Patents

Literature

71results about How to "Perfect operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Task scheduling method and system

ActiveCN102981904APerfect task scheduling systemImprove scheduling efficiencyProgram initiation/switchingProgram planningResult list

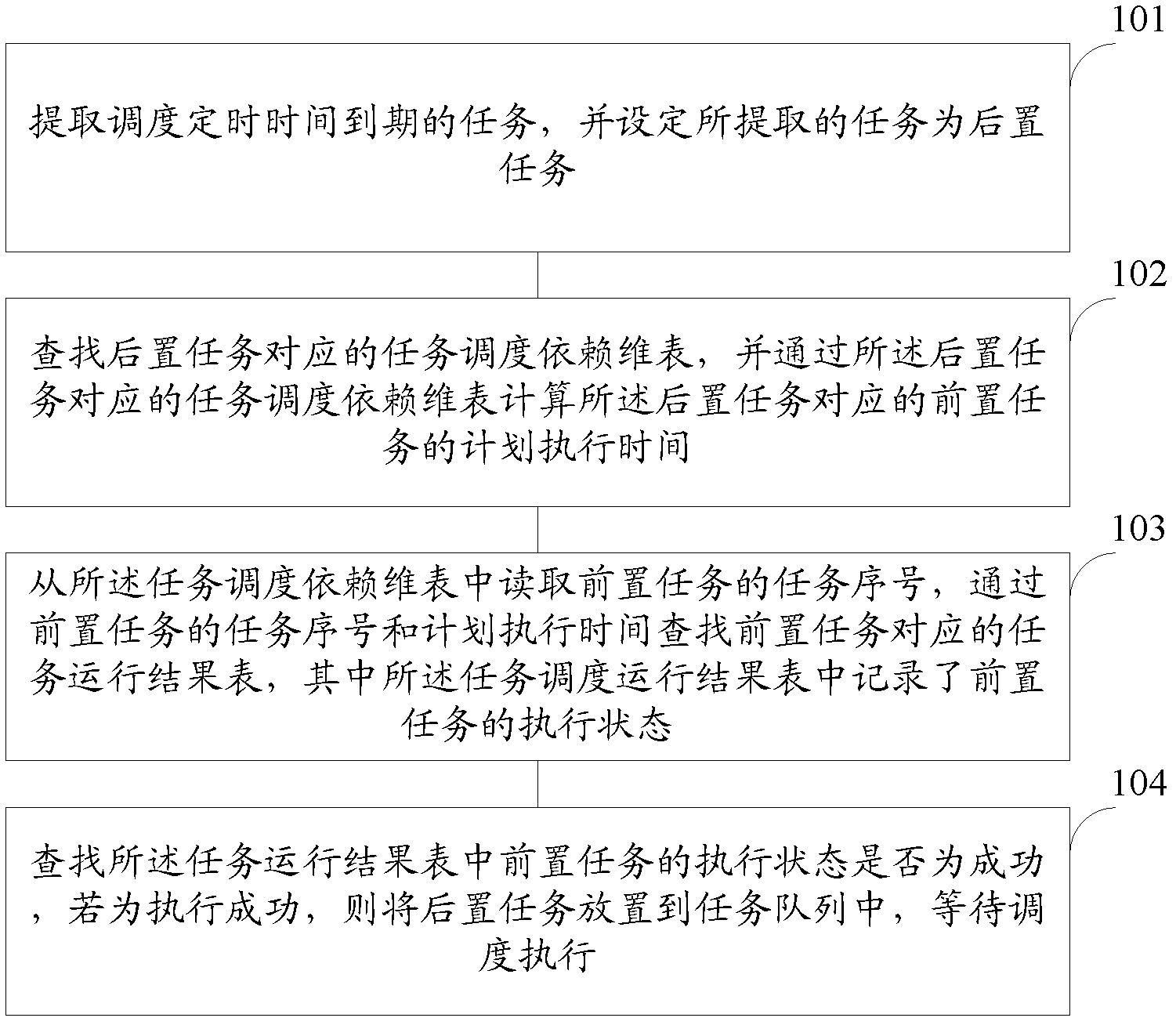

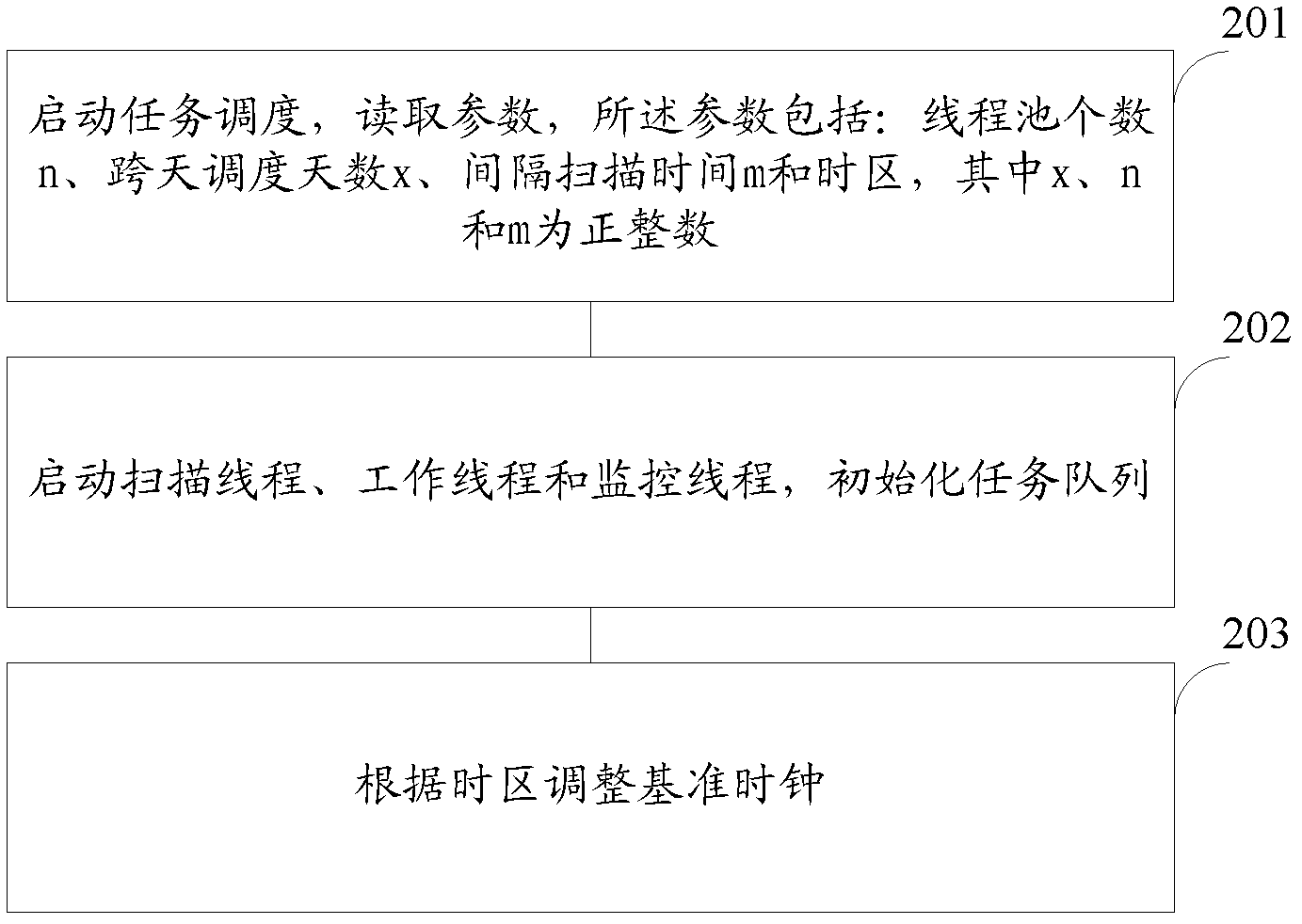

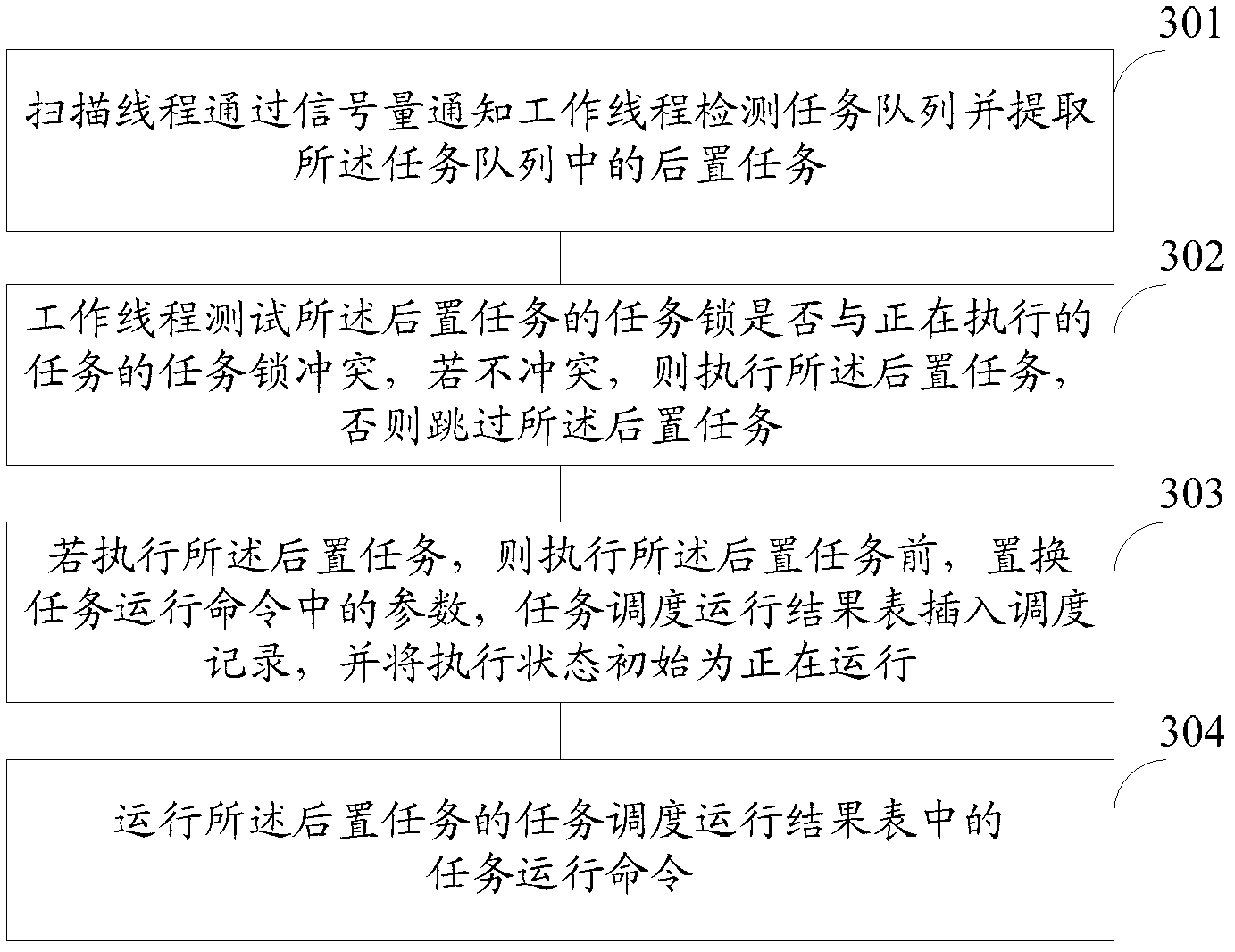

The invention provides a task scheduling method and a system and aims at solving the problem of limitation of a system in task scheduling. The task scheduling method includes the following steps. Firstly, a task which is mature based on a set time are selected and designated as a postposed task. Plan performing time of a preposed task is calculated through a task scheduling reliance dimension table of the postposed task and a task sequence number of the preposed task is read from the task scheduling reliance dimension table. A performing state of the preposed task in a task scheduling operation result list is found out according to the task sequence number and the plan performing time of the preposed task. If performing is successful, the postposed task is lined up in a task queue and waits for scheduling performing. Under all circumstances, as long as a postposed task is confirmed, a preposed task can be found out and the postposed task can be performed as the preposed task is successfully performed so that the task scheduling system is modified. Scheduling time is shortened, scheduling efficiency is improved and fault rate is reduced.

Owner:ALIBABA GRP HLDG LTD

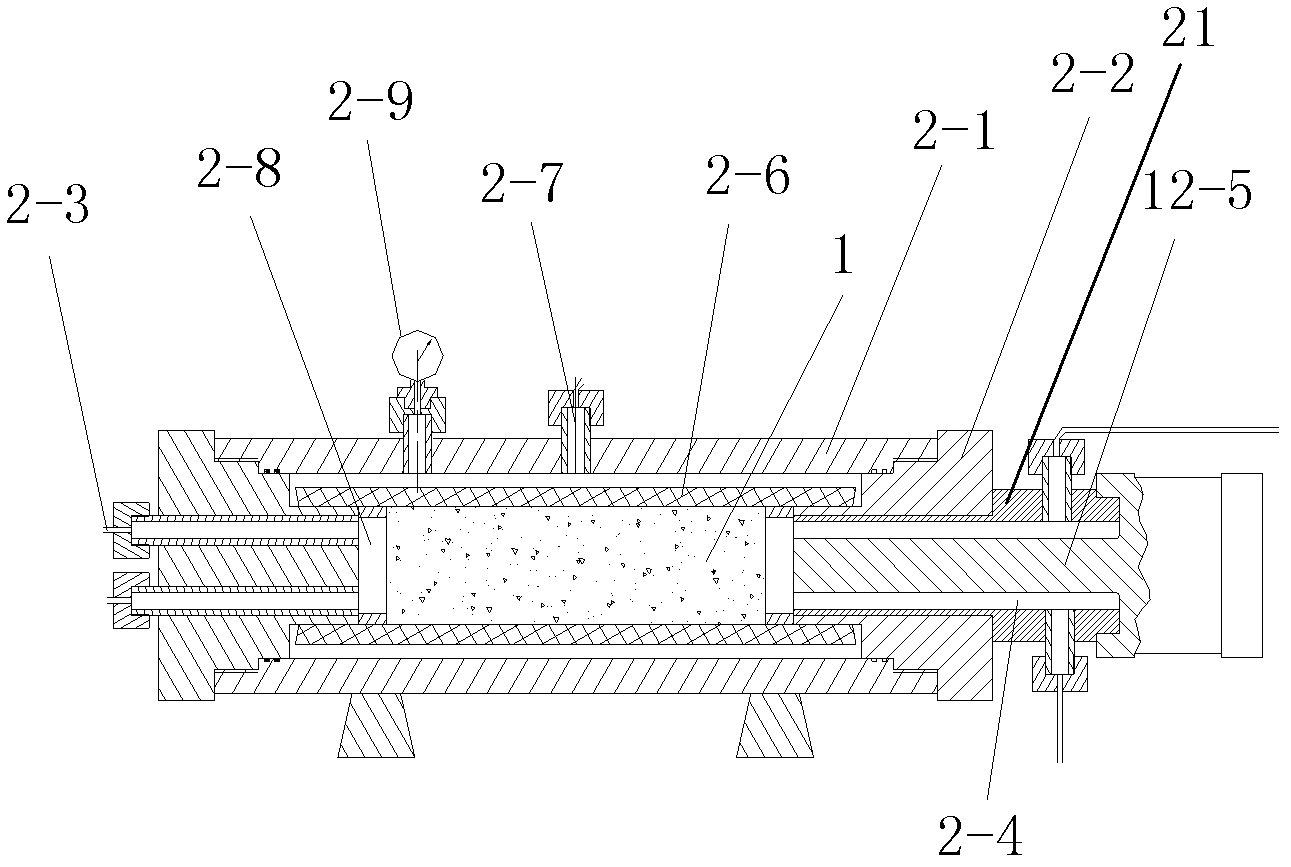

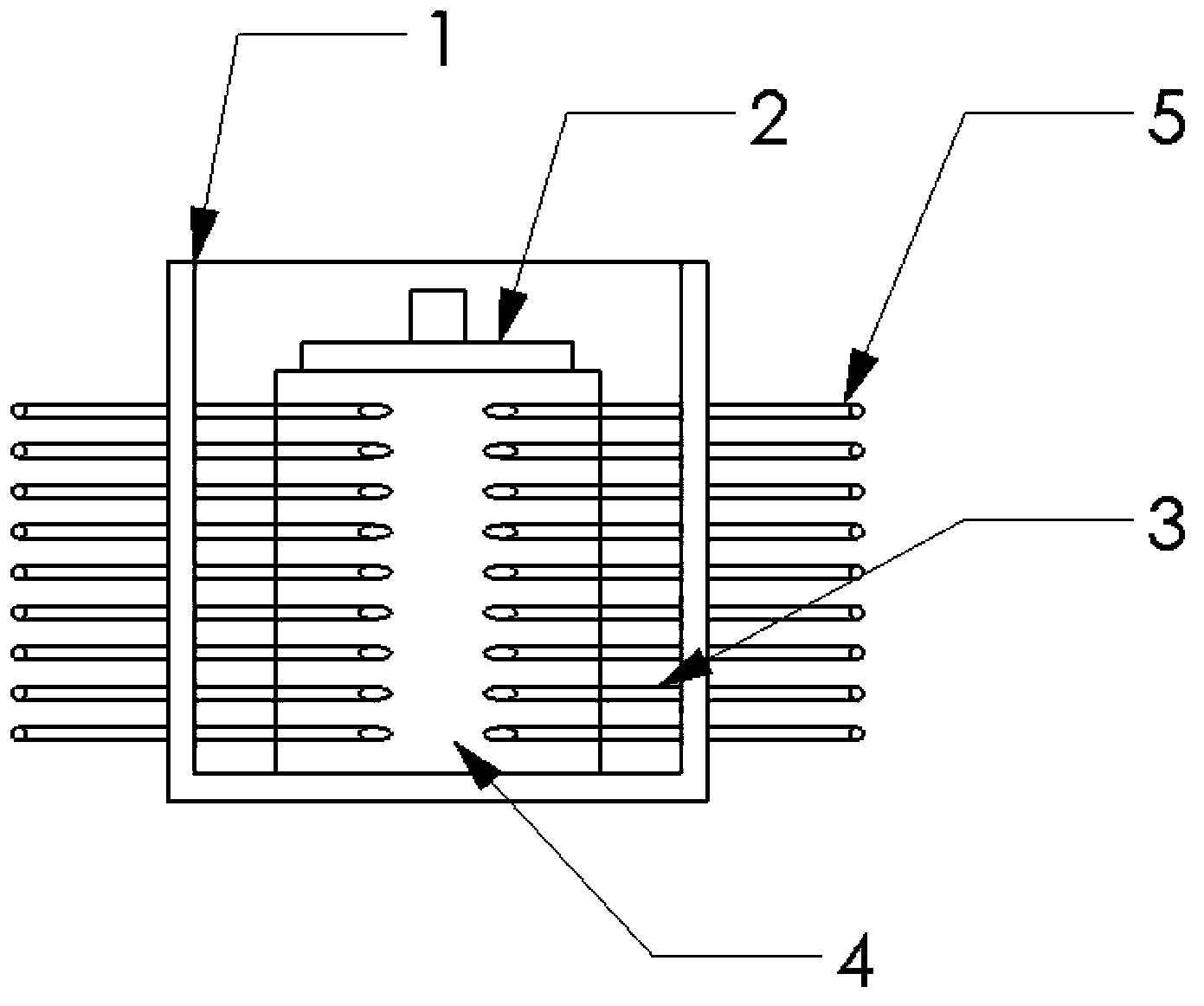

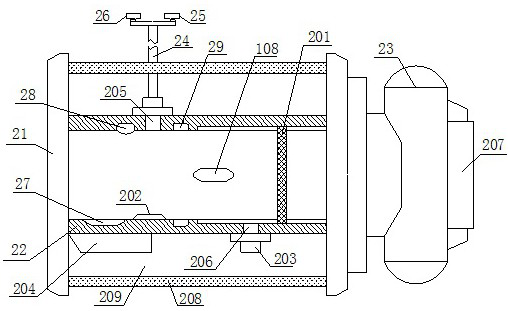

Experimental device and experimental method for hydrothermal catalytic pyrolysis in heavy oil layer by means of ultrasonic wave

ActiveCN102587874AComplete efficientlyFinish quicklySurveyFluid removalCatalytic pyrolysisExperimental methods

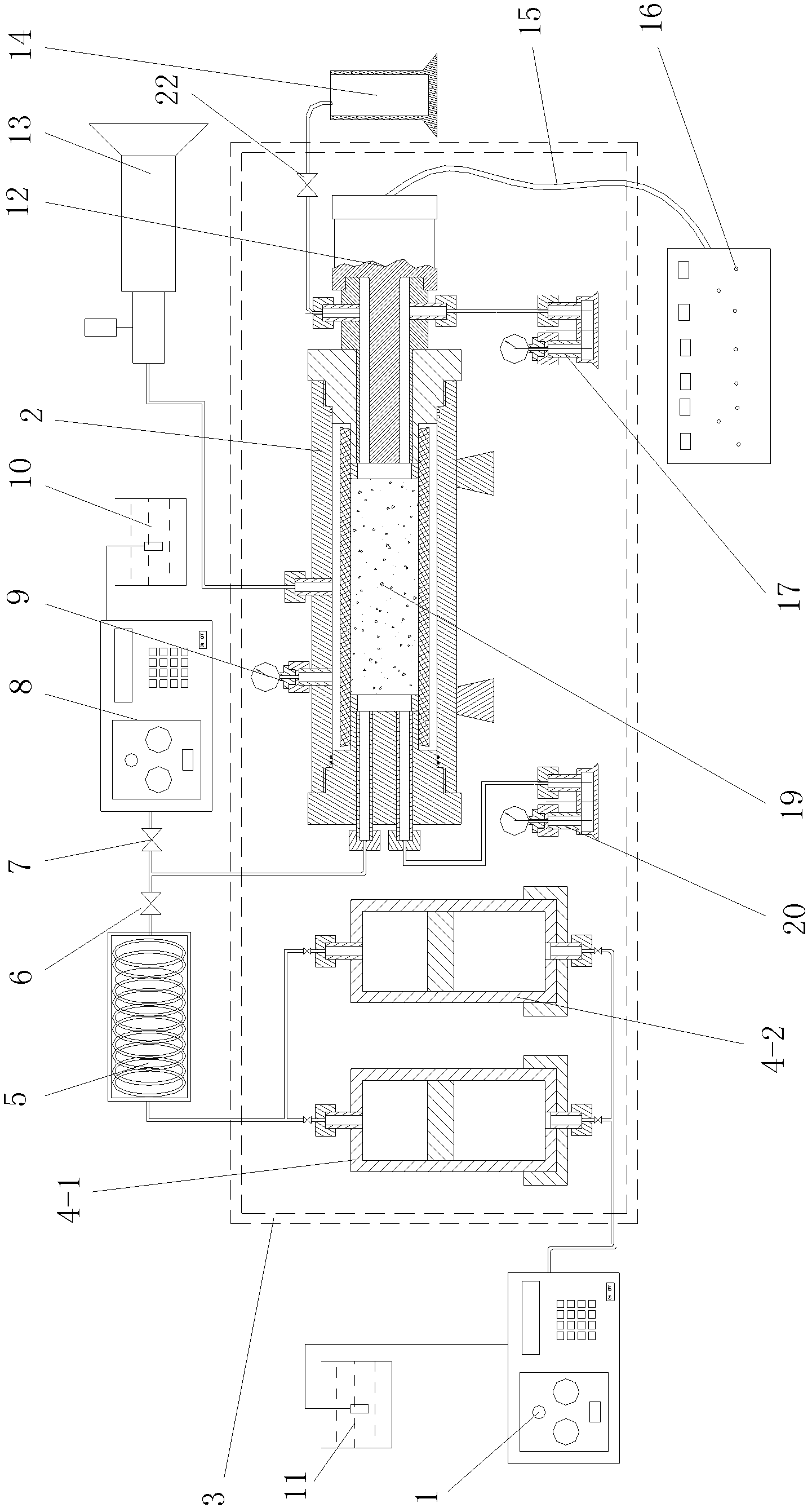

The invention discloses an experimental device and an experimental method for hydrothermal catalytic pyrolysis in a heavy oil layer by means of ultrasonic wave, wherein the experimental device comprises a core holder, a ring pressure supply device, a water storage tank, an oil storage tank, an ultrasonic transducer, an ultrasonic generator, a liquid container, a catalyst, a reaction assistant storage device and a constant temperature box; a steam generator is arranged on a water pipe between the water storage tank and the core holder; the experimental method comprises the following steps: 1, pre-treating tested core; 2, performing water-flooding experiment and measuring original water-flooding permeability of the tested core; 3, performing oil-flooding experiment and measuring original oil saturation degree of the tested core; 4, performing hydrothermal pyrolysis simulation experiment; and 5, preparing data. The experimental device and the experimental method have rational design. The device is convenient to install and distribute, has complete function, is convenient to use and operate and has good usage effect. The problems that the prior normal steam thermal driving heavy oil has easily-rebounding viscosity and short measure validity period, and the normal hydrothermal catalytic pyrolysis technology has limited effect during the heavy oil recovery process can be solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

