Conveying operation method and conveying operation device

A kind of operation device and operation technology, applied in the direction of conveyor control device, feeding device, automatic control device, etc., can solve the problems of input, production efficiency reduction, workpiece movement, etc., and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

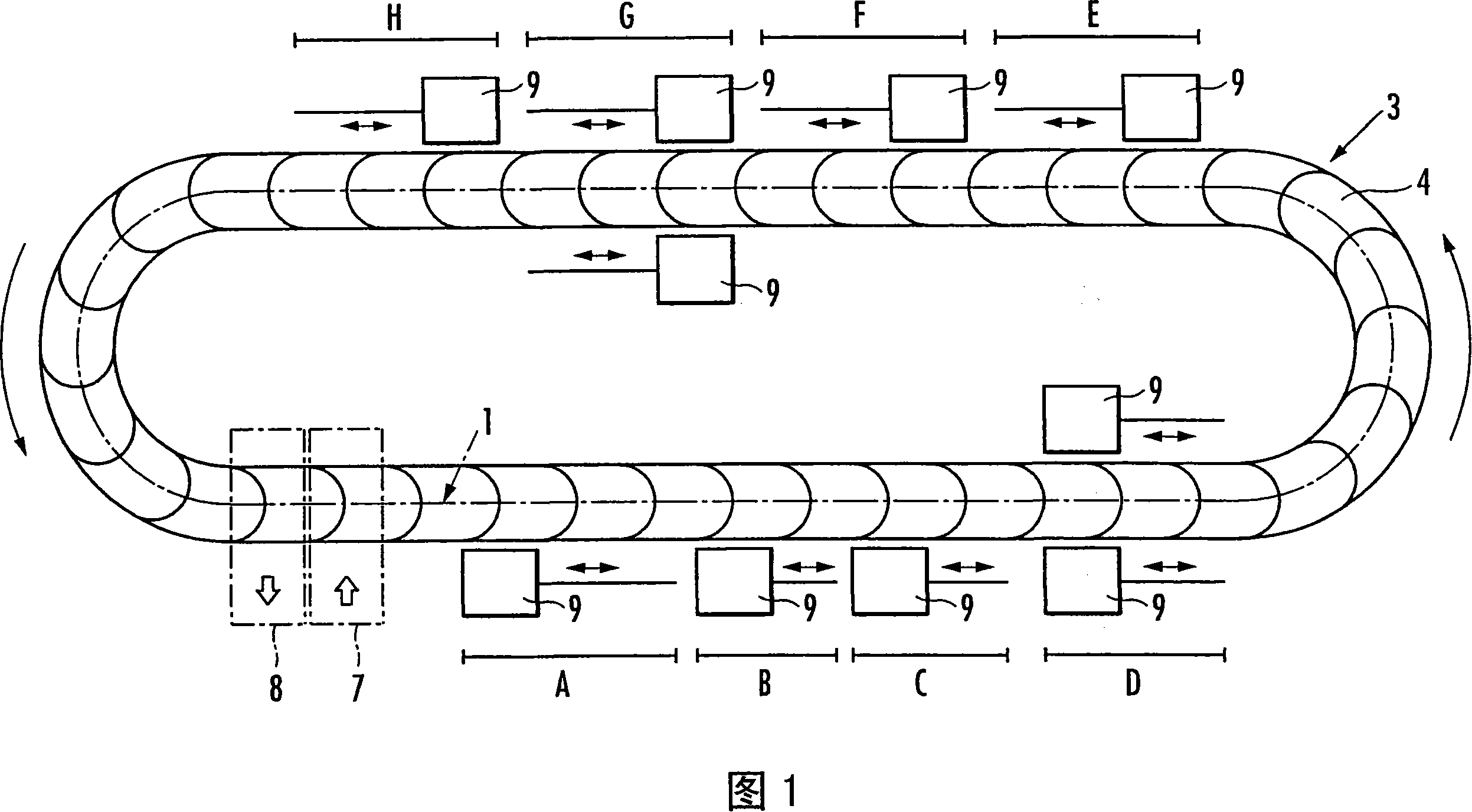

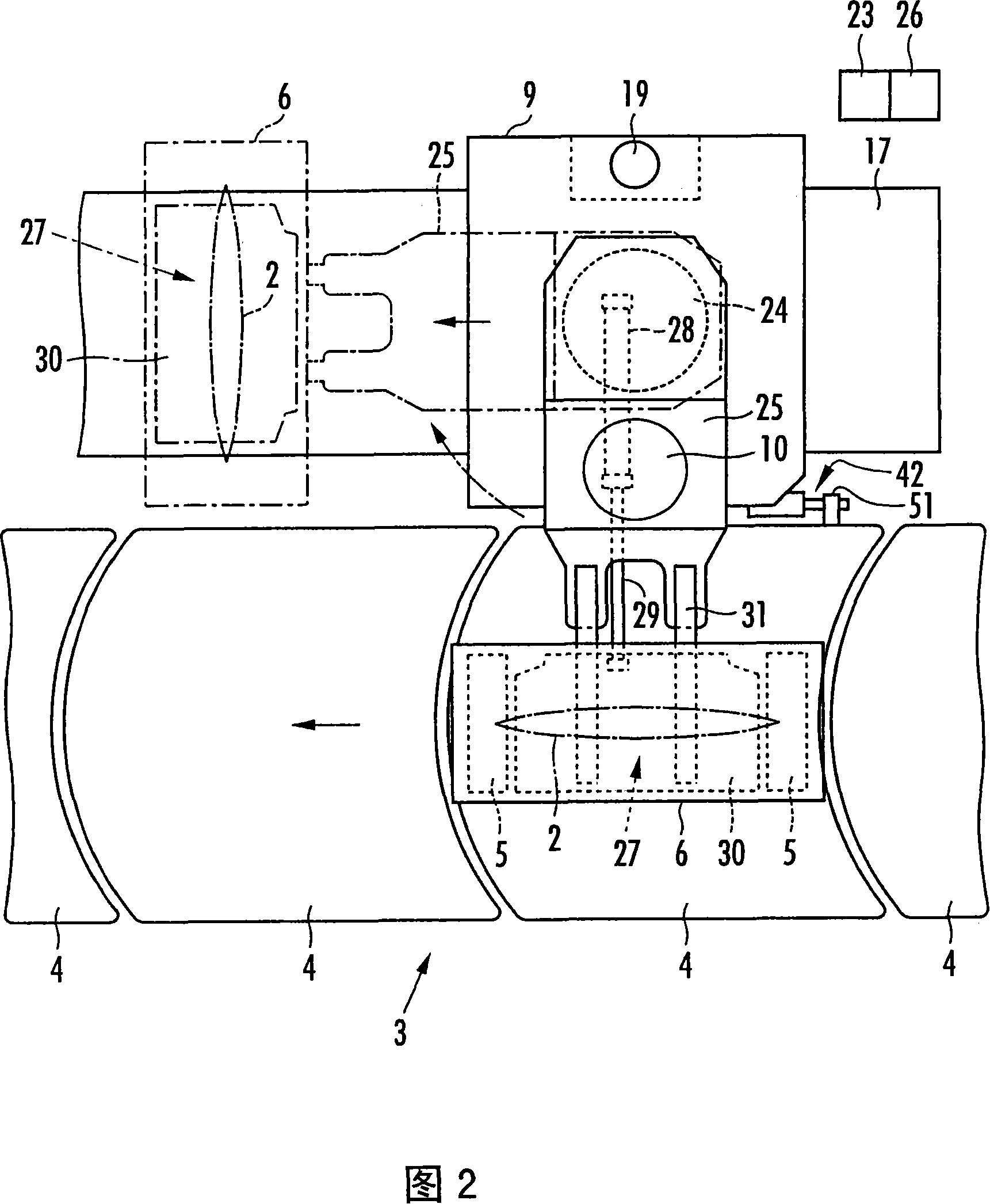

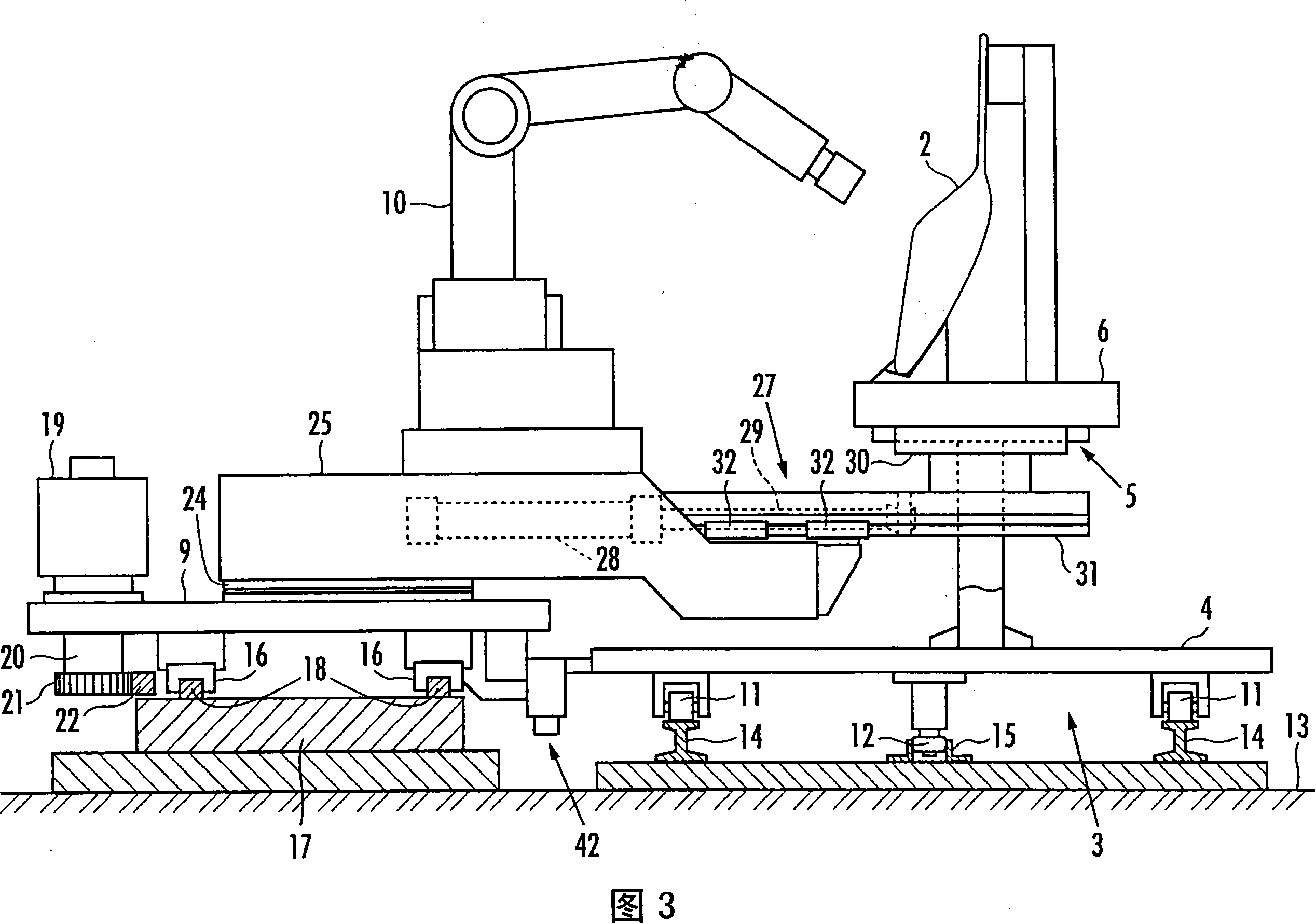

[0054] The conveying operation device of this embodiment is installed as a production line for automobile doors, and as shown in FIG. Shape workpiece conveying mechanism 3. The workpiece conveying mechanism 3 is a conveyor in which a conveying surface is formed by connecting a plurality of moving plates 4 in a ring shape, and the moving plates 4 circulate along an elliptical conveying path driven by a driving mechanism not shown. The workpiece 2 is held by the workpiece conveyance mechanism 3 with a predetermined interval therebetween. More specifically, as shown in FIGS. 2 and 3 , the workpiece 2 is held by the workpiece conveyance mechanism 3 by a plurality of workpiece holding portions 5 provided on the moving plates 4 at predetermined intervals. The workpiece 2 is held by the workpiece holding portion 5 in a state supported by the pallet 6 , and the pallet 6 is detachably held by the workpiece holding portion 5 .

[0055] Moreover, as shown in FIG. 1 , a part of the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com