Lining structure of large-scale pre-baking aluminium electrolysis trough

An aluminum electrolytic cell and electrolytic cell technology, which is applied in the field of large-scale prebaked aluminum electrolytic cell lining structure, can solve the problems of ineffective prevention of sodium expansion, inability to form a regular furnace, and high sodium expansion rate, so as to prolong the life of the electrolytic cell, Effects of prevention of furnace bottom sedimentation and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

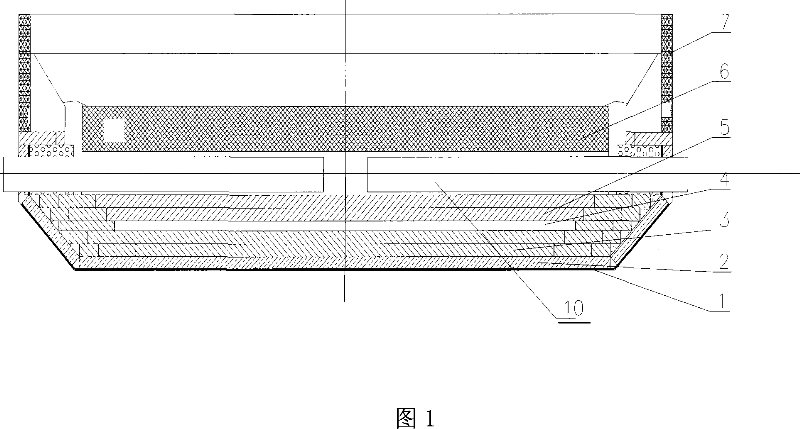

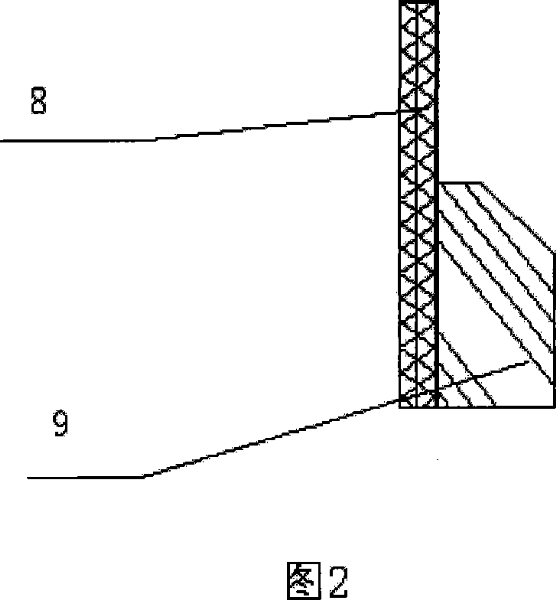

[0016] As shown in Fig. 1 and Fig. 2, the bottom of the electrolytic cell shell with the inner lining structure of the present invention is successively built with asbestos board layer 1, a heat insulating layer 2 made of high temperature resistant calcium silicate board, and two layers of lightweight bricks. Insulation layer 3, anti-seepage layer 4 composed of one layer of alumina, anti-seepage layer 5 composed of two layers of refractory bricks, semi-graphite cathode composite TiB 2 Coating 6, the side is a special-shaped side block 7; the bottom is made of 30% semi-graphite cathode composite TiB 2 Coating, because this kind of cathode carbon block has high thermal conductivity, low resistivity and low electrolytic sodium expansion rate, it can effectively prevent the sodium expansion caused by the penetration of sodium in the electrolyte, and can reduce the cathode carbon The temperature gradient in the block and the current distribution in the cathode carbon block are more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com