Substrate relay transfer system

A substrate-in-substrate technology, which is applied in the field of substrate-in-substrate transfer systems, can solve the problems of wasting waiting time, affecting substrate production efficiency and cost, and reducing substrate transportation and moving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

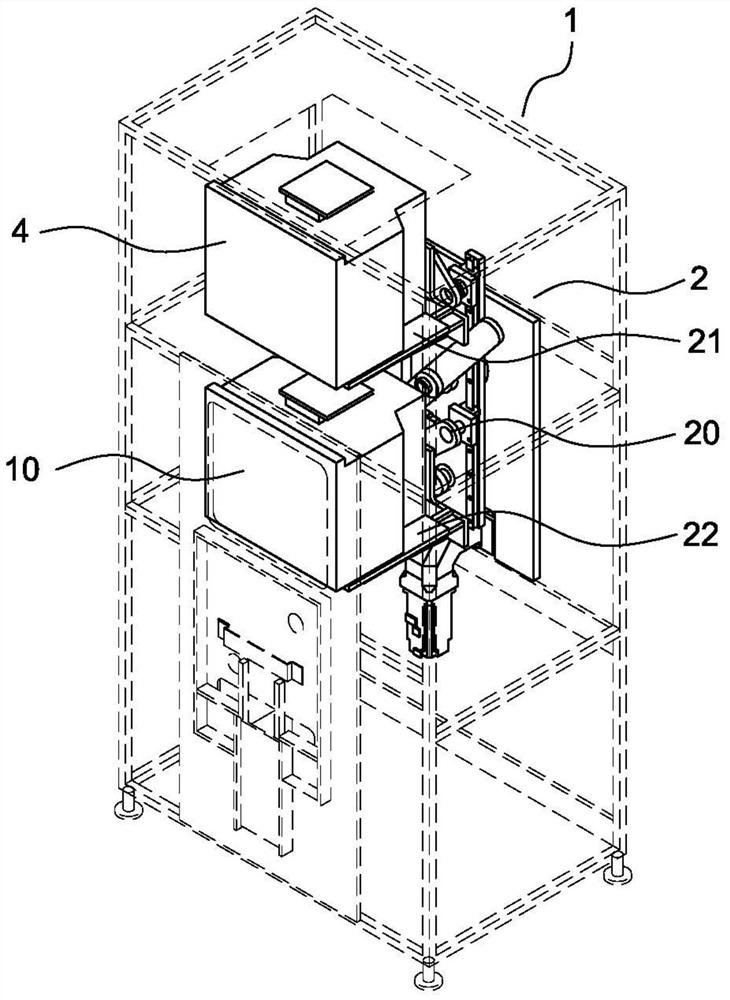

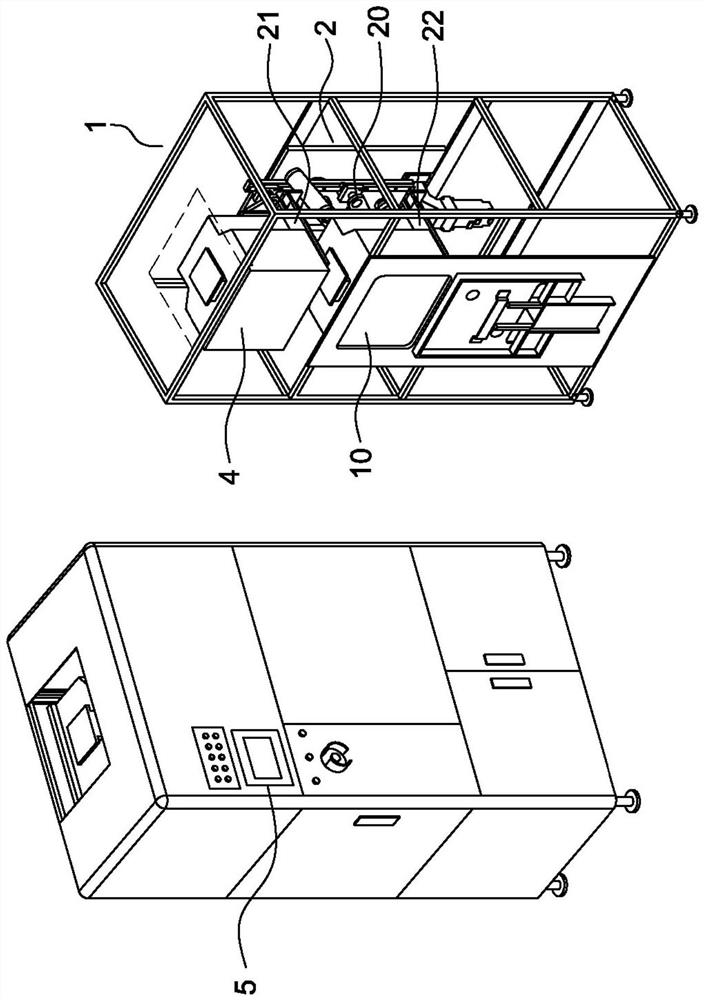

[0022] see figure 2 As shown, the present invention relates to a substrate relay transfer system, which includes a casing 1, and the casing 1 is used to protect internal mechanisms.

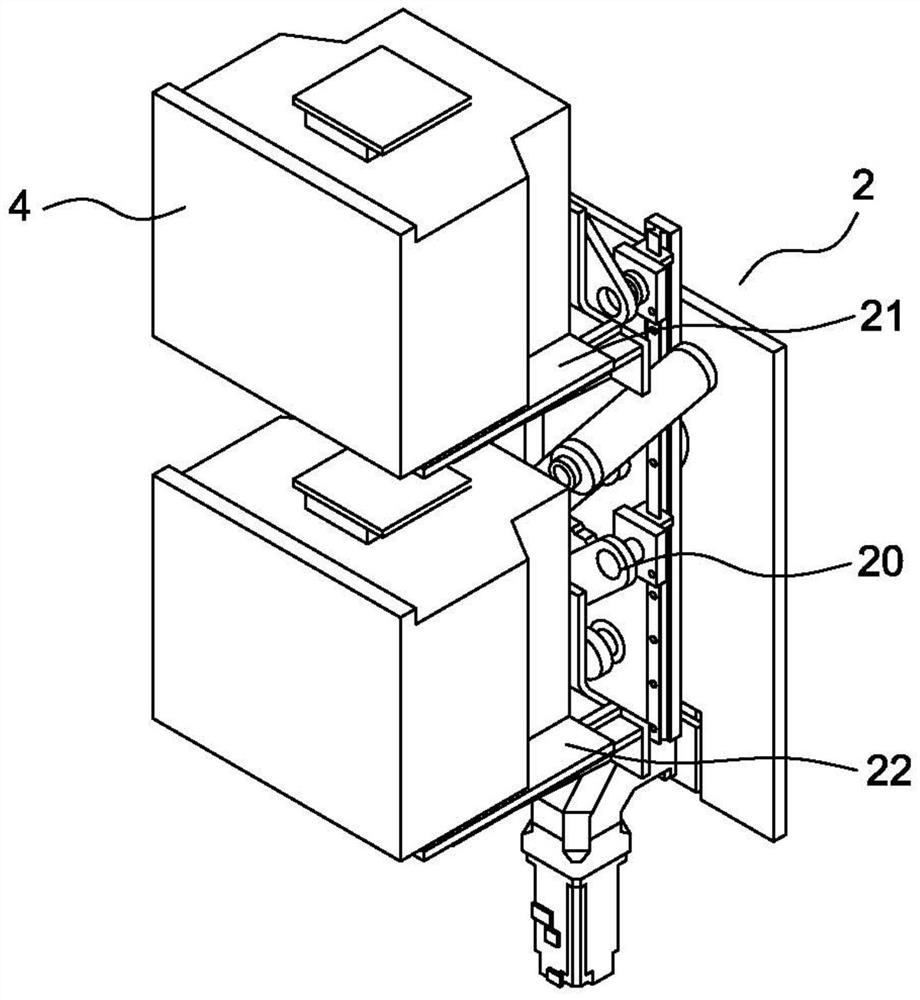

[0023] Cooperate figure 1 As shown, a transfer body 2 is arranged inside the casing 1, and the transfer body 2 can be used for temporarily storing materials while waiting for other conveying equipment to move intermediate products to different process positions.

[0024] The rotating body 2 of the present invention includes a pivot shaft 20, and the pivot shaft 20 extends outwards to a first loading port 21 and a second loading port 22 at two intervals, and there may be even more without being limited to the first loading port port 21 and the second bearer port 22 .

[0025] Cooperate Figure 4 As shown, an external conveying device 3 is further provided, and the external conveying device 3 can regularly place a substrate-type cassette 4 at the position of the first loading port 21; the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com