Cooling manipulator of die-casting machine for automobile aluminum alloy hub

An aluminum alloy wheel hub and die-casting machine technology, which is applied in the field of automobile wheel hub production equipment, can solve the problems of wheel hub damage, asynchronous movements of the first clamping arm and the second clamping arm, and complicated equipment, so as to achieve the effect of avoiding injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

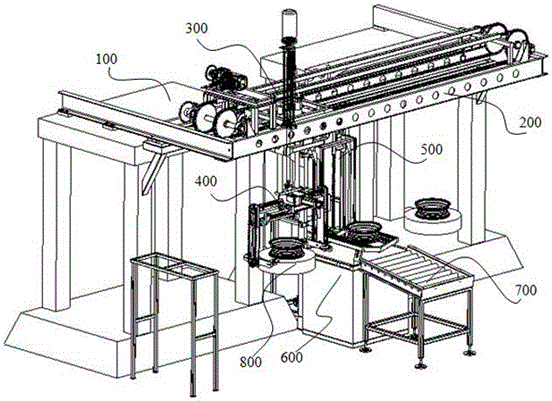

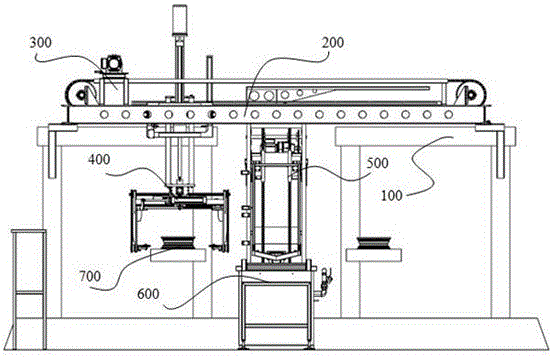

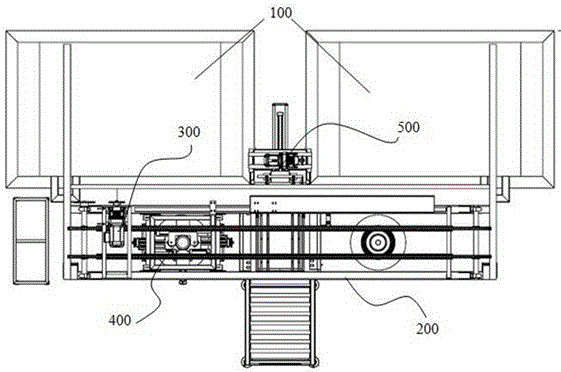

[0035] Example: A cooling manipulator of an automobile aluminum alloy wheel hub die casting machine.

[0036] Reference Figure 1 to Figure 11 As shown, a cooling manipulator for an automotive aluminum alloy wheel hub die-casting machine includes: two parallel support seats 100;

[0037] A bracket 200 installed on two parallel support seats 100, the rear end of the bracket 200 is fixed on the support seat 100, the front end of the bracket 200 is suspended, the bracket 200 is provided with a horizontal pulley track, and the front end of the bracket 200 is suspended for convenience Install the manipulator to the discharge port of the die casting machine to facilitate the grasping of the wheel hub 800. The bracket 200 is provided with a horizontal pulley track to ensure that the mechanical gripper 400 moves stably along the horizontal pulley track;

[0038] The lateral drive mechanism 300 is installed on the hanging position at the front end of the bracket 200, and the function of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com