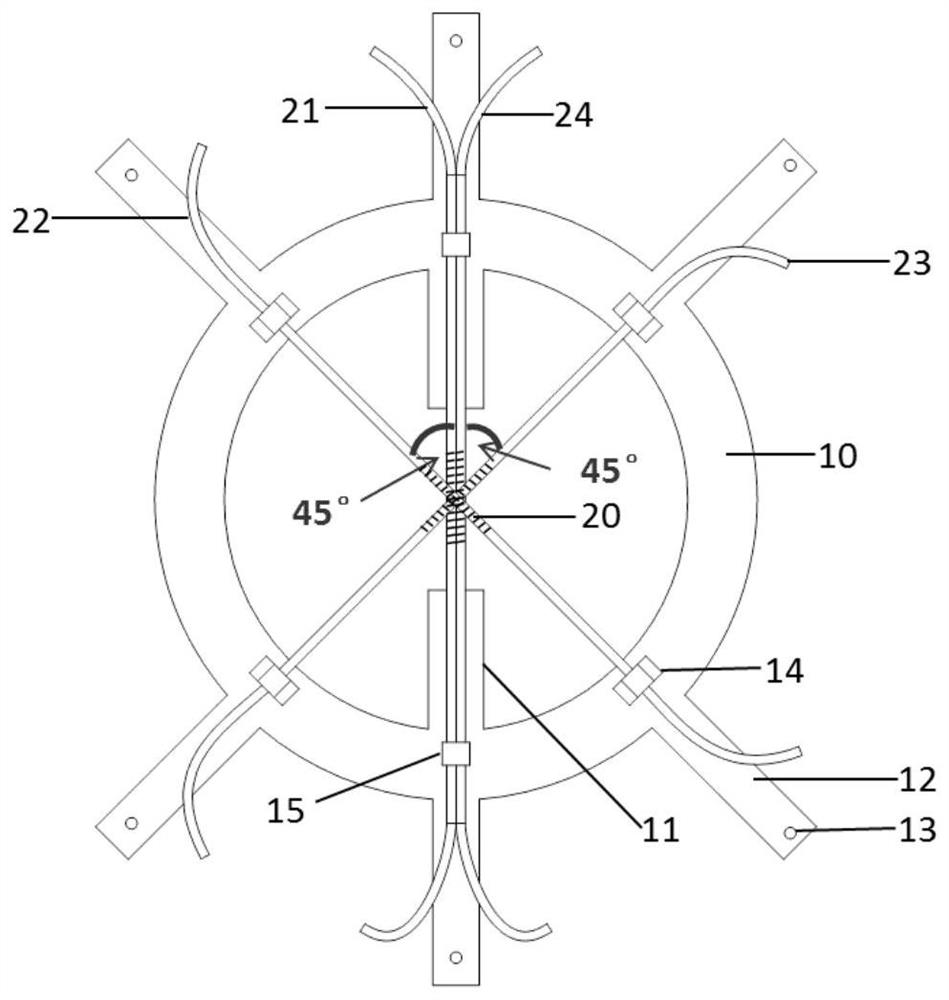

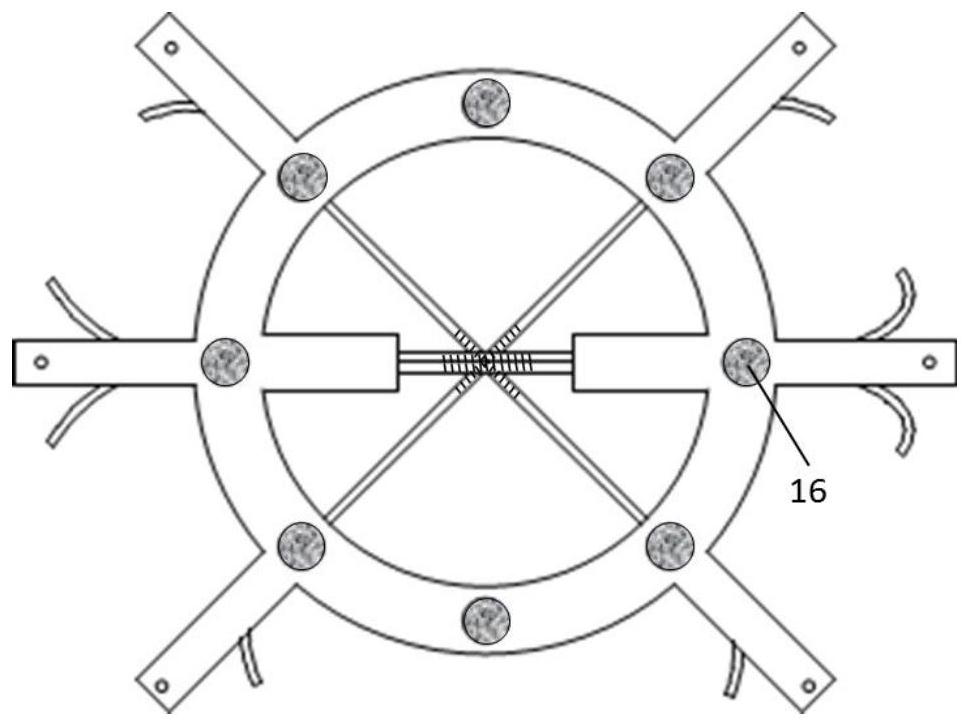

Fiber bragg grating high-temperature strain gauge and calibration method thereof

ActiveCN112833809AHigh measurement accuracySimple structureUsing optical meansStrain gaugeFiber crossing

The invention discloses a fiber bragg grating high-temperature strain gauge which comprises a sensor substrate, an optical fiber mounting arm and optical fibers, wherein the optical fiber mounting arm and the optical fiber are arranged on the sensor substrate, the sensor substrate is in a circular ring shape, the optical fiber mounting arm is formed by extending inwards along the inner circumference of the sensor substrate, and the optical fibers are arranged along the diameter direction of the sensor substrate; the optical fibers comprises a temperature optical fiber used for sensing temperature only; the sensor substrate is provided with bosses with different heights, the bosses are used for fixing the optical fibers, and the bosses are used for avoiding cross contact between different optical fibers. According to the fiber bragg grating high-temperature strain gauge, the influence of temperature on strain measurement is eliminated; the boss design on the sensor substrate can effectively avoid the chirp phenomenon caused by cross contact of FBG optical fibers; the strain gauge has the advantages of simple structure, synchronous measurement of multidirectional strain, temperature compensation, high measurement precision and the like, and can be used for synchronous measurement of multidirectional strain on the surface of a structure.

Owner:SUZHOU NUCLEAR POWER RES INST +2

Fiber laser cavity optical engine package and method of making the same

Embodiments of the invention include a fiber laser cavity package having improved fiber management and thermal management capability and methods of making such fiber laser cavity package. Each element of the fiber laser cavity is grouped into plurality of sections and each section is placed onto a heat conducting surface within the fiber laser cavity package to dissipate unwanted heat from the elements. When the fiber laser cavity is stored in the package, the fiber laser cavity is arranged such that fiber crossings are substantially reduced or eliminated within the package.

Owner:OFS FITEL LLC

Preparation method of anti-flaming washable filter material

