Feeding device for bar-shaped cartridges

A medicine roll and rod-shaped technology, which is applied in the field of rod-shaped medicine roll feeding device, can solve the problems of short buffer stop time of the cylinder, inability to align the upper and lower layers, and increase the positioning mechanism, etc., to achieve reliable direction control, slow material pushing speed, and smooth operation. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of the present invention, the present invention will be described more comprehensively and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

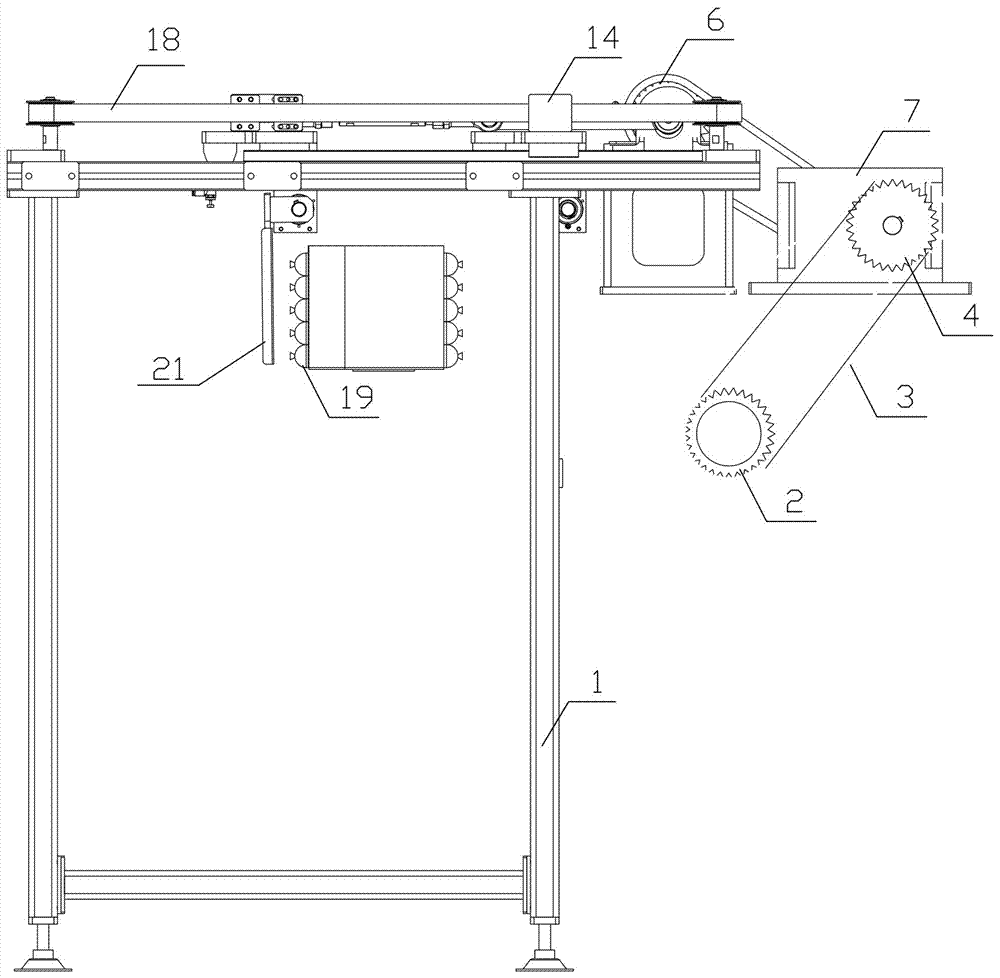

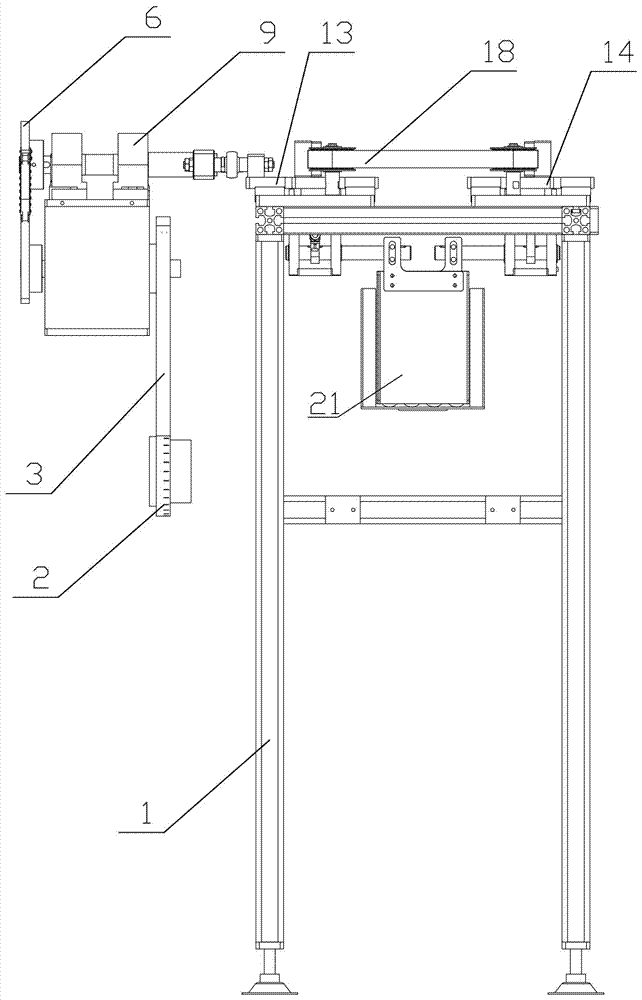

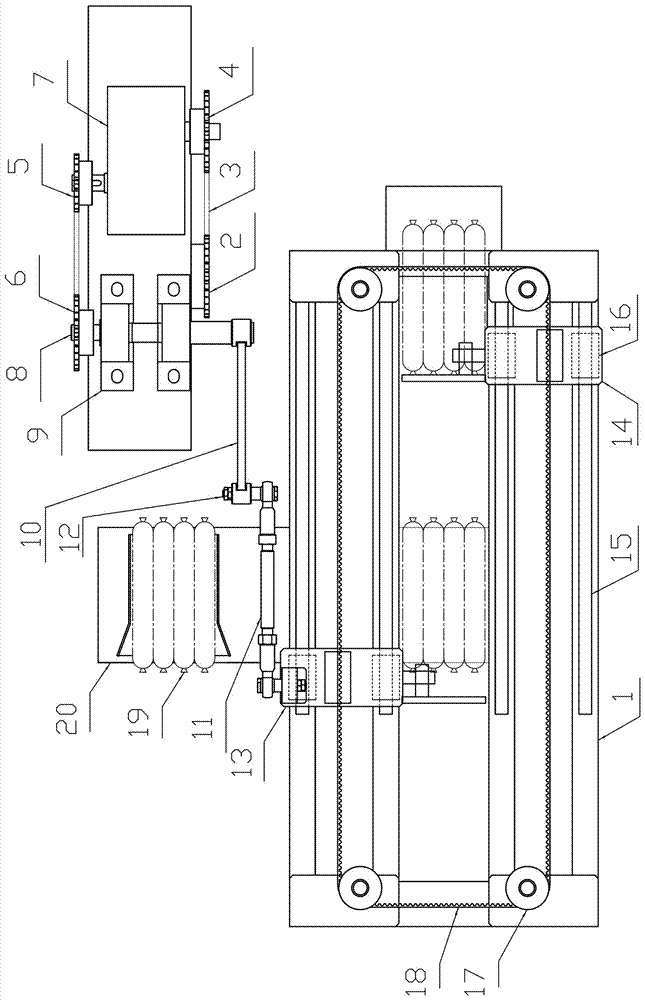

[0023] like figure 1 , figure 2 , image 3 As shown, a feeding device embodiment of a rod-shaped drug roll of the present invention includes a frame-shaped frame 1, a synchronous belt assembly, and two groups of rod-shaped drug rolls that are sent from a chain conveyor 20 to a feeding station. Roll 19 to the pushing mechanism, slider crank mechanism and transmission mechanism of the next process. The transmission mechanism is driven by the continuous rotation power of the next process and can convert the continuous rotation power into intermittent rotation power output. The timing belt assembly is located on On the frame-shaped frame 1, two sets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com