PCB surface copper thickness measuring machine and measuring method

A PCB board, copper thickness measuring machine technology, applied in the direction of measuring devices, conveyor objects, transportation and packaging, etc., can solve the problems of unfavorable assembly line production efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

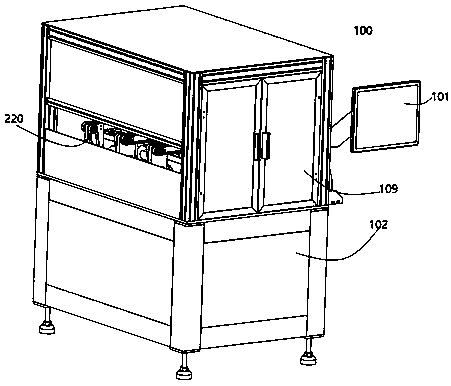

[0028] refer to figure 1 , the PCB board thickness measuring machine 100, which includes a frame 102 for supporting the entire testing equipment, and a conveying mechanism 220, a thickness measuring mechanism 106, and a computer control system 105 are arranged on the frame 102. The frame 101 is provided with an electric box for power supply, and the side of the frame 102 is provided with a protective sheet metal 109 .

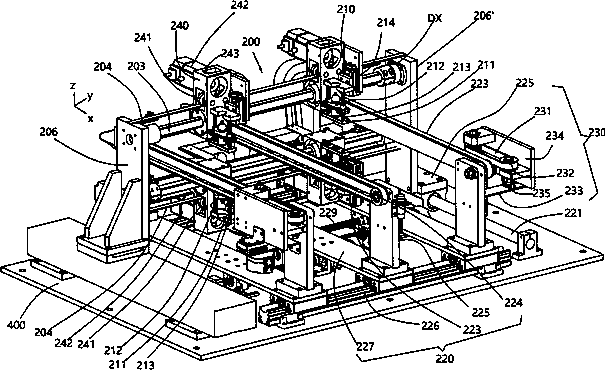

[0029] refer to figure 2 and image 3 , the inside of the PCB board thickness measuring machine has a conveying device. In the present invention, the conveying device includes three conveying belts 223 parallel to each other. The pulleys 224 at both ends of the conveying belts 223 are installed on the base 225. One of the pulleys 224 is provided with a drive motor to drive the belt 223 to rotate at a certain speed, and the rotation speed of the belt 223 can be controlled by the computer control system 101 . The bases on both sides where the belt pulley 224 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com