Novel on-line continuous preparation profile control oil displacement device

A new type of profile control technology, applied in the direction of production fluid, wellbore/well components, machines/engines, etc., can solve the problems of continuous configuration of liquid, low effective content of emulsion polymer, high cost of emulsion polymer, etc., to achieve Equipment intensiveness, reducing equipment weight and floor space, ensuring the effect of high concentration preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below through specific embodiments and accompanying drawings. The embodiments of the present invention are for better understanding of the present invention by those skilled in the art, and do not limit the present invention in any way.

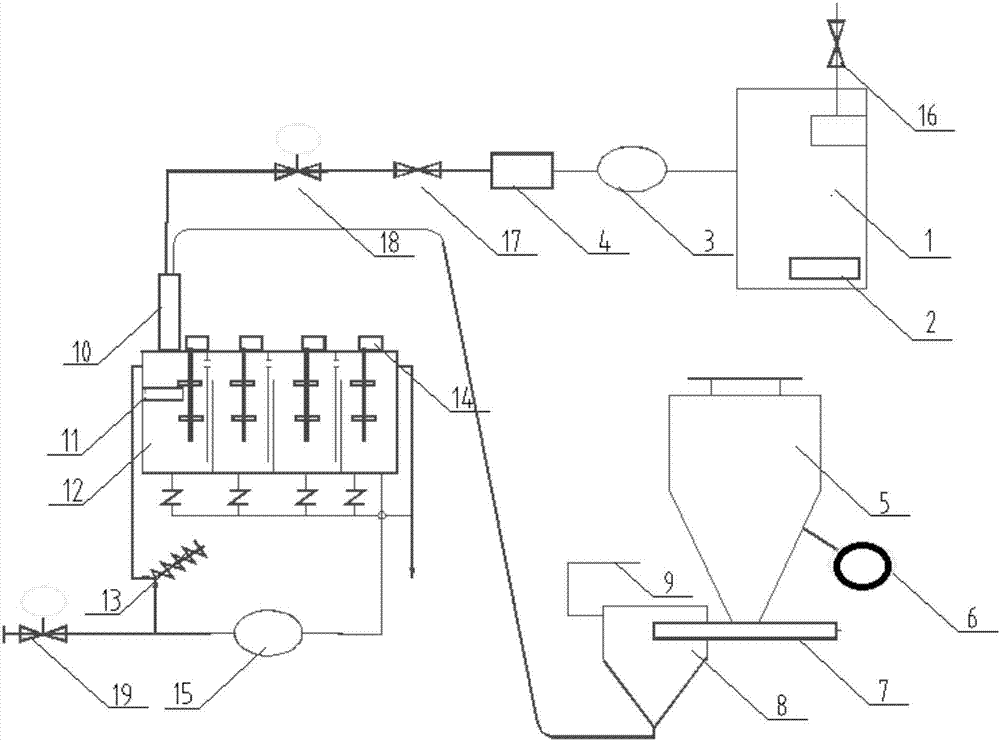

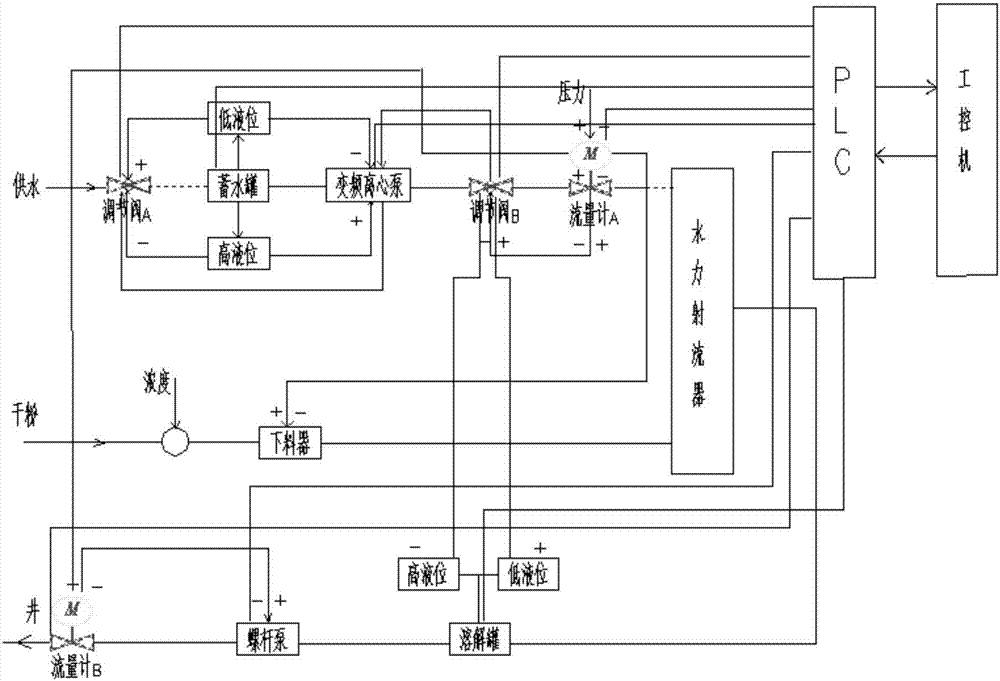

[0025] The present invention is a novel on-line continuous configuration profile control and flooding device, comprising an incoming water decompression system, a dispersed dissolving system, and an automatic control system; the incoming water decompression system, the dispersed dissolving system and the automatic control system are installed in their respective skids.

[0026] Such as figure 1 As shown, the incoming water decompression system includes a high-pressure end and a low-pressure end; the high-pressure end is connected to the water storage tank 1 by a high-pressure water supply line provided with a regulating valve A16, and a water level gauge 2 is provided at the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com