The invention discloses a preparation method of a flame-retardant and washable filter material. The flame-retardant and washable filter material is the filter material which is prepared by the following steps: a basic material is acupunctured and compounded by a polyester or a polypropylene fiber fine filter layer with a polyester or a polypropylene rough fine filter layer, then is emerged into aflame-retardant solution which is prepared by waterborne polyurethane, an acyclic phosphate flame retardant and sodium dihydrogen phosphate according to a certain proportion and then compacted by a twin-roll and dried and ironed out after being sprayed with the flame-retardant solution; and the formed fiber crossing points are fixed by gel points with the filter material with the fiber surface being covered by a smooth glue layer. The filter material is flame-retardant and washable.

Owner:HENAN ANKELIN FILTER IND

Stereo braiding-based carbon sulfur composite electrode for sodium sulfur battery

ActiveCN102142532BImprove power densityLarge capacityElectrode carriers/collectorsActive material electrodesCarbon fibersSulfur electrode

The invention relates to a stereo braiding-based carbon sulfur composite electrode for a sodium sulfur battery. The carbon sulfur composite electrode is characterized by consisting of a graphite felt and high-purity sulfur, namely the carbon sulfur composite electrode consists of the porous graphite felt with adjustable carbon fiber crossing angles and combined fiber layers and the sulfur, wherein the sulfur in the composite electrode enters pores of the graphite felt after being melted with a penetration method. The graphite felt prepared by a stereo crossing braiding mode has the characteristics of high tensile strength and low elastic modulus; and by adjusting the crossing angles among the fibers, optimization of the sulfur on the wetting performance of the carbon felt is realized, theelectric conductivity of a sodium sulfur battery anode is improved, the contact performance of the sulfur electrode and ceramic electrolyte is enhanced, polarization is reduced, the working property of the anode in the battery is improved, and the performance (see embodiments) of the sodium sulfur battery is improved. The carbon sulfur composite electrode is particularly suitable for the sulfur pole of the high-power sodium sulfur battery.

