Joint feeding device of inner liner layer and cord fabric layer in radial ply tire building machine

A radial tire and feeding device technology, applied in the field of tire machinery, can solve the problems of large inertia moment of power machine, poor positioning accuracy, complex structure, etc., and achieve the effects of ensuring positioning accuracy, low power consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The inner liner and carcass ply bonding feeding device in the radial tire building machine provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

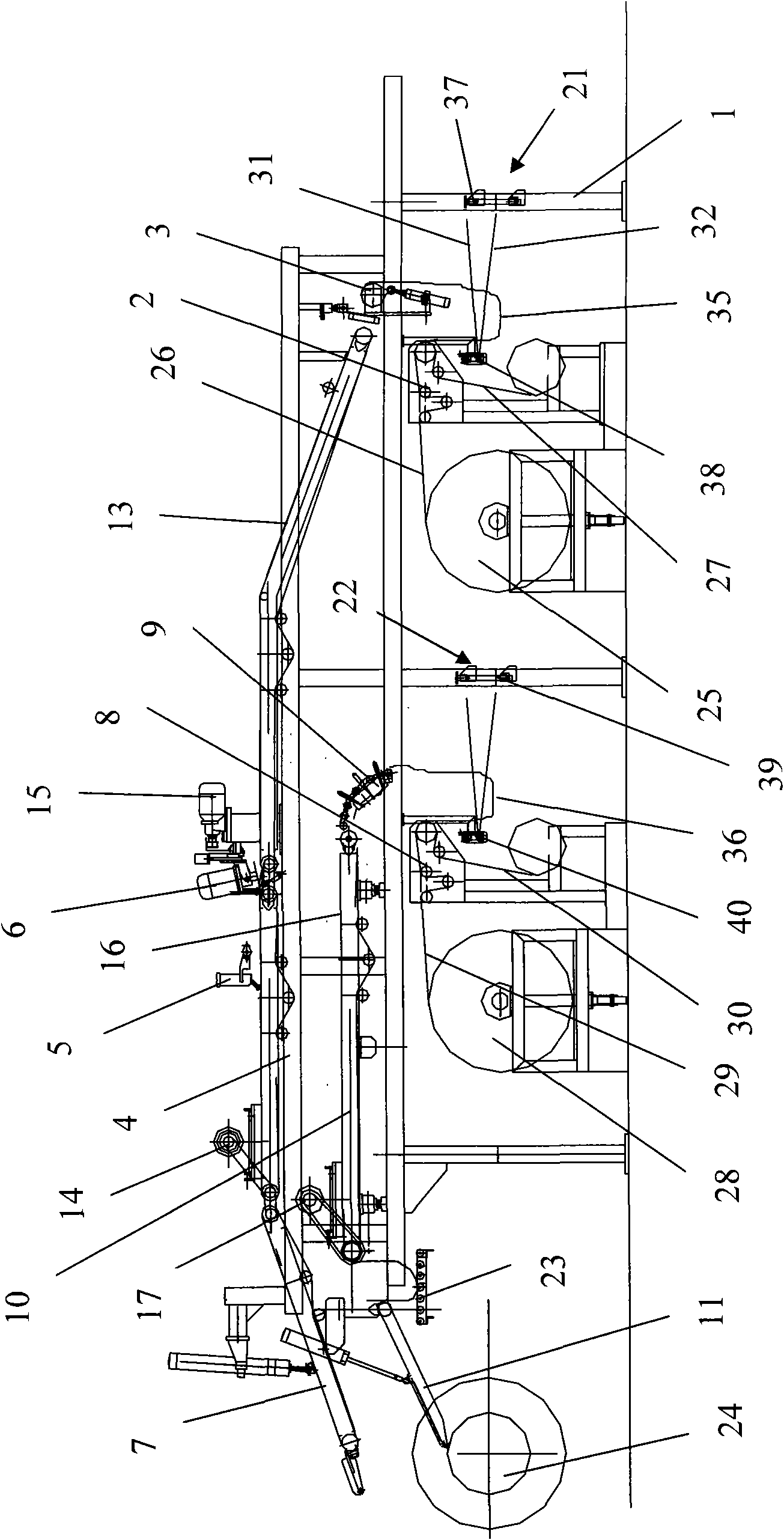

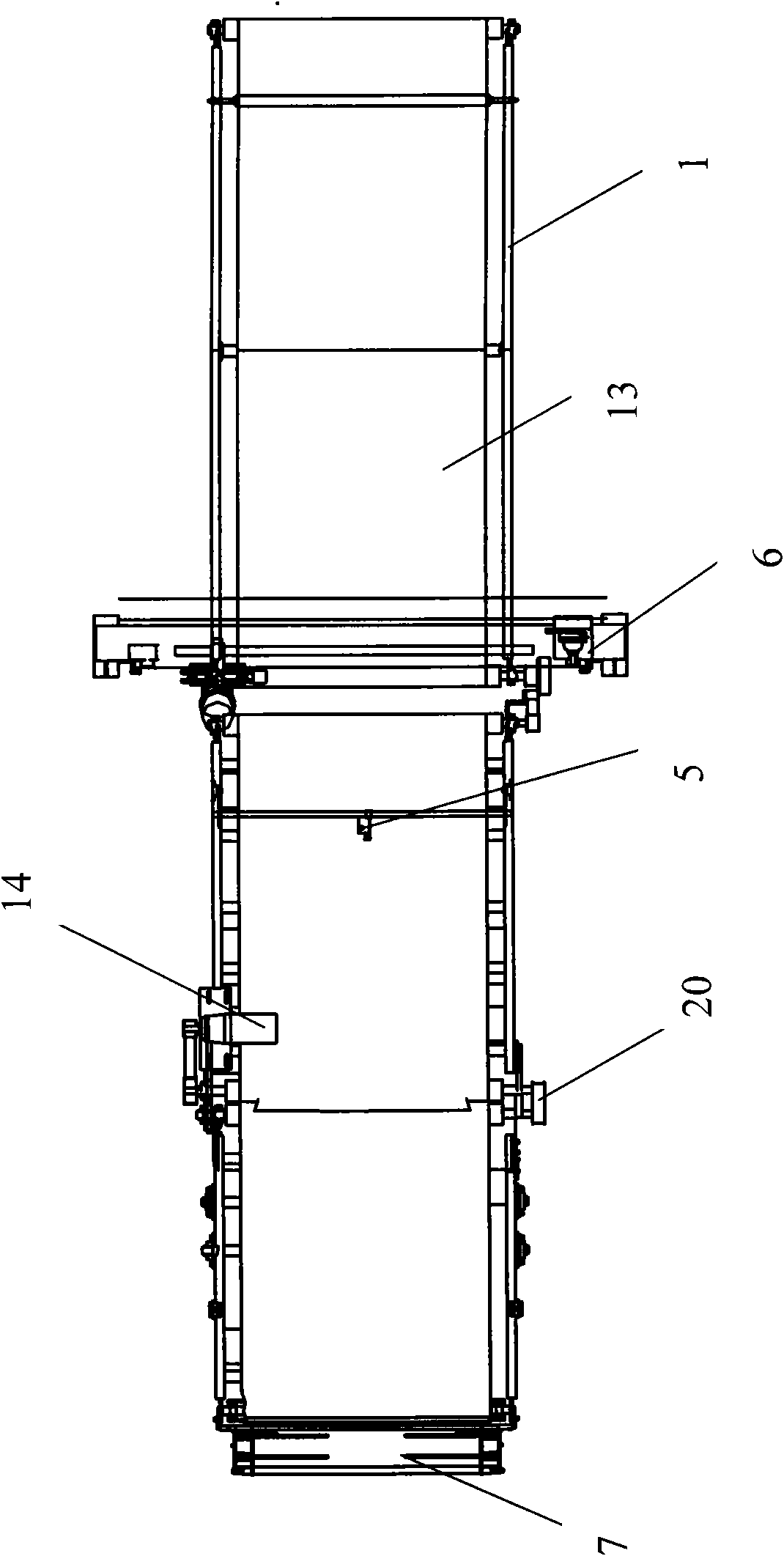

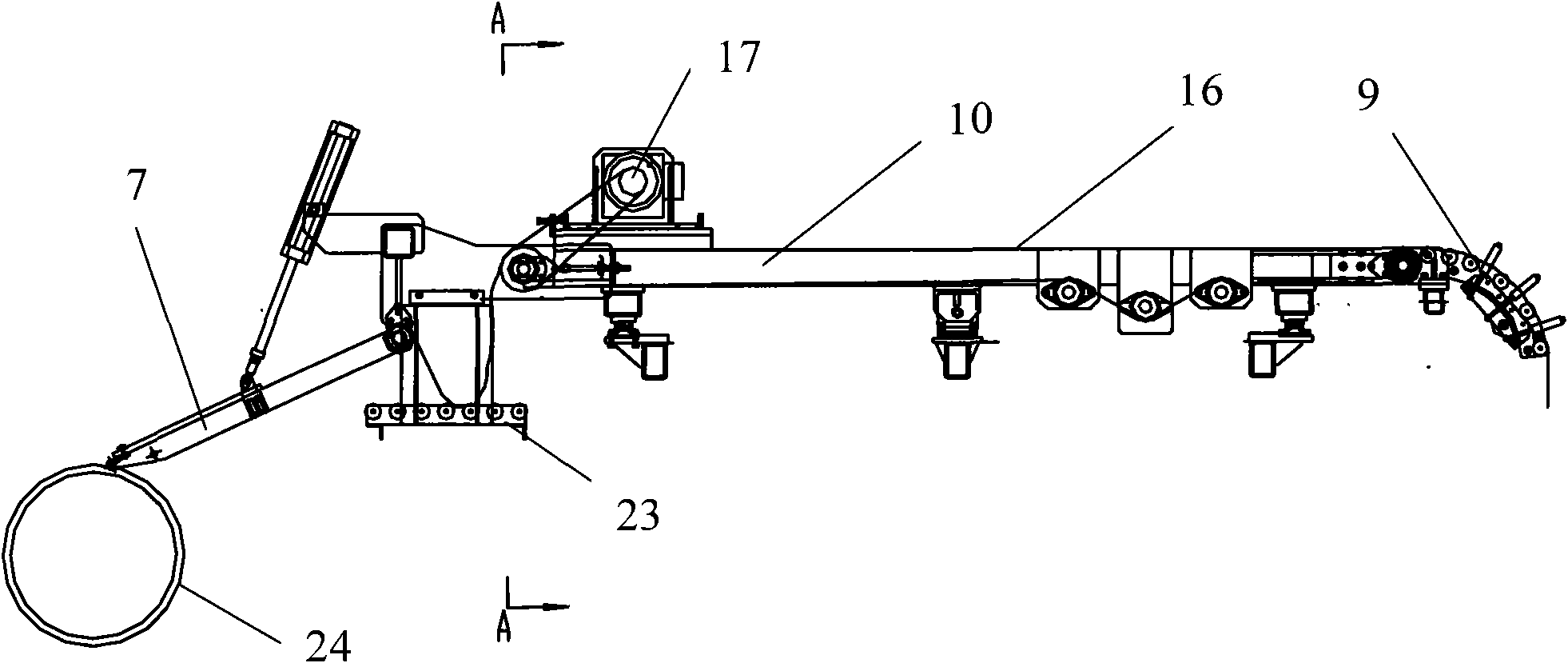

[0017] Such as Figure 1-Figure 4 As shown, the inner liner and carcass bonding feeding device in the radial tire building machine provided by the present invention includes a frame 1, an inner liner guiding device 2, an inner liner deviation correction device 3, and an inner liner feeding rack 4 , length measuring sensor 5, disc cutter 6, inner lining layer swing frame 7, ply layer guide device 8, ply layer guide frame 9, ply layer feeding frame 10, ply layer swing frame 11 and multi-position cylinder 12; Wherein the lower end of the frame 1 is installed on the ground; the lining layer guiding device 2 is arranged on the rear lower part of the frame 1; The inner lining layer feeding frame 4 is arranged on the top of the frame 1 along the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com