Back-bending gradually-expanding refrigeration wave rotor capable of outputting shaft work

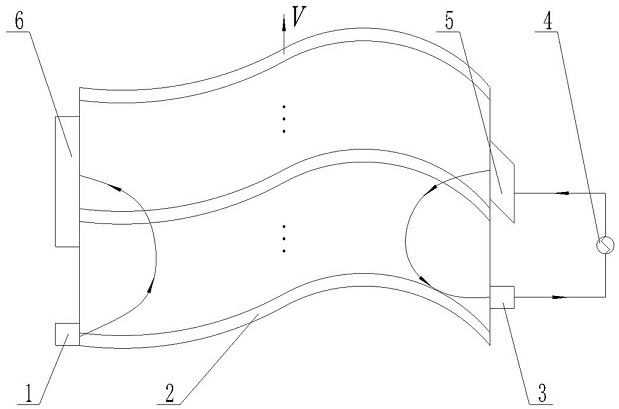

A wave rotor and output shaft technology, which is applied in the field of curved and gradually expanding cold wave rotors, can solve the problems of affecting refrigeration efficiency, limited volume expansion of high-pressure gas, and insufficient expansion work output capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

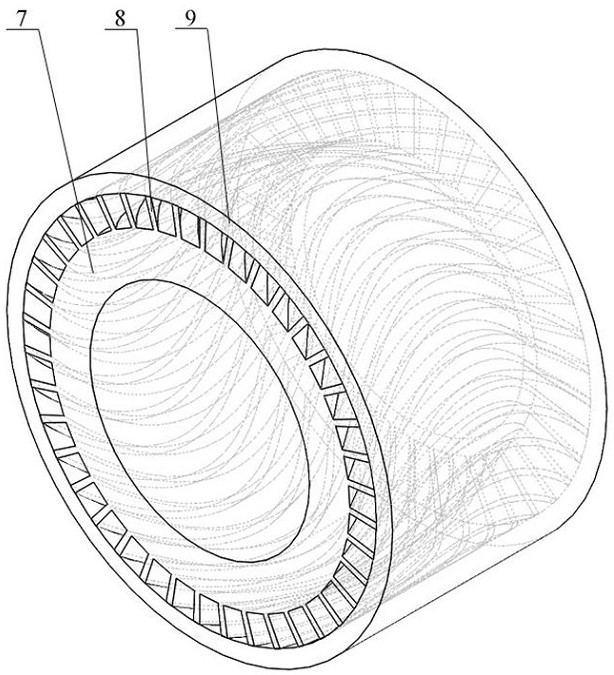

[0020] figure 2 A structural schematic diagram of a curved and gradually expanding axial wave rotor is shown. In the figure, the structure of the curved and gradually expanding axial wave rotor mainly includes an inner shell 7, a partition 8 and an outer shell 9, and the inner shell 7 , The diaphragm 8 and the shell 9 form 40 evenly distributed curved and gradually expanding pressure oscillating tubes in the circumferential direction. The shape of the pressure oscillating tube is a Bezier curve, and the cross-sectional area gradually increases from the inlet to the outlet, and the appearance is curved. Expanded shape. where P 1 P 2 with P 1 P 4 Angle θ 1 for 30 degrees, P 4 P 3 with P 4 P 1 Angle θ 2 is 30 degrees; the cross-sectional area of the rear end is twice that of the front end. The line P connecting the two ends of the axis of the curved and gradually expanding pressure oscillating tube 1 P 4 The included angle with the axial direction of the wave roto...

Embodiment 2

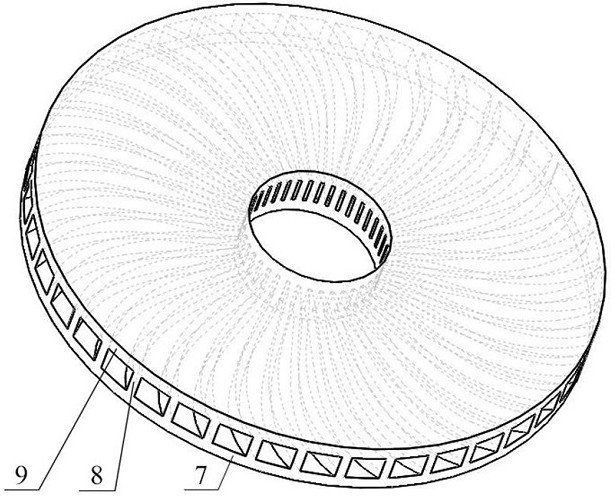

[0022] image 3 A structural schematic diagram of a radial wave rotor with gradually expanding curvature is shown. In the figure, the radial wave rotor structure with gradually expanding back bend mainly includes an inner casing 7, a partition 8 and an outer casing 9, and the inner casing 7, the partition 8 and the outer casing 9 form 40 uniformly distributed curved and gradually expanding rotors in the circumferential direction. Expansion pressure oscillating tube, the shape of the pressure oscillating tube is a Bezier curve, the cross-sectional area gradually increases from the inlet to the outlet, and the appearance presents a curved and expanding shape. Among them, P 1 P 2 with P 1 P 4 Angle θ 1 is 0 degrees, P4 P 3 with P 4 P 1 Angle θ 2 is 30 degrees; the cross-sectional area of the rear end is 10 times that of the front end. The line P connecting the two ends of the axis of the curved and gradually expanding pressure oscillating tube 1 P 4 with P 1 The an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com