Method for creating three-dimensional microscopic cell model of composite material based on random-sequence growth method

A composite material and random sequence technology, applied in 3D modeling, image data processing, instrumentation, etc., can solve problems such as low execution efficiency, time-consuming calculation, and low fiber volume fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

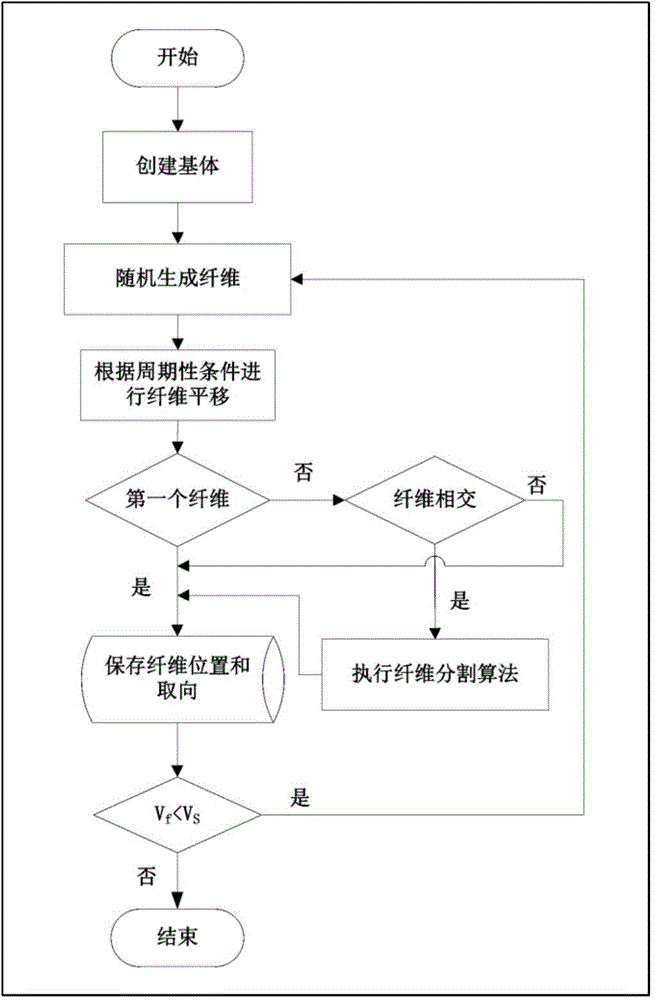

Embodiment 1

[0088] Example 1: Take the chopped carbon fiber reinforced magnesium-based composite material (Csf / Mg composite material) prepared by the vacuum imbibition liquid-solid extrusion process as an example. In the Csf / Mg composite material, the fibers are randomly distributed in space, and the average fiber aspect ratio is 13-15. In this example, we take the minimum fiber aspect ratio as 5 and the maximum fiber aspect ratio as 15. The method proposed based on the present invention can create the microscopic periodic soma model of Csf / Mg composite material with higher fiber volume fraction, set up steps (flow chart sees attached figure 1 )as follows:

[0089] Step 1: Create the matrix of the microscopic periodic somatic model of the Csf / Mg composite material, the size is 187.5 μm×187.5 μm×187.5 μm, and the center is (93.75 μm, 93.75 μm, 93.75 μm).