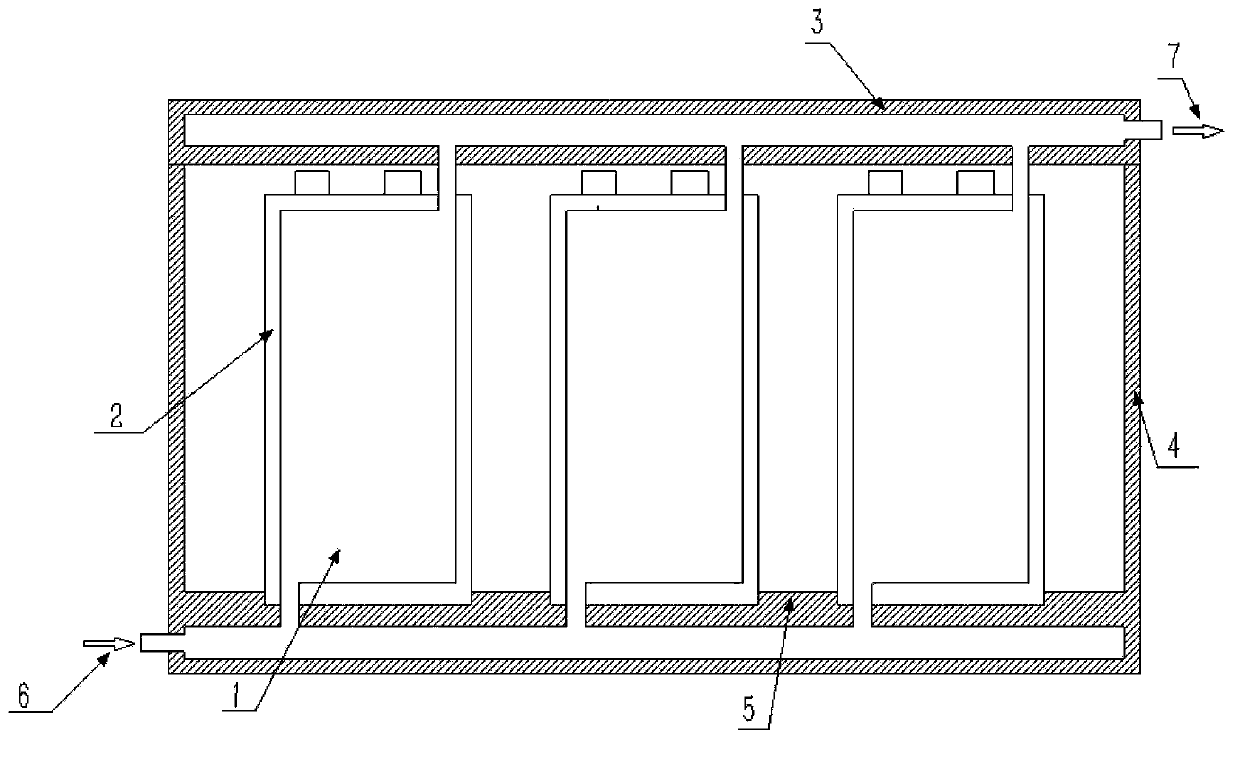

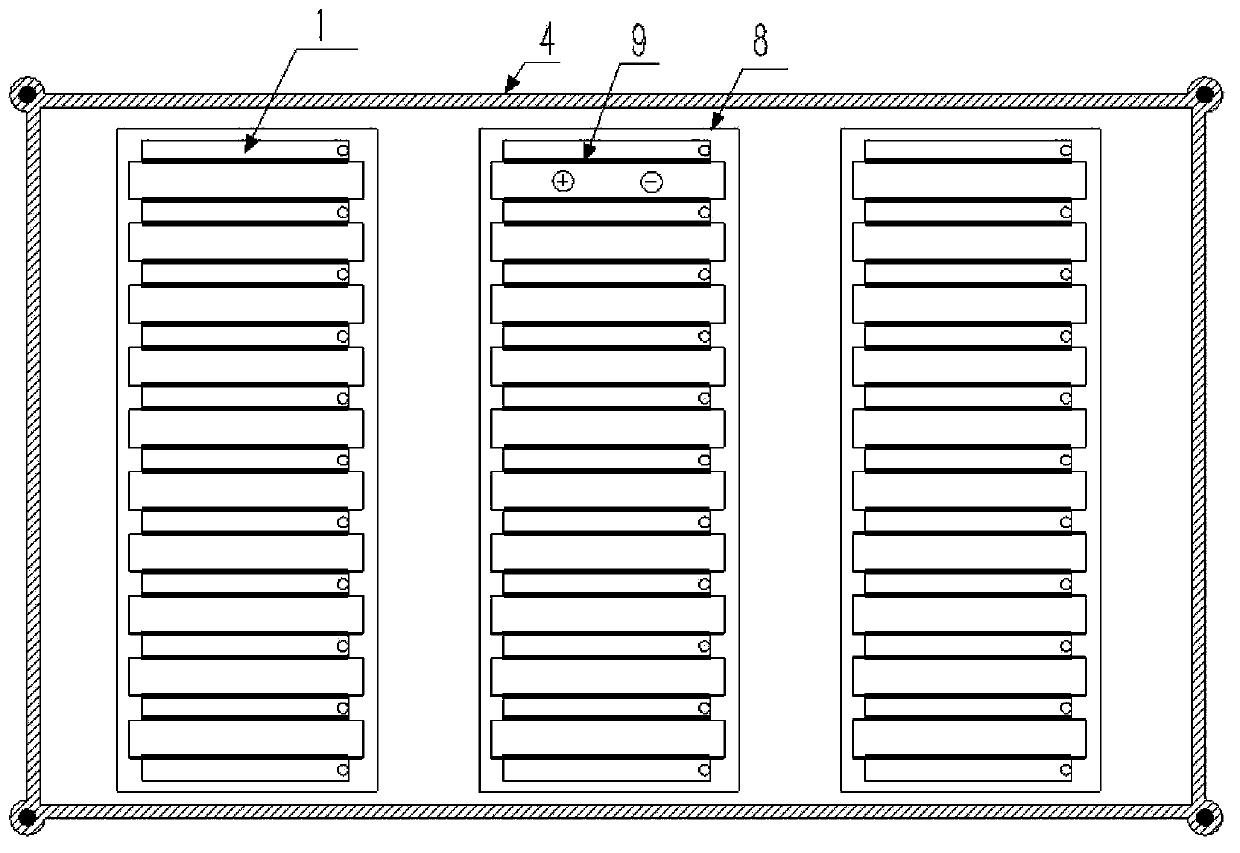

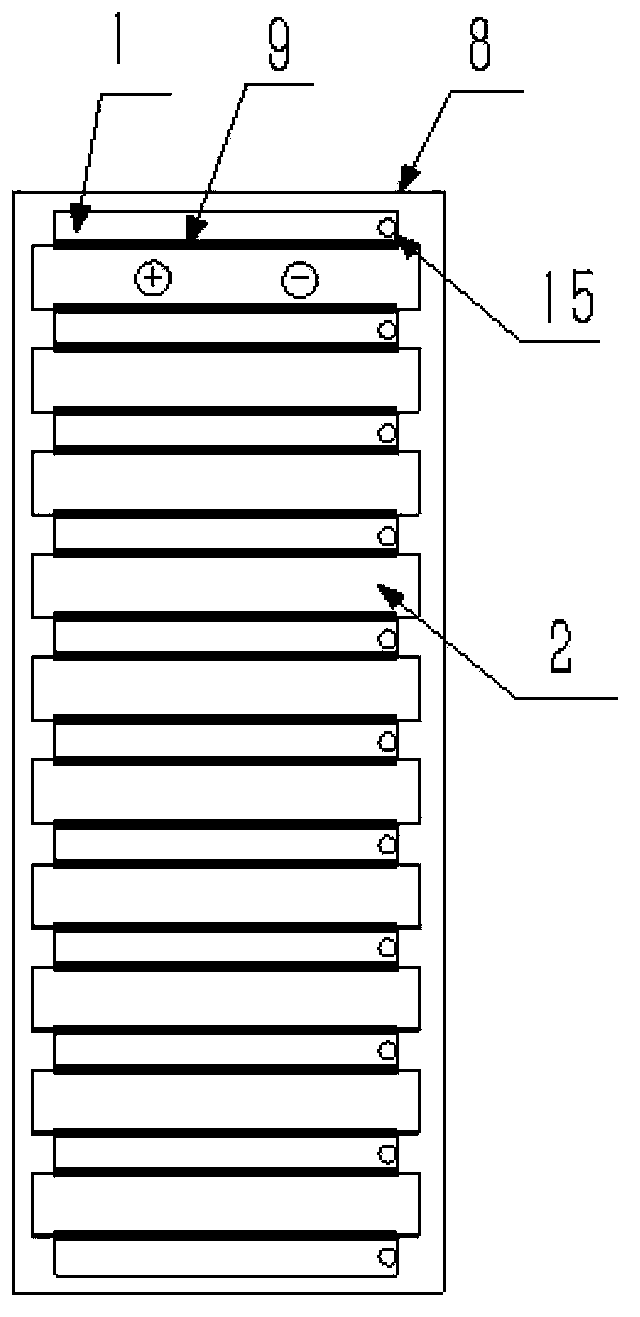

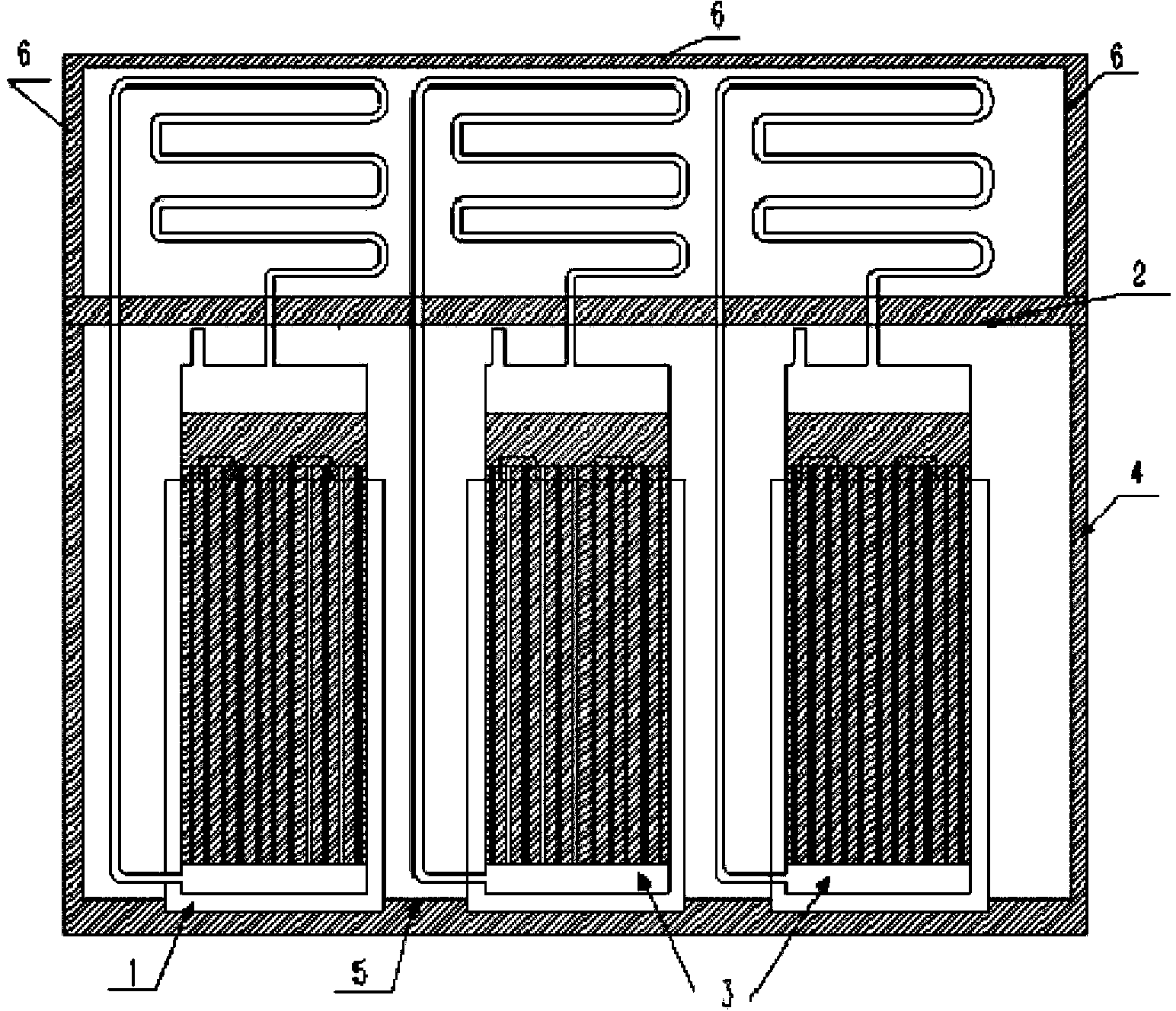

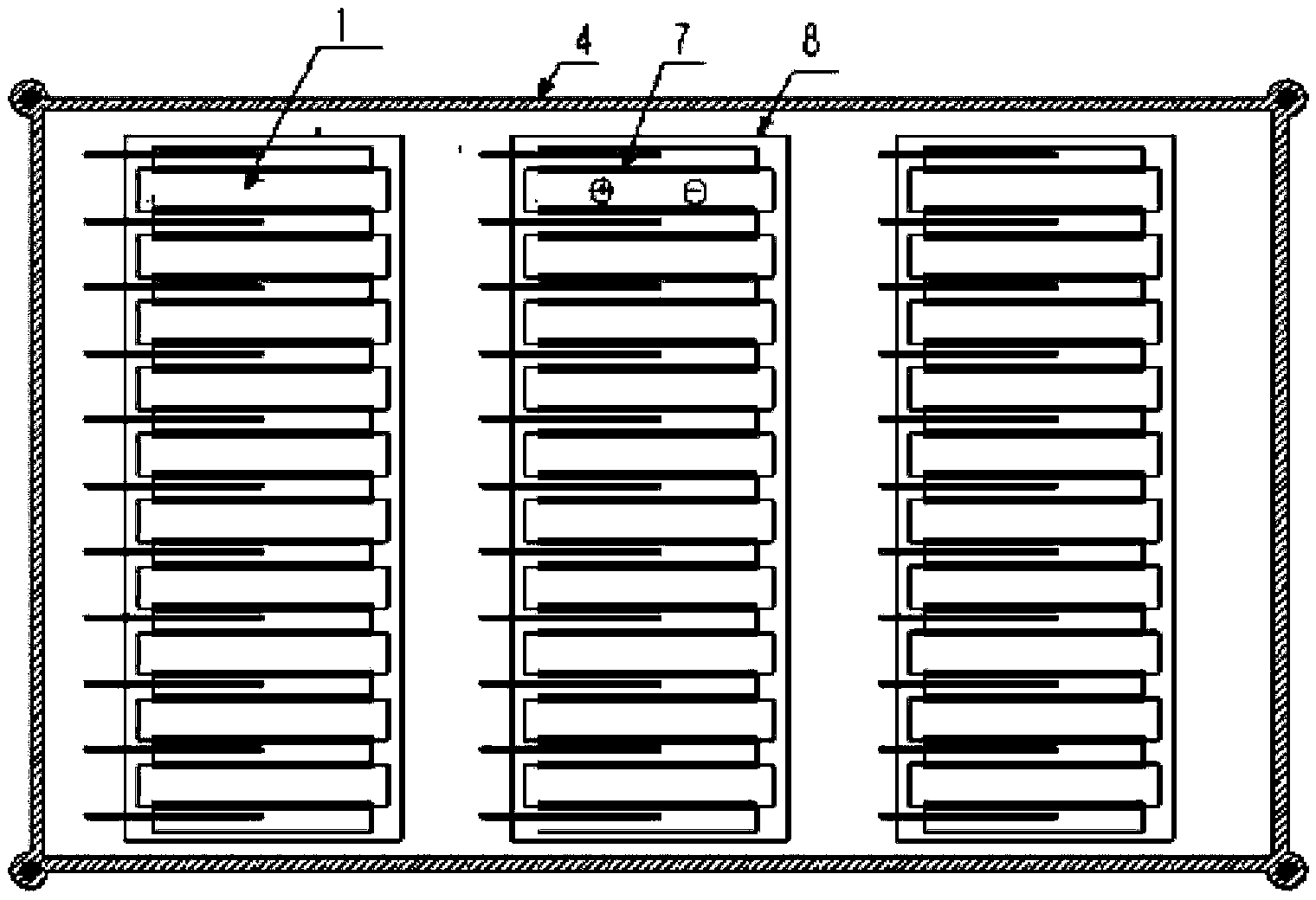

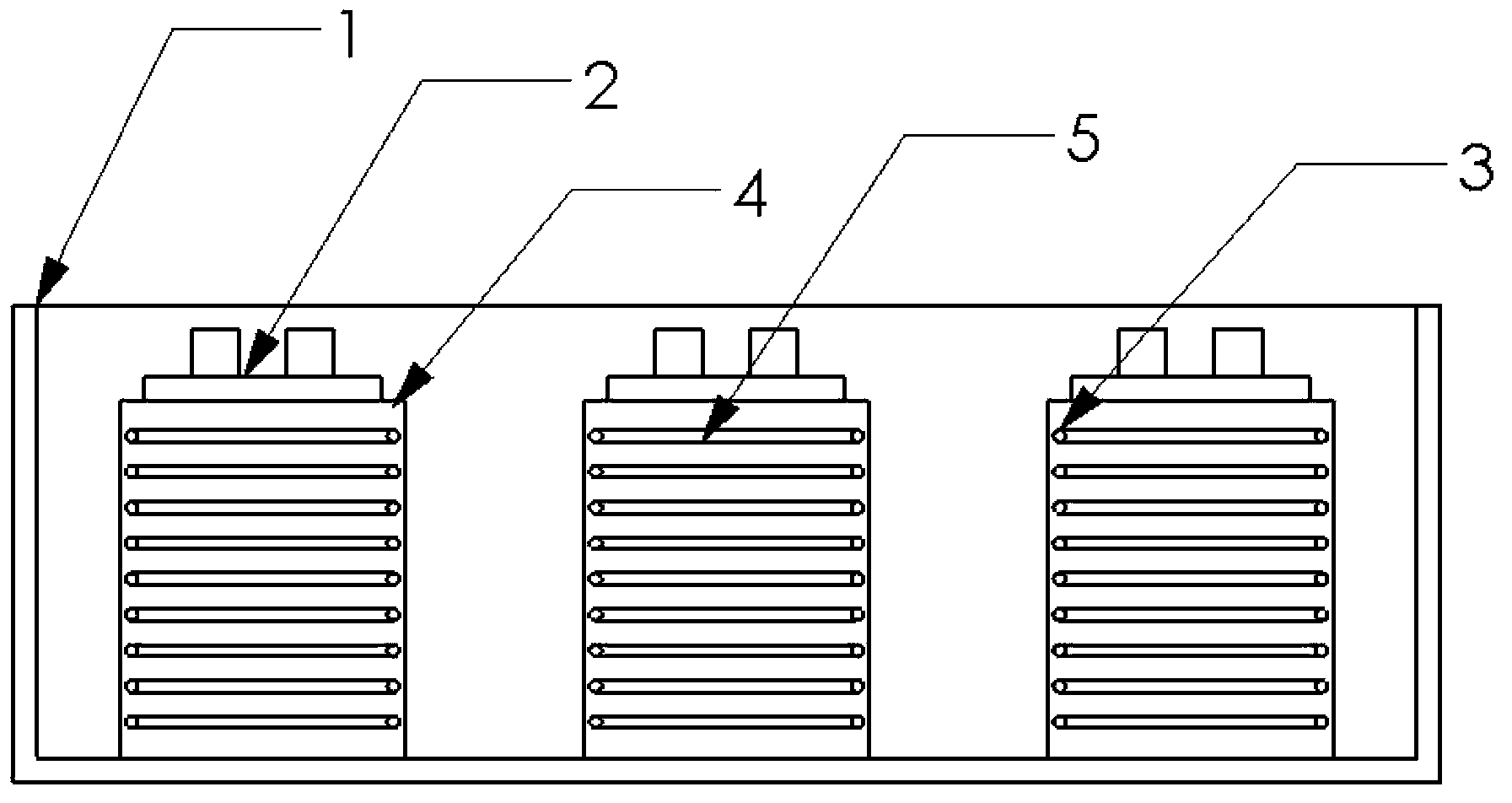

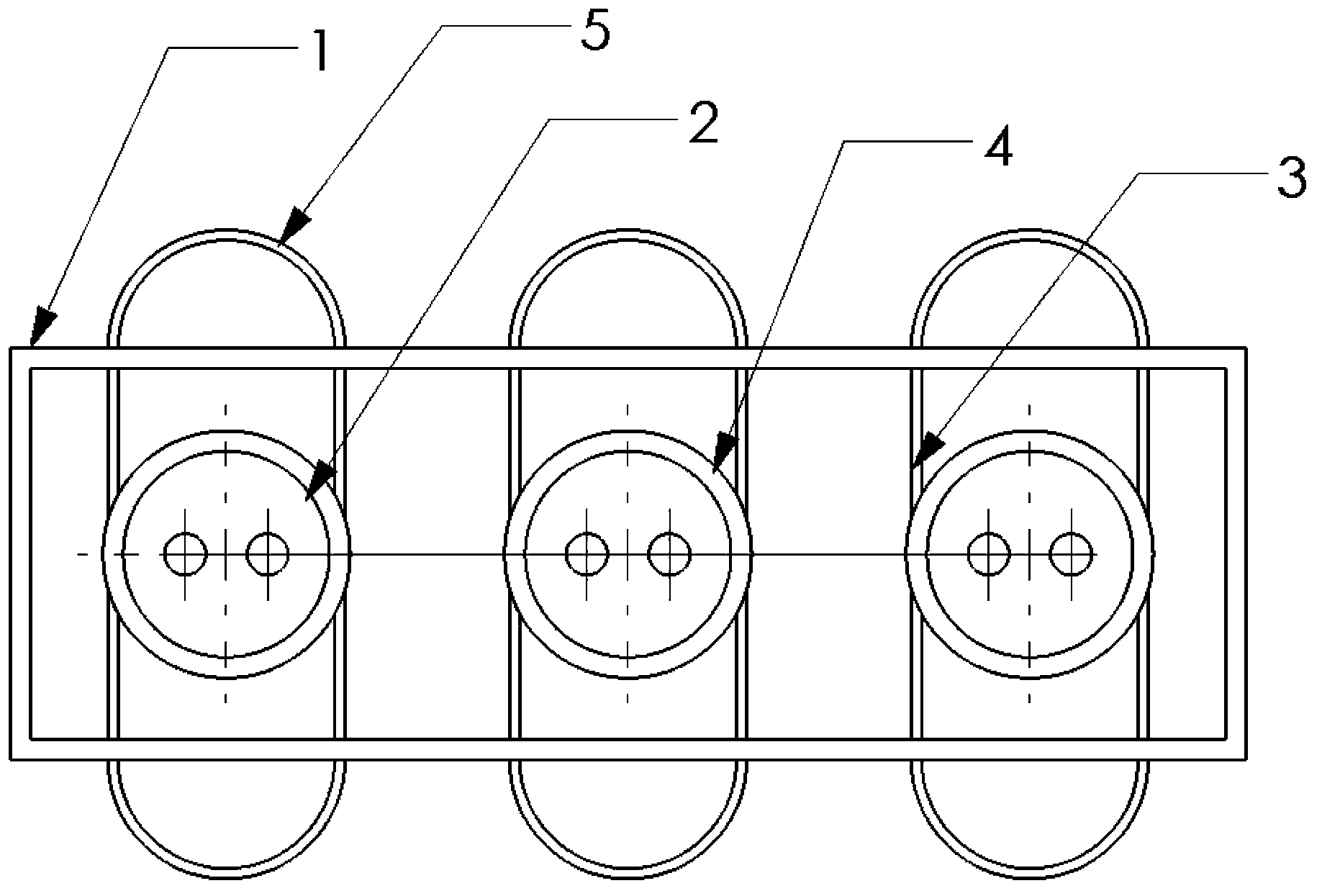

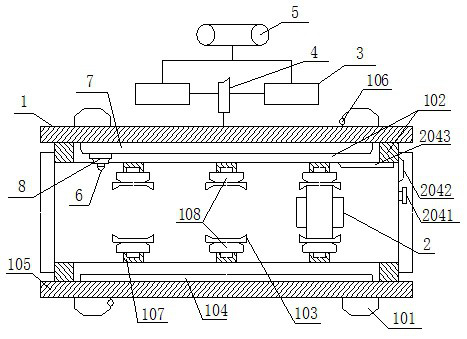

Power battery heat management system based on flat plate heat pipes

ActiveCN103401044AImprove cooling effectImprove cooling efficiencySecondary cellsPower batteryHeat management

The invention discloses a power battery heat management system based on flat plate heat pipes. The power battery heat management system comprises a module box body and a module box body top cover, wherein at least two individual battery group shells are placed in the module box body; at least two battery module groups formed by connecting individual batteries in series or in parallel are placed in each individual battery group shell; a flat plate heat pipe with a cooling system is arranged on the surface of each individual battery and is attached to the surface of the corresponding individual battery; cooling water circulates in the flat plate heat pipes. The power battery heat management system has the advantages of high efficiency, simple structure, stable and reliable operation, functional diversity and the like, is used for performing efficient heat management, including heat dissipation, heating, waste heat recycling and the like, on a power battery under various charge-discharge conditions, is applicable to various types of electric equipment driven by power batteries, and has wide market prospect.

Owner:SANMENXIA SUDA TRANSPORTATION ENERGY SAVING TECH

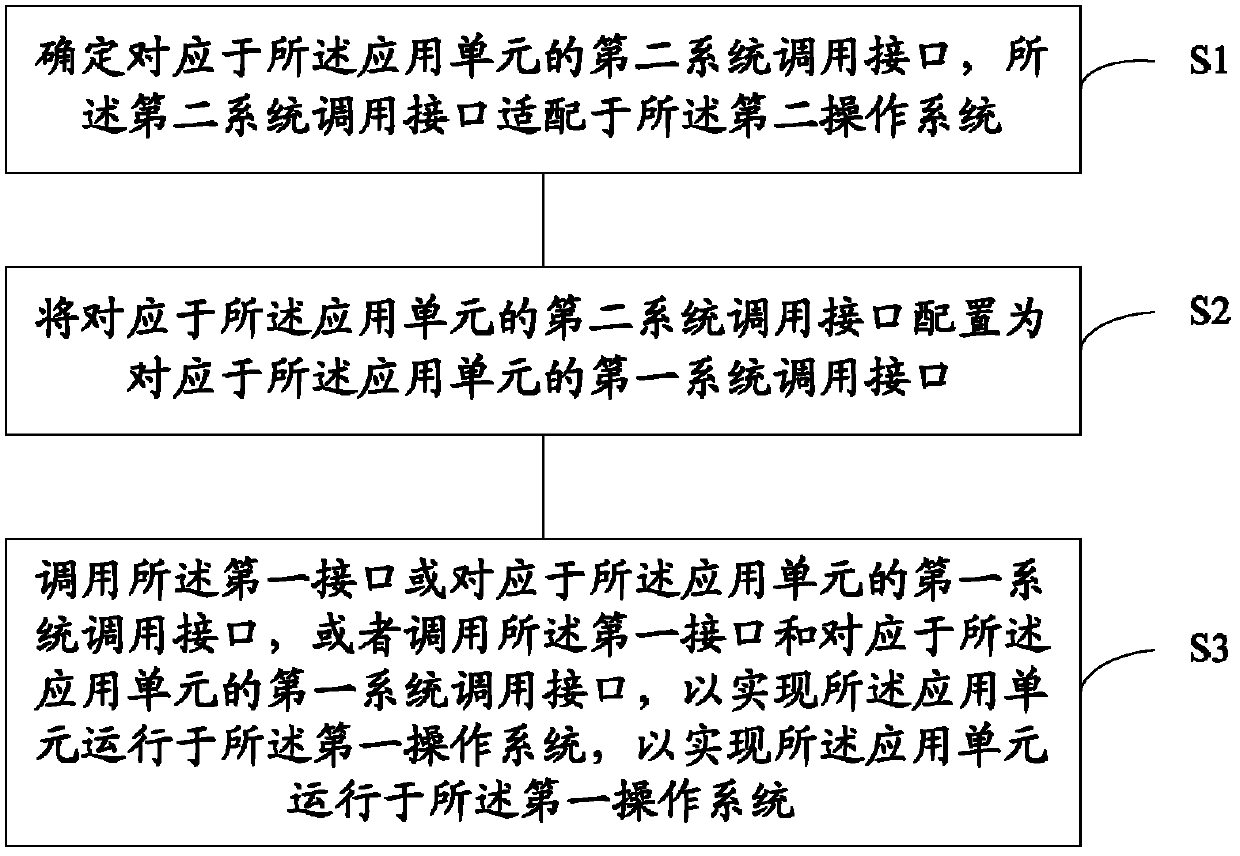

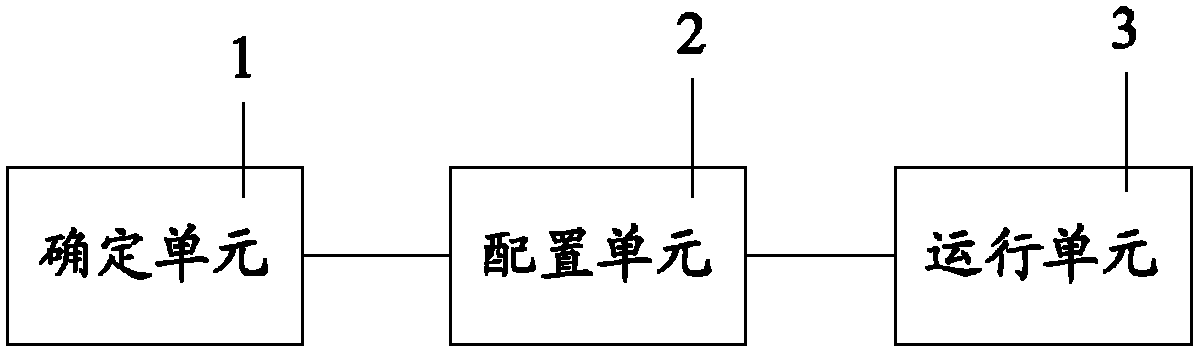

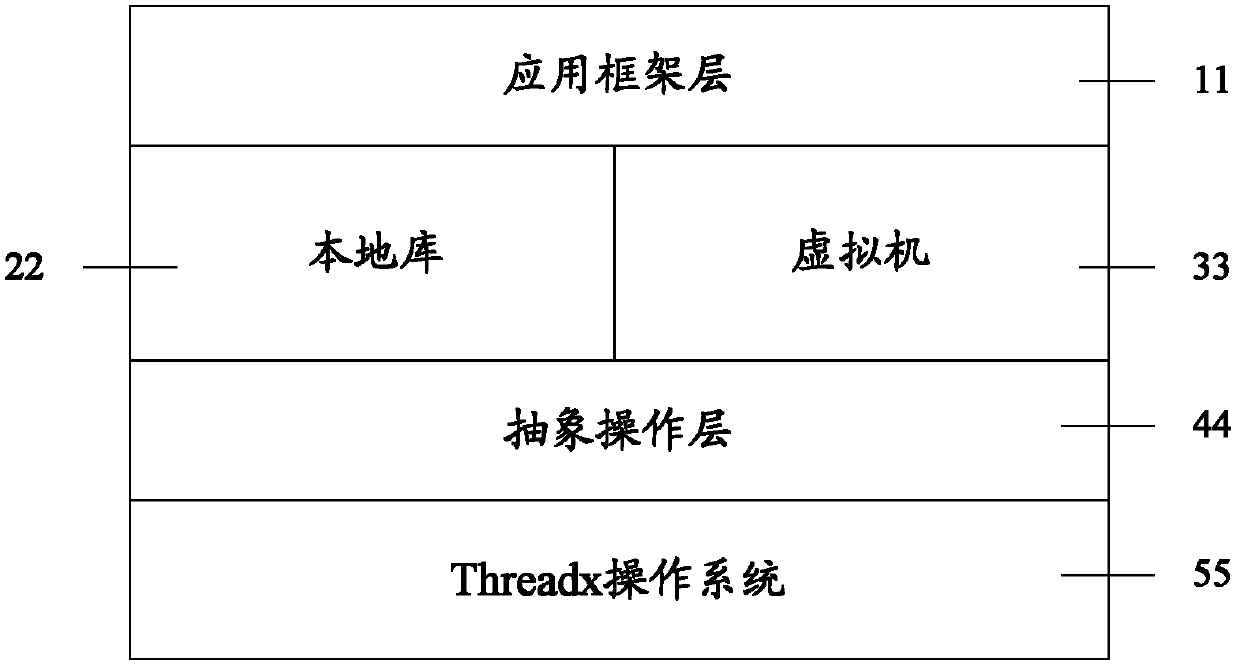

Terminal, device and method for terminal application running and application program running method

