Multifunctional blending and liquid supplying vehicle

A multi-functional and mixed technology, applied in the direction of motor vehicles, goods transport vehicles, vehicles for freight, etc., can solve the problems of high operation cost, low work efficiency and high labor cost, and achieve high work efficiency and reduce labor cost. , the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

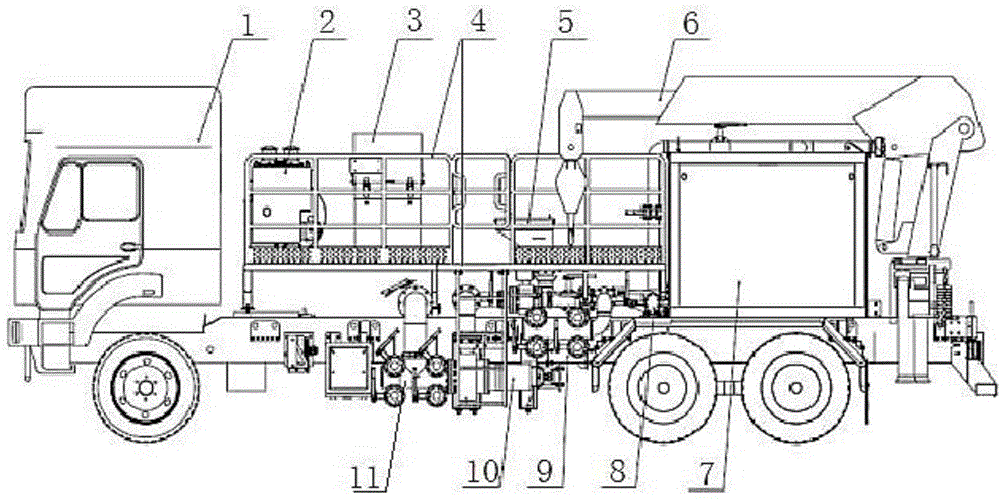

[0016] like figure 1 As shown in the figure, a multifunctional mixed liquid supply vehicle includes a chassis vehicle 1, a hydraulic system 2, an electrical control system 3, an operation platform 4, a dry powder feeder 5, a truck-mounted crane 6, a liquid filling tank 7, and a liquid filling pump 8 , a centrifugal pump 10, a discharge manifold 9 and a suction manifold 11, the hydraulic system 2 includes a hydraulic oil tank, a hydraulic pump and a hydraulic multi-way valve, an operating platform 4 is fixed above the main beam of the chassis 1, and bolts are installed on the operating platform 4 The hydraulic oil tank and the operation box of the electrical control system 2 are fixedly connected. The truck-mounted crane 6 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com