Heating furnace discharging roller way control system

A technology of control system and furnace roller table, which is applied in the direction of furnace control device, lighting and heating equipment, furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

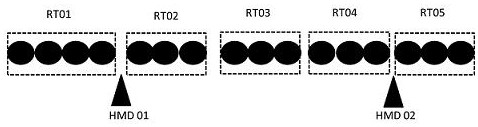

[0012] Such as figure 1 The shown control system of the heating furnace outlet roller table includes a heating furnace control system and a rolling line control system, and also includes a furnace outlet roller control system for controlling the heating furnace outlet roller table; System and rolling line control system; realize the matching between the speed of the heating furnace cantilever roller table and the speed of the 1# rolling mill front, the heating furnace outlet roller table is driven by 16 motors, and the furnace outlet roller table is divided into 5 sections , which is divided into RT01 section, RT02 section, RT03 section, RT04 section and RT05 section; the first hot metal detector HMD01 is arranged between the roller tables of the RT01 section and RT02 section, and the first hot metal detector HMD01 is set between the RT04 section and RT05 section. There is a second hot metal detector HMD02; the first hot metal detector HMD01 and the second hot metal detector H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com