ActiveCN103377079AApp runs richReduce development costsProgram initiation/switchingOperational systemSoftware engineering

Disclosed are a terminal, a device and a method for terminal application running and an application program running method. The method for terminal application running includes determining a second system calling interface corresponding to an application unit and matched with a second operation system, configuring the second system calling interface corresponding to the application unit into a first system calling interface corresponding to the application unit, calling a first interface or the first system calling interface corresponding to the application unit, or calling both the first interface and the first system calling interface corresponding to the application unit so as to realize running of the application unit in a first operation system. According to the technical scheme, applications running in the real-time operation systems are enriched while development cost and development difficulty are reduced.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

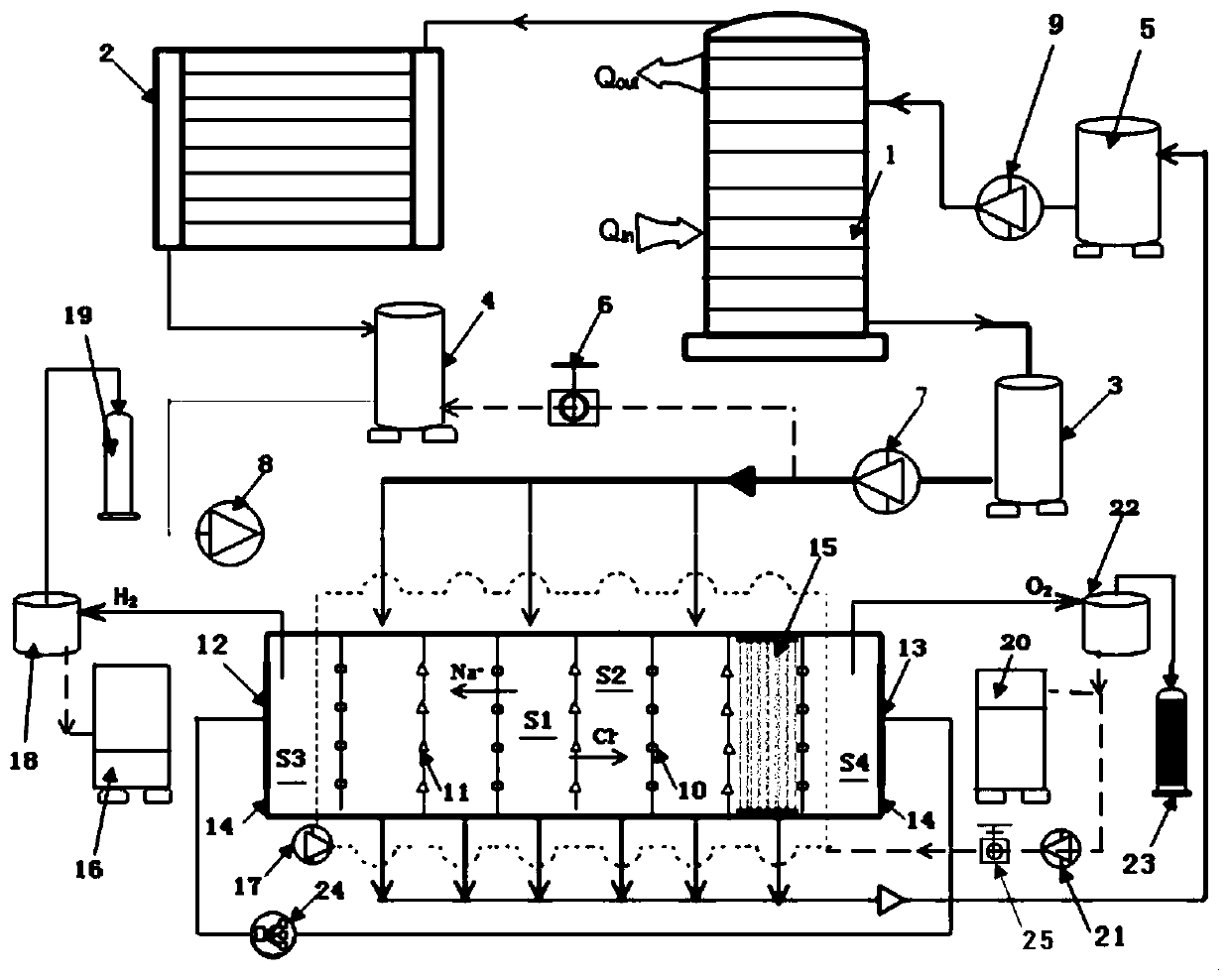

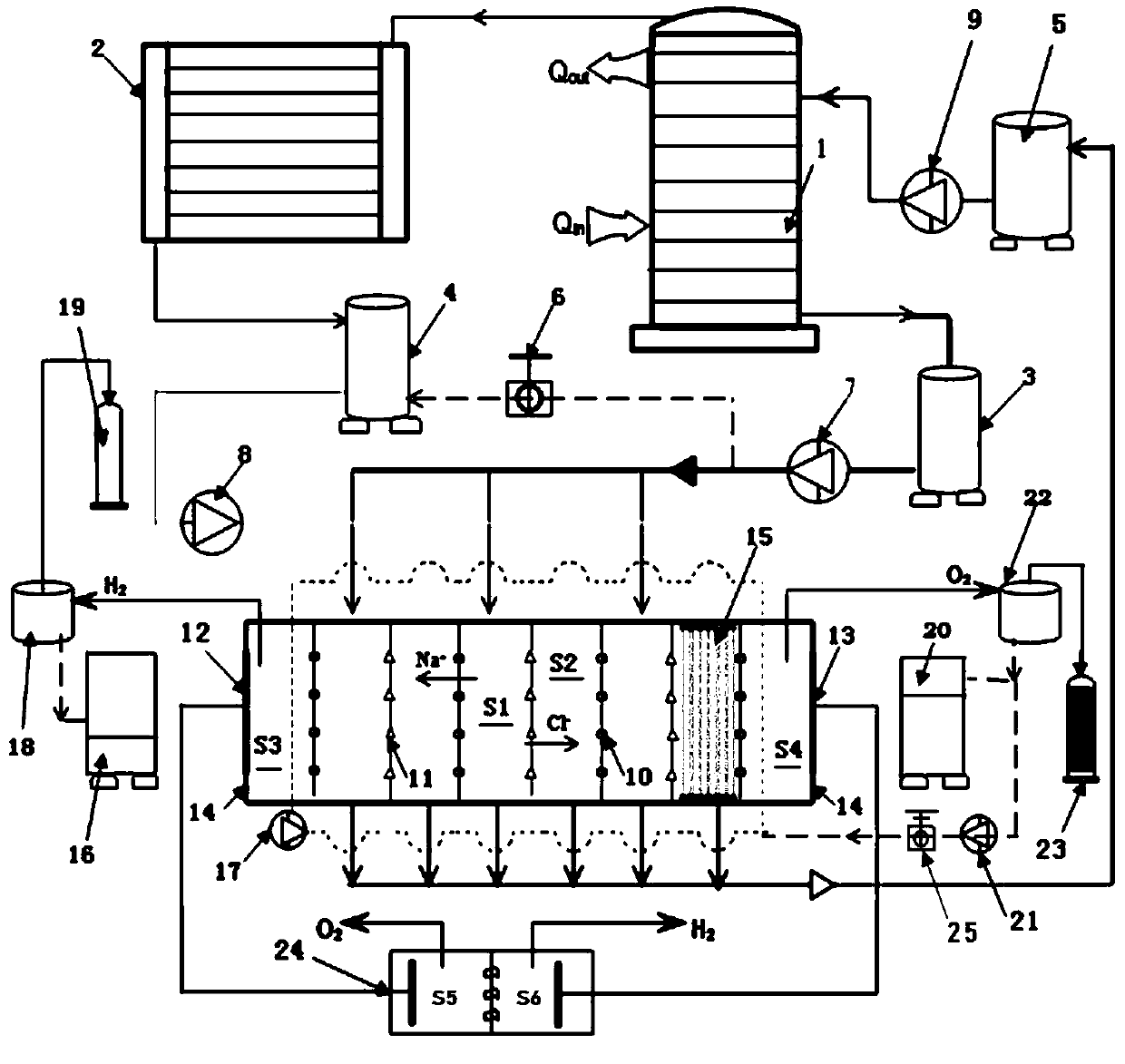

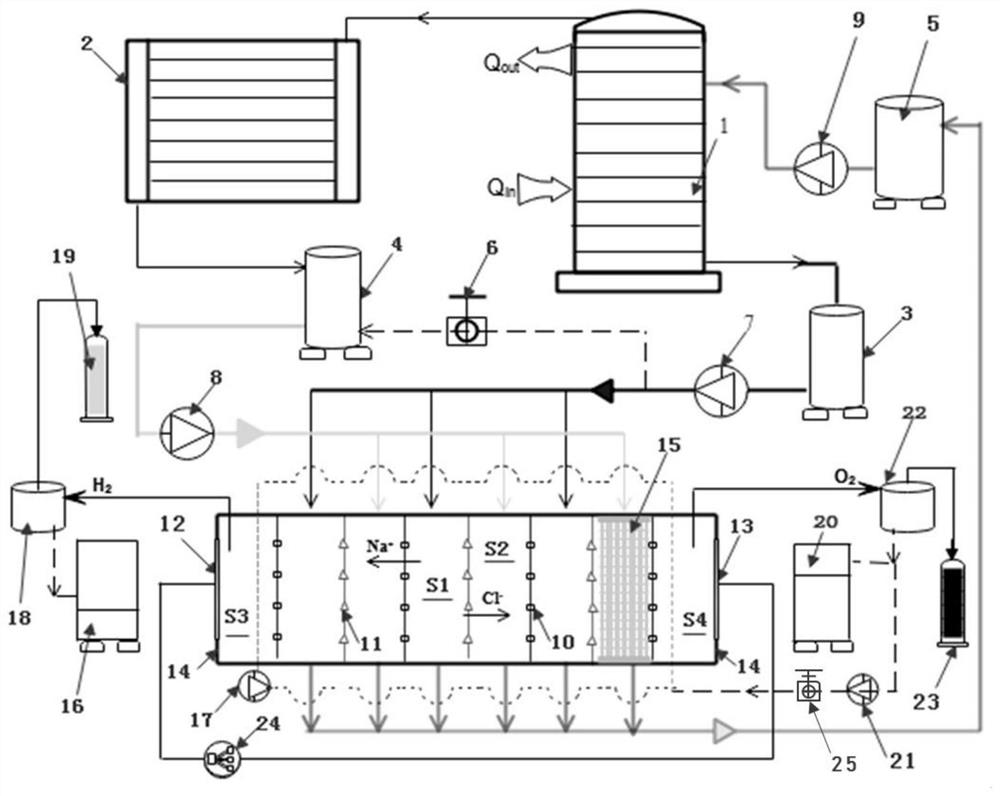

Low-grade heat energy driven electrode liquid self-circulating hydrogen production method

The invention discloses a low-grade heat energy driven electrode liquid self-circulating hydrogen production method, and belongs to the technical field of new energy. Low-grade heat energy serves as driving force, and continuous hydrogen production is achieved through the concentration change of a working solution. The low-grade heat energy driven electrode liquid self-circulating hydrogen production method comprises the steps: firstly, the low-grade heat energy is converted into chemical potential energy of the working solution through a low-temperature multi-effect distillation method; thenthe chemical potential energy is converted into the potential difference between two electrodes of a cell stack based on the reverse electrodialysis principle; and then hydrogen and oxygen are produced through a reduction reaction or an oxidation reaction occurring on the hydrogen production electrode and the oxygen production electrode in the same electrode liquid. The waste solution losing partof the chemical potential energy is recycled after flowing out from the cell stack, and then regenerated under driving of the low-grade heat energy; the electrode liquid is self-circulated between a hydrogen production electrode liquid cavity and an oxygen production electrode liquid cavity in the two ends of the cell stack; the low-grade heat energy can be continuously, efficiently and steadily converted to be utilized; a hydrogen production system does not need to operate at the high temperature and high pressure, mechanical moving parts are few, and capacity configuration is flexible; and the single-type electrode liquid is adopted and is in an electrolyte closed cycle, and long-time operation can be achieved only by supplying deionized water.

Owner:DALIAN UNIV OF TECH

Power battery thermal management system based on flat loop heat pipes

InactiveCN103367837AImprove cooling effectImprove cooling efficiencySecondary cellsLiquid lineEvaporation

The invention discloses a power battery thermal management system based on flat loop heat pipes. The system is characterized in that: it includes a module upper box, a module lower box and a middle partition board. The middle partition board is arranged between the module upper box and the module lower box, the module lower box is internally provided with at least two battery pack monomer shells, at least over two battery module groups composed of battery monomers connected in series or in parallel are placed in each battery pack monomer shell, wherein each battery monomer is provided with a flat loop heat pipe on the surface, the flat loop heat pipe falls into an evaporation section, a liquid storage chamber, a gas line, a liquid line and a condensation section, the evaporation section is disposed on the battery monomer surface, the condensation section is located in the module upper box, and the liquid storage chamber is arranged over the battery monomer in the module lower box. With the characteristics of large heat dissipating capacity, high heat dissipating efficiency, and simple processing, the power battery thermal management system provided in the invention can efficiently solve the technical problems of high-temperature heat dissipation, low temperature heating thermal preservation and heat recycling in power batteries.

Owner:SANMENXIA SUDA TRANSPORTATION ENERGY SAVING TECH

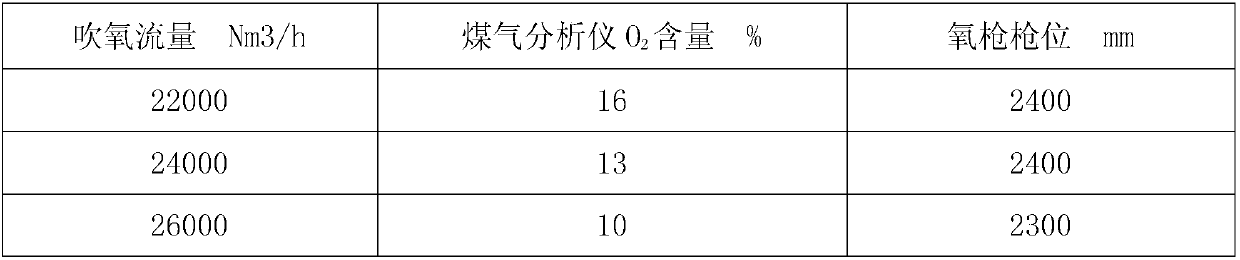

Method for preventing explosion venting after converter blowing interruption

InactiveCN107794333AIncrease generation speedRealize zero explosion ventingManufacturing convertersMode controlSlag

The invention provides a method for preventing explosion venting after converter blowing interruption. Under the condition of lance lifting in the time period from the time when converter blowing is conducted for 5 min to the time when the carbon content of molten steel is higher than 0.2%, namely after converter blowing interruption, a converter is shaken to the zero position during next blowing,an oxygen lance adopts a manual slag splashing mode, a valve is manually opened for nitrogen blowing, and a nitrogen screen is manufactured in a flue; after nitrogen blowing is completed, the oxygenlance adopts a manual blowing mode; when the oxygen lance is descended for oxygen blowing, the oxygen lance position and oxygen flow are controlled in an automatic mode; and after the O2 content in agas analysis meter is lower than 6% and the oxygen blowing flow reaches 40000 Nm<3> / h, control over the oxygen lance position and oxygen flow is switched into a manual control mode. Through the method, carbon-oxygen reactions in the converter can be prevented from being too intensely, thus, the CO generation speed is slowly increased, the explosion venting limit of CO and O2 in smoke is passed, the explosion venting phenomenon is prevented, zero explosion venting of dry dedusting after blowing interruption is achieved, smelting control is stabilized, and whole operation of dry method dust blowing equipment is ensured.

Owner:ANGANG STEEL CO LTD

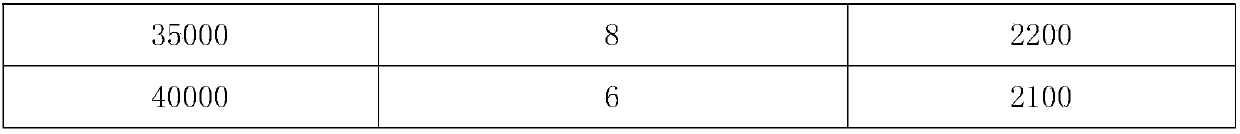

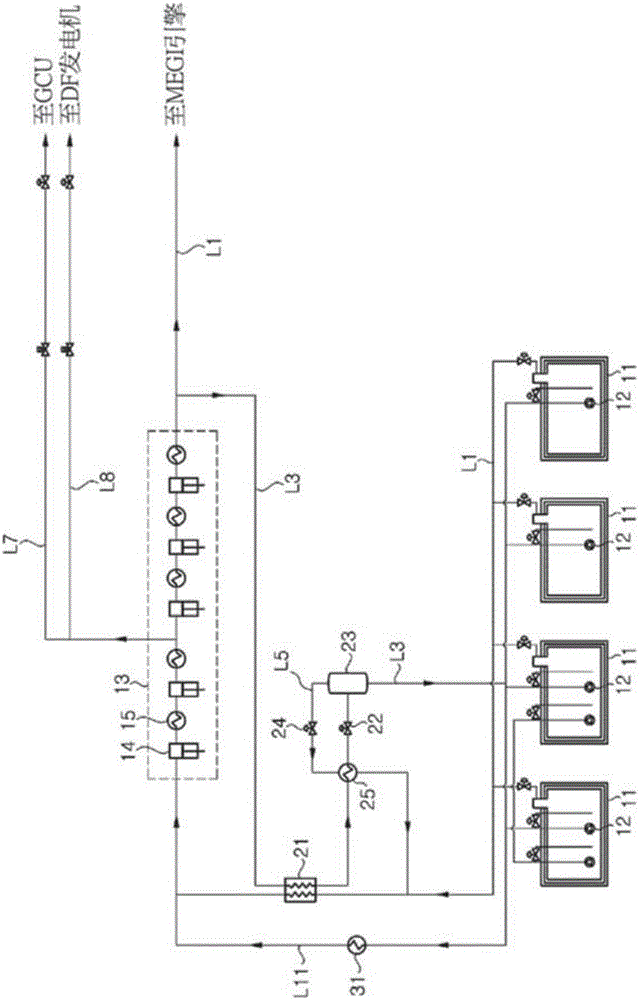

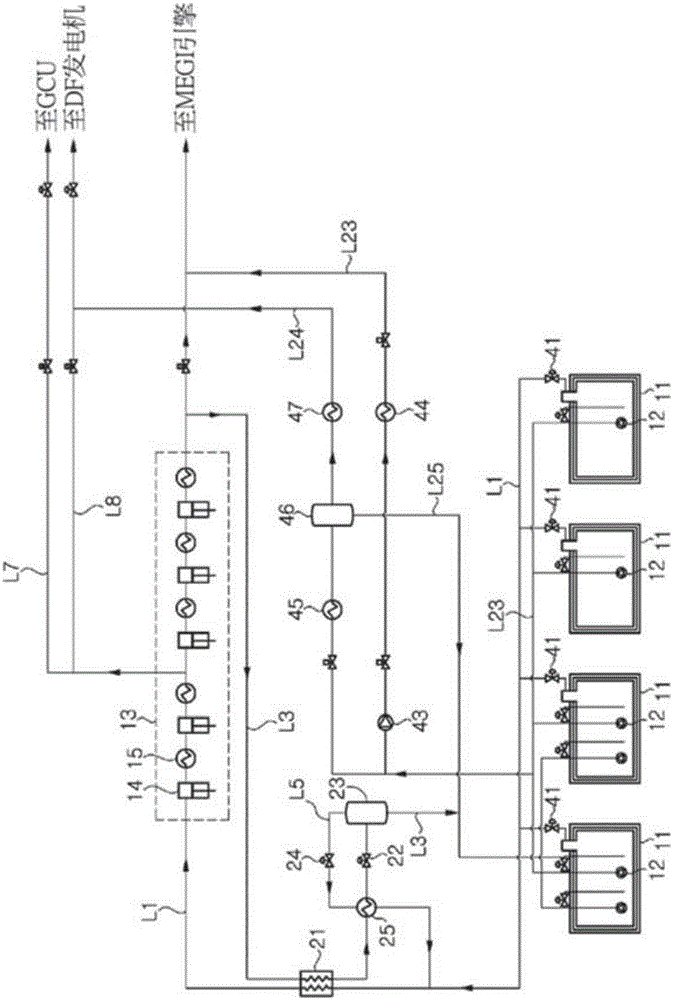

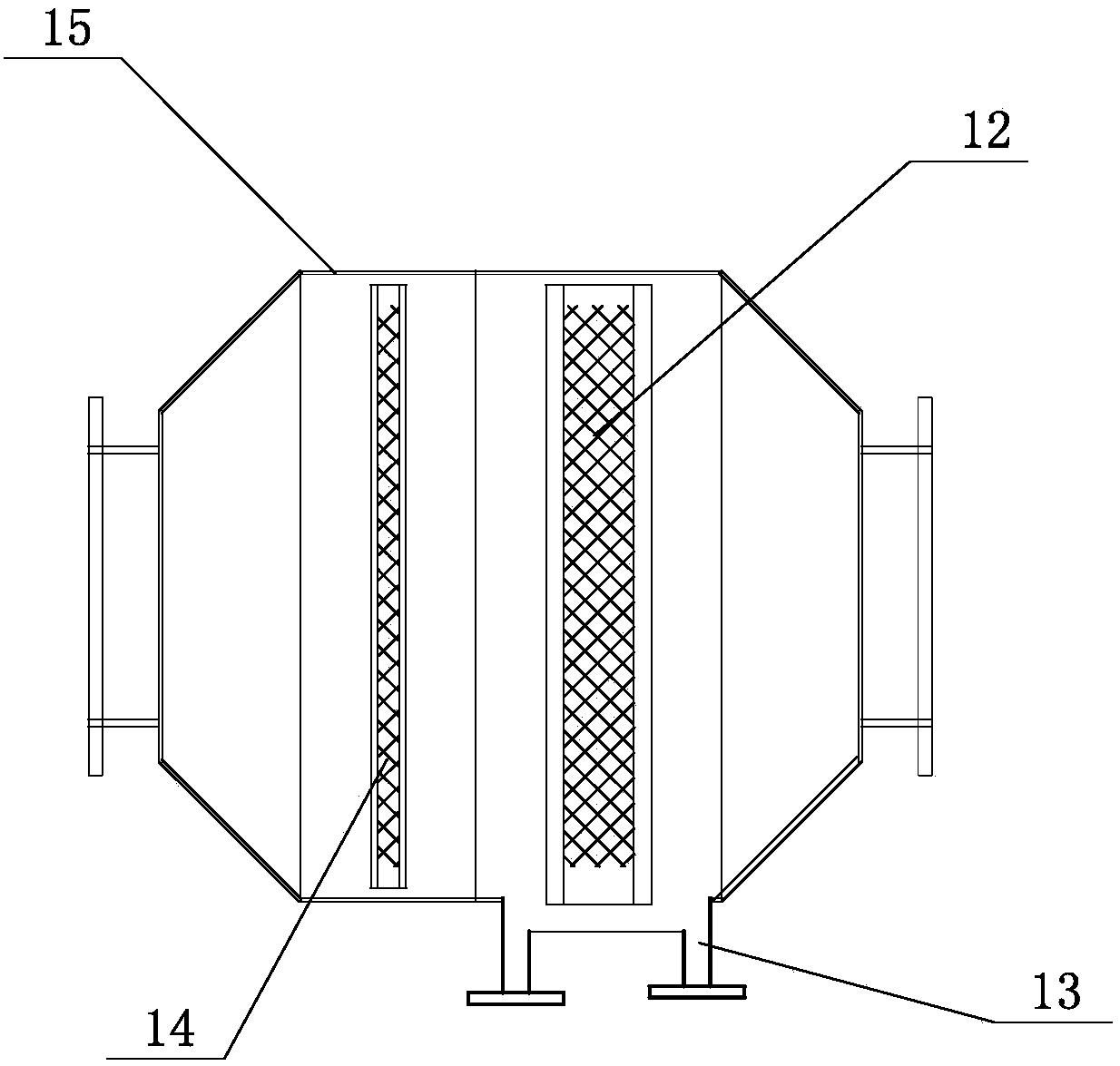

Boil-off gas treatment system

ActiveCN106029491ALower initial installation costsReduce equipment sizeSolidificationLiquefactionProcess engineeringEngineering

A boil-off gas treatment system is disclosed. The boil-off gas treatment system according to the present invention comprises: a compressor which compresses boil-off gas that is generated in an LNG storage tank of a ship or floating structure; a heat exchanger which cools the boil-off gas that has been compressed in the compressor using boil-off gas that is to be introduced into the compressor by means of exchanging heat therebetween; an expansion means which adiabatically expands the boil-off gas that was cooled in the heat exchanger; a gas-liquid separator which separates the boil-off gas that was adiabatically expanded in the expansion means into gas and liquid, and supplies liquefied natural gas to the LNG storage tank; and a bypass line which supplies the adiabatically-expanded boil-off gas from the downstream of the expansion means to the downstream of the gas-liquid separator.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

Power battery thermal management system based on loop heat pipes

InactiveCN103367835ASolve the cooling problemSolve insulation problemsBattery isolationSecondary cellsPower batteryEvaporation

The invention discloses a power battery thermal management system based on loop heat pipes. The power battery thermal management system includes a module box, in which at least two battery pack monomer shells are placed. At least over two battery module sets composed of battery monomers connected in series or in parallel are placed in each battery pack monomer shell, wherein loop heat pipes are distributed on the surface of each battery monomer. Each loop heat pipe comprises an evaporation end and a condensation end. The evaporation end fits the battery monomer surface, and the condensation end extends beyond the battery monomer surface. With the characteristics of large heat dissipation capacity, high heat dissipation efficiency and simple processing, the power battery thermal management system can efficiently solve the technical problems of high-temperature heat dissipation, low temperature heating and heat preservation, as well as heat recycling of power batteries, and is suitable for various electrical equipment dependent on power batteries to drive, thus having broad market prospects.

