Design method capable of eliminating hydraulic pulsation and device capable of eliminating hydraulic pulsation

A design method and technology of hydraulic pulse, applied in the field of hydraulic pump, can solve the problems of unstable rotation speed, high noise, adverse effects of the system, etc., achieve the effect of uniform liquid supply and avoid fluctuation of liquid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

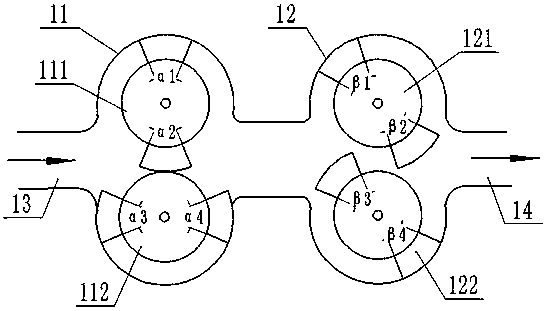

[0038] The method of the present invention can be applied to all types of gear pumps, including internally cut gear pumps and externally cut gear pumps. The present embodiment is an example of externally cut gear pumps, such as figure 1 As shown, it is a structure for eliminating the hydraulic pulse of the circumscribed gear pump, including the gear pump A11 and the gear pump B12 arranged in series, the gear pump A11 and the gear pump B12 are arranged in the same cavity, and one end of the cavity It is connected with the oil supply pipeline A13, and the other end is connected with the working pipeline A14. The gear pump A11 and the gear pump B12 are connected with the driving device, and are driven by the driving device to rotate at constant angular speed. The gear pump A11 includes a rotary piston a 111 and a rotary piston b 112 arranged in cooperation, and the gear pump B12 includes a rotary piston c 121 and a rotary piston d 122, and each of the rotary pistons a-rotary pisto...

Embodiment 2

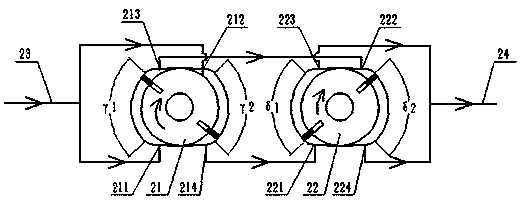

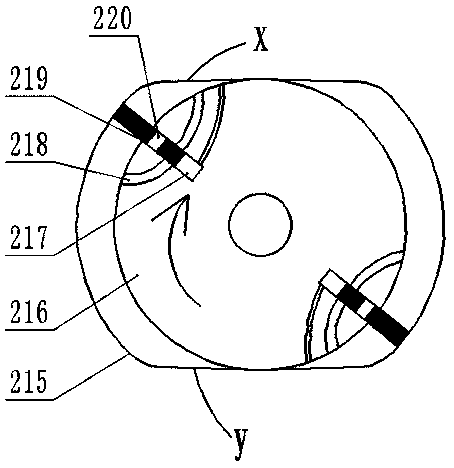

[0044] Such as figure 2 As shown, it is an embodiment of a vane pump designed using the method of the present invention. Taking two pump bodies in series as an example, the vane pump liquid supply system of this embodiment specifically includes a vane pump A21 and a vane pump B22. The vane pump Both A21 and vane pump B22 include a stator and a rotating rotor. The stator includes two sections of arcs whose profiles are positive arcs. The two sections of positive arcs are located within the pump oil angle range. The liquid angles are γ1 and γ2, and the pumping liquid angle of the vane pump B22 is that the sum of the sum of the angles of γ1, γ2, δ1, and δ2 is at least 360°; and the transition curve connecting the two ends of the positive arc is located at In the non-pumping angle range, the transition curve is in tangential contact with the rotor. The rotor is connected with a driving device, and the driving device drives the rotor to rotate at a constant angular velocity.

[...

Embodiment 3

[0051] Such as Figure 5 As shown, the plunger pump is an implementation mode when the technical solution of the present invention is applied. In this embodiment, two single plunger pumps are connected in series as an example for description.

[0052] The plunger pump liquid supply system of this embodiment includes two single plunger pumps in series, plunger pump A31 and plunger pump B32, said plunger pump A31 includes hydraulic cylinder a311 and hydraulic cylinder b312, said hydraulic cylinder A311 and the piston rod of hydraulic cylinder b312 are rigidly connected by connecting piece a313, such as Figure 6 As shown, the connecting piece a313 is a C-shaped piece, and the two outer surfaces are respectively connected with the piston rods of the hydraulic cylinder a311 and the hydraulic cylinder b312, and the two inner surfaces of the connecting piece are in tangential contact with the cam a 314, so that The piston rod moves horizontally with the rotation of the cam. Since the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com