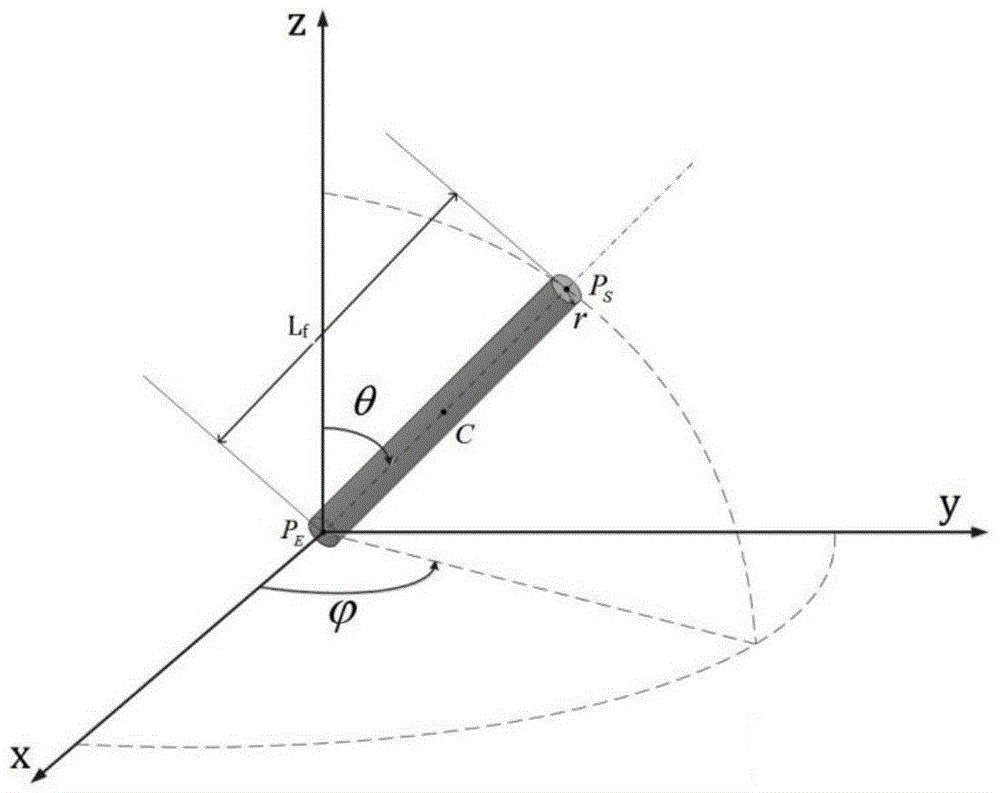

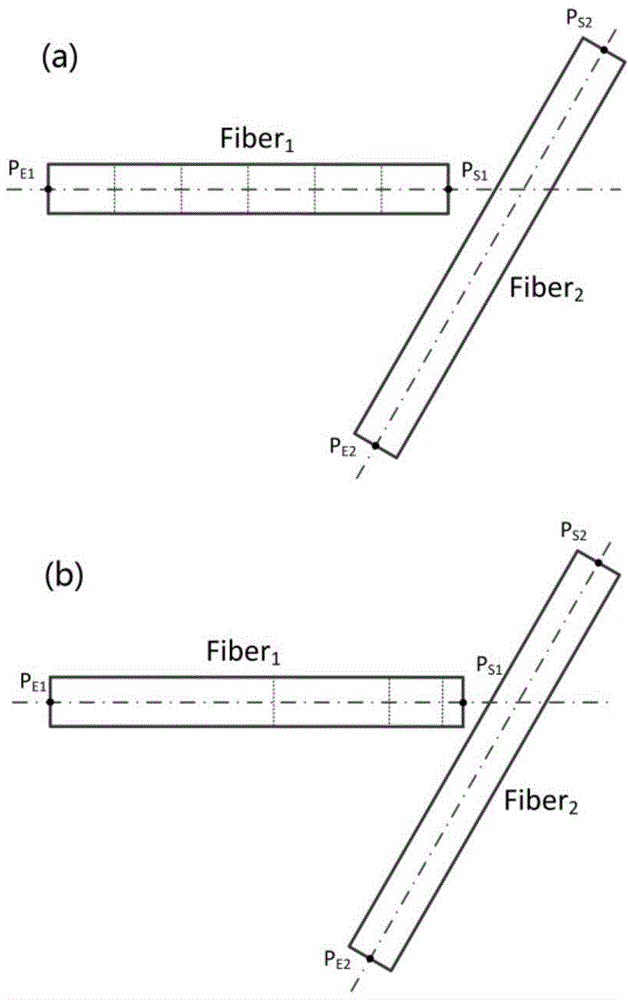

[0090] Step 2: Randomly generate fiber starting points P within the composite matrix (187.5 μm × 187.5 μm × 187.5 μm) E , fiber unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com