Owner:SANMENXIA SUDA TRANSPORTATION ENERGY SAVING TECH

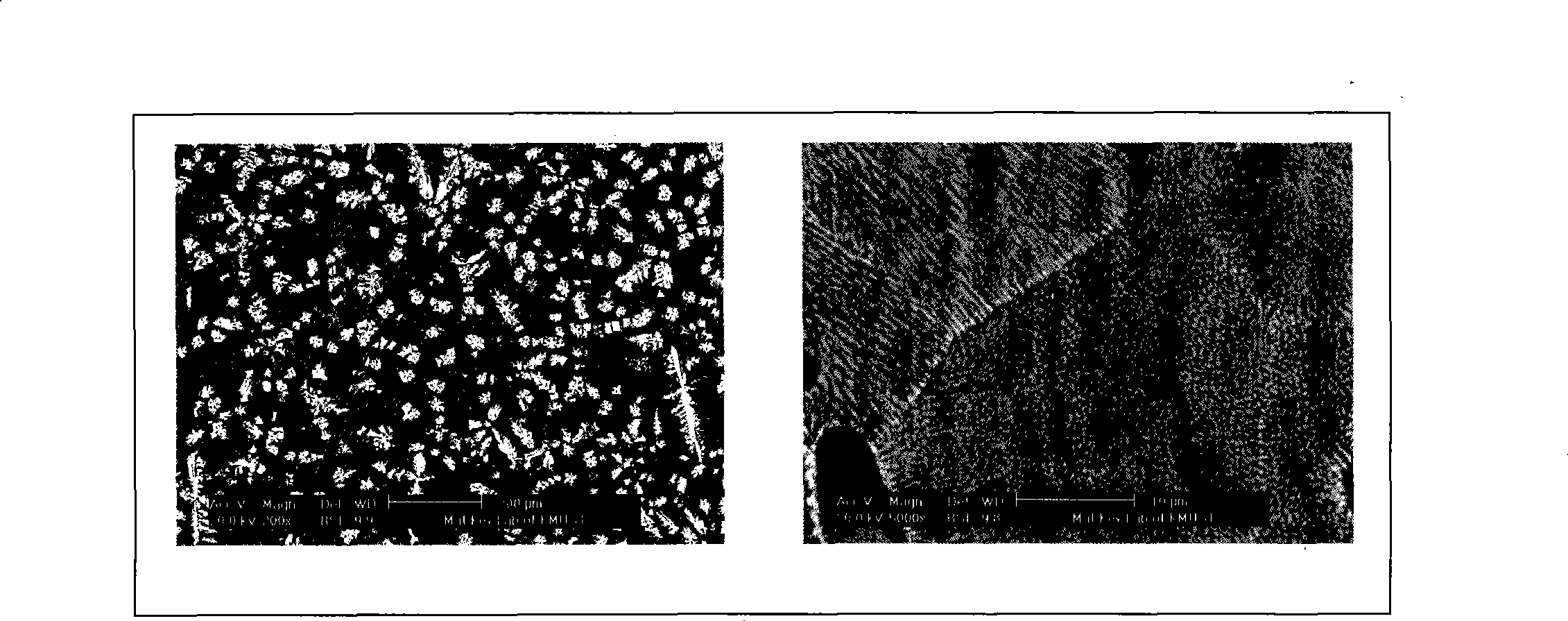

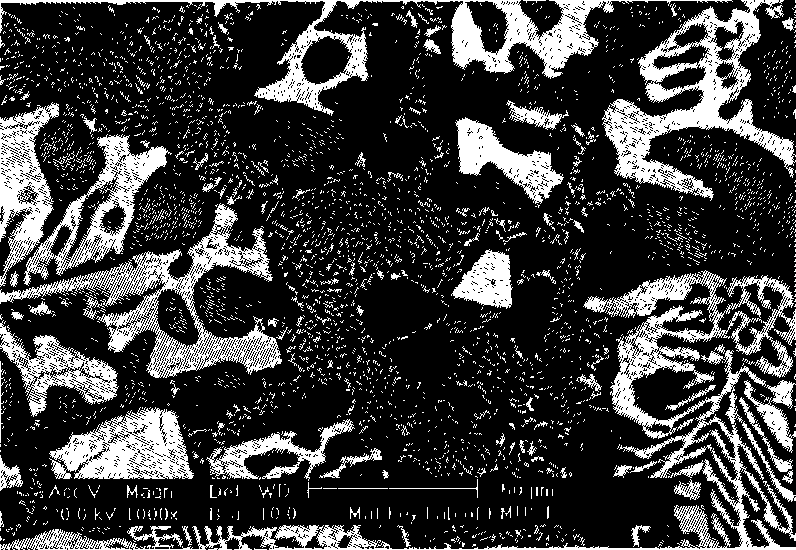

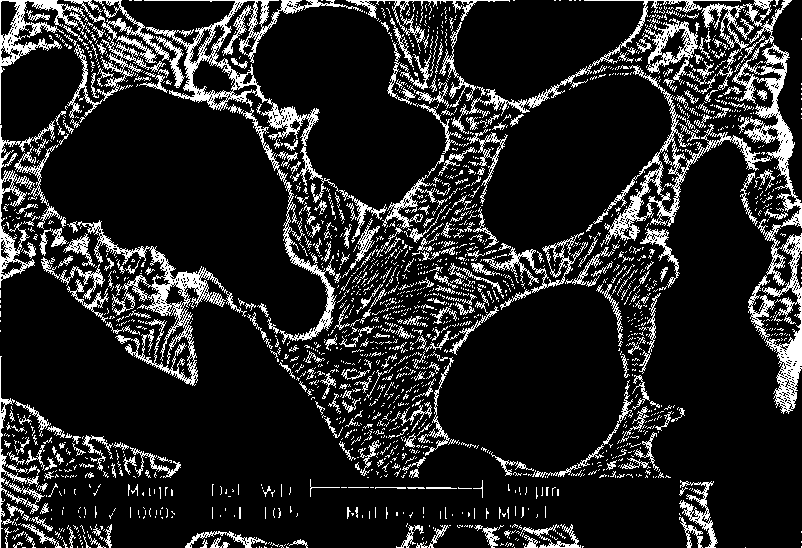

High strength lead alloy and manufacturing method thereof

The invention belonging to a nuclear screening composite material for nuclear energy development and a preparation technique thereof provides a high-strength lead alloy and a method for preparing the same.The method comprises steps of melting the second group component metal, adding metallic lead, stirring for performing reaction in-situ, and then the second group component metal and the blue lead generating an intermetallic compound combined by hybrid bonds of metallic bond and covalent bond. The strength of lead alloy is greatly improved by using the intermetallic compound generated by the reaction of lead and the second group component metal and using the excellent high-strength character of the intermetallic compound. The ultrahigh strength lead alloy prepared by using the technology possesses enough mechanics bearing capacity at the same time of maintaining excellent gamma-ray and X-beam shielding character, and thus the material has a shielding function / structure integrated character, and it is hopeful to further improved the combination property of nuclear screening materials.

Owner:KUNMING UNIV OF SCI & TECH +1

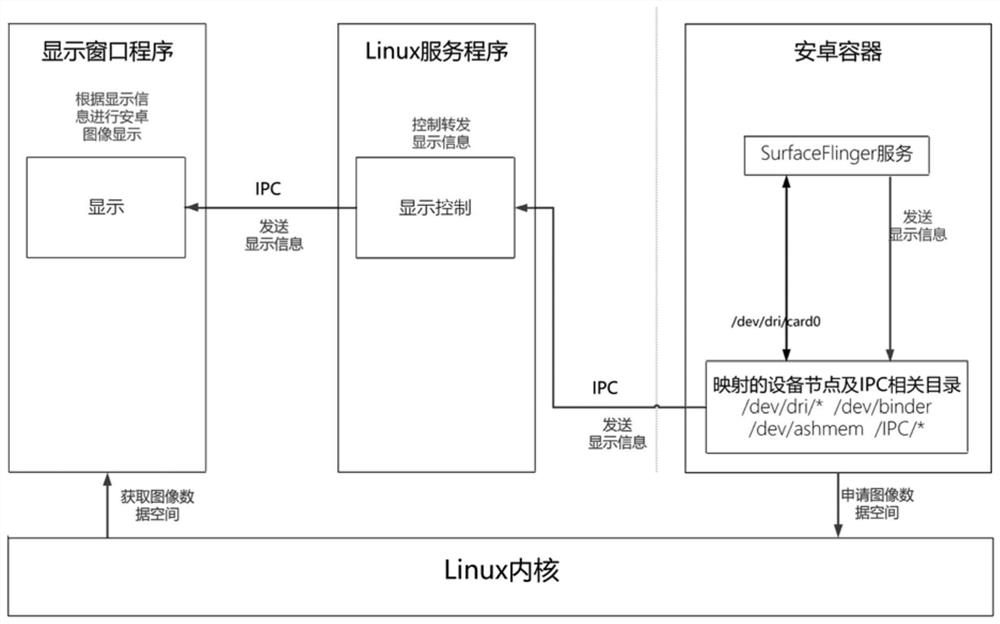

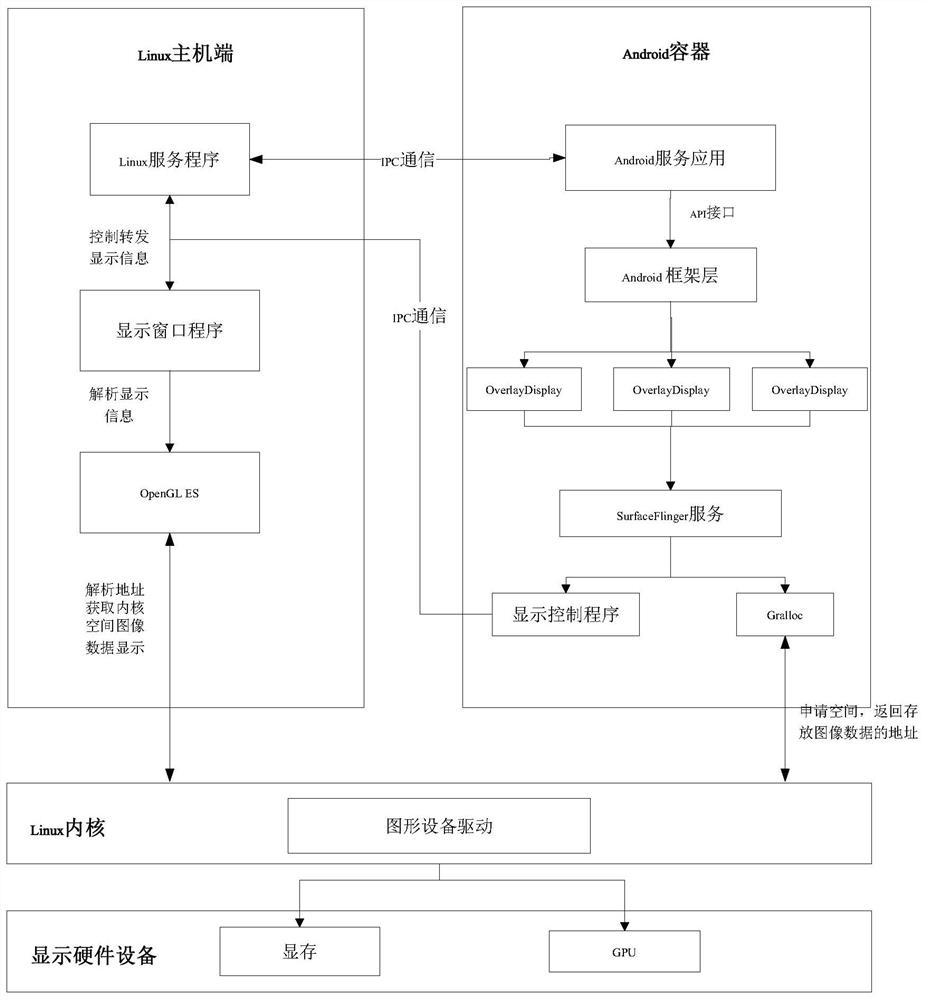

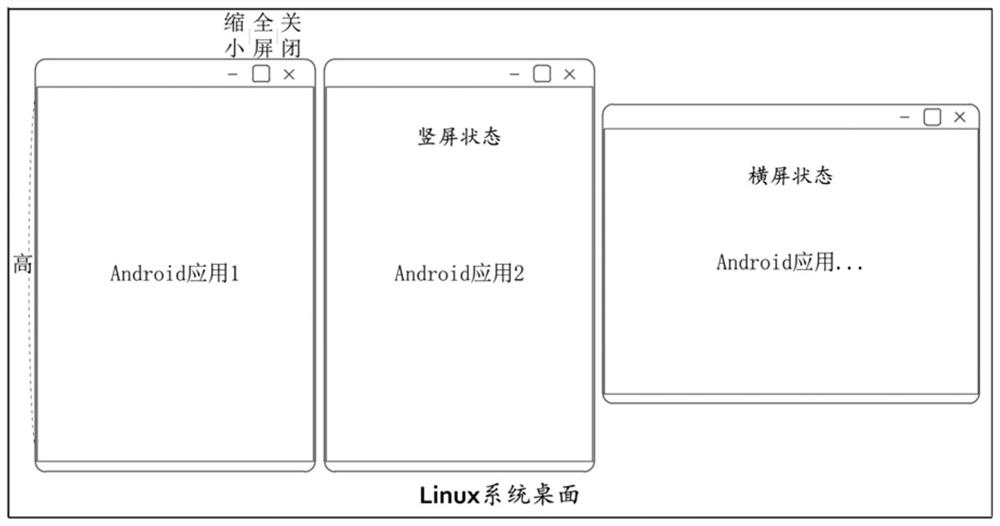

Android multi-window display method applied to Linux

ActiveCN113157362AAddressing the lack of appsMeet special needsExecution for user interfacesGraphicsSoftware engineering

The invention discloses an Android multi-window display method applied to Linux. The method comprises the following steps: writing an Android application starting multi-window management service program; modifying an Android graphic display scheme; and enabling the Linux system to execute a graphic display program. The method has the advantages that the problem that software applications of the Linux operating system are deficient is solved, rich application ecological advantages of Android are played, compared with a traditional Android simulator, the Android application can smoothly run on the Linux system like a Linux application through multi-window display, and performance loss is reduced; and research and development personnel even can customize own Linux window management programs and Android systems to meet special requirements of users.

Owner:KYLIN CORP +1

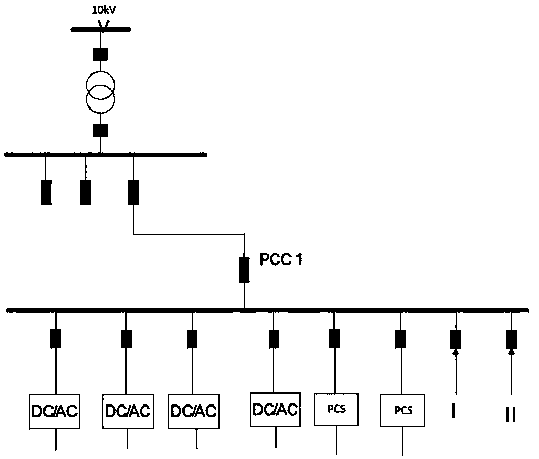

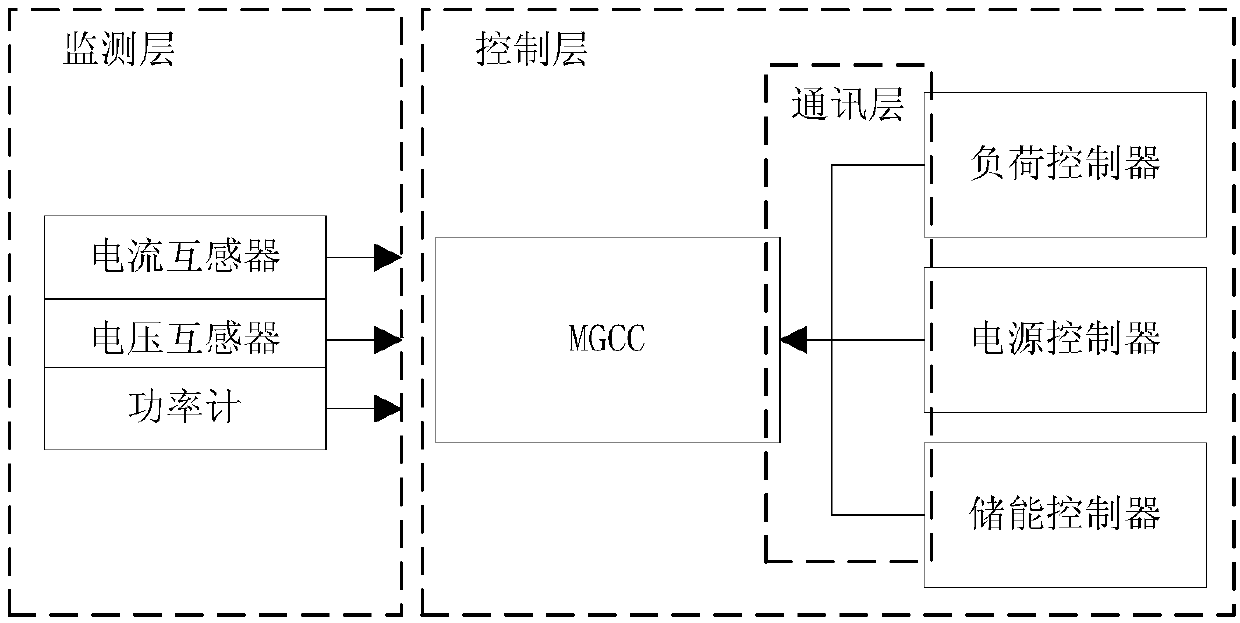

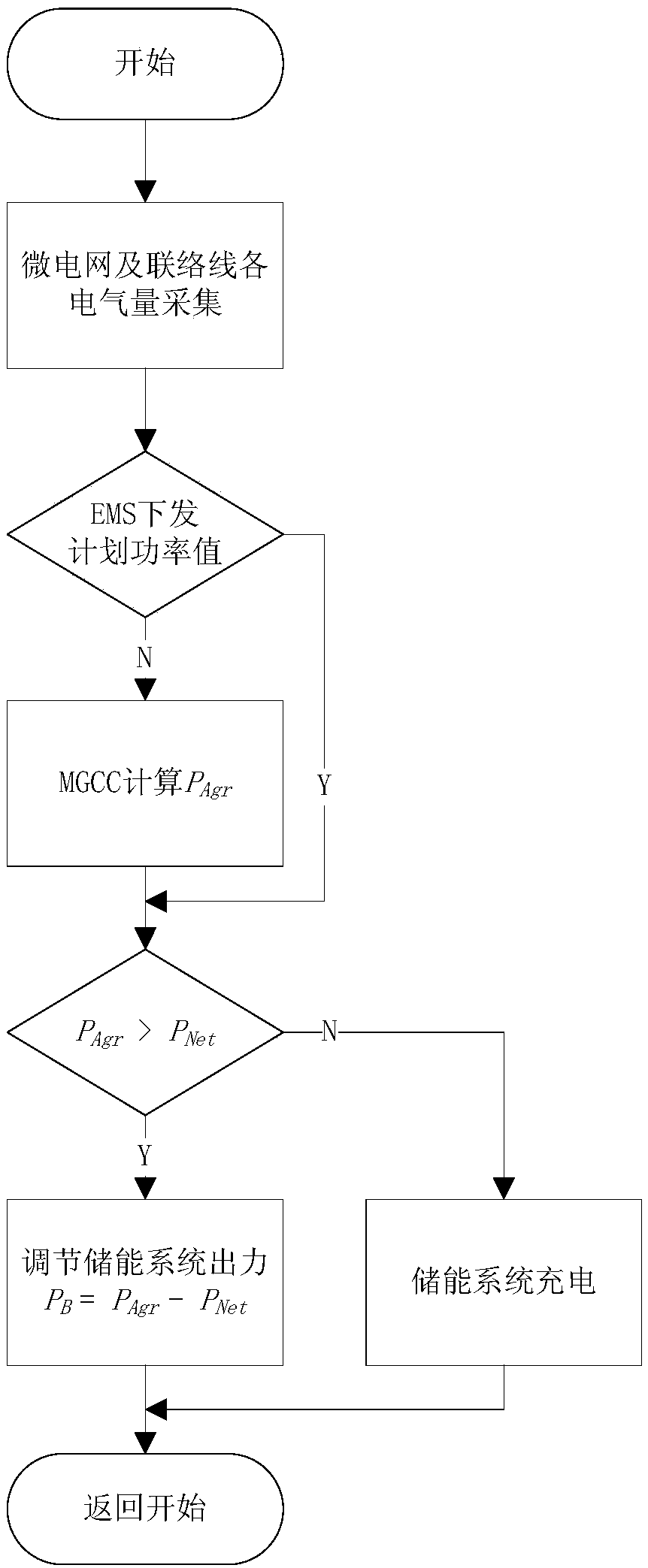

System and method for controlling power of micro-grid grid-connected tie line

InactiveCN109842147AGuaranteed reliabilityGuaranteed stabilitySingle network parallel feeding arrangementsAc network load balancingControl powerControl system

The invention discloses a system and method for controlling the power of a micro-grid grid-connected tie line. The method comprises the steps that: a micro-grid central controller collects electricalquantities of a micro-grid and a tie line; the relationship between a protocol power PAgr and a micro-grid net load Pnet is judged, the predicted value of the protocol power PAgr is given by an energymanagement system, if the energy management system does not give a value, the value of the protocol power Pagr is an average value of the micro-grid net load Pnet in the time Delta t, when Pagr is larger than Pnet, the micro-grid central controller issues a command to a battery management system to adjust the output of an energy storage unit, the output value of the energy storage unit is PB=Pagr-Pnet, when Pagr is smaller than or equal to PNet, the micro-grid central controller issues a command to the battery management system to stop the output of the energy storage unit, and the charging of the energy storage unit is started. The system and method have the advantages of quick response, simple scheme and good stability.

