Tile shaped magnet grinding method and device

A tile-shaped and magnet technology, which is applied in grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve the problems of low automation and low precision in tile-shaped magnet processing, avoid printing and chipping, and achieve high processing accuracy. , Improve the effect of processing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

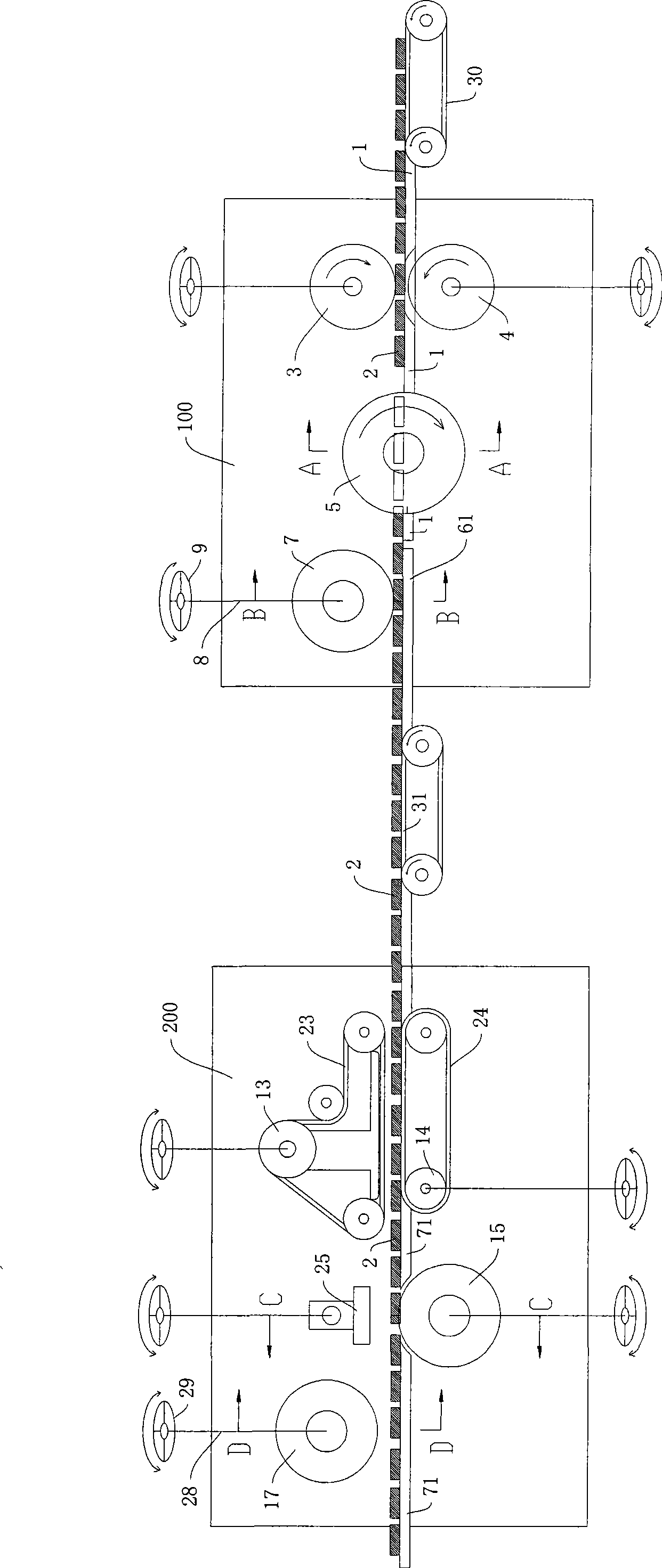

[0023] figure 1 The grinding machine shown is a grinding machine for grinding the chord width, outer arc surface and inner arc surface of the tile-shaped magnet, and then finely grinding the outer arc surface. The grinding machine 100 for grinding the arc surface, and the other part is the grinding machine 200 for grinding the inner arc surface of the tile-shaped magnet and finely grinding the outer arc surface.

[0024] The grinding machine 100 for grinding the chord width and outer arc surface of a tile-shaped magnet will be described first.

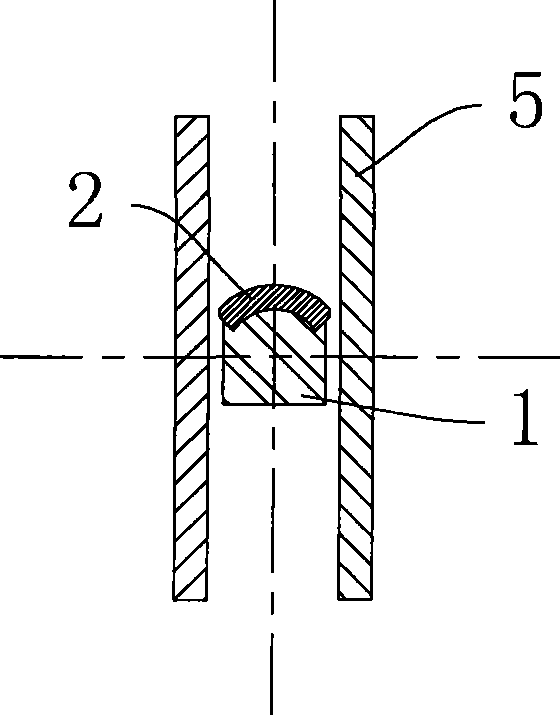

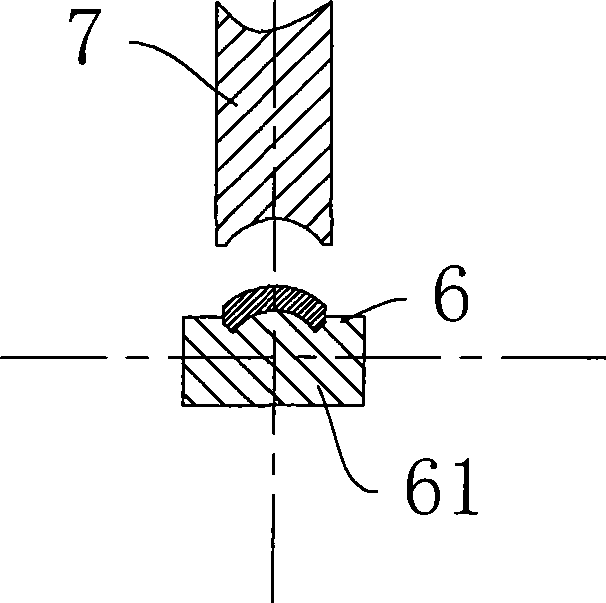

[0025] see Figure 1-3 , in the grinder 100 for grinding the chord width and the outer arc surface of the tile-shaped magnet, the upper surface of the tile holder 1 is an arc surface corresponding to the inner arc surface of the tile-shaped magnet 2, and a plurality of tile-shaped magnets 2 are sequentially arranged on it On the surface. The upper feeding pinch wheel 3 and the lower feeding pinch wheel 4 are relatively arranged abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com