Owner:上海电气企业发展有限公司

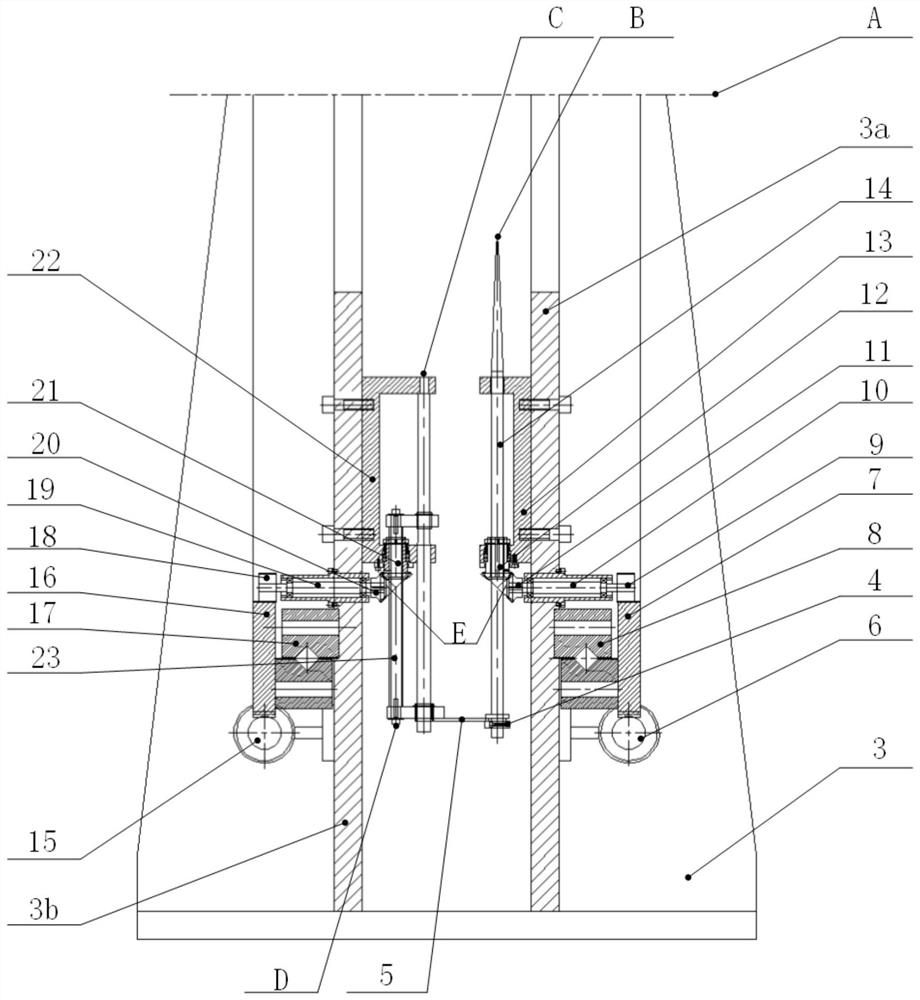

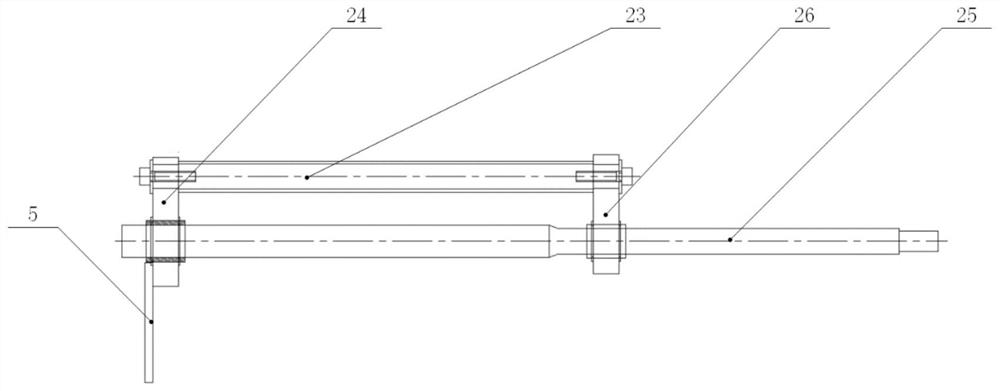

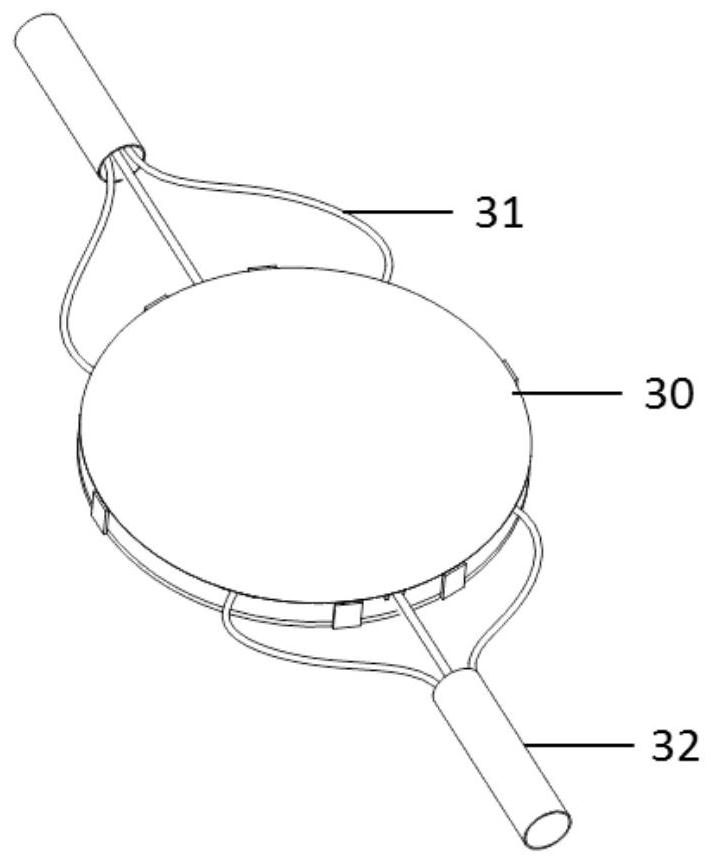

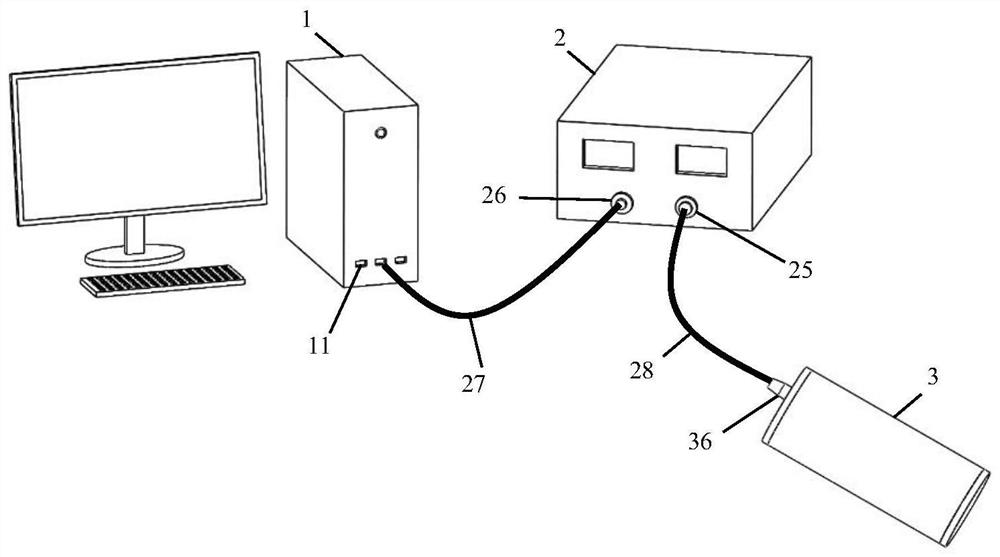

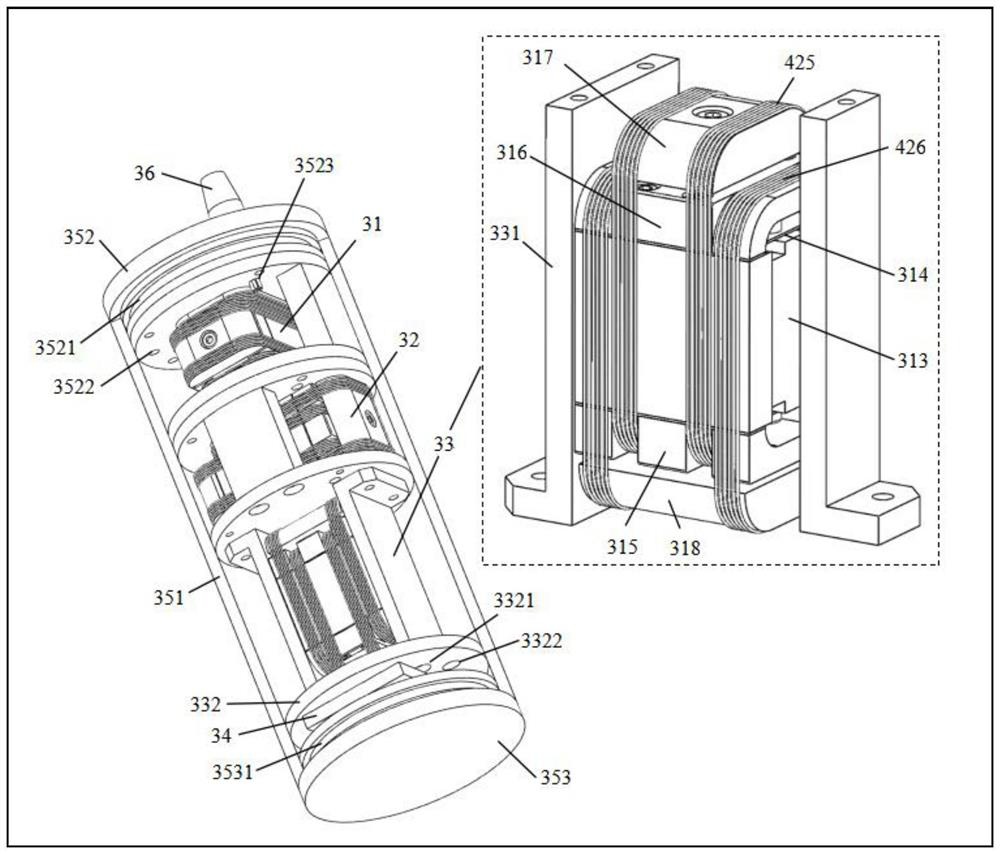

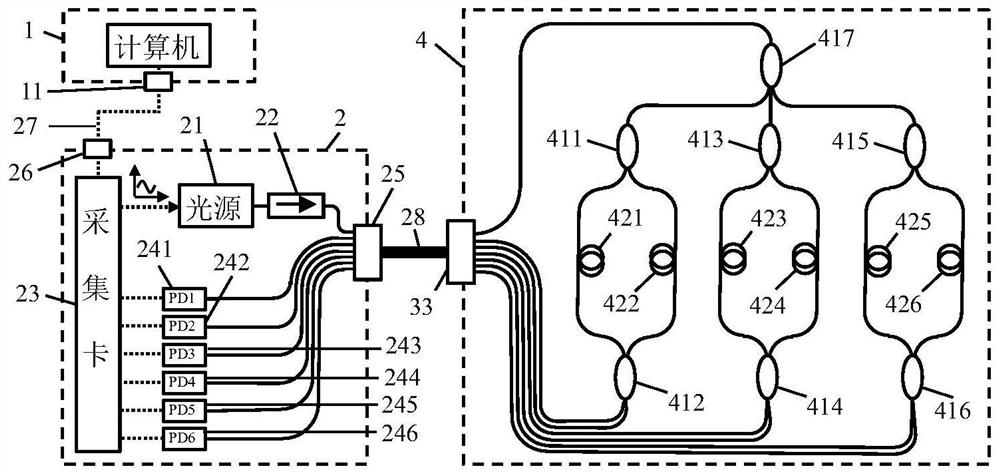

A cross-wound push-pull downhole three-component fiber optic seismometer

ActiveCN112946729BImprove vibration directionImprove transfer efficiencySubsonic/sonic/ultrasonic wave measurementSeismic signal receiversInterference (communication)Accelerometer

The invention provides a cross-wound push-pull downhole three-component optical fiber seismometer, which belongs to the field of optical fiber interference measurement. It mainly includes a signal processing system, a signal acquisition system, a vector accelerometer, a communication cable and an optical cable. Two sensing units with the same structure are orthogonally stacked to form a three-dimensional vector sensing probe. The outside is protected by an outer cylinder and a sealed end cap. The sensitive optical fiber adopts the form of external winding, and the main structural components are enclosed inside the sensitive optical fiber. At the same time, the sensitive optical fiber is cross-wound between the two leaf spring fixing blocks and the two fiber winding columns, and together with the mass block forms a push-pull structure, wherein the mass block directly stretches the sensitive fiber through the fiber winding columns at both ends. The advantages of the device are that the vibration direction of the mass block is good, the lateral crosstalk is low, high strain transfer efficiency and sensitivity can be achieved, and the structure is compact, which can meet the measurement requirements in narrow spaces, and is especially suitable for deep well seismic observation.