Owner:DAQO GROUP CO LTD +1

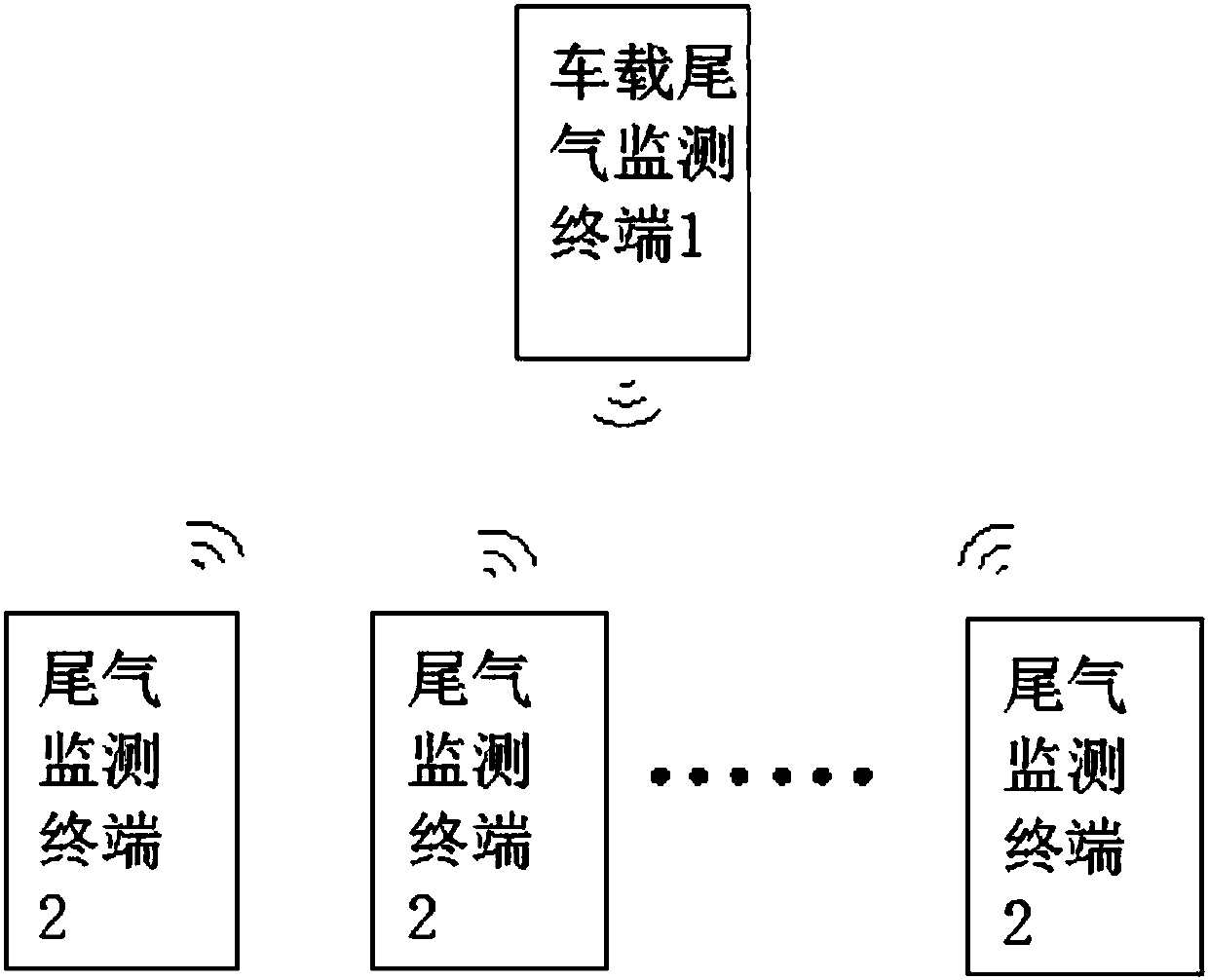

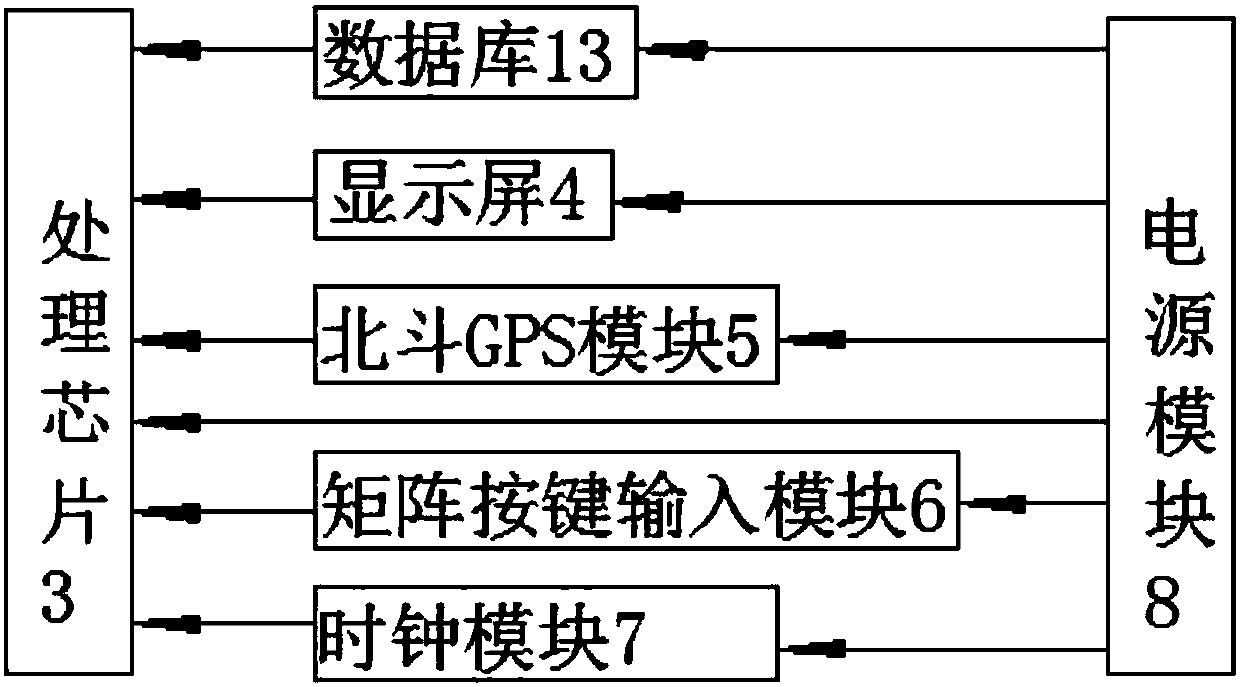

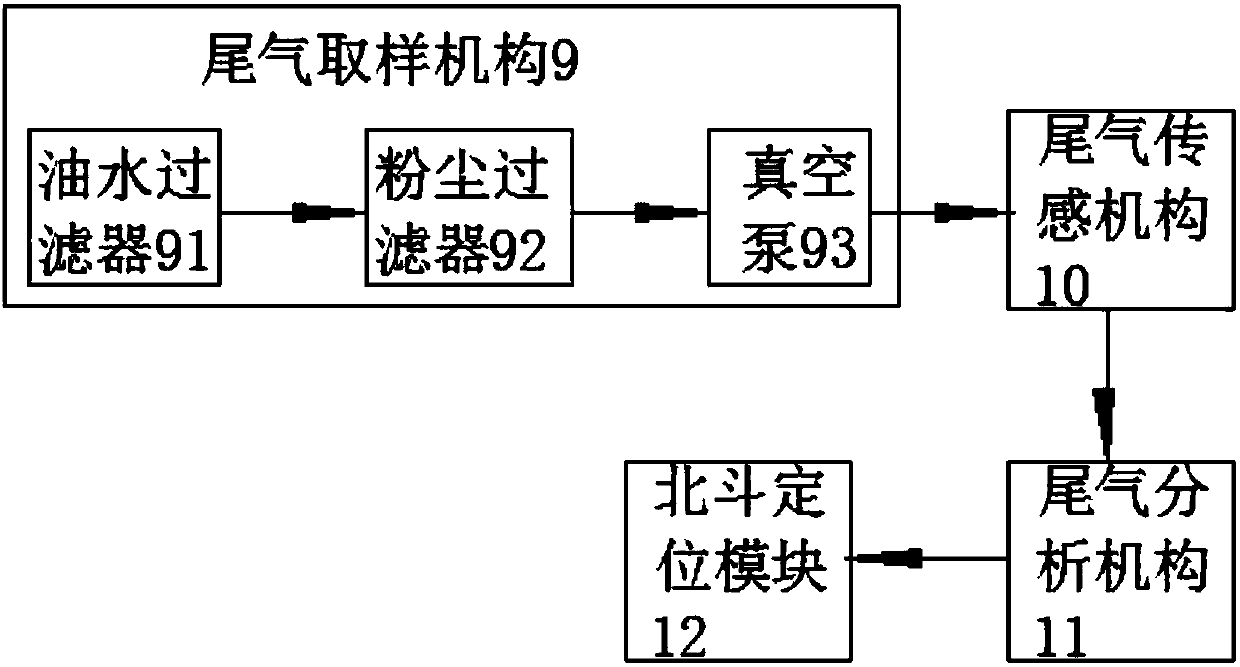

Vehicle-mounted tail gas monitoring terminal of beidou system

InactiveCN107607682ASimple structureSimple and efficient operationParticular environment based servicesSatellite radio beaconingExhaust gasCar driving

The invention discloses a vehicle-mounted tail gas monitoring terminal of a beidou system. The terminal has the advantages that the structure is simple; the operation is simple and convenient. According to the monitoring method, a beidou GPS (global positioning system) module is effectively utilized; the problem of inaccurate positioning in the prior art is solved; the tail gas exhausted by each automobile can be remotely monitored in real time in the automobile driving process; the tail gas exhaust standard exceeding automobiles can be screened out, and the located position can be found; in addition, the warning and disposition can be performed on standard exceeding automobiles in time, so that the control on the automobile tail gas exhaust can be enhanced; the air quality improvement isensured. The advantages of high automation degree, high monitoring efficiency, continuous operation and the like are realized. The contents of various kinds of gas in the automobile tail gas can be detected at the same moment; in addition, other parameters of the exhausted tail gas can be detected at the same time, so that the automobile exhaust tail gas can be comprehensively and completely judged; the detection efficiency is high.

Owner:NANJING RUIANTENG ENTERPRISE MANAGEMENT CONSULTING CO LTD

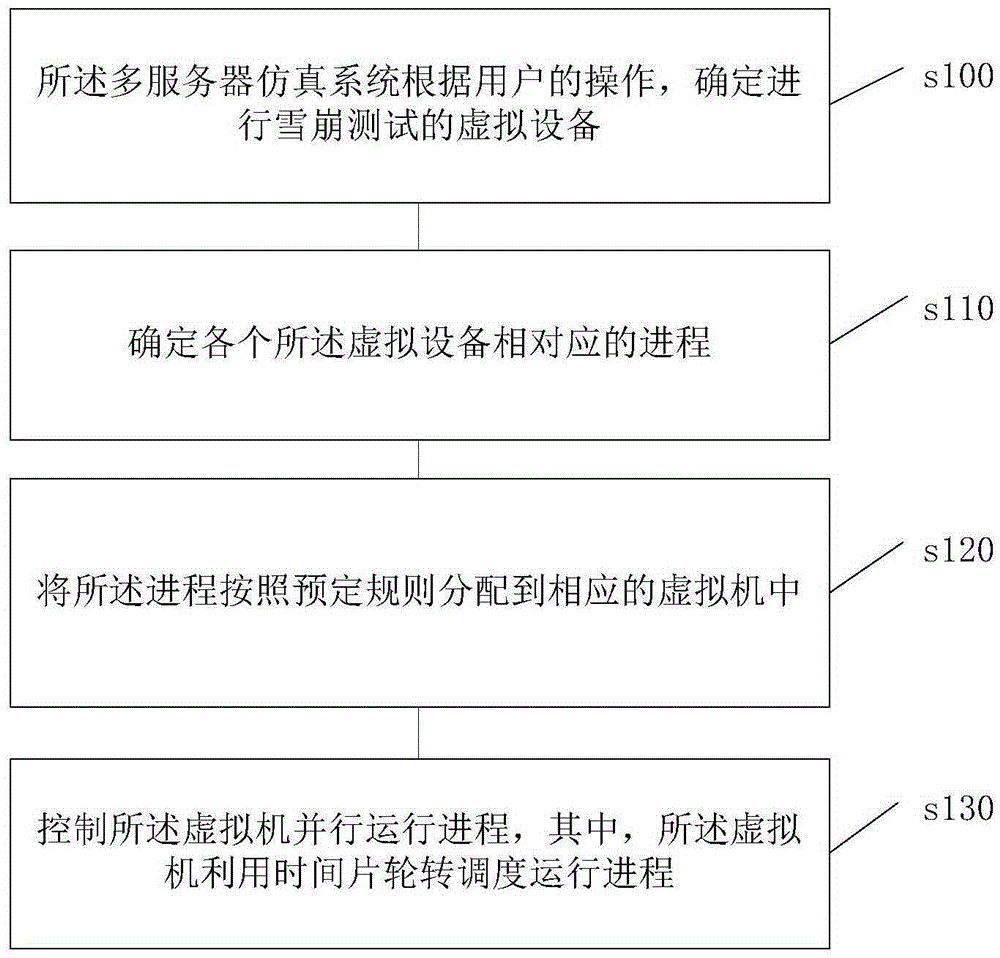

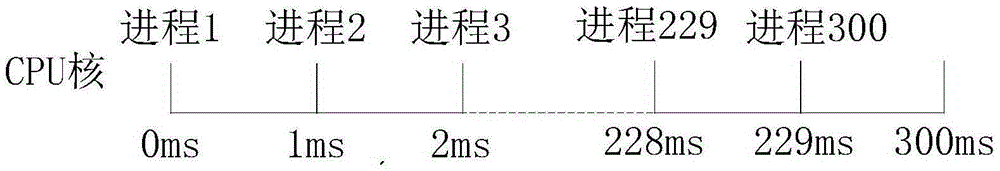

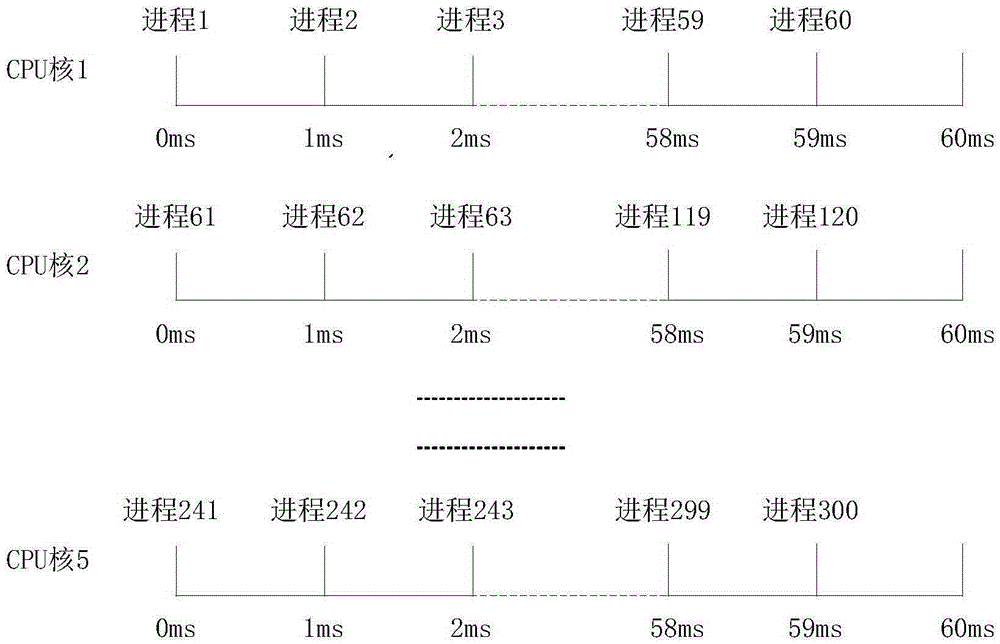

Multi-server-simulation-based avalanche testing method, apparatus, and system

InactiveCN105391597AIncrease speedHigh Rate Avalanche TestingData switching networksSoftware simulation/interpretation/emulationVirtual machineSimulation based

The invention discloses a multi-server-simulation-based avalanche testing method to construct a multi-server simulation system. The method comprises: the multi-server simulation system determines virtual equipment for carrying out avalanche testing according to an operation of a user; processes corresponding to all virtual equipment are determined; the processes are distributed to corresponding virtual machines according to a predetermined rule; and the virtual machines are controlled to operate the processes in parallel, wherein the virtual machines use time slice round-robin scheduling to operate processes. According to the method, the construction time of an avalanche testing environment can be shortened; the rate of the avalanche concurrence testing is optimized; the operation is flexible; the arrangement becomes convenient; the operation becomes stable and reliable; the functions are complete; and the testing efficiency is high. In addition, the invention also discloses a multi-server-simulation-based avalanche testing apparatus and system.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +2

A low-grade thermal energy-driven electrode liquid self-circulation hydrogen production method

ActiveCN109811358BLow costReduce consumptionCellsRegenerative fuel cellsElectrolytic agentThermodynamics

The invention discloses a low-grade heat energy driven electrode liquid self-circulating hydrogen production method, and belongs to the technical field of new energy. Low-grade heat energy serves as driving force, and continuous hydrogen production is achieved through the concentration change of a working solution. The low-grade heat energy driven electrode liquid self-circulating hydrogen production method comprises the steps: firstly, the low-grade heat energy is converted into chemical potential energy of the working solution through a low-temperature multi-effect distillation method; thenthe chemical potential energy is converted into the potential difference between two electrodes of a cell stack based on the reverse electrodialysis principle; and then hydrogen and oxygen are produced through a reduction reaction or an oxidation reaction occurring on the hydrogen production electrode and the oxygen production electrode in the same electrode liquid. The waste solution losing partof the chemical potential energy is recycled after flowing out from the cell stack, and then regenerated under driving of the low-grade heat energy; the electrode liquid is self-circulated between a hydrogen production electrode liquid cavity and an oxygen production electrode liquid cavity in the two ends of the cell stack; the low-grade heat energy can be continuously, efficiently and steadily converted to be utilized; a hydrogen production system does not need to operate at the high temperature and high pressure, mechanical moving parts are few, and capacity configuration is flexible; and the single-type electrode liquid is adopted and is in an electrolyte closed cycle, and long-time operation can be achieved only by supplying deionized water.

Owner:DALIAN UNIV OF TECH

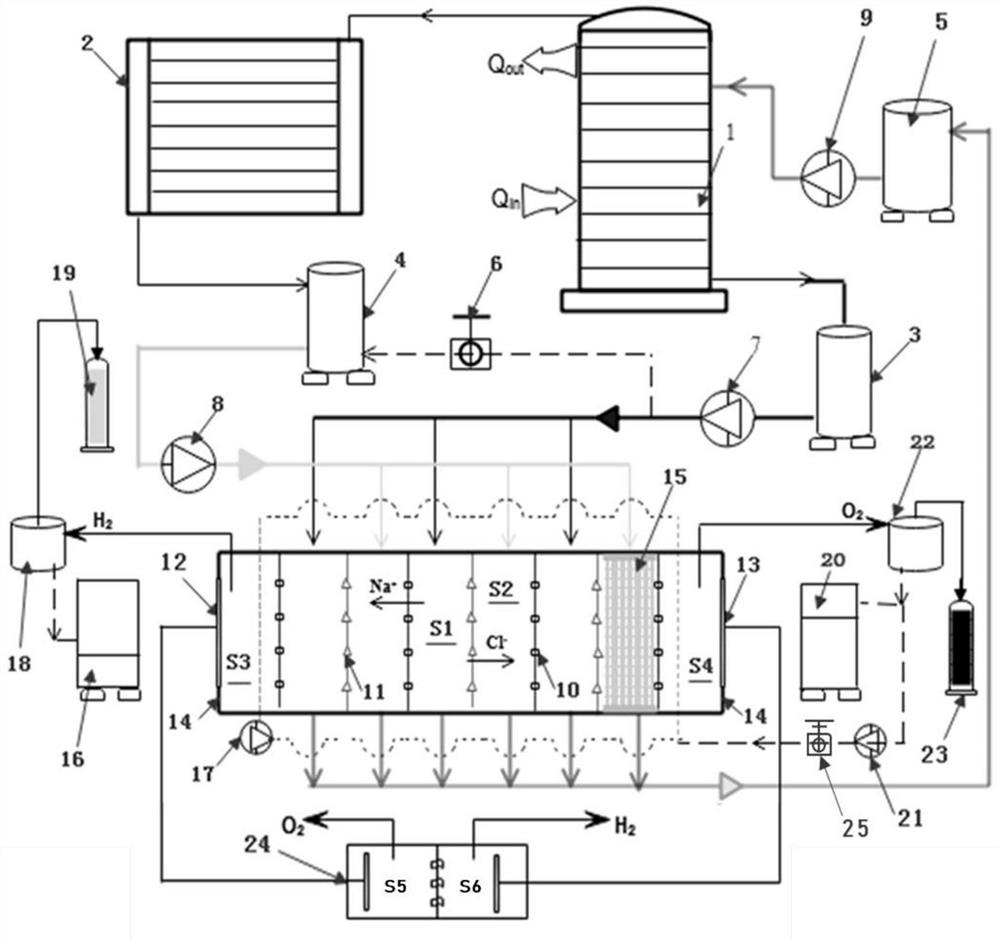

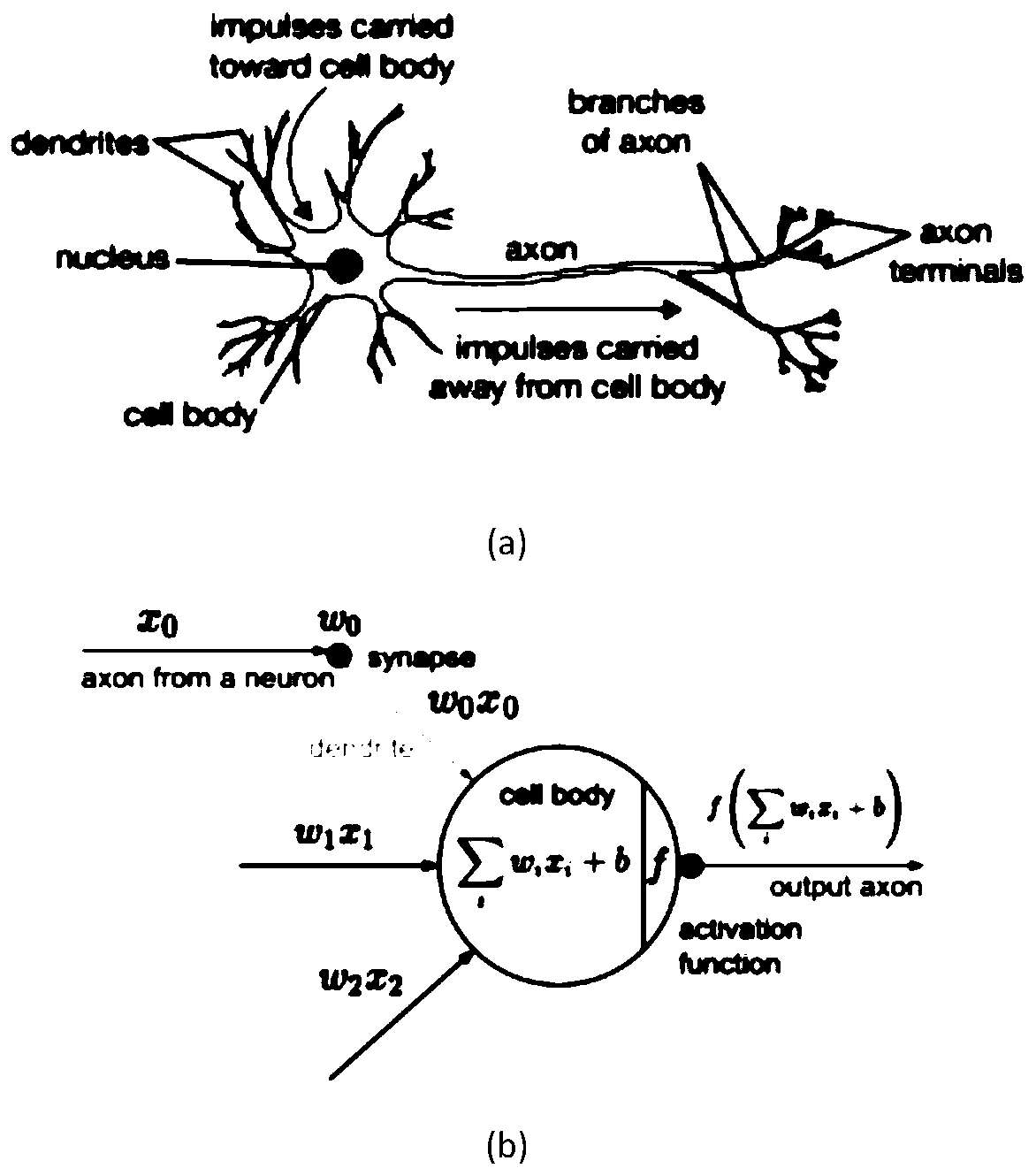

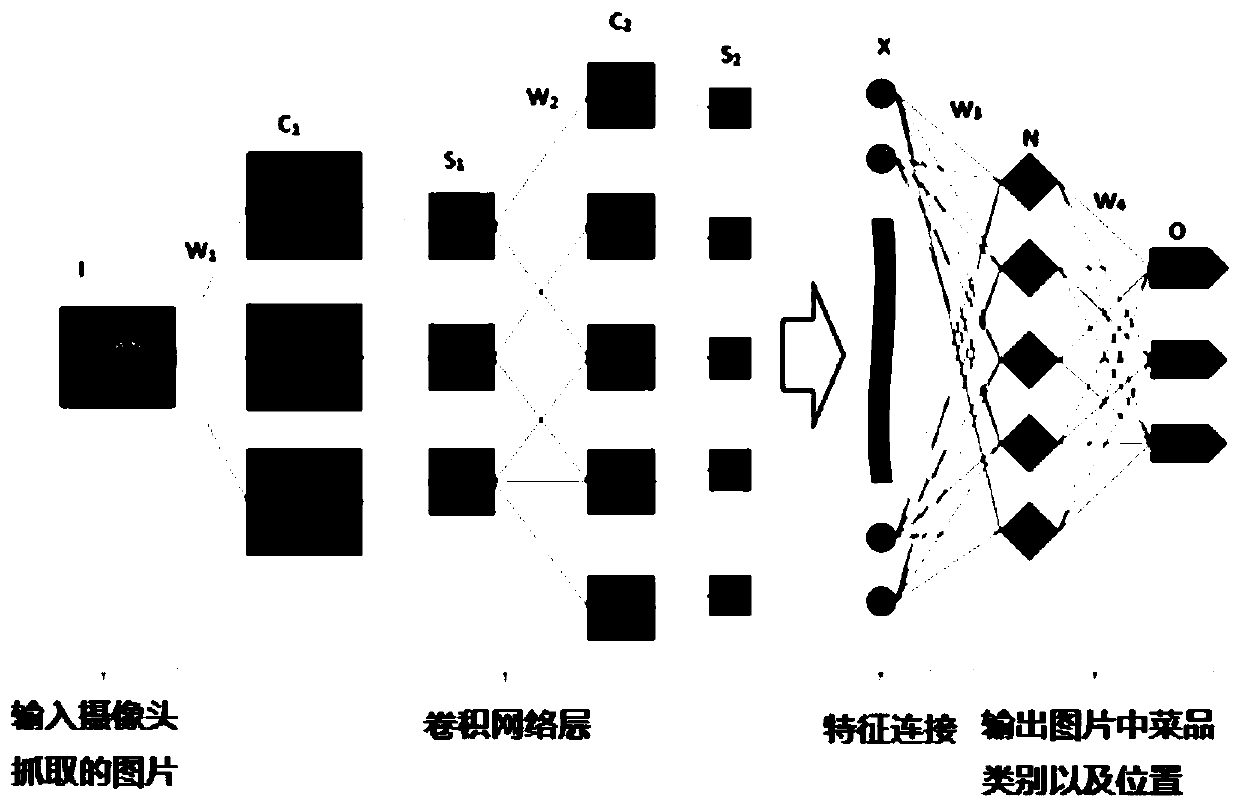

Convolutional neural network-based self-service checkout system and convolutional neural network-based self-service checkout method

InactiveCN110020603ATechnological innovationReduce waiting timeCharacter and pattern recognitionCash registersSystem identificationSelf-service

The invention discloses a convolutional neural network-based self-service checkout method. The method comprises the following steps of establishing a self-service checkout system based on a neural convolutional network; shooting the selected dish image information, and identifying the number and types of actually selected dishes in the dish image information through the self-service checkout system; and according to the actually selected dish quantity and type, calculating the price and completing the checkout. According to the self-service checkout system, the dining process can be simplified, the ordering system can be optimized, inconvenience and complexity caused by manual settlement can be overcome, and the cost can be reduced. The invention also discloses a self-service checkout system based on the convolutional neural network.

Owner:EAST CHINA NORMAL UNIV

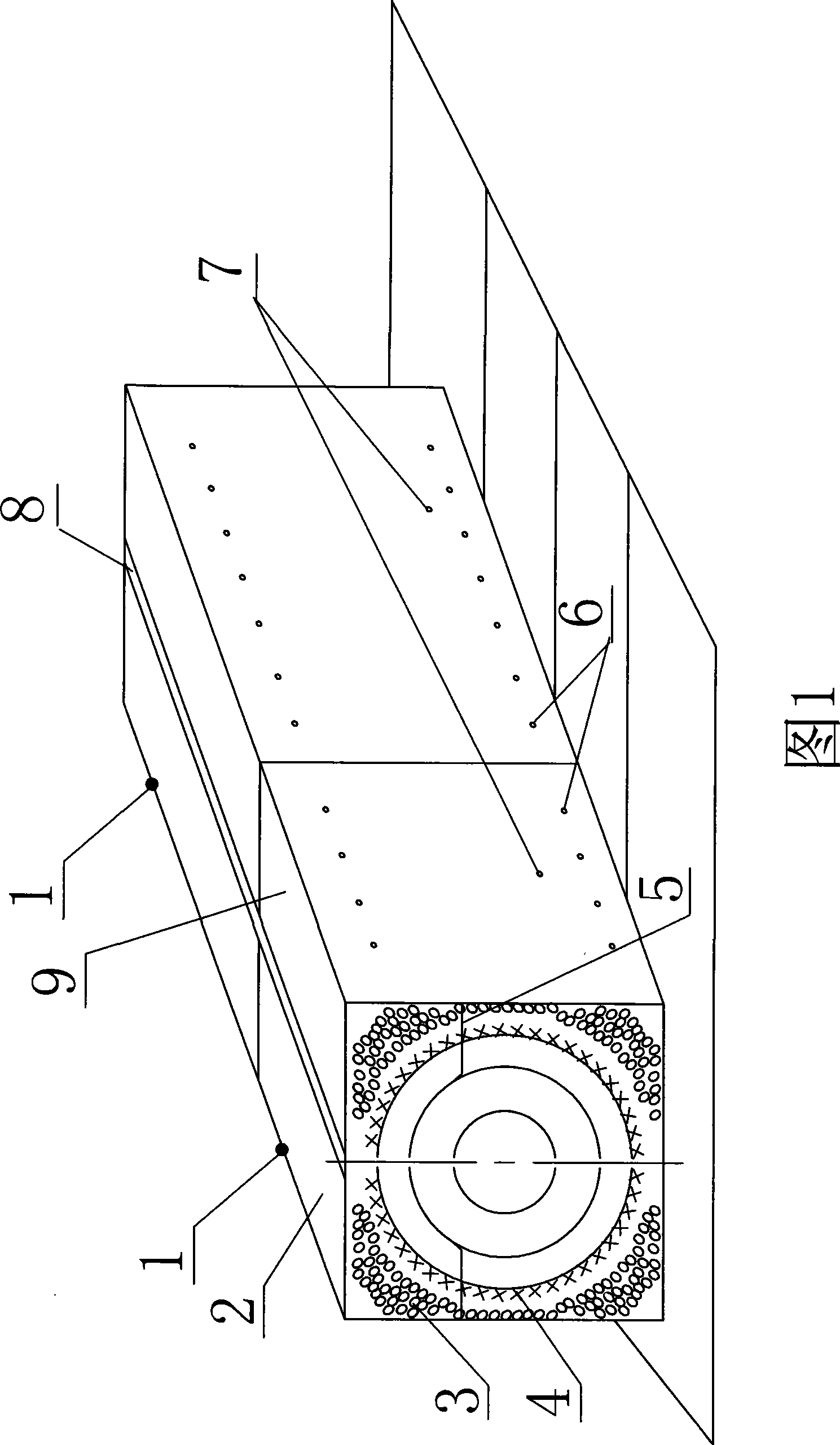

Roller cladding heating kiln

InactiveCN101397661AGuaranteed uptimePerfect operationMetallic material coating processesLaser beam welding apparatusTemperature controlButt joint

The invention relates to a roller cladding heating furnace which comprises a furnace body, a heating band, an insulating layer and a powder receiving pan. The furnace body is provided with a right furnace box and a left furnace box which are in a mutual butt joint way; the upper cover of the furnace body is provided with a laser operation window; the inner wall of the furnace box is provided with the insulating layer; the inner circle of the insulating layer is provided with the heating band; and the upper part in the furnace box is provided with the powder receiving pan that is fixedly connected with the inner wall of the furnace box. The side of the furnace box is provided with a temperature detecting point and is connected with the temperature control input end of a controller. Or a plurality of furnace bodies are in head-to-tail connection to form a long furnace body. The furnace has excellent cladding quality, little thermal loss during the cladding process, simple structure, flexible assembly, high efficiency, constant temperature control, low energy consumption, energy conservation, cleanliness and sanitation and no pollution. The furnace is applicable to roller manufacturing industry.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

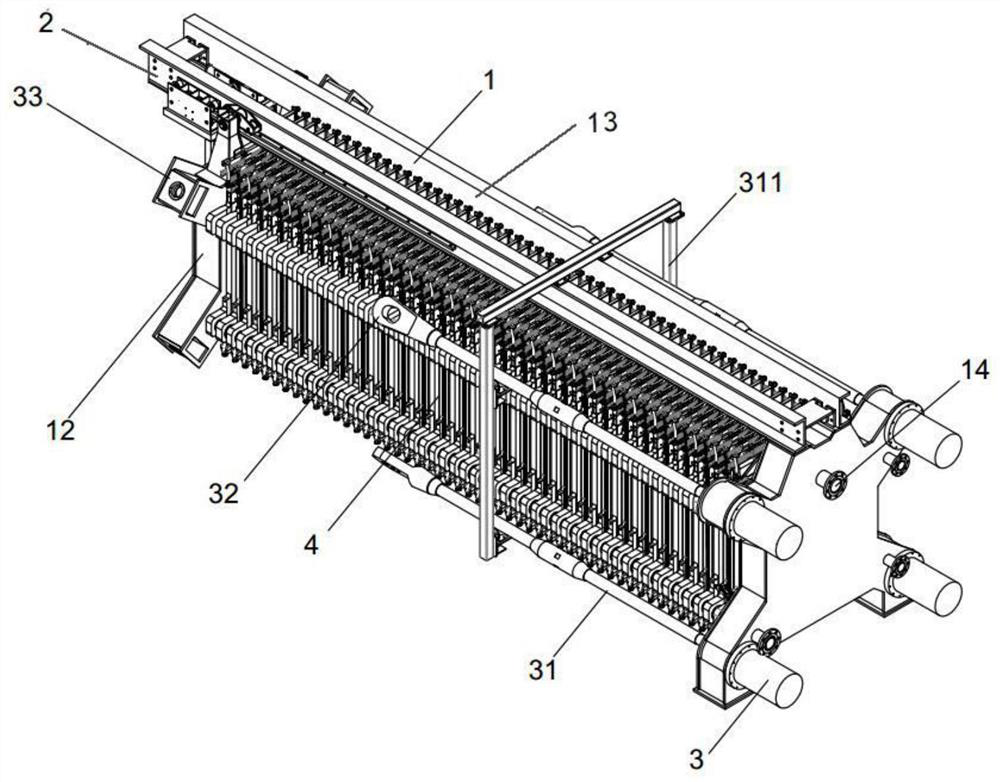

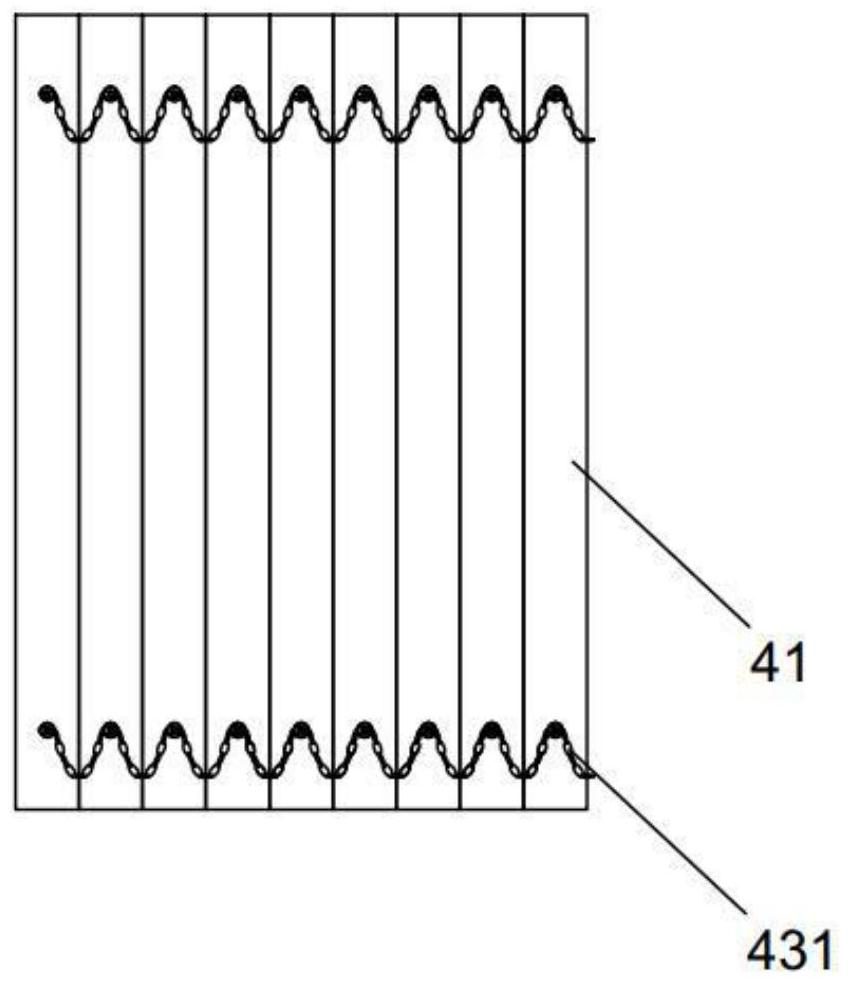

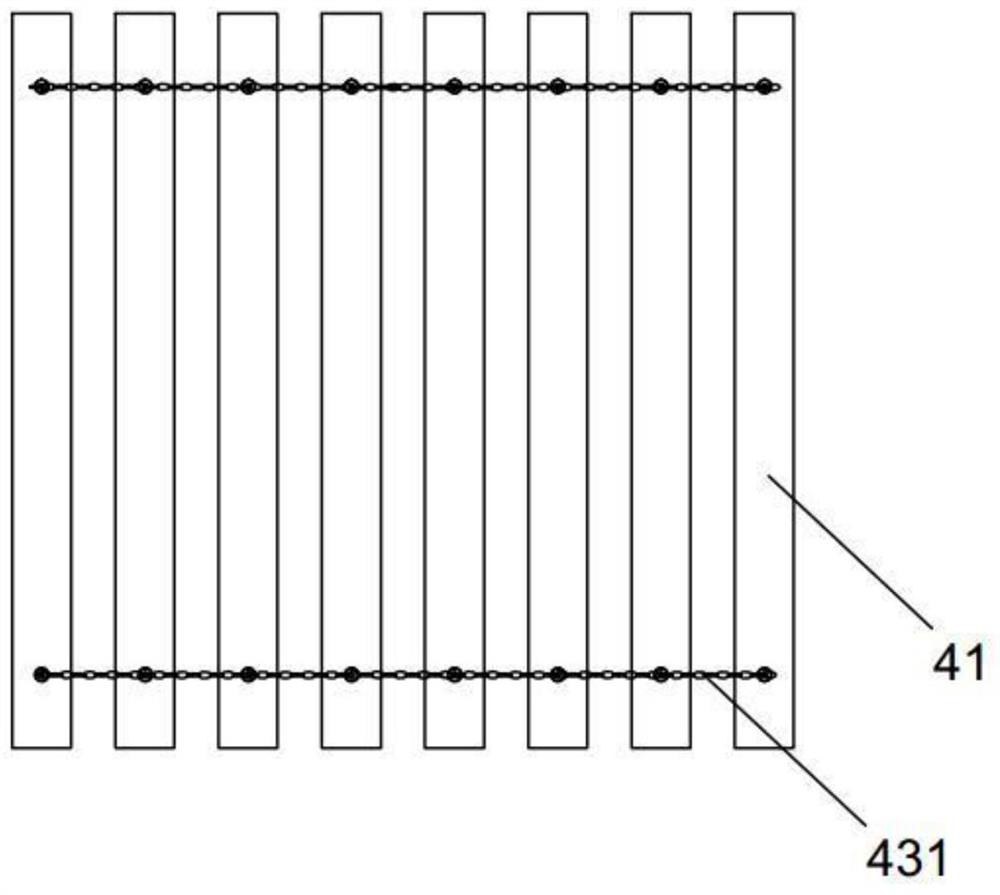

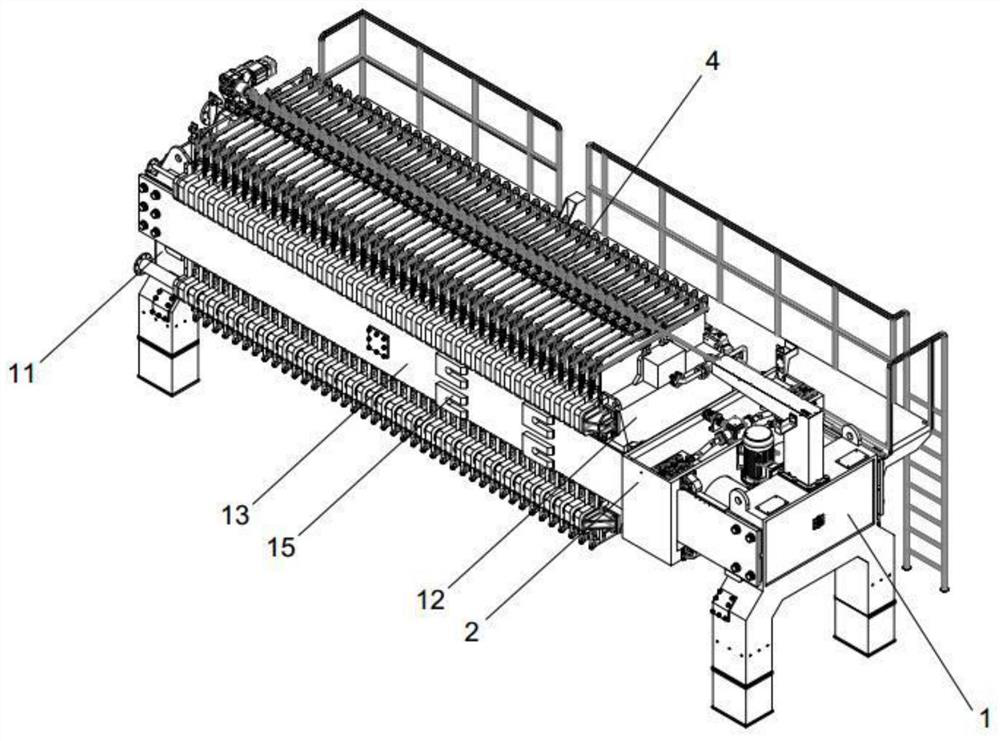

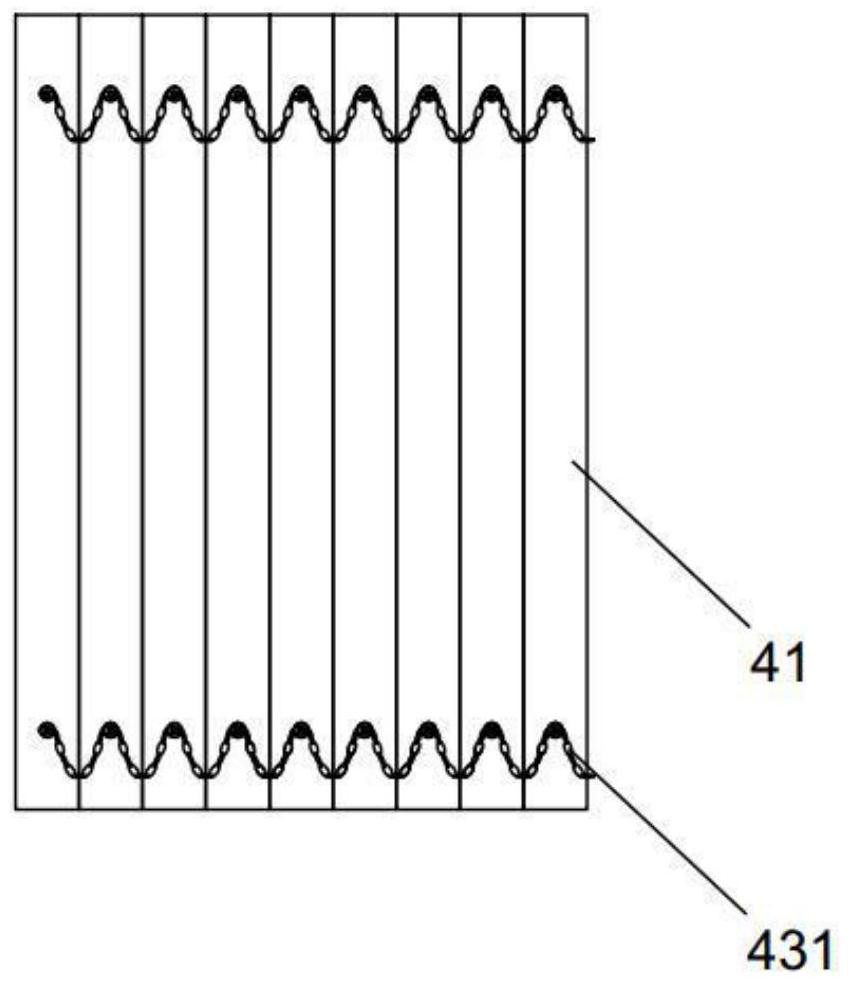

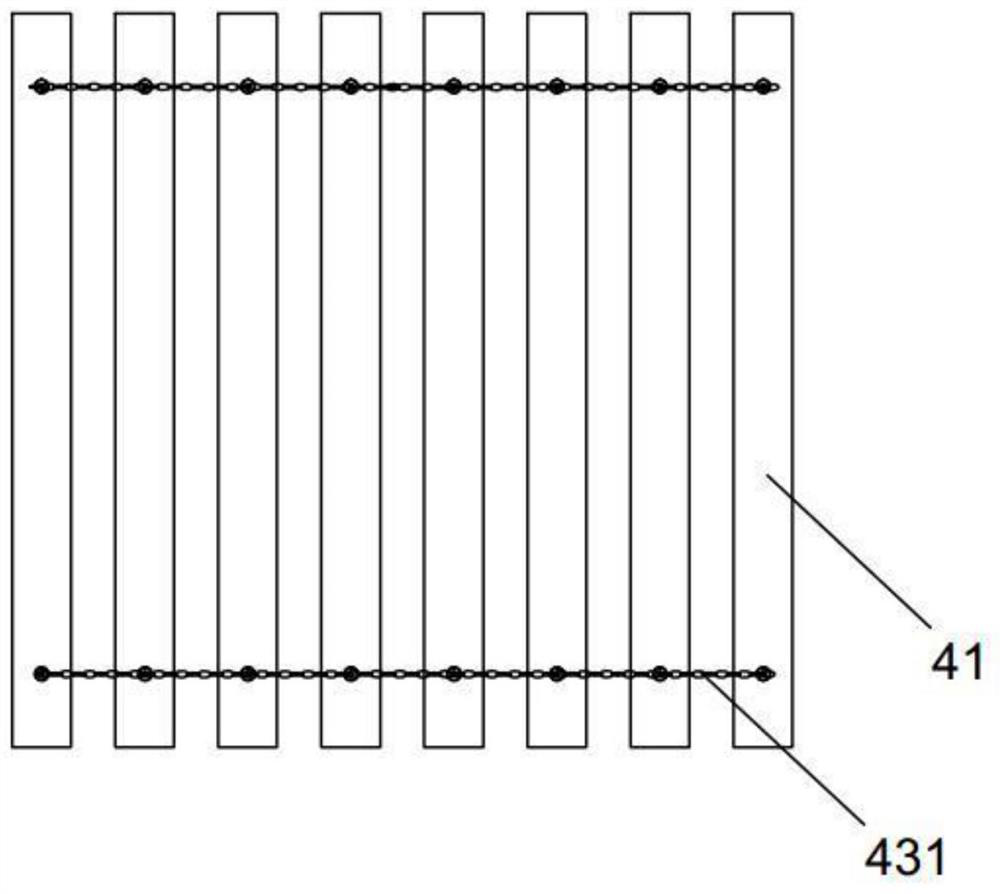

Cantilever type filter press

ActiveCN112121482AImprove work efficiencyRealize synchronous opening and closingFiltration separationMechanical equipmentFilter press

The invention provides a cantilever type filter press, which belongs to the field of mechanical equipment and comprises a rack, a fixed end plate is arranged at one end of the rack, and a movable endplate is arranged at the other end of the rack; the filtering device is arranged on the rack and comprises a plurality of filtering plate units provided with filtering cloth and a filtering cloth driving mechanism, and the filtering plate units are arranged between the movable end plate and the fixed end plate; the driving device is connected with the movable end plate and drives the movable end plate to move in the length direction of the rack; The tensioning oil cylinder is arranged on the rack; when the device is used, the driving device drives the movable end plate to push the filter plateunits in the filter device to be pressed, then materials are injected into the filter plate units, and the tensioning oil cylinder contracts to extrude and filter the materials; and after the filterpressing is finished, the driving device drives the filter plate units to separate, and then the filter cloth driving mechanism drives the corresponding filter cloth in the plurality of filter plate units to synchronously move so as to unload a filter cake.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

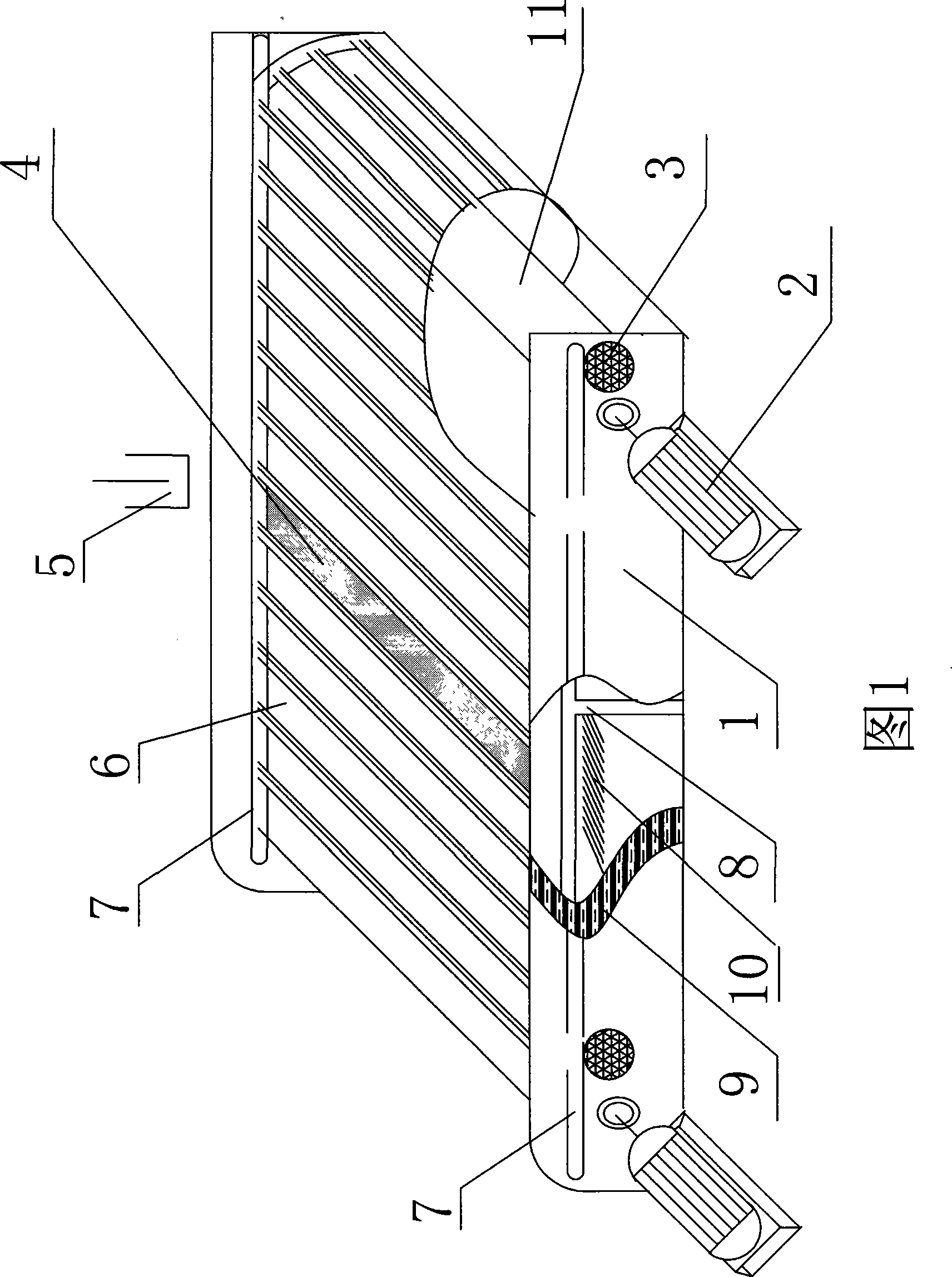

Flat-plate laser cladding composite alloy layer heater

InactiveCN101397660AGuaranteed uptimePerfect operationMetallic material coating processesLaser beam welding apparatusMetalAlloy

The invention relates to a slab laser cladding compound alloy layer heater which comprises a furnace body, a rolling screen orbit and a thermal insulation rolling screen cover plate. The upper ends of the two sides of the furnace body are provided with the rolling screen orbit where the thermal insulation rolling screen cover plate is arranged in; the two ends of the thermal insulation rolling screen cover plate are respectively fixed on a winding axle that is connected with a synchronous motor; and the synchronous motor is connected with a controller by a lead. A scaffolding is positioned below the thermal insulation rolling screen cover plate and a heating band connected with the controller by the lead is positioned below the scaffolding. The two ends of the furnace body are respectively provided with a thermocouple that is connected with the controller by a compensation lead. The heater satisfactorily solves the problems that two different metals are clad together, and the operation of a laser head is uniform and complete, thus leading to excellent cladding quality, small thermal loss, high efficiency, constant temperature control, low energy consumption, energy conservation, cleanliness and sanitation and no pollution. The heater is applicable to metallurgy industry and equipment manufacturing and repair industry.

Owner:成都大陆激光技术有限公司

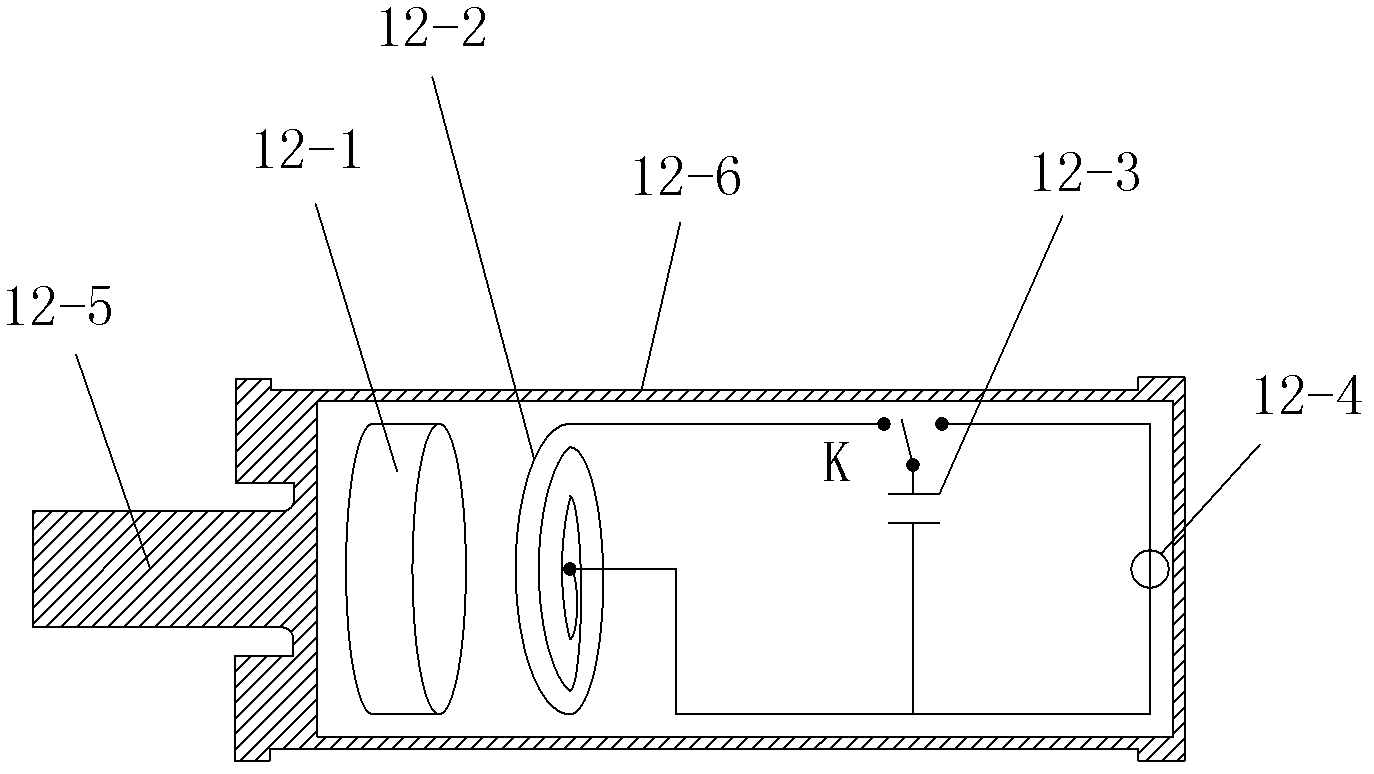

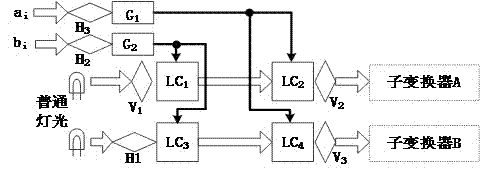

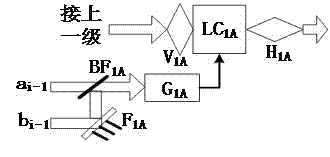

All-symbol MSD (modified signed-digit) fast adder

InactiveCN104503729AQuick calculationExpand the field of addition operationComputation using non-contact making devicesOperandElectric signal

The invention discloses an all-symbol MSD (modified signed-digit) fast adder. The all-symbol MSD fast adder is provided with an all-symbol input converter which is connected with a subconverter C, a subconverter A, a subconverter V and a subconverter D through a light path 00, a light path 10, a light path 01 and a light path 11 respectively; electrical signals ui and vi are connected to a control end of the all-symbol input converter; output ends of the four subconverters (C, A, V and D) output final results. The all-symbol MSD fast adder divides symbol conditions of input operands (mainly researches input symbols containing 0, 1 and -1), expands the application range of an original one-step adder which limits the input symbols, and can still perform fast MSD computation in allusion to an all-symbol input condition; through implementation of the all-symbol MSD fast adder, the one-step adder can operate more perfectly, so that the computational efficiency of an all-parallel add operation of a three-value optical computer is improved and application of the three-value optical computer to the field of numerical computation is expanded.