Owner:HARBIN ENG UNIV

Double-loop armored optical fiber cross dense tapping structure and method

PendingCN111552037AMeet the needs of useSmall outer diameterCoupling light guidesFibre mechanical structuresFiberEngineering

The invention relates to a double-loop armored optical fiber cross dense tapping structure and method. The tapping structure comprises at least two first line concentration ends and at least two second line concentration ends, the first line concentration ends extend to form a plurality of armored optical fibers capable of being bent at will, and each second line concentration end comprises a partof armored optical fibers extending out of at least one first line concentration end. By arranging the armored optical fiber, the arranged fiber core is effectively protected and is not easily damaged by external force, the degree of deformation during bending can be larger, smooth transition can be kept, the degree of freedom of deformation of the fiber core is increased while the protection ofthe fiber core is improved, and the use requirements of the optical fiber are met.

Owner:SHENZHEN ACE ARMORED CABLE CO

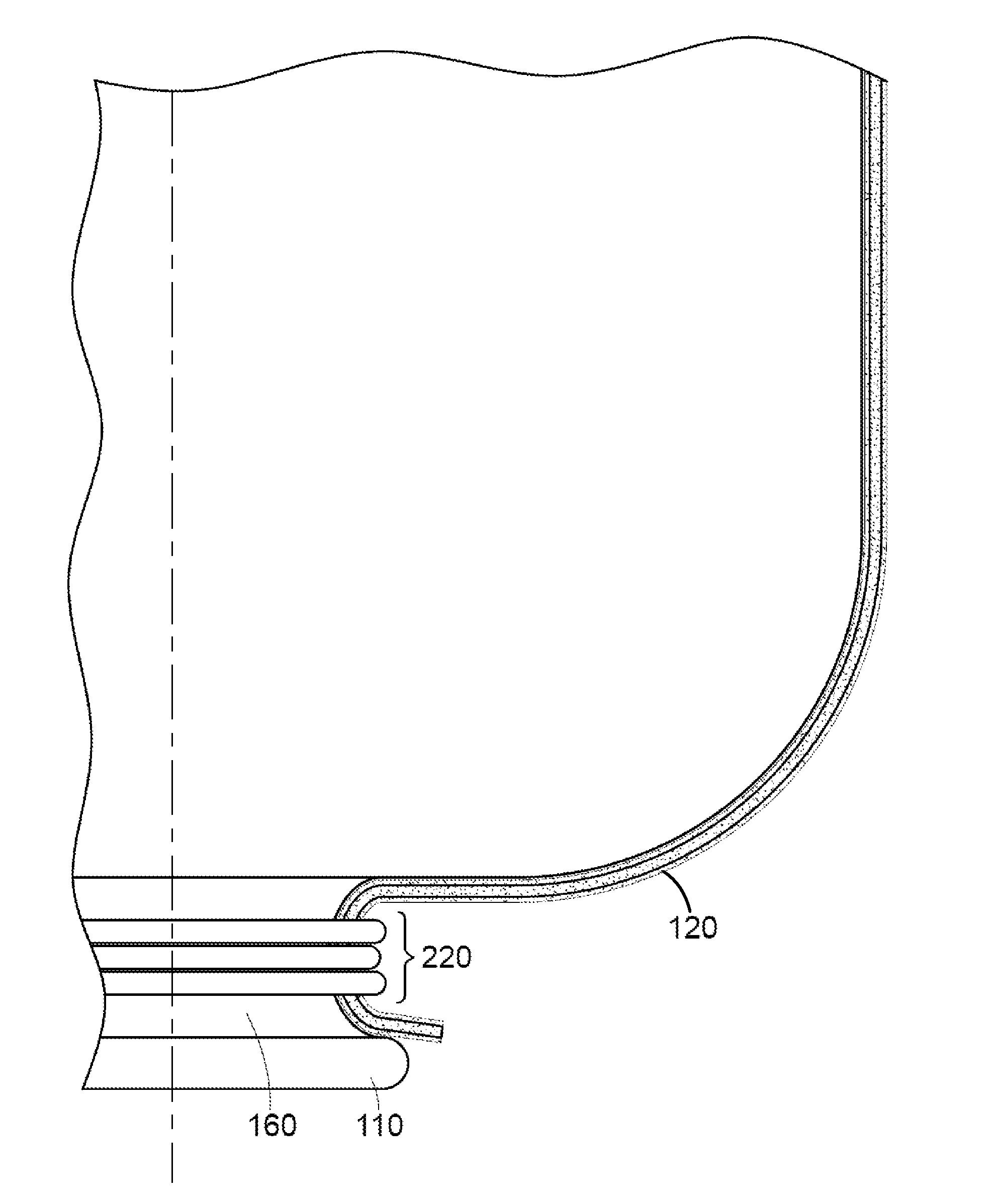

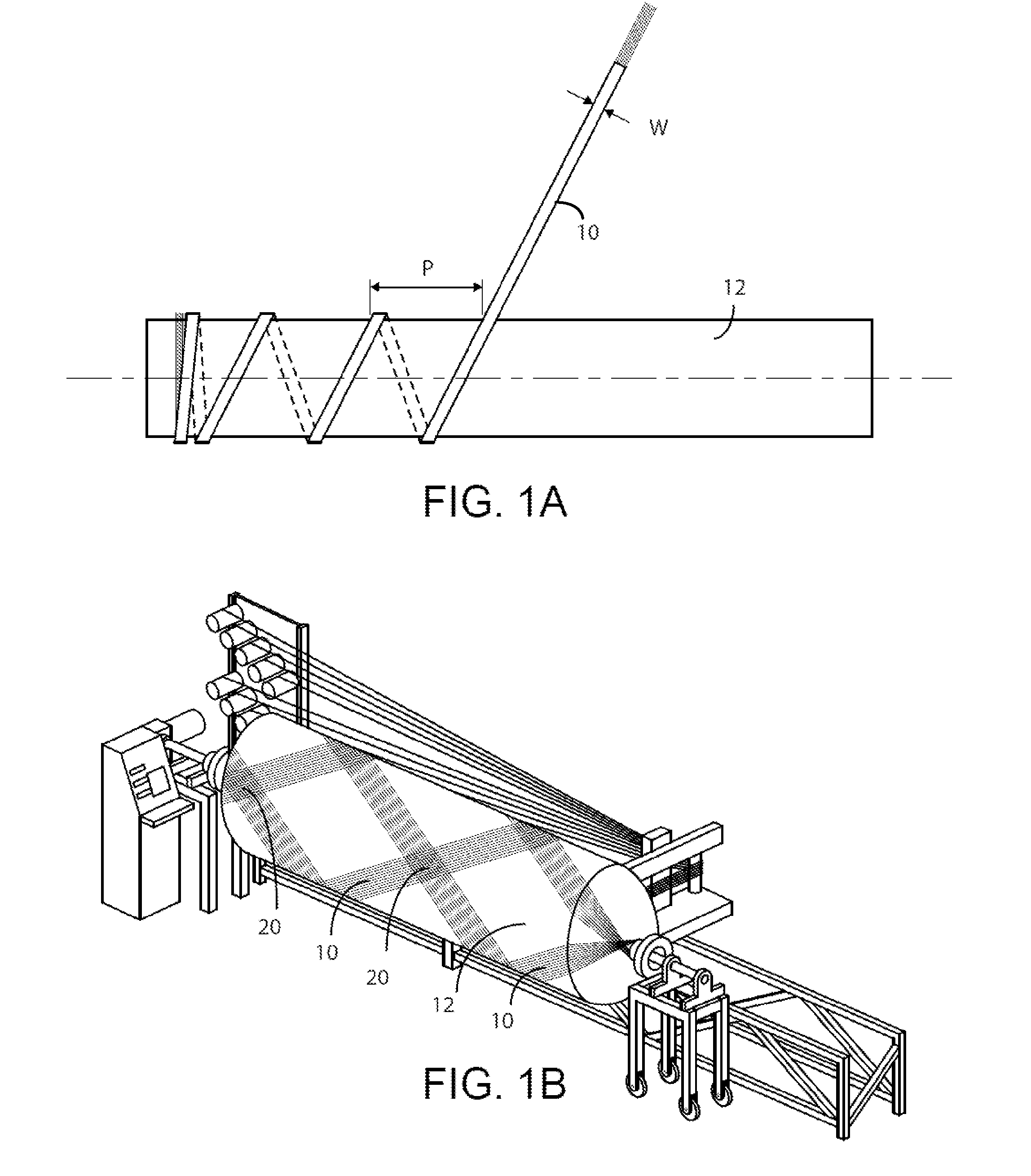

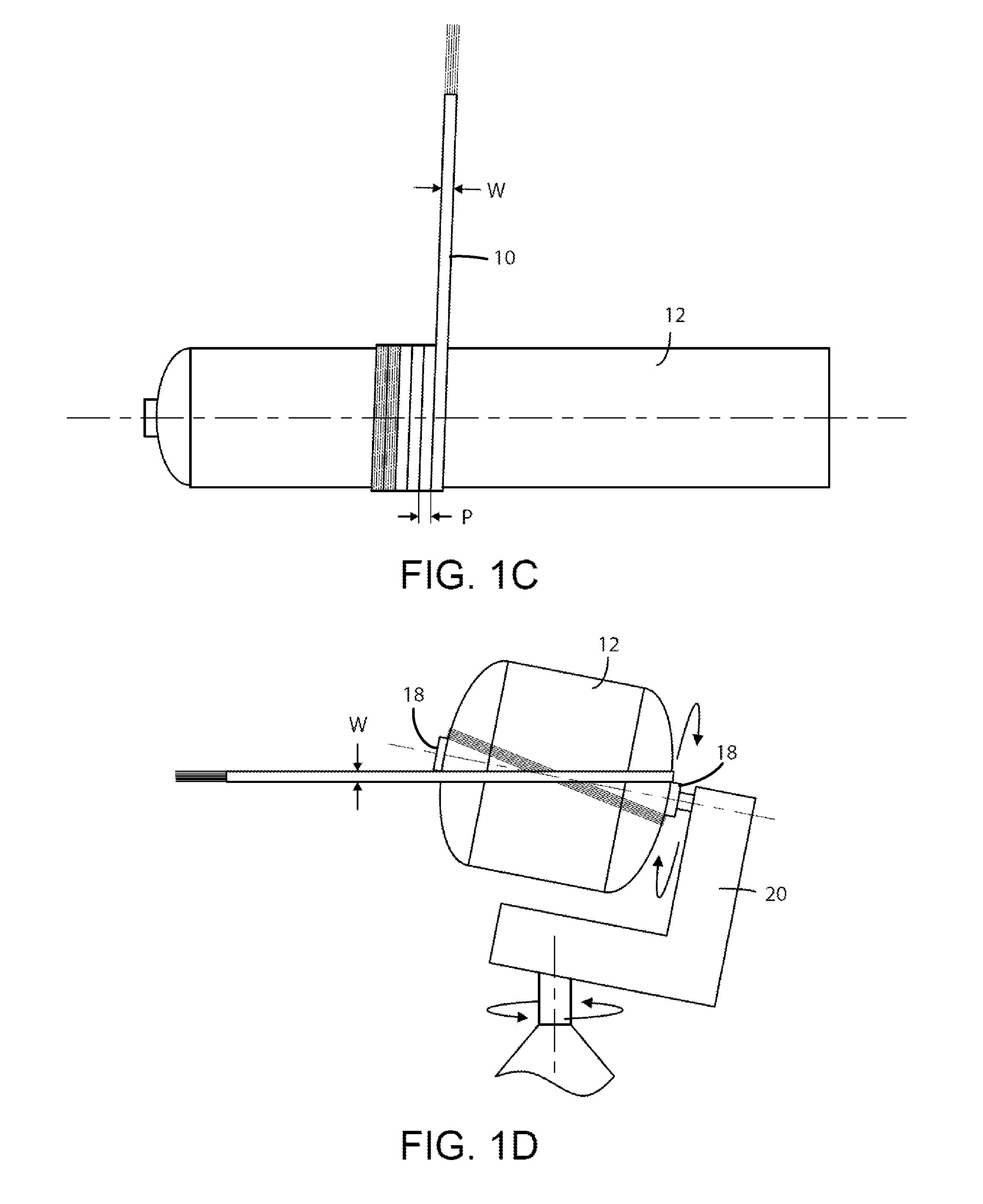

System and methods for creating wrapped filament reinforced vessels, and vessels created thereby

InactiveUS20140199504A1Increasing rate can be appliedRelieve stressEnvelopes/bags making machineryLayered productsMethods of productionFilament winding

A manufacturing apparatus for producing filament-wound products such as pressure vessels and pipes includes a mandrel for supporting a pre-form vessel, a mandrel driver structured to rotate the pre-form vessel, and an array of individual filament supports for guiding individual filaments used in producing the vessel. Using the unique aspects of the apparatus which avoids the customary high-angle fiber crossings significantly speeds up manufacturing and thus lowers product cost, increases product lifetime, reduces fatigue stress, and reduces weight of the finished product. Methods of production are also disclosed.

Owner:ANDERSON JOSEPH W +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com