Owner:SHANGHAI UNIV

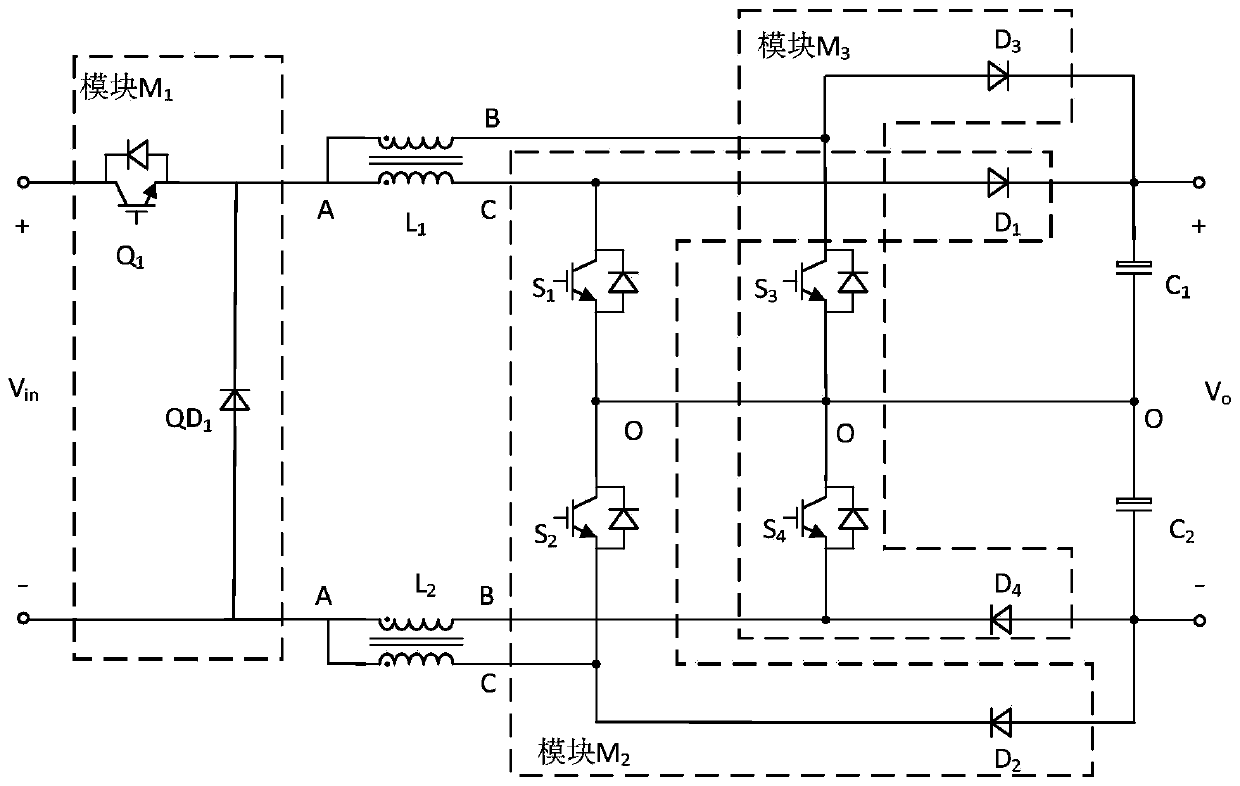

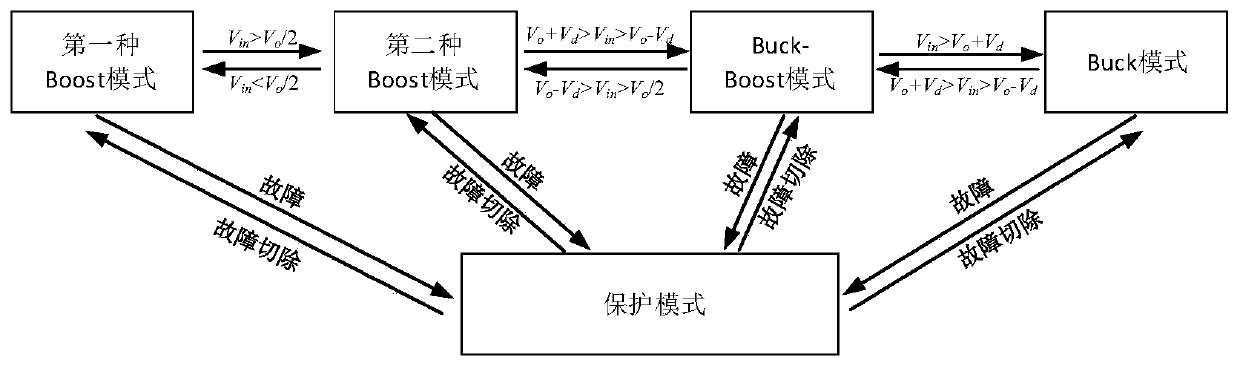

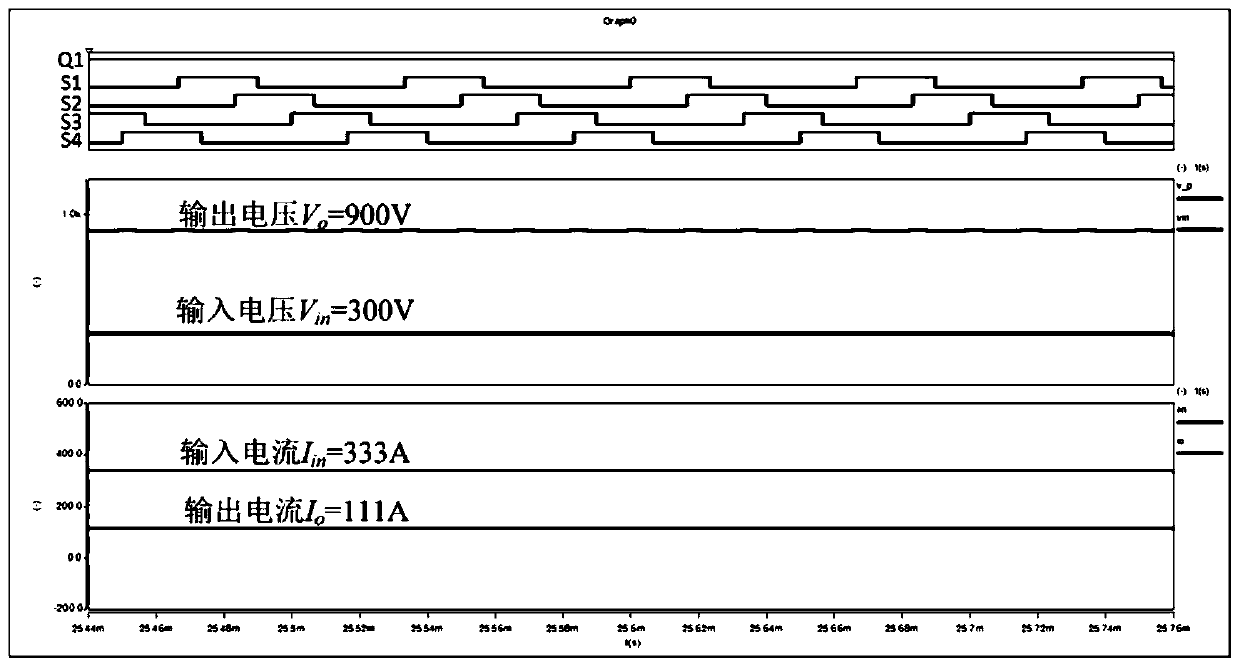

Novel wide-range high-frequency direct-current conversion device

ActiveCN110912407AImprove power densityReduce weight and sizeDc-dc conversionElectric variable regulationCapacitanceSoft switching

The invention discloses a novel wide-range high-frequency direct-current conversion device. The direct-current conversion device comprises a Buck module M1, a first coupling inductor L1, a second coupling inductor L2, a first three-level Boost module M2, a second three-level Boost module M3, a first supporting capacitor C1 and a second supporting capacitor C2. According to the Boost circuit, an interleaved three-level control strategy is adopted, the inductive current frequency is increased to four times of the switching frequency, soft switching of a switching device and a diode can be achieved through coupling inductance leakage inductance, the device loss is reduced, and the EMI characteristic is improved. Besides, the front-stage Buck circuit and the rear-stage Boost circuit are cascaded so that the application range of the input and output voltage can be broadened and short-circuit current-limiting operation of the output side can be realized. Meanwhile, the pre-stage Buck circuitcan realize a soft power-on function, an additional soft power-on circuit is not needed, and the power density of the device is further improved.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

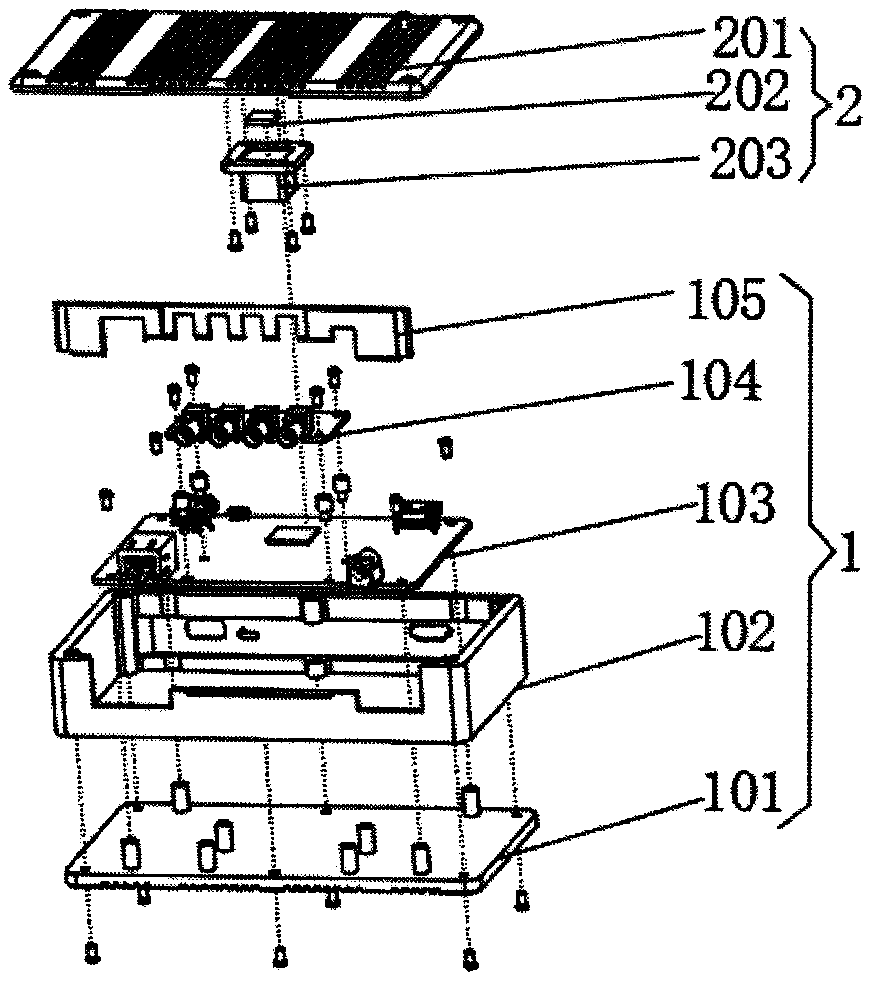

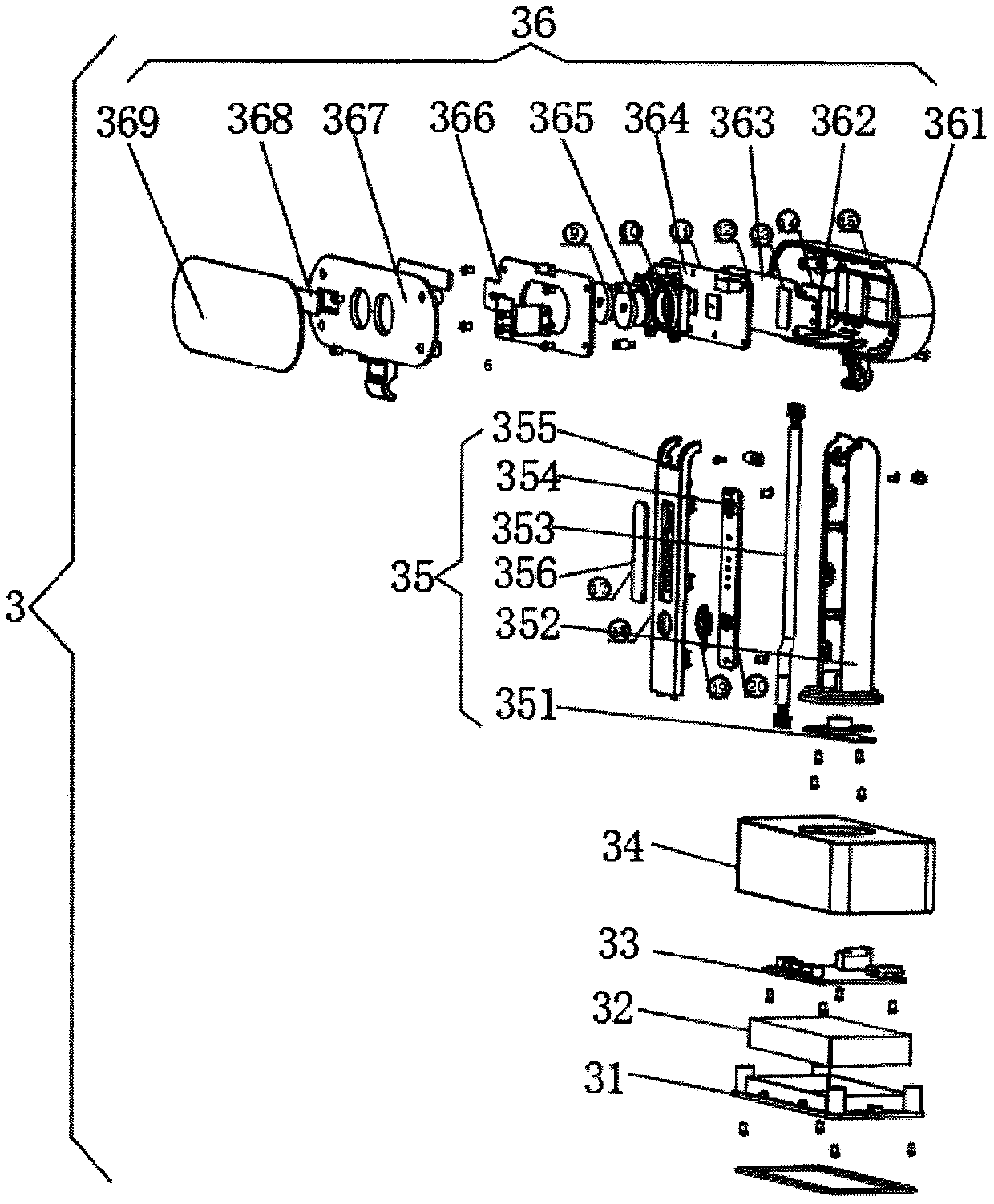

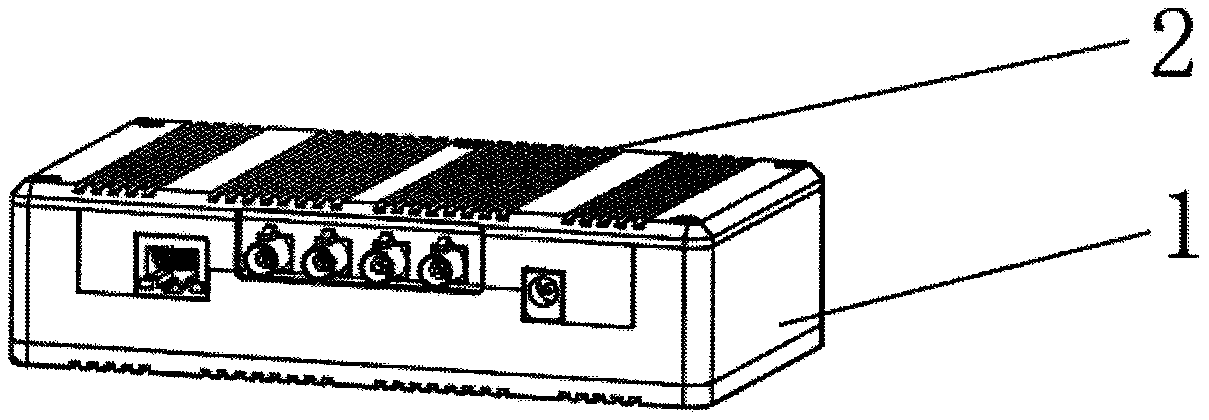

AI image living body identification detection camera

InactiveCN109660699AGuaranteed uptimeImprove performanceTelevision system detailsColor television detailsFeature extractionEngineering

The invention discloses an AI image living body identification detection camera, comprising a lower shell assembly, wherein an upper shell assembly is fixedly connected with periphery of the top of the lower shell assembly through screws. An output end of the lower shell assembly is connected with a binocular camera through utilization of an LVDS connection line. The upper shell assembly fits withthe lower shell assembly. Grooves are set on the top of the upper shell assembly and at the bottom of the lower shell assembly. The invention relates to the technical field of the camera. According to the AI image living body identification detection camera provided by the invention, operation is relatively smooth; the camera is efficient; performance is excellent; the camera has high expandability; single, double and four-way video input is supported; parallel processing is realized; performance of hardware equipment is exerted to the greatest extent; redundancy is avoided; through adoptionof a box form, interfaces are abundant; volume is small; the camera is beautiful; wiring is simple; a plug and play function is realized; and power consumption is very low. The camera has local side capture, feature extraction and identification functions, also has high expandability and is applicable to requirements of various scenes.

Owner:SHENZHEN DVITEC IND

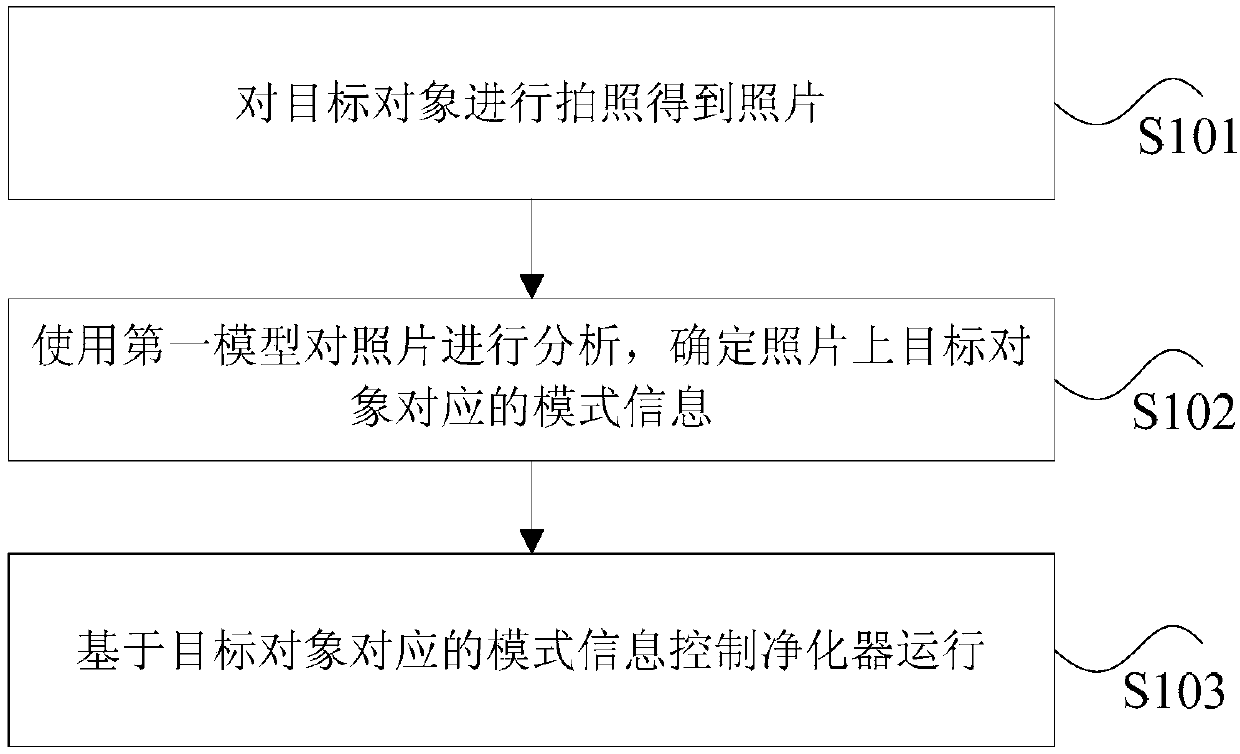

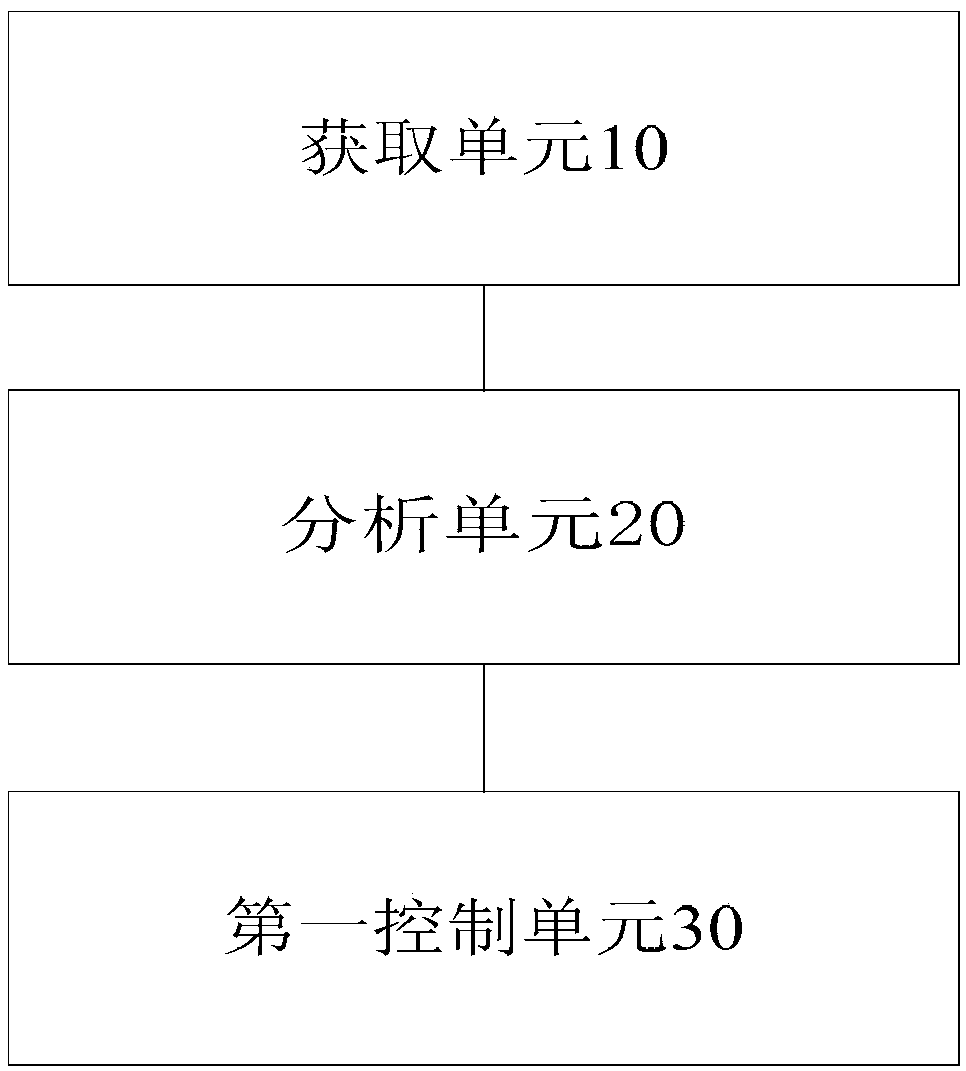

Control method and device of purifier

InactiveCN107680278APerfect operationSolve the problem of low experienceCharacter and pattern recognitionApparatus for meter-controlled dispensingControl mannerControl engineering

The invention discloses a control method and device of a purifier. The method comprises the steps that a target object is photographed to obtain a picture, wherein the target object is an object who uses the purifier; the picture is analyzed by using a first model so as to determine the mode information corresponding to the target object on the picture, wherein the mode information is the information about the running mode of the purifier when the target object uses the purifier, the first model is trained through machine learning by using multiple groups of data, and each group of data in themultiple groups of data at least comprises the picture of the object and the mode information corresponding to the object; based on the mode information corresponding to the target object, the purifier is controlled to run. By means of the control method, the problems that in the correlation techniques, the purifier has a single control mode and the user experience is low are solved, so that theeffects of enriching the control modes of the purifier and improving the experience degree of users are achieved.

Owner:GREE ELECTRIC APPLIANCES INC

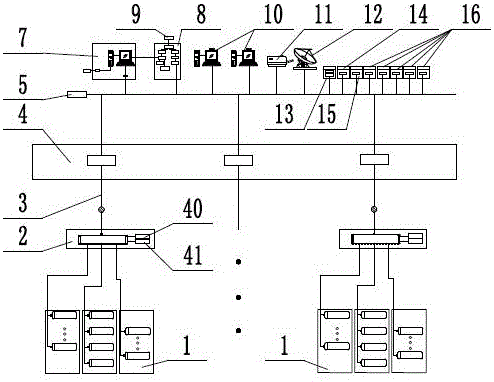

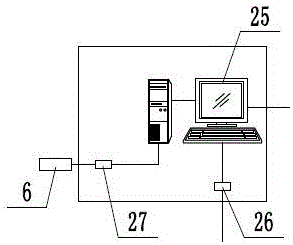

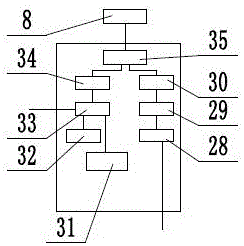

Monitoring system of photovoltaic generation

ActiveCN105071540ARealize real-time monitoringEasy maintenanceProgramme controlComputer controlMonitoring systemEngineering

The invention, which belongs to the technical field of photovoltaic generating, provides a monitoring system of photovoltaic generation. The monitoring system comprises a measurement control device and a dispatching communication cabinet. An output terminal of the measurement control device is connected with one end of an ethernet fiber converter by a four-core single-mode fiber; and the other end of the ethernet fiber converter is connected with an input terminal of a switch. An output terminal of the switch is connected with a luminous power prediction cabinet and the dispatching communication cabinet. A monitoring host is also connected to the output terminal of the switch. Besides, a network printer and a time synchronization and setting device are also connected to the output terminal of the switch; and the output terminal of the switch is also connected with an integrated protection screen, a first switch cabinet, a second switch cabinet, and third switch cabinets. According to the invention, real-time monitoring of the data and state of the photovoltaic generating device operation can be realized; and continuous and high-efficiency operation of photovoltaic generation can be realized well.

Owner:嘉兴市创辉电气工程有限公司

Side beam type filter press

ActiveCN112121487AImprove work efficiencyRealize synchronous opening and closingFiltration separationMechanical equipmentFilter press

The invention provides a side beam type filter press, which belongs to the field of mechanical equipment and comprises a rack, wherein a fixed end plate is arranged at one end of the rack, and a movable end plate is arranged at the other end of the rack; a filtering device which is arranged on the rack and comprises a plurality of filtering plate units provided with filtering cloth and a filteringcloth driving mechanism, wherein the filtering plate units are arranged between the movable end plate and the fixed end plate; a driving device which is connected with the movable end plate and drives the movable end plate to move in the length direction of the rack; when the filter press is used, the driving device drives the movable end plate to push the filter plate units in the filter deviceto be pressed, and then materials are injected into the filter plate units for filter pressing; and after the filter pressing is finished, the driving device drives the filter plate units to separate,and then the filter cloth driving mechanism drives the corresponding filter cloth in the plurality of filter plate units to synchronously move so as to unload a filter cake.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

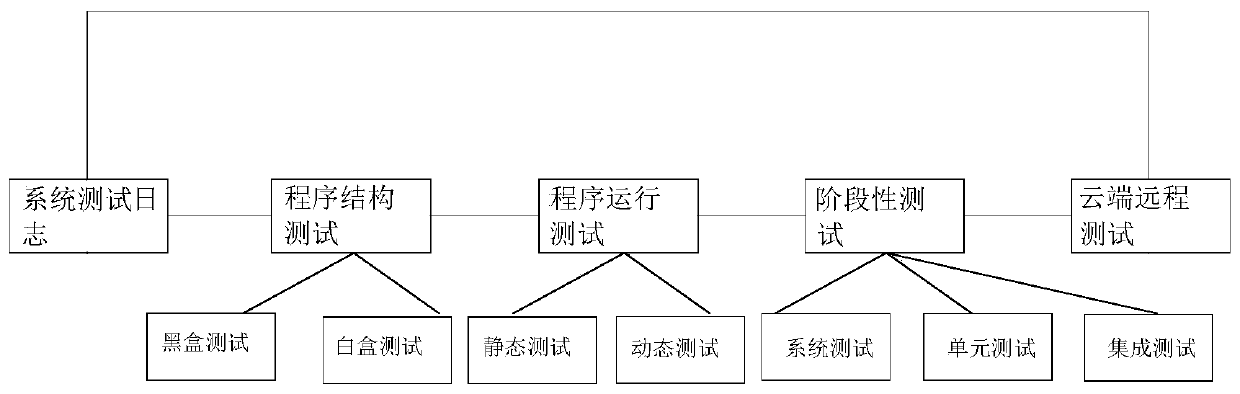

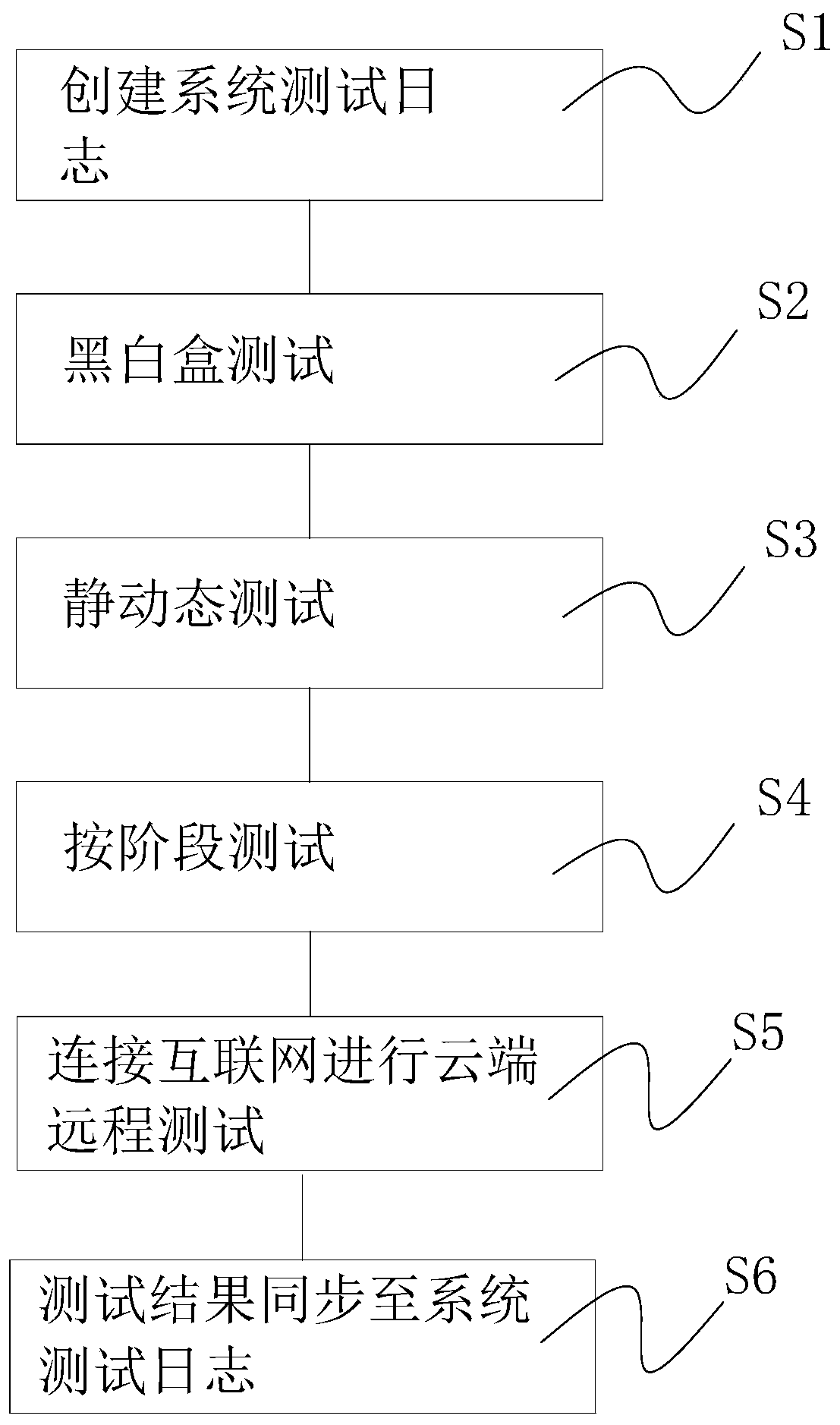

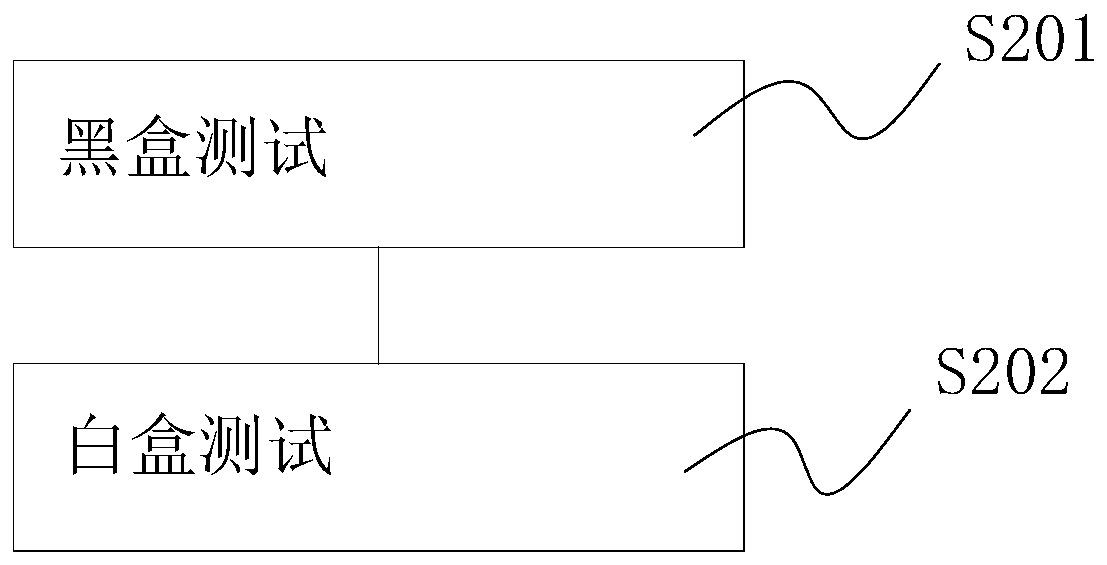

Industrial control software test system and software test method

The invention discloses an industrial control software test system and a software test method. The industrial control software test system comprises a system test log, a program structure test unit, aprogram running unit, a staged test unit and a cloud remote test unit; the program structure testing unit comprises a black box testing unit and a white box testing unit which are respectively used for testing results and internal structures; the program running unit has a static test and a dynamic test, the static test is carried out when a program does not run, and the dynamic test is carried out when the program runs; the staged test unit comprises a system test, a unit test and an integration test. The invention provides an industrial control software test system and a software test method, which cover creation of a system test log, test of a program structure, test of program operation, periodic test and cloud remote test, test software more comprehensively, scientifically and reasonably, and are beneficial to normal operation of the software.

Owner:NANJING CHENXIAO SOFTWARE TECH CO LTD

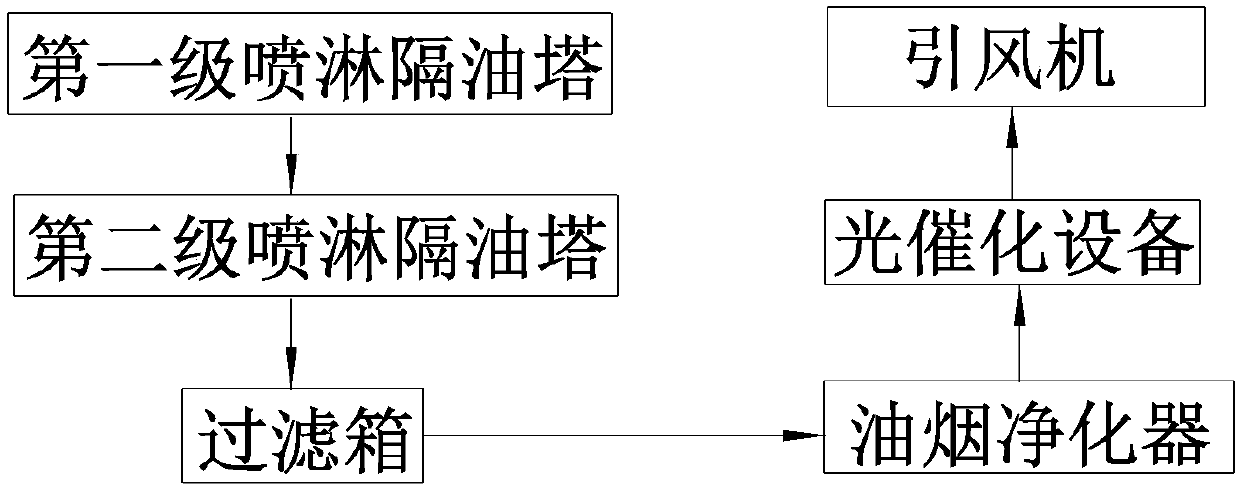

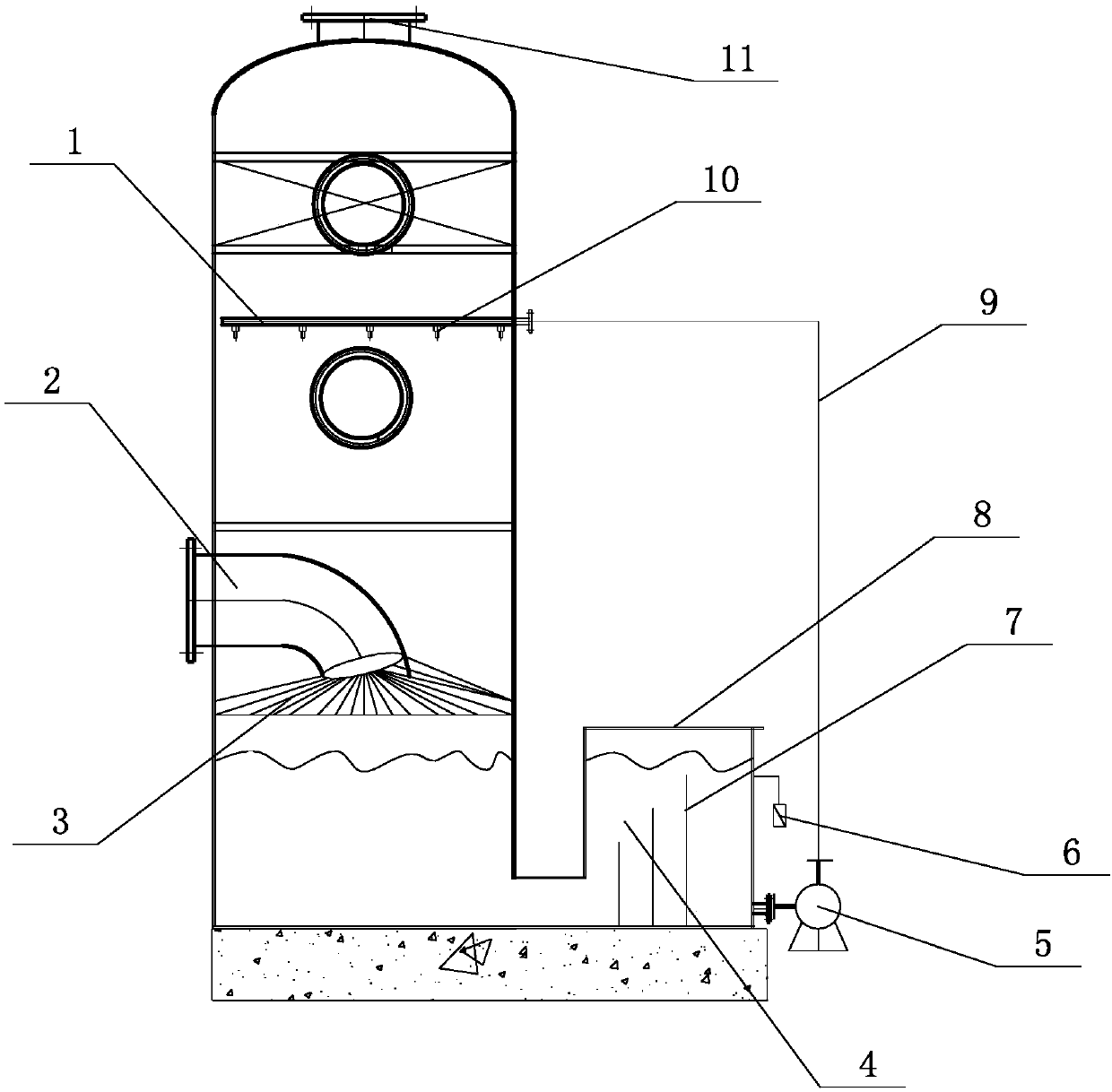

A plastic granulation waste gas treatment system and a waste gas treatment process

InactiveCN107913572AExtended stayReduce the concentration of pollutantsCombination devicesGas treatmentFiltrationPollution

The invention relates to the technical field of waste gas purification, and particularly relates to a plastic granulation waste gas treatment system and a waste gas treatment process. The system includes two stages of spraying oil separating columns, a filtration tank, an oil fume purifier and a photocatalytic oxidation device which are connected in order. The two stages of spraying oil separatingcolumns include a first-stage spraying oil separating column and a second-stage spraying oil separating column. The system and the process are simple, can efficiently treat peculiar-smell gas in plastic granulation, perform staged treatment and purification for different components, and are high in purification efficiency, resistant to impact load, relatively low in investment and free of secondary pollution. Waste gas purification effects can meet environment protection requirements.

Owner:山东天泓环保工程有限公司

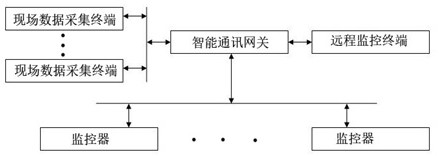

Weak current intensive pipe network intelligent fluid transportation monitoring system and method thereof

InactiveCN112558534AReduce labor intensityLow running costProgramme controlMeasurement devicesData connectionFluid transport

The invention relates to a weak current intensive pipe network intelligent fluid transportation monitoring system and a method, and the system comprises a bearing rack, monitors, aon-site data collection terminal, an intelligent communication gateway, and a remote monitoring terminal. The bearing rack is of a cylindrical frame structure, and the monitors are embedded in the bearing rack and are uniformly distributed in the axis direction of the bearing rack; the monitors are in data connection with the on-site data collection terminal through the intelligent communication gateway, the intelligent communication gateway and the remote monitoring terminal are both communicated with an external power supply system through wires, and the intelligent communication gateway is in data connection with the remote monitoring terminal. The operation method comprises two steps of monitoring network arrangement, pipe network supervision operation and the like. On one hand, the structure of the monitoring system is effectively simplified, and the environmental adaptability and use flexibility of the monitoring system are improved; on the other hand, the intelligent degree is high, the working efficiency and precision of pipe network system control operation can be effectively improved, and the labor intensity and operation cost of pipe network monitoring operation are effectively reduced.

Owner:NANJING HUAFU INFORMATION TECH

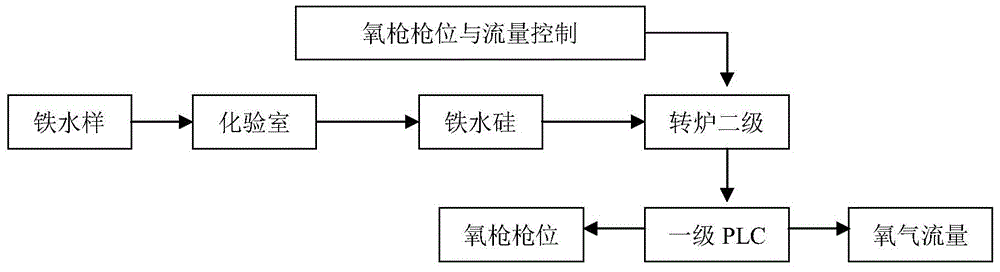

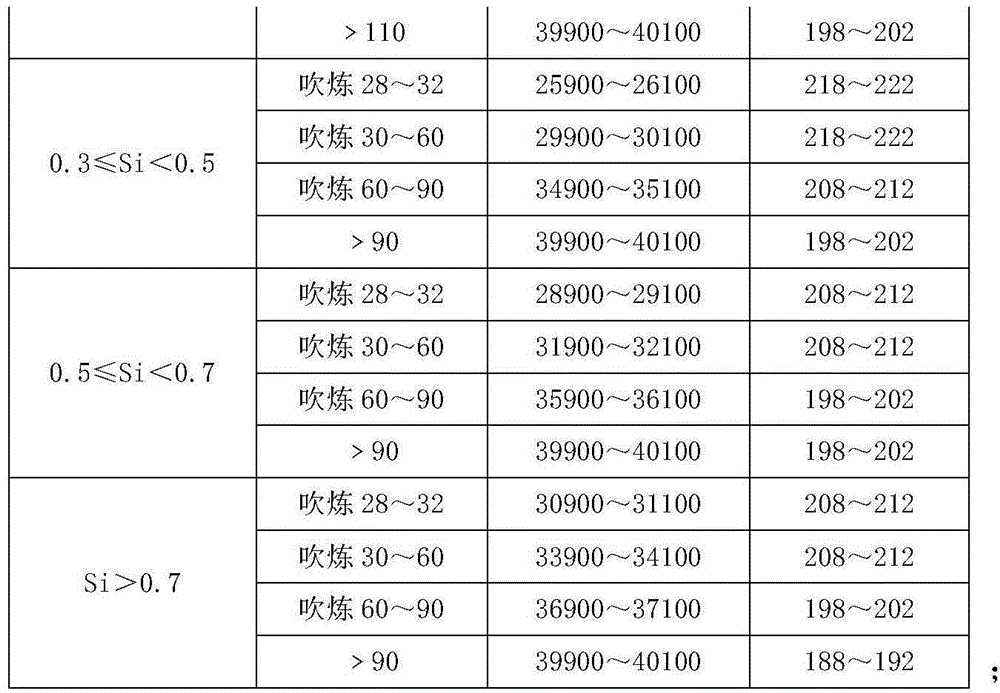

Control method for preventing earlier-stage explosion venting of converter dry dedusting

ActiveCN106544465AStable Smelting ControlImprove converter operating rateManufacturing convertersTime scheduleEngineering

The invention relates to a control method for preventing earlier-stage explosion venting of converter dry dedusting, and the earlier-stage control of converting is reinforced. The control method for preventing earlier-stage explosion venting of converter dry dedusting comprises the following steps that (1) a molten iron sample is obtained in a desulphurization station and sent to a test cabinet for a chemical examination as soon as possible, and chemical examination components of the molten iron sample in the test cabinet are sent to a converter second stage; (2) the lance position of an oxygen lance and the blowing oxygen flow are confirmed according to the content of molten iron silicon before converting of the converter second stage is started, and a control corresponding table of the lance position of the oxygen lance and the flow is sent to a converter first stage PLC; and (3) after converting is started, the converter first stage PLC controls the blowing oxygen flow and the oxygen lance lance position according to the converting time schedule. The control method for preventing earlier-stage explosion venting of converter dry dedusting has the advantages that the reasonable converting flow and lance position are confirmed according to a different molten iron silicon quantity, the silicon manganese oxidizing period of converting is stably spent, the phenomenon that the reaction in a furnace is too intense is avoided, and the CO generating speed is slowly increased, so that the explosion venting limitation of CO and O2 in smoke gas is missed. According to the control method for preventing earlier-stage explosion venting of converter dry dedusting, the oxygen flow and lance position in the earlier stage of converting are reasonably controlled, and zero explosion venting of earlier-stage converting dry dedusting is achieved.

Owner:ANGANG STEEL CO LTD

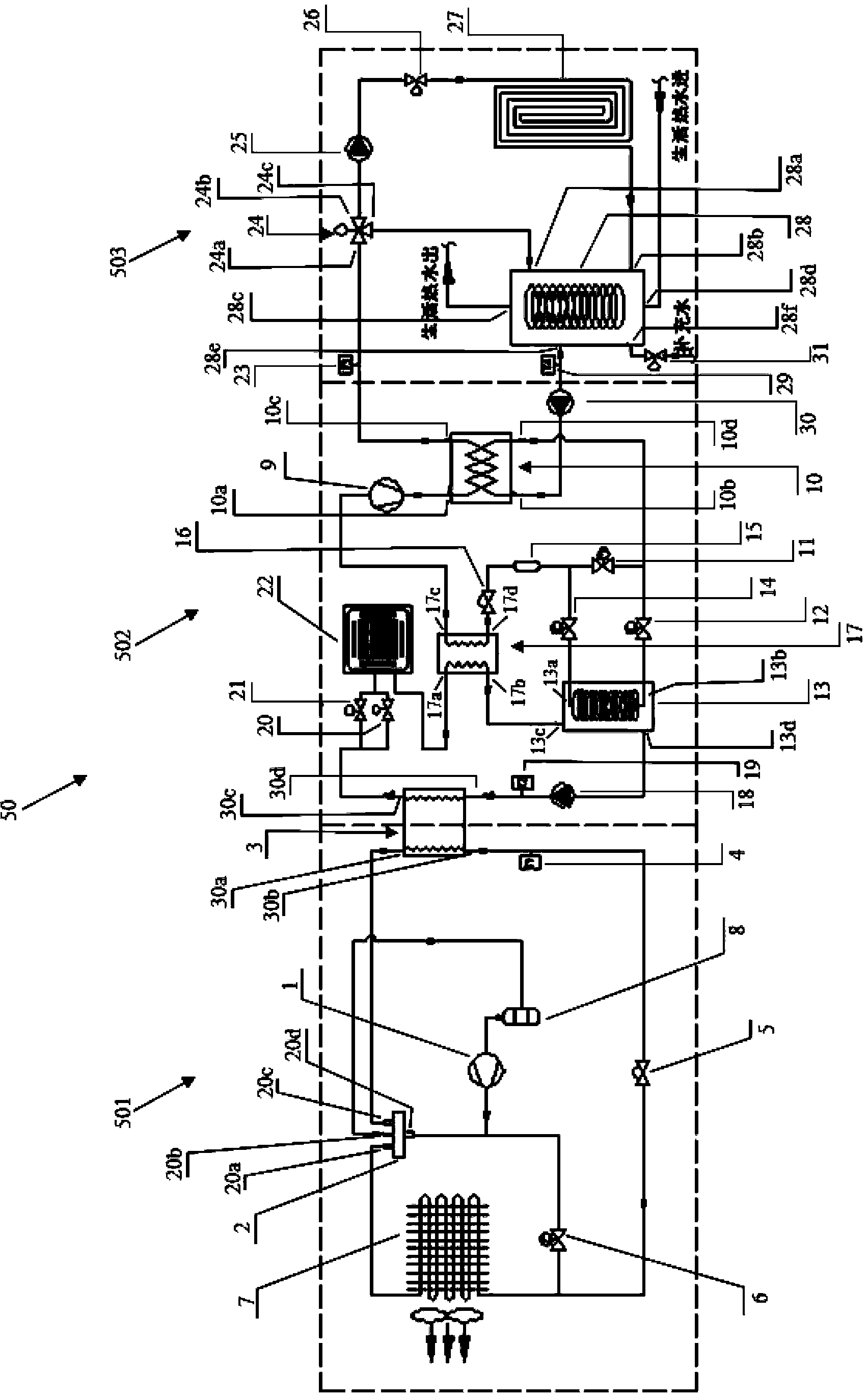

Secondary heat pump combined system

InactiveCN103363721AReduce power consumptionIncrease profitHeat pumpsRefrigeration safety arrangementWater storageElectricity

The invention provides a secondary heat pump combined system, which comprises a primary side heat pump system, a secondary side heat pump system and a hot water storage side system. The primary side heat pump system is connected with the secondary side heat pump system through a first plate heat exchanger. The secondary side heat pump system is connected with the hot water storage side system through a second hot water storage tank. The system is provided with a heating operation mode, a refrigeration operation mode and a defrosting operation mode to prevent frost crack operation and overheating operation of the hot water storage tank, wherein the heating operation mode is further divided into a heat pump heating operation mode, a heat pump heat storage operation mode and a hot water storage tank heating operation mode; the refrigeration operation mode is divided into a pure refrigeration operation mode and a refrigeration plus domestic hot water operation mode. The modes can be freely switched according to the needs and the conditions. The off-peak electricity and low-cost electricity at night are fully used. The secondary heat pump combined system has the advantages of flexible control, diversified selection, energy saving